Method for removing carbon dioxide in recycle gas for synthesizing ethylene oxide/glycol

A technology of ethylene oxide and carbon dioxide, which is applied in the field of gas purification, can solve the problems of increasing the split ratio of circulating gas to the decarbonization unit, making it difficult to pass through, and increasing the amount of circulating gas entering the decarbonization absorption tower, so as to reduce CO2 content and heat The effect of reducing and lowering the CO2 content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

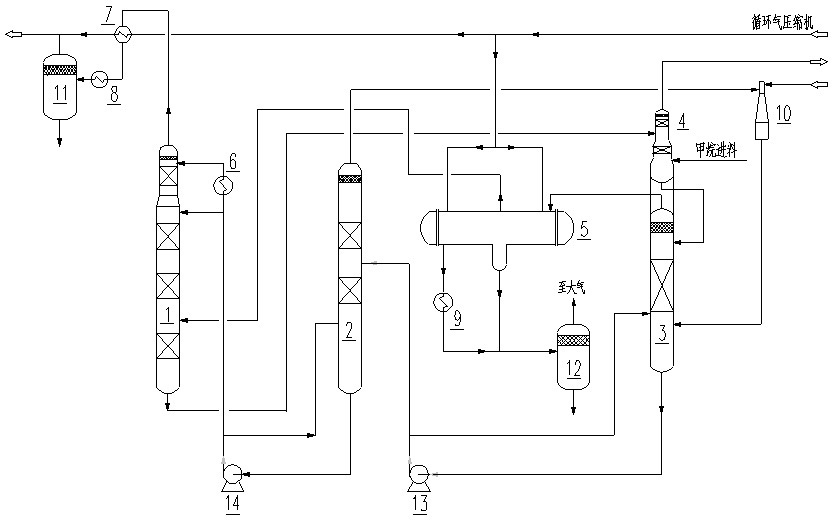

[0028] An ethylene oxide / ethylene glycol synthesis cycle gas decarburization unit uses potassium carbonate concentration of 15 (m)%, activator potassium metavanadate KVO 3 Concentration 5 (m)%, activator boric acid H 3 BO 3 The concentration is 20 (m)%, and the activator selenous acid is 2 (m)%. The absorption tower adopts two-stage absorption, and the circulating gas entering the tower bottom contacts with the cold and hot lean liquid coming in from the top and middle of the tower to remove carbon dioxide and absorb The operating temperature is 70°C at the top of the tower, 105°C at the bottom of the tower, and the pressure is 2.2 Mpa (table), and the circulating gas enters the tower CO 2 The content is 4 mol %, leaving the absorption tower residual CO 2 2 <1.0 mol % requirement. A new double-tower variable pressure regeneration is adopted, and the pressure at the top of the pressurized regeneration tower is 0.08MPa (gauge), which is kept stable through the pressure regula...

Embodiment 2

[0030] An ethylene oxide / ethylene glycol synthesis cycle gas decarburization unit uses potassium carbonate concentration of 20 (m)%, activator potassium metavanadate KVO 3 Concentration 1(m)%, activator boric acid H 3 BO 3 The concentration is 4 (m)%; the absorption tower (2.1 meters in diameter) adopts two-stage absorption, and the 3886 Kmol / h circulating gas entering the bottom of the tower contacts with the cold and hot lean liquid coming in from the top and middle of the tower to remove carbon dioxide in countercurrent, and the absorption operation The temperature at the top of the tower is 80°C, the bottom of the tower is 109°C, the pressure is 1.8 Mpa (table), and the circulating gas enters the tower CO 2 The content is 3 mol %, leaving the absorption tower residual CO 2 2 <0.9 mol % requirement. A new double-tower pressure-swing regeneration is adopted. The top pressure of the pressurized regeneration tower is 0.08MPa (gauge) and is kept stable through the pressure r...

Embodiment 3

[0032] An ethylene oxide / ethylene glycol synthesis cycle gas decarburization unit uses potassium carbonate concentration of 30 (m)%, activator potassium metavanadate KVO 3 Concentration 8 (m)%, activator boric acid H 3 BO 3 The concentration is 30 (m)%, the activator selenous acid is 1 (m)%; the absorption tower (2.6 meters in diameter) adopts two-stage absorption, and the 7350 Kmol / h circulating gas entering the bottom of the tower is contacted with cold and hot lean liquid countercurrently to remove Carbon dioxide, the temperature of the absorption operation is 70°C at the top of the tower, 110°C at the bottom of the tower, and the pressure is 1.8 Mpa (table), and the circulating gas enters the tower CO 2 The content is 2.36 mol %, leaving the absorption tower residual CO 2 2 <0.4 mol % requirement. The new double-tower variable pressure regeneration is adopted, the pressure at the top of the pressurized regeneration tower is 0.09MPa (table), the boiling point of the carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com