Multi-side stereo combustion boiler capable of realizing clean combustion of coal and combustion method thereof

A multi-faceted three-dimensional, combustion furnace technology, applied in the direction of combustion equipment, solid fuel combustion, lighting and heating equipment, etc., can solve the problems of easy black smoke, low efficiency, slow pyrolysis speed, etc., to solve the problem of poor combustion stability, Effects of CO emission reduction and high gasification pyrolysis intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

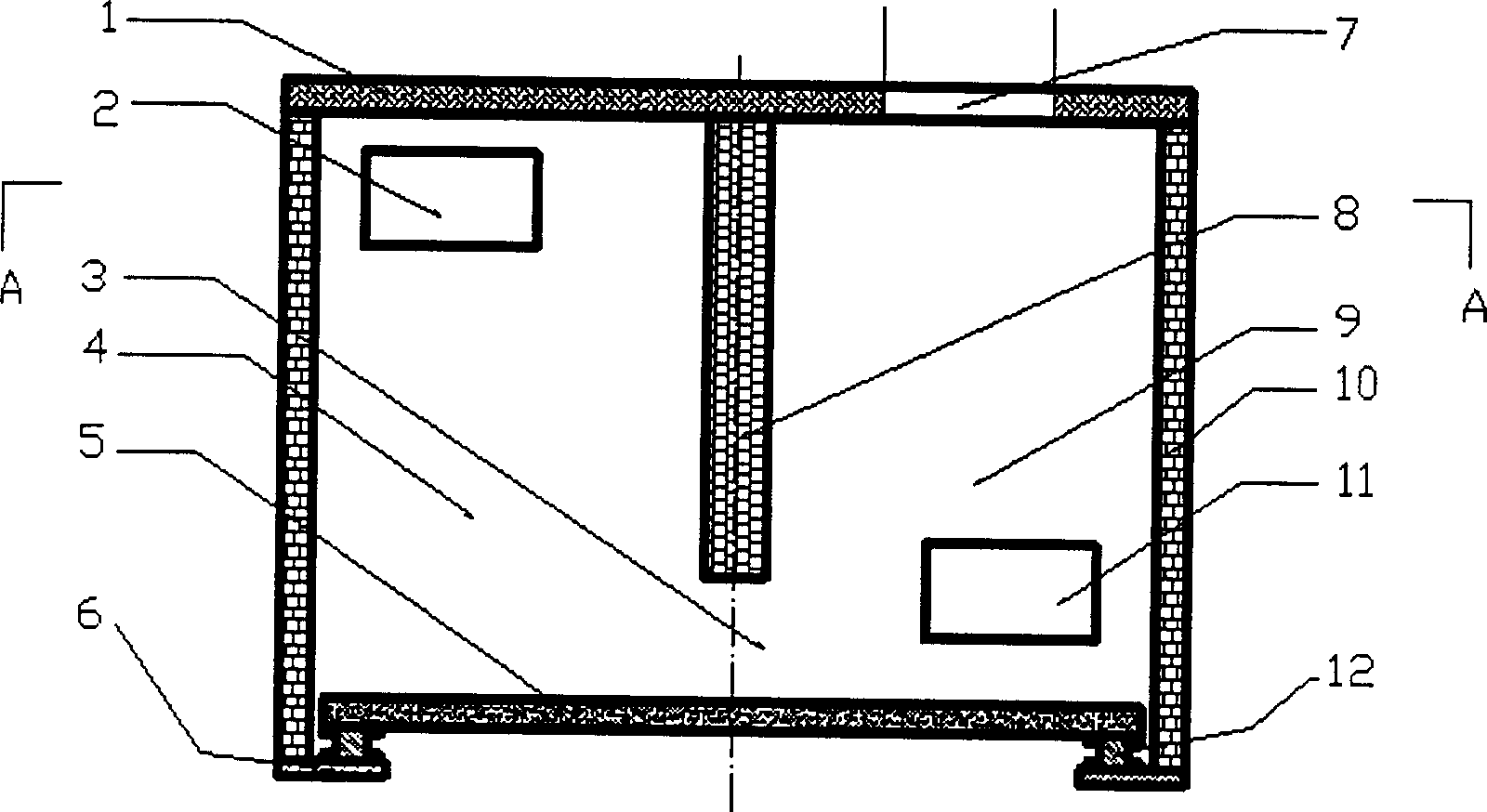

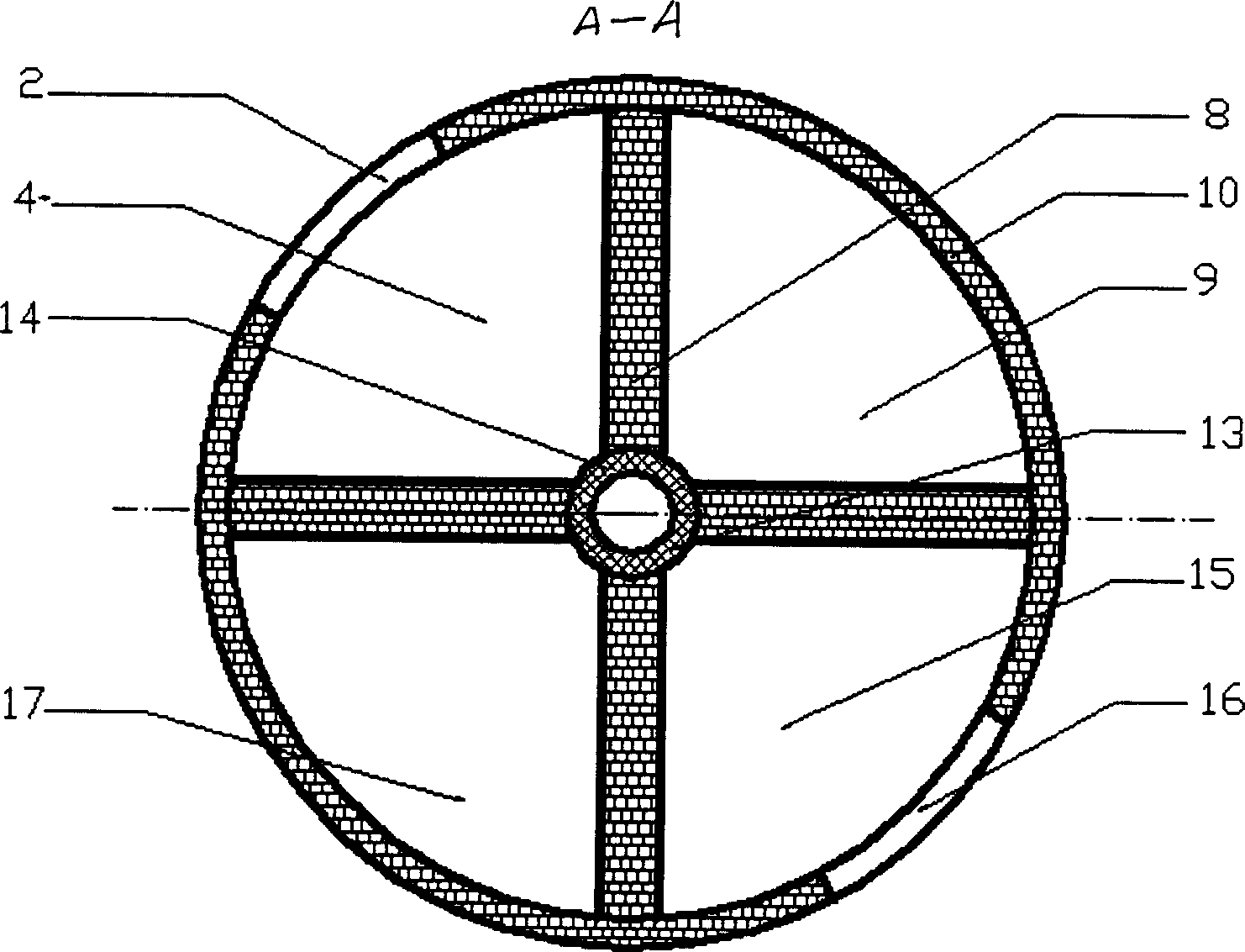

[0030] figure 1 A longitudinal sectional view of an embodiment of a multi-faceted three-dimensional combustion furnace for realizing clean combustion of coal; figure 2 for figure 1 Fig. 3 is a three-dimensional structure schematic diagram of a multi-faceted three-dimensional combustion furnace for realizing clean coal combustion; as can be seen from the figure, the multi-faceted three-dimensional combustion furnace for realizing clean coal combustion provided by the present invention includes:

[0031] A cylindrical furnace body 10, the upper cover 1 is provided with a flue outlet 7, and it is characterized in that it also includes a rotary fire grate 5 arranged at the bottom of the cylindrical furnace body 10;

[0032] A vertical symmetrical cross partition assembly that divides the inner cavity of the cylindrical furnace body 10 vertically into at least two symmetrical gasification chambers and combustion chambers, the lower end of the partition assembly is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com