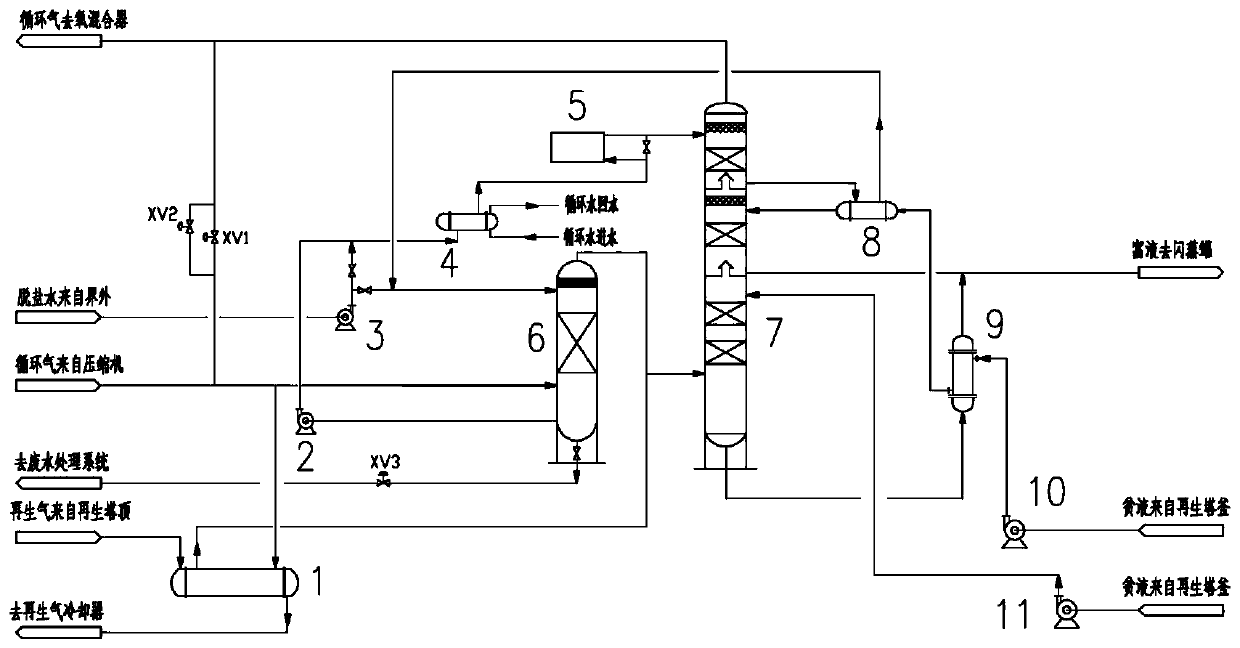

Method and system for removing carbon dioxide in reaction gas and application thereof

A carbon dioxide and reaction gas technology, applied in chemical instruments and methods, separation methods, organic chemistry, etc., can solve the problems of increased steam consumption in decarbonization systems, and achieve the goal of reducing required steam, increasing gas temperature, and reducing energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0124] A certain scale of 70,000 tons / year of ethylene synthesizes ethylene oxide under the action of a silver catalyst, and the by-reaction product of the oxidation synthesis reaction is CO 2 The decarburization unit adopts potassium carbonate decarburization process. In order to use a highly selective catalyst, the CO in the recycle gas at the reactor inlet needs to be 2 The concentration is reduced from 2% to less than 1%, so the amount of reaction tail gas entering the decarbonization system is increased from 50% to 100%, that is, from 83654.2kg / h to 164284.7kg / h. The tail gas is pressurized by the compressor, and the reaction gas with a pressure of 1.82MPa(A) and a temperature of 56.5°C enters the system of the present invention, and the gas volume is 164284.7kg / h, of which CO 2 Concentration 1.59mol%, ethylene concentration 28.02mol%, O 2 Concentration 5.86mol%, the rest is CH 4 、C 2 h 6 , N 2 , Ar and a small amount of water vapor and MEG. Using the process of th...

Embodiment 2

[0135] A newly-built 800,000-ton / year ethylene oxide / ethylene glycol plant, the oxidation synthesis reaction is completed under the action of silver catalyst, and the side reaction product CO 2 The removal unit adopts hot potassium carbonate decarburization process. The reaction gas with a pressure of 2.40MPa(A) and a temperature of 56.6°C enters the decarburization system, and the circulating gas volume is 1774479.3kg / h, of which CO 2 Concentration 1.71mol%, ethylene concentration 28.50mol%, O 2 Concentration 5.97mol%, the rest is CH 4 、C 2 h 6 , N 2 , Ar and a small amount of water vapor and MEG. Adopt technology of the present invention, flow process is identical with embodiment 1, because scale is big, under the situation that reaches same carbon dioxide removal effect, steam consumption is from common hot potassium carbonate decarburization process (that is to directly decarburize reaction gas with decarburization liquid) carbon treatment without heat recovery measu...

Embodiment 3

[0137] A newly built 200,000 tons / year ethylene refined ethylene oxide plant, the oxidation synthesis reaction is completed under the action of a silver catalyst, and the side reaction product CO 2 The removal unit adopts hot potassium carbonate decarburization process.

[0138] The reaction cycle gas with a pressure of 2.38MPa(A) and a temperature of 49.2°C enters the decarbonization system, and the amount of cycle gas is 668822.04kg / h, of which CO 2Concentration 1.44mol%, ethylene concentration 28.61mol%, O 2 Concentration 5.68mol%, the rest is CH 4 、C 2 h 6 , N 2 , Ar and a small amount of water vapor and MEG. Adopt technology of the present invention, flow process is substantially the same as embodiment 1, under the situation of reaching same carbon dioxide removal effect, steam consumption is from common hot potassium carbonate decarburization process (that is to directly carry out decarburization treatment to reaction gas with decarburization liquid, Instead of ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com