Method and device for measuring air density in weight mass measurement

A technology for air density and mass measurement, applied in the field of metrology, can solve the problems of large influence weight, placed outside the windshield, or even placed far away from the mass comparator, without consideration, etc., to achieve accurate results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

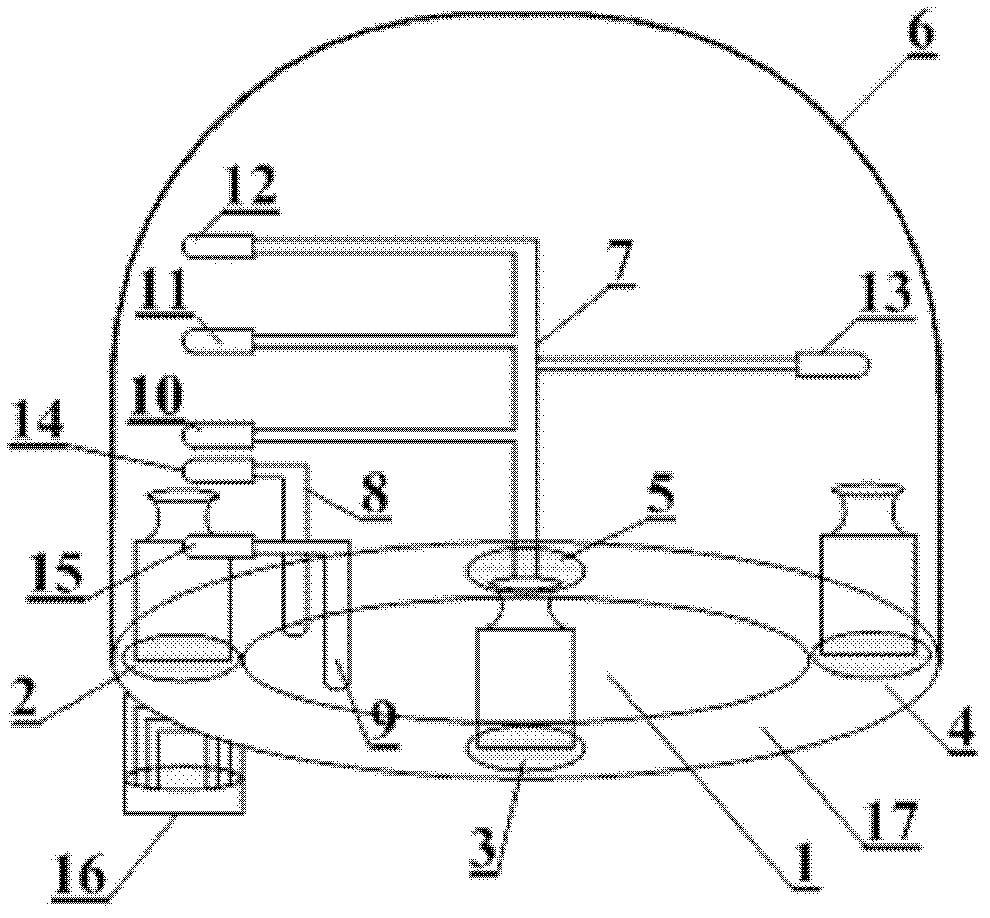

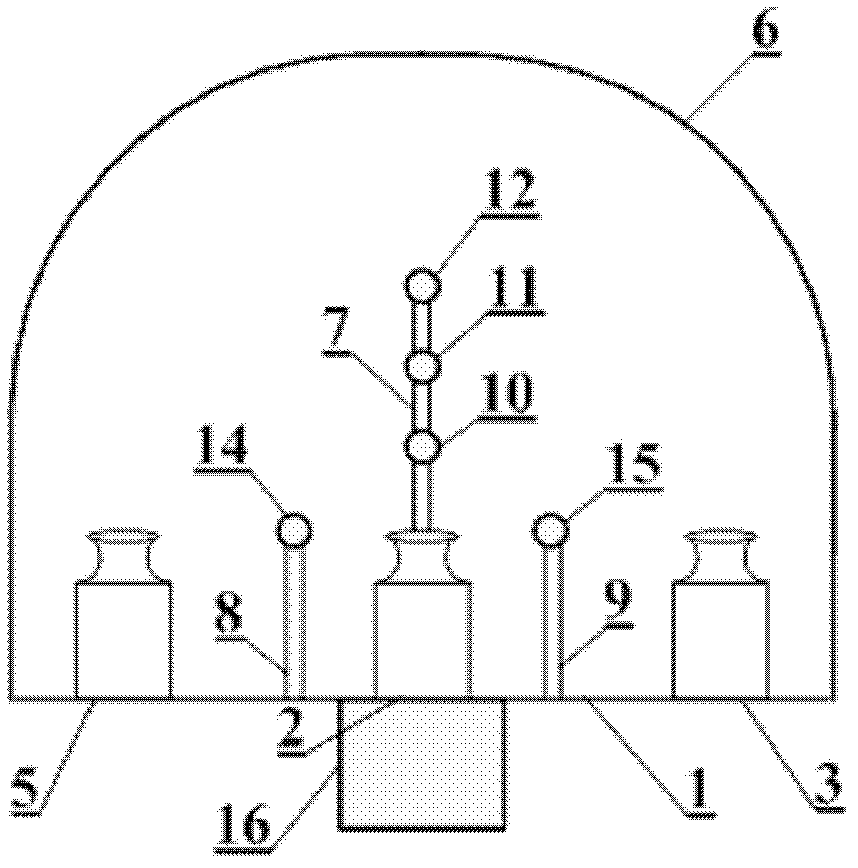

[0044] Below in conjunction with accompanying drawing, the present invention is described in further detail:

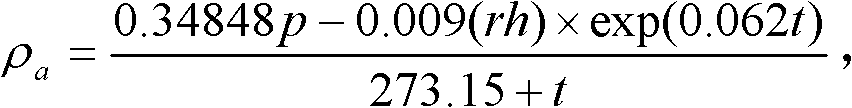

[0045] An example of the present invention is figure 1 , 2As shown, the balance 1 includes a fixed part in the middle and a ring 17 that can rotate around the center of the balance at the periphery. There are four working positions 2, 3, 4 and 5 evenly distributed on the circumference of the ring 17. The position of the weight, wherein the initial state is 2 is located at the measuring station; there is a windshield 6 above the balance. Hollow brackets 7, 8, and 9 are fixed on the middle fixed part of the balance in the windshield, wherein there are three branches on one side of the bracket 7, and each branch end has a measurement point, and the three measurement points 10, 11, 12 are in the vertical direction. The same position in the vertical direction, that is, above the measuring station 2. However, the heights increase sequentially and are arranged at equal in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com