Method for reducing energy consumption during regeneration process of amine technology

A technology of regeneration process and amine method, which is applied in the fields of environmental protection, energy saving and consumption reduction, and gas purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

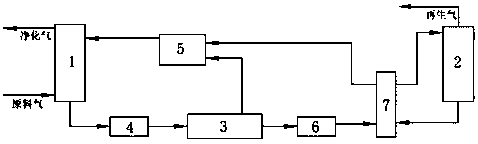

[0022] as attached figure 1 Basic amine process flow diagram with water removal system at higher operating pressures shown. For natural gas, synthetic gas and other amine processes operating under relatively high absorption pressure, the water removal system of the present invention can be used in conjunction with a turbine system, that is, the rich liquid first goes to the turbine system to recover part of the high-pressure energy, and then the turbine outlet The depressurized rich liquid is introduced into the dewatering removal system and then sent to the regenerator. The present invention uses N-methyldiethanolamine (MDEA) absorbent with a mass fraction of 50% for testing. The pressure of the absorbent entering the water removal system is 1.45MPa. After water removal, about 25% of the total weight of the absorbent is removed. After the water is removed, the rich liquid is regenerated to the regenerator until no water is used. Removing the degree of absorbent regeneration...

Embodiment 2

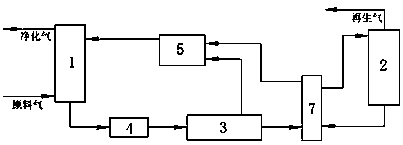

[0024] Reference attached figure 2 , for the amine process operated under lower absorption pressure, such as power plant flue gas, the water movement system of the present invention needs to pressurize the amine liquid entering the system before removing the water. The present invention uses ethanolamine (MEA) absorbent with a mass fraction of 20% for testing. The rich liquid coming out of the absorber is pressurized to 0.70MPa by the rich liquid pump and then enters the water removal system. After water removal and movement, the water accounting for about 43% of the total weight of the absorbent is removed. After the water is removed, the rich liquid Regeneration of the liquid de-regenerator to the extent of absorbent regeneration without the use of the water removal system was calculated to reduce the regeneration heat consumption by about 27%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com