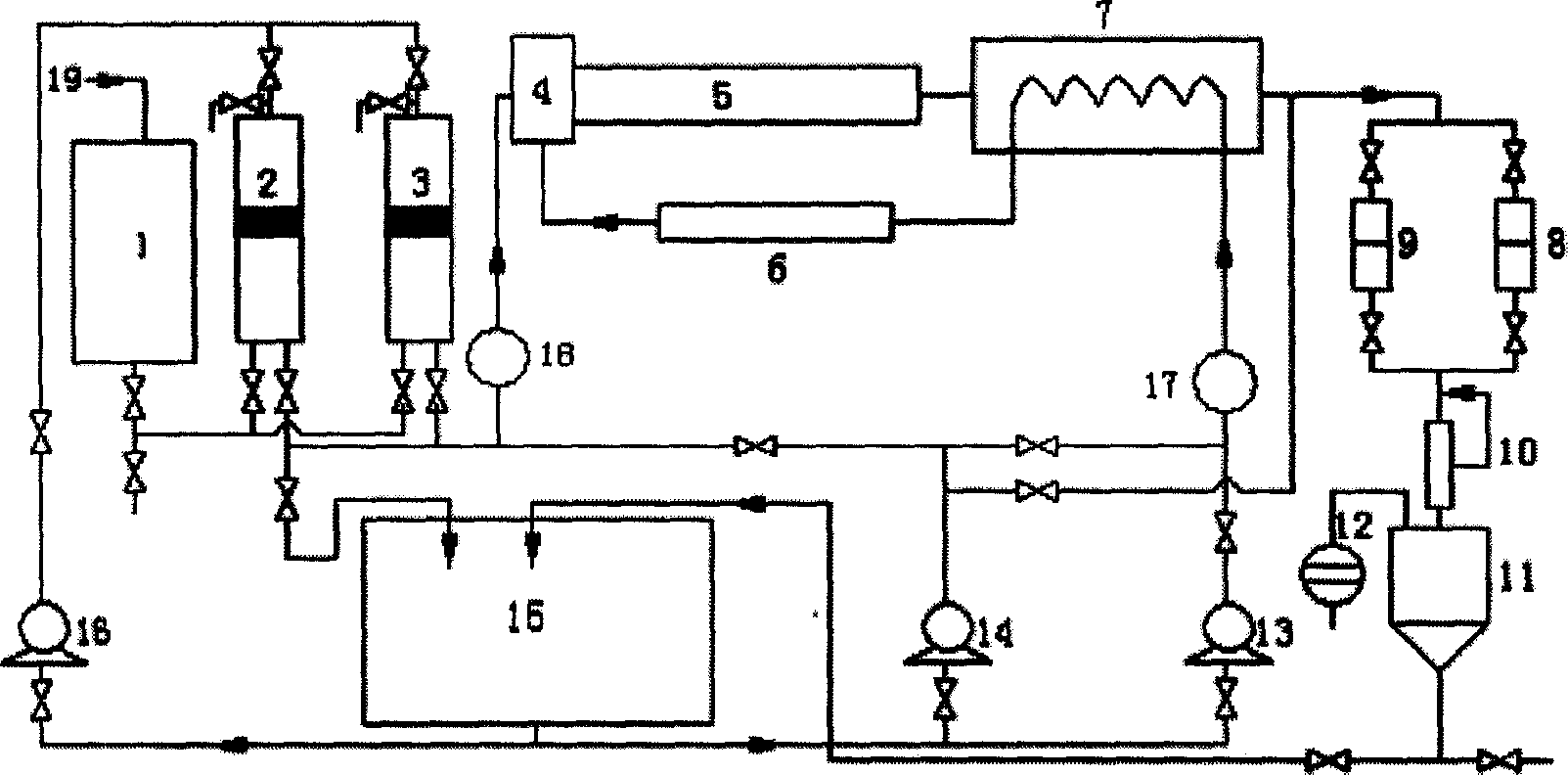

Coal-biomass co-overcritical water catalysis-gasification hydrogen production plant and method

A technology of supercritical water and hydrogen production equipment, which is applied in the production of hydrogen and bulk chemical production, etc. It can solve the problems of increased investment, unfavorable separation and treatment of carbon dioxide, and easy blockage of pipelines, and achieves a simple and easy reactor structure. Control and process, keep the effect of the system unimpeded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) according to 0.1wt% sodium hydroxide, 1wt% coal, 0.25wt% sodium carboxymethyl cellulose, all the other are water, prepare reaction raw material, pour into feeding tank after stirring evenly, with 1MPa nitrogen, react raw material from The feeding tank is pressed into the feeder, and the amount of nitrogen gas depends on the amount of reaction raw materials pressed in. Press 80% to 90% of the reaction raw materials in the feeding tank into the feeder, and the remaining 20% to 10% of the reaction raw materials are required in the feeding tank to prevent Nitrogen enters the feeder;

[0036] (2) water pump makes more than 2 times of the reaction raw material flow through water mass flow meter 17, preheater 6, mixer 4, reactor 5, cooler 7, filter 8, back pressure valve 10, gas-liquid separation Device 11. Then adjust the back pressure valve 10 to boost the pressure, and the pressure is 25MPa. Then, the heating devices of the preheater 6 and the reactor 5 are turned o...

Embodiment 2

[0040] (1) according to 0.1wt% sodium hydroxide, 1wt% coal, 0.5wt% sodium carboxymethyl cellulose, all the other are water, mix reaction raw material, pour into feeding tank after mixing evenly, with 1.5MPa nitrogen gas, react raw material Press into the feeder from the feeding tank, the amount of nitrogen depends on the amount of reaction raw materials pressed in, press 80% to 90% of the reaction raw materials in the feeding tank into the feeder, and the remaining 20% to 10% of the reaction raw materials are required in the feeding tank;

[0041] (2) Water pump makes more than 3 times of the reaction raw materials flow through water mass flow meter 17, preheater 6, mixer 4, reactor 5, cooler 7, filter 8, back pressure valve 10, gas-liquid separation Device 11. Then adjust the back pressure valve 10 to boost the pressure, and the pressure is 22.5MPa. Then, the heating devices of the preheater 6 and the reactor 5 are turned on to raise the temperature of the water, and the t...

Embodiment 3

[0045] (1) according to 0.1wt% sodium hydroxide, 1wt% coal, 1.0wt% sodium carboxymethyl cellulose, all the other are water, prepare reaction raw material, pour into feeding tank after mixing evenly, with 2MPa nitrogen, reaction raw material is from The feeding tank is pressed into the feeder, and the amount of nitrogen depends on the amount of the reaction raw materials pressed in. Press 80% to 90% of the reaction raw materials in the feeding tank into the feeder, and the remaining 20% to 10% of the reaction raw materials are required in the feeding tank;

[0046] (2) Water pump makes more than 4 times of the reaction raw materials flow through water mass flow meter 17, mixer 4, reactor 5, cooler 7, filter 8, back pressure valve 10, gas-liquid separator 11. Then adjust the back pressure valve 10 to boost the pressure, and the pressure is 20MPa. Then, the heating devices of the preheater 6 and the reactor 5 are turned on to raise the temperature of the water to 750° C., there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com