High-selectivity desulfurization system and compounding method of desulfurization agent of high-selectivity desulfurization system

A desulfurization system and high-selectivity technology, applied in separation methods, chemical instruments and methods, gas fuels, etc., can solve the problems of low desulfurization purification degree, high viscosity, secondary pollution, etc., and achieve fast absorption speed and large absorption capacity. , The effect of low regeneration energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

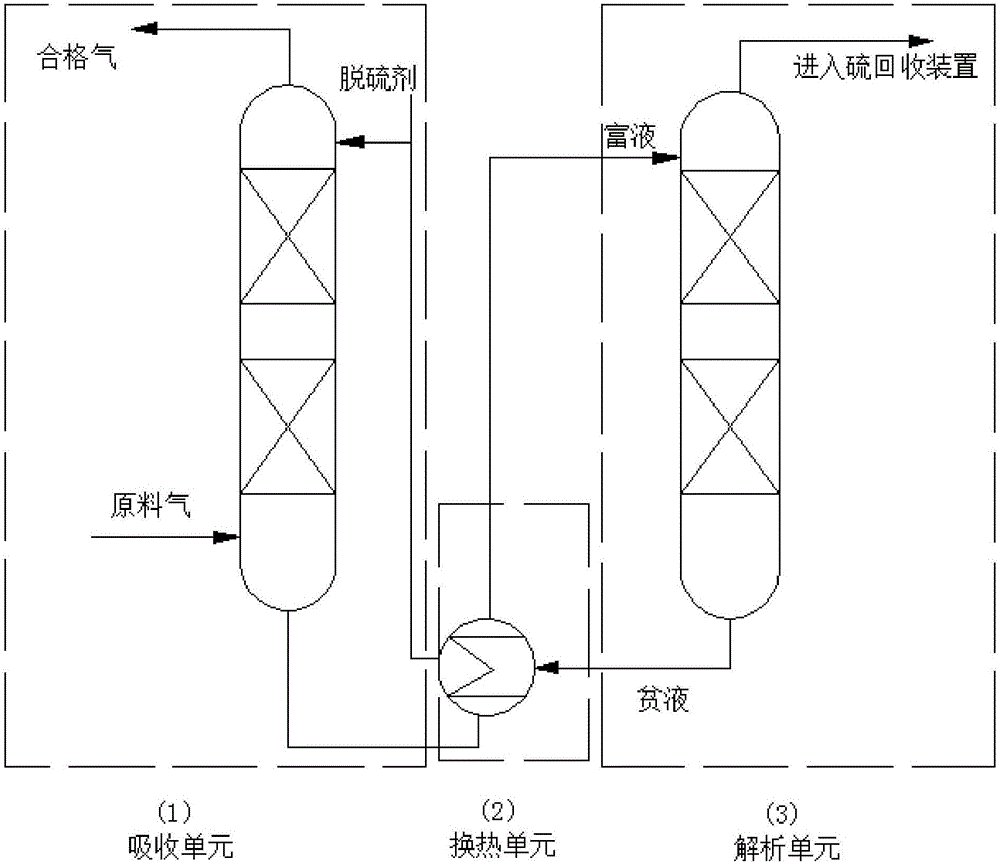

[0013] at a certain 50,000 Nm 3 / h (liquefied natural gas, CO 2 / H 2 S=20:1, molar ratio) desulfurization device selects the highly selective desulfurization system and its desulfurizer (MDEA content is 41wt%; DES content is 2wt%; water content is 57wt%) according to the present invention for desulfurization. The desulfurization system consists of an absorption tower, a heat exchanger and a desorption tower. A double-layer wire mesh corrugated packing with a diamond-shaped flow window is used. The operating pressure of the absorption tower is 2.6MPa and the temperature is 70°C; the operating pressure of the desorption tower is 0.15MPa and the temperature 110°C; H in qualified gas after selective desulfurization 2 The S content is 9ppm, and the H that enters the sulfur recovery unit after analysis 2 S gas recovery rate is 82% and CO 2 The content is 18ppm.

Embodiment 2

[0015] at a certain 50,000 Nm 3 / h (liquefied natural gas, CO 2 / H 2 S=30:1, molar ratio) desulfurization device selects the highly selective desulfurization system and its desulfurizer (MDEA content is 42wt%; DES content is 3wt%; water content is 55wt%) according to the present invention for desulfurization. The desulfurization system consists of an absorption tower, a heat exchanger and a desorption tower. A double-layer wire mesh corrugated packing with a diamond-shaped flow window is used. The operating pressure of the absorption tower is 2.6MPa and the temperature is 70°C; the operating pressure of the desorption tower is 0.15MPa and the temperature 110°C; H in qualified gas after selective desulfurization 2 The S content is 7ppm, and the H entering the sulfur recovery unit after analysis 2 S gas recovery rate is 85% and CO 2 The content is 15ppm.

Embodiment 3

[0017] at a certain 50,000 Nm 3 / h (liquefied natural gas, CO 2 / H 2 S=40:1, molar ratio) desulfurization device selects the highly selective desulfurization system and its desulfurizer (MDEA content is 48wt%; DES content is 4wt%; water content is 48wt%) according to the present invention for desulfurization. The desulfurization system consists of an absorption tower, a heat exchanger and a desorption tower. A double-layer wire mesh corrugated packing with a diamond-shaped flow window is used. The operating pressure of the absorption tower is 2.6MPa and the temperature is 70°C; the operating pressure of the desorption tower is 0.15MPa and the temperature 110°C; H in qualified gas after selective desulfurization 2 The S content is 5ppm, and the H that enters the sulfur recovery unit after analysis 2 S gas recovery rate is 88% and CO 2 The content is 12ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com