Patents

Literature

38results about How to "Increase combustion space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Decoupling combustion furnace and decoupling combustion method

ActiveCN101650025AIncrease combustion spaceImprove combustion intensityAir supply regulationCarburetting by solid carbonaceous material pyrolysisCombustionProcess engineering

The invention provides a decoupling combustion method, which comprises the following steps: a) firstly, performing pyrolysis and gasification of fuels to generate semicoke and gas; b) secondly, combusting part of gas and semicoke to perform oxidation reaction and reduction reaction to generate coke, and applying the generated heat to the pyrolysis and gasification in step a); c) thirdly, combusting the coke and the left gas generated in step a) under the condition that an excess air coefficient is less than 1, and simultaneously generating smoke in the combustion; and d) finally, performing full secondary combustion of the smoke and the remained gas after the steps. The decoupling combustion method can increase the decoupling combustion space and intensity with a smaller floor area; the increase of the gasification zone and the gasification intensity greatly improve the load increasing capability of a decoupling combustion furnace; and in addition, because the high-temperature smoke strongly heats the fuels in the upper part of a pyrolysis and gasification chamber and has higher pyrolysis and gasification intensity, the gas output is increased and the combustion amount of solid semicoke is reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

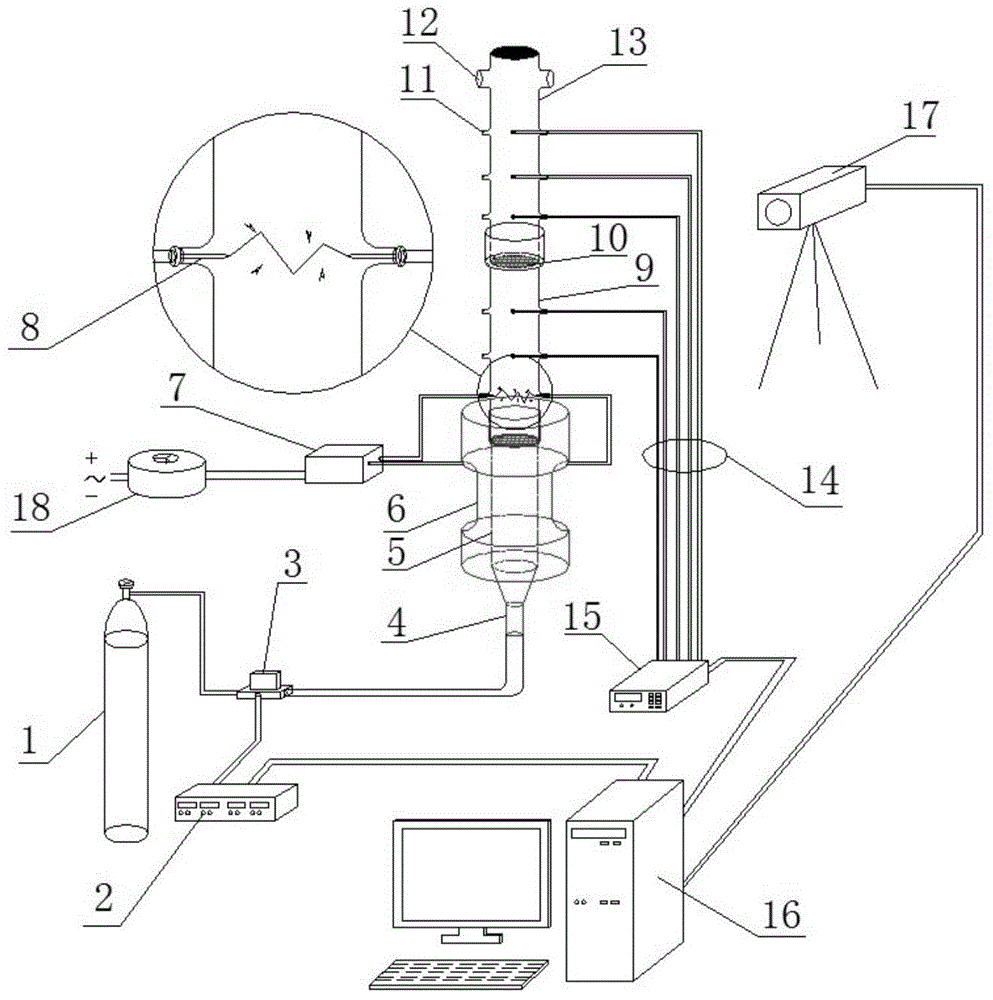

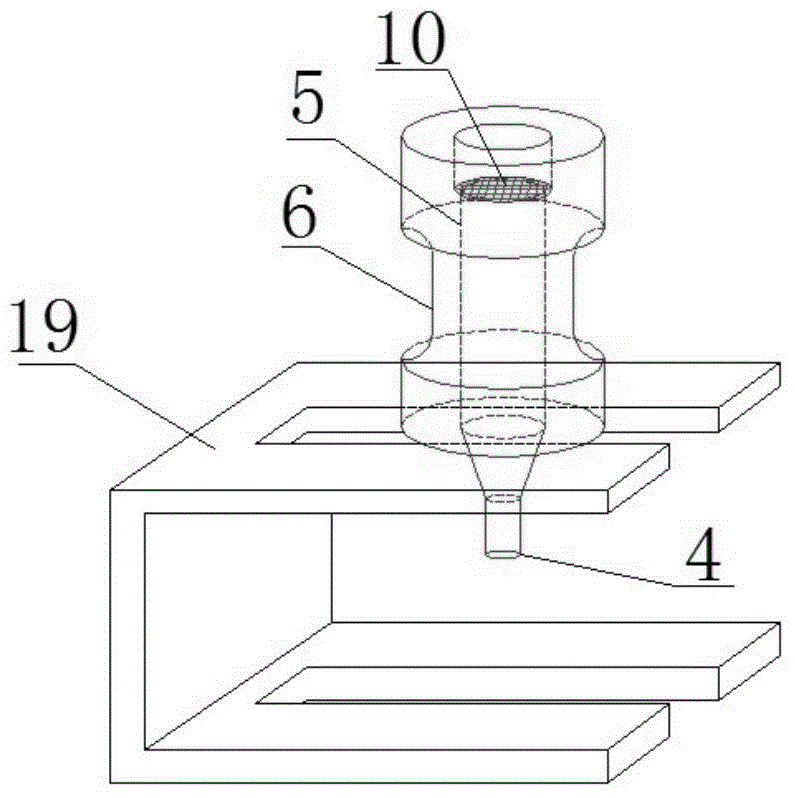

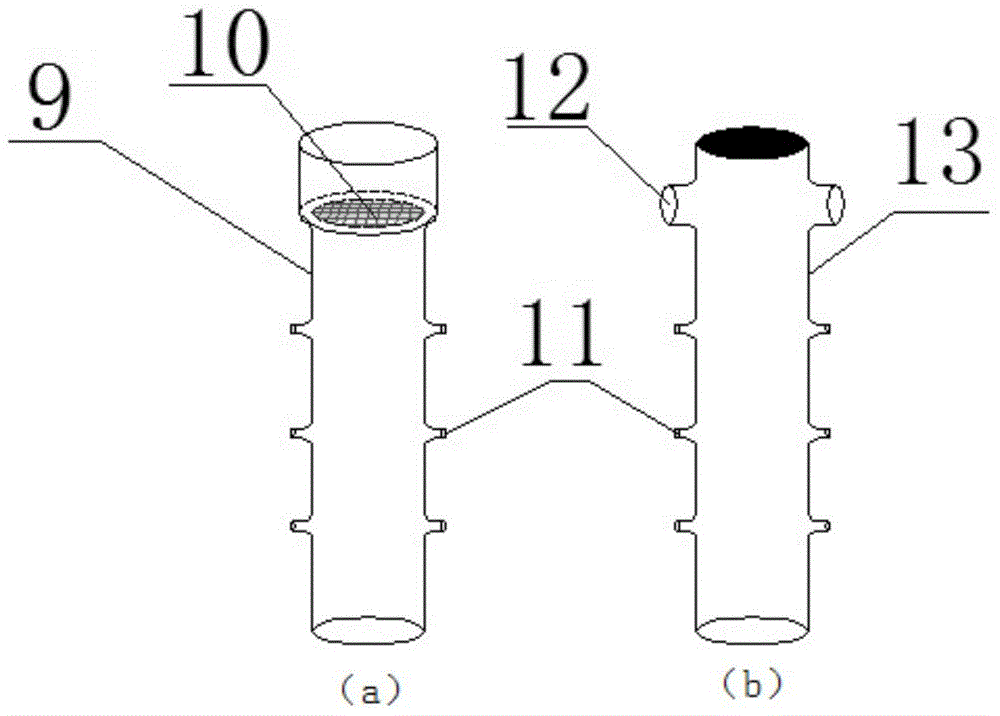

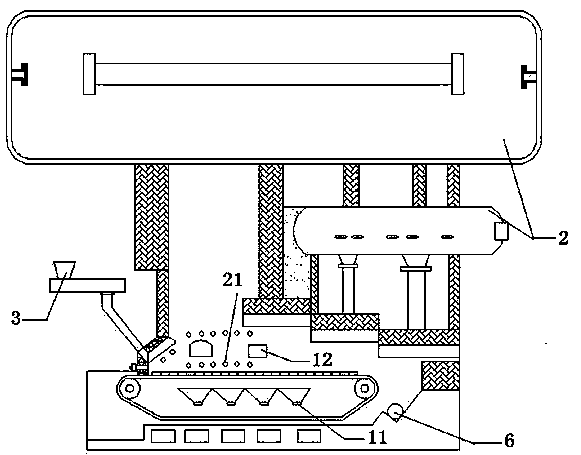

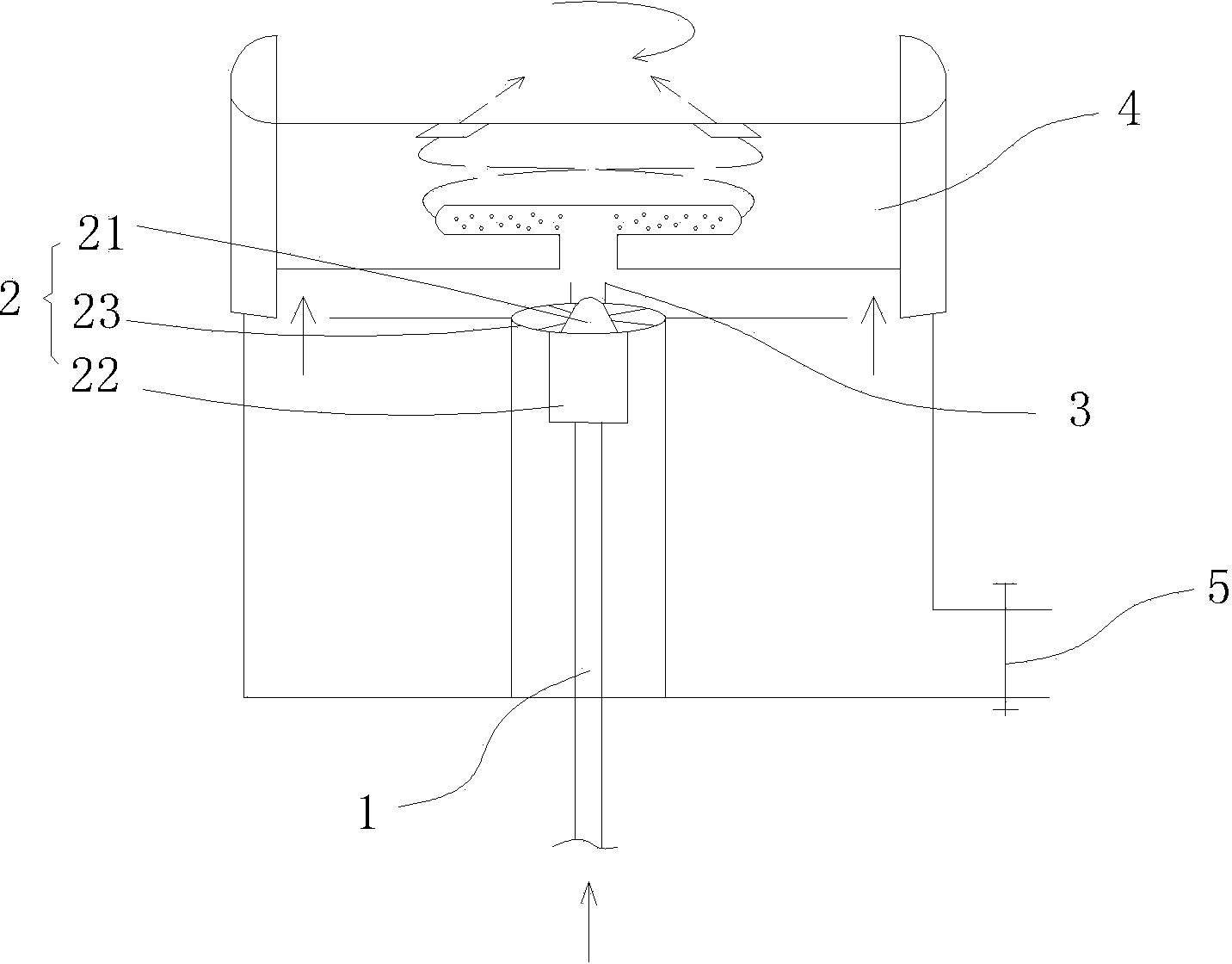

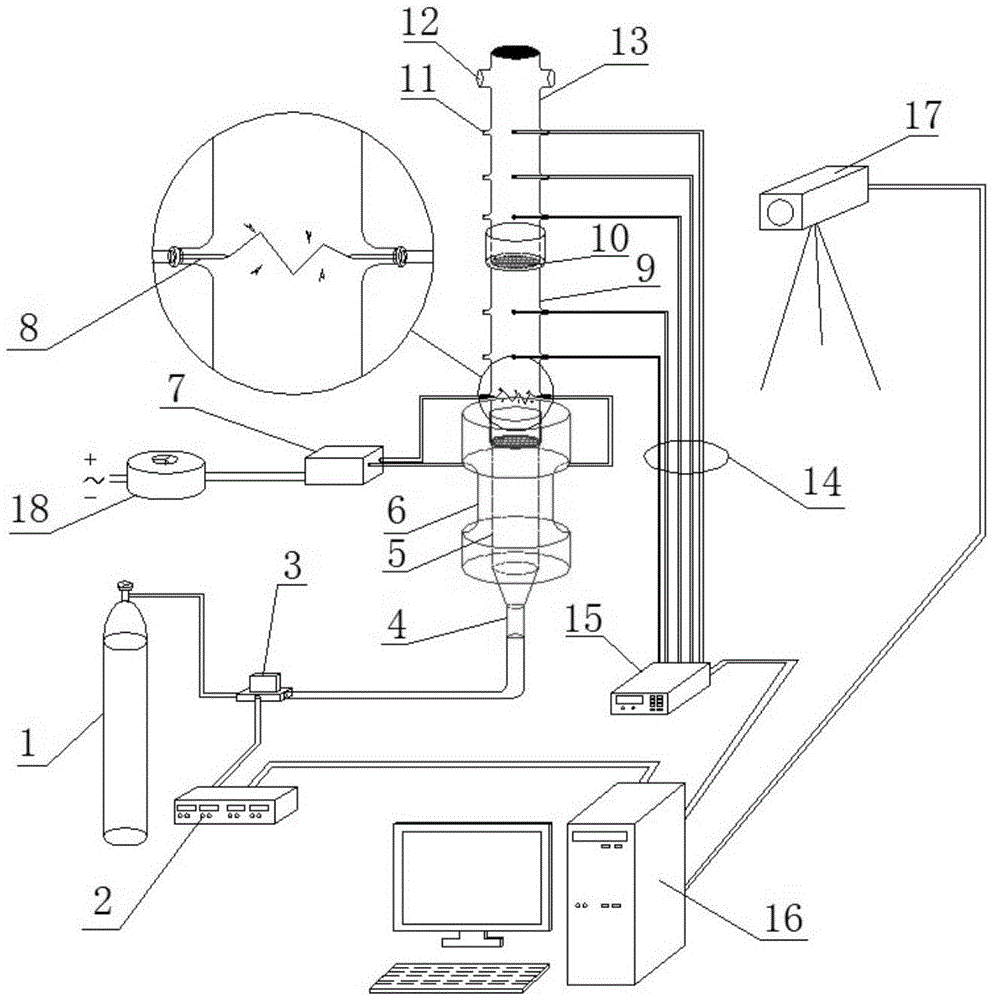

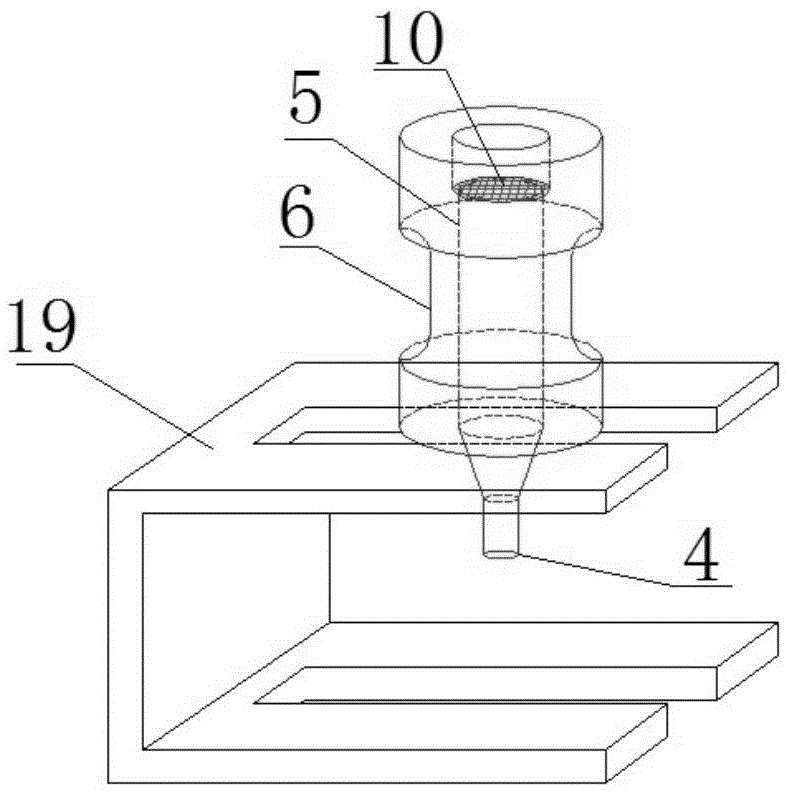

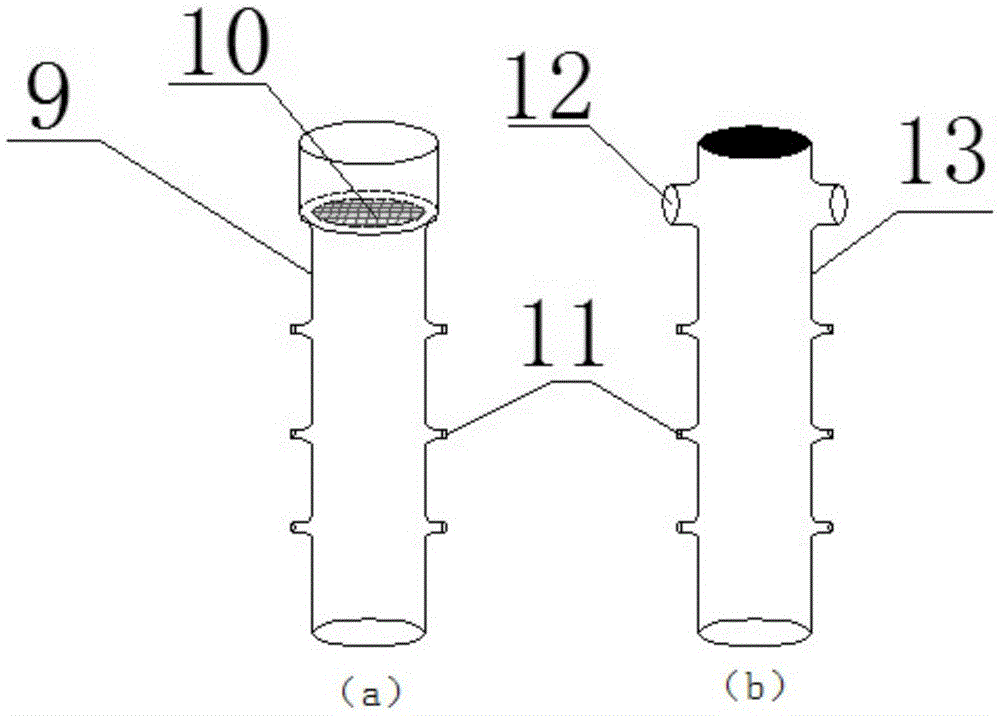

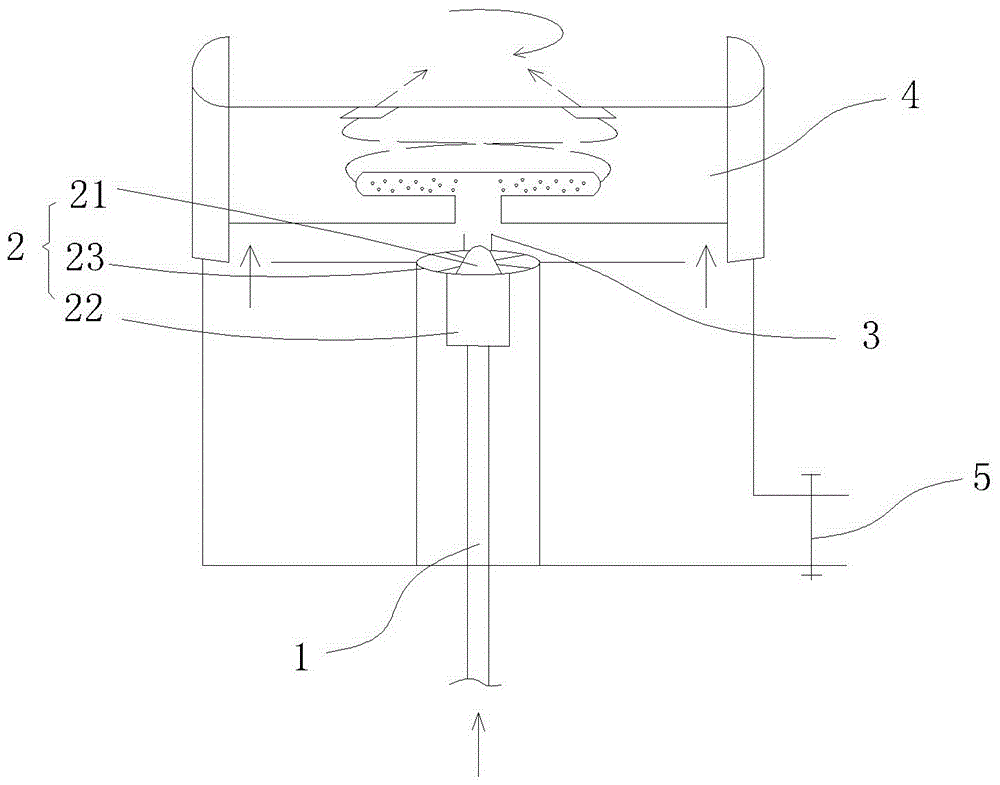

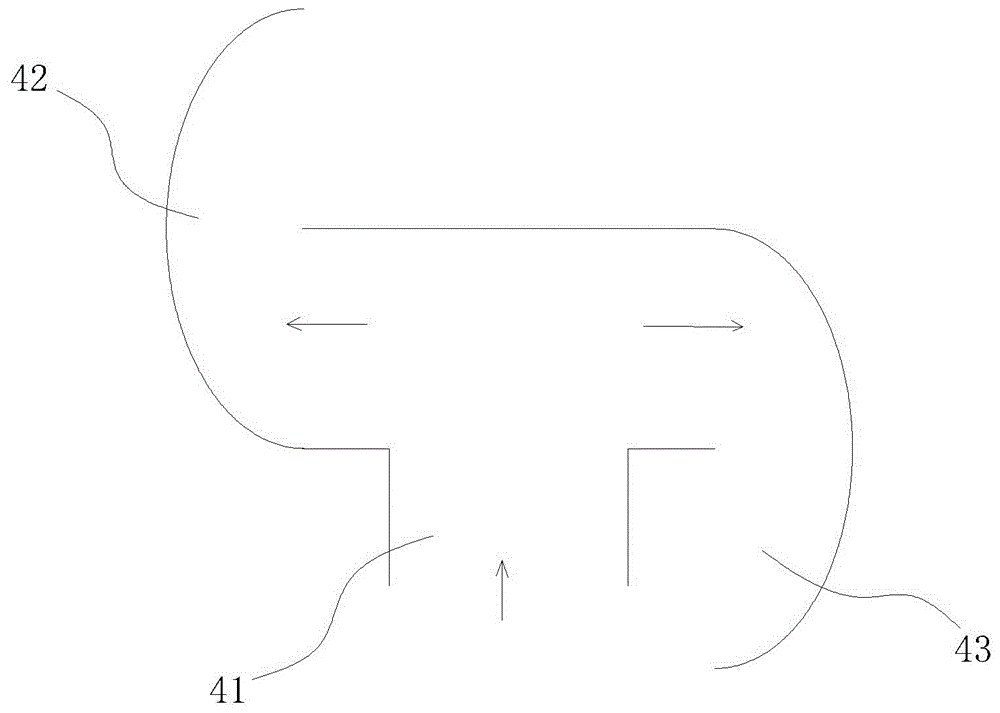

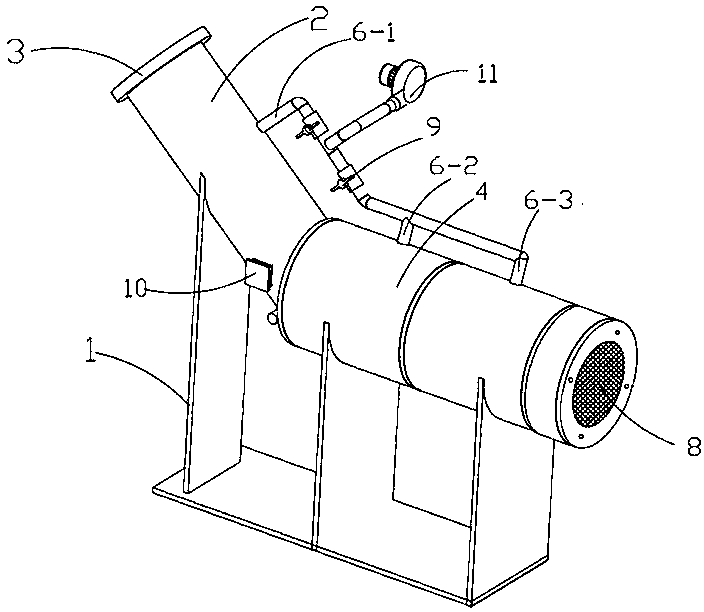

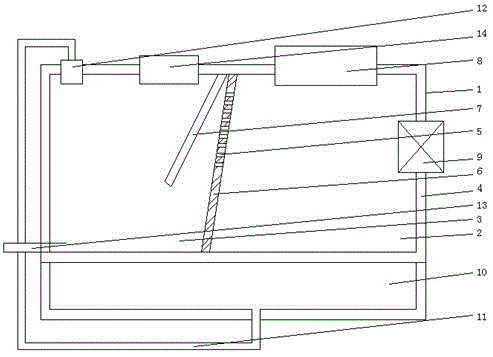

Detachable solid fuel suspension combustion experiment testing device and detachable solid fuel suspension combustion experiment testing method

ActiveCN104634922ASolve the problem of not easy to igniteEasy to igniteChemical analysis using combustionData acquisitionSolid fuel

The invention discloses a detachable solid fuel suspension combustion experiment testing device and a detachable solid fuel suspension combustion experiment testing method, belonging to the technical field of a solid fuel combustion experiment. The testing device comprises a suspension combustion mechanism, a combustion data acquisition mechanism, a gas supply mechanism and an ignition mechanism; a base is arranged on a base bracket; the lower end hole of a primary combustion pipe is communicated and in detachable connection with the upper end hole of an inner pipe of the base; the lower end hole of a secondary combustion pipe is communicated and in detachable connection with the upper end hole of the primary combustion pipe; two porous metal plates are respectively arranged at the upper end hole of the inner pipe of the base and the upper end hole of the primary combustion pipe. The testing method comprises the steps of placing fuel; enabling the fuel to suspend; burning; acquiring combustion data; finishing the experiment. The device and the method mainly have the functions of realizing visualization of a combustion state, realizing uniform combustion at a suspended state, carrying out a combustion test on multiple samples for once and enabling the large-particle samples to be easily ignited.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

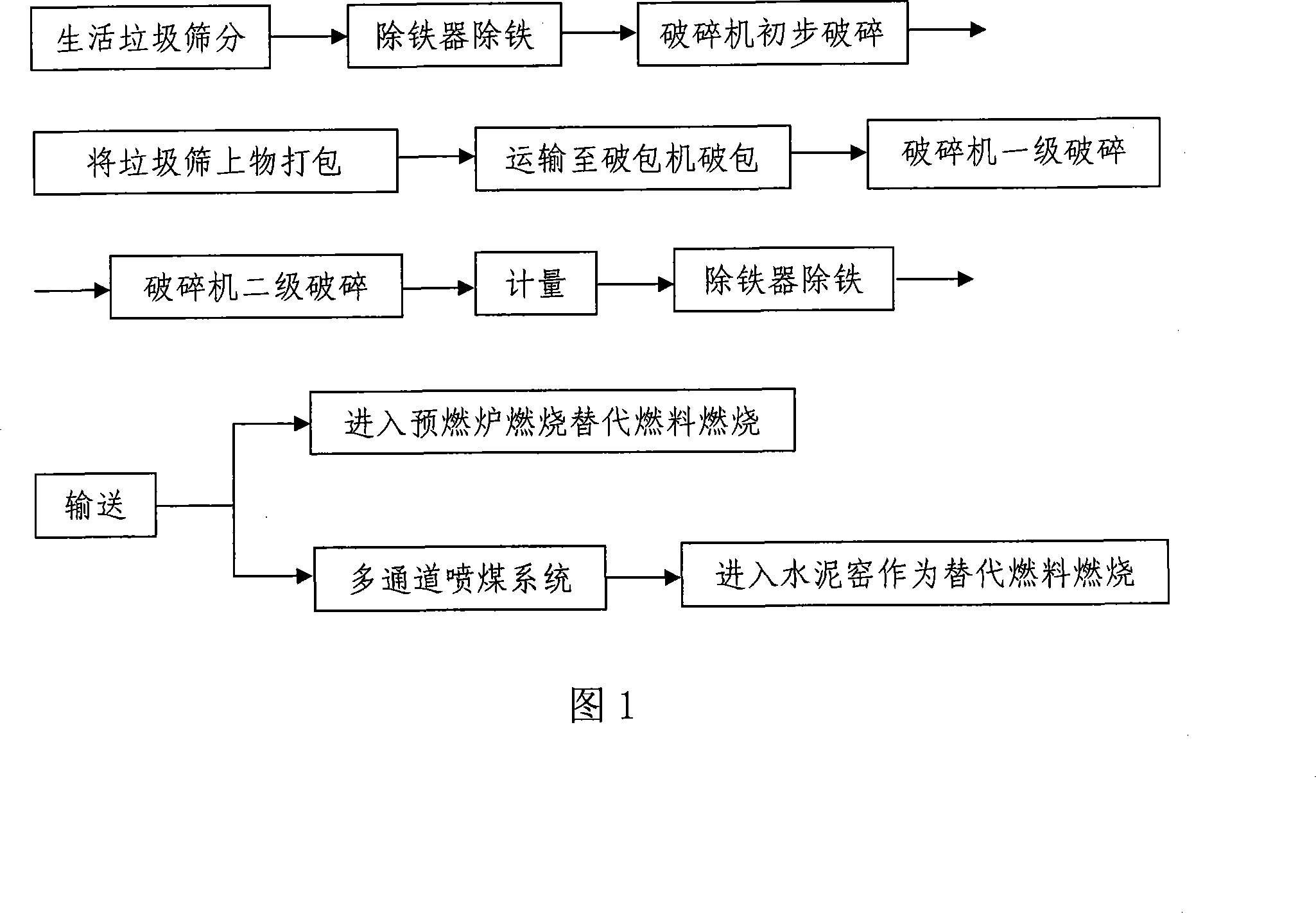

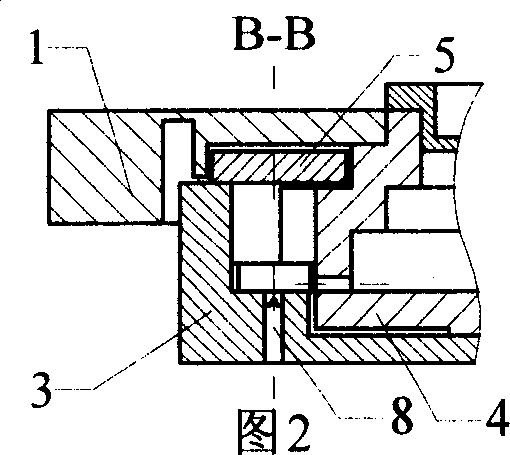

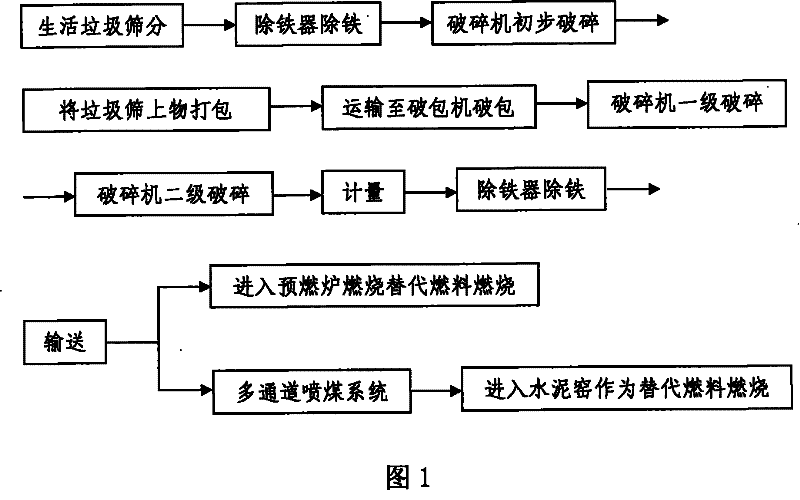

Method for substituting cement kiln fuel with garbage derived overtails

ActiveCN101173196AHigh calorific valueAvoid enteringBiofuelsSolid fuelsAlternative fuelsProcess engineering

The invention relates to a method for adopting waste derivative oversize material as substitute for cement kiln fuel, which is characterized in that the domestic waste in refuse reclamation station is separated and sorted, broken in packages, crushed and completely stirred and mixed, one part of the waste enters a precombustion furnace in the kiln tail of a cement kiln for combustion, while the other part of the waste enters the cement kiln from the kiln hood for combustion, thus the substitute fuel for cement production is produced. The invention has the advantages that the waste derivative oversize material having calorific value is adopted to substitute for industrial fuel in the cement kiln, thus resources of waste derivative oversize material are fully utilized, and coal energy resources are saved; simultaneously the cement kiln has the characteristics of high temperature, large carrying capacity, no residue after waste treatment and no secondary pollution, therefore the invention has the great advantages of energy saving and environmental protection.

Owner:LINGCHUAN JINYU CEMENT

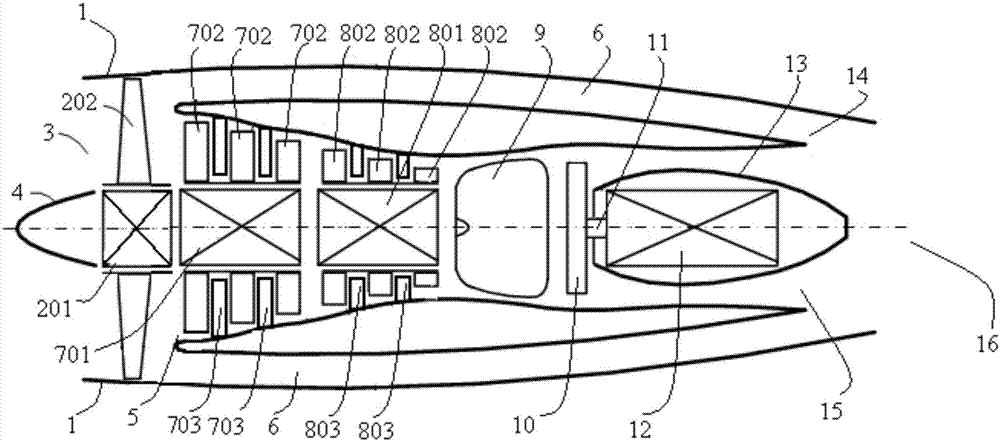

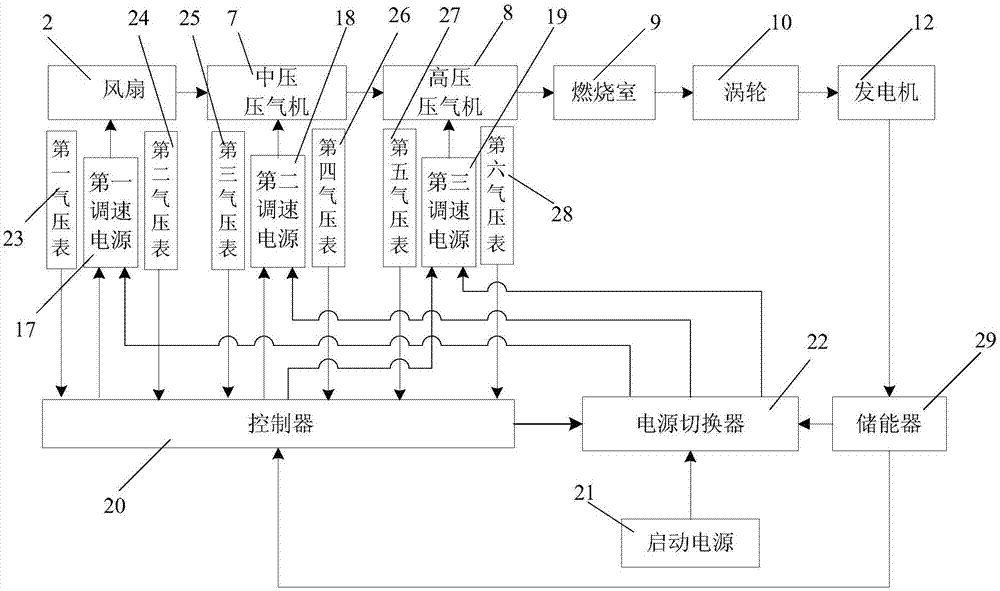

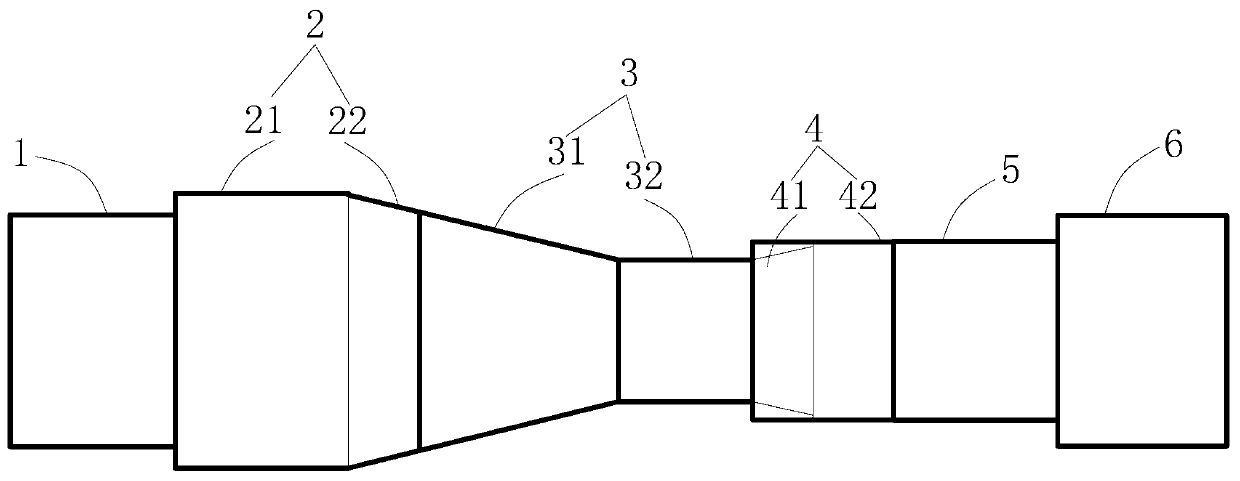

Segmented serial electric rotor turbofan engine and control method thereof

InactiveCN107355314AReduce the probability of surgeSimple mechanical structureJet propulsion plantsAviationCombustion chamber

The invention belongs to the technical field of aviation gas turbine engines, and discloses a segmented serial electric rotor turbofan engine and a control method thereof. The segmented serial electric rotor turbofan engine comprises an intermediate-pressure gas compressor, a high-pressure gas compressor, a combustion chamber, a turbine, a generator, a first speed adjusting power source, a second speed adjusting power source, a third speed adjusting power source, a controller, a power switcher, a starting power source and the like. A fan is driven by the first speed adjusting power source, the intermediate-pressure gas compressor is driven by the second speed adjusting power source, the high-pressure gas compressor is driven by the third speed adjusting power source, and therefore rotors of the fan, the intermediate-pressure gas compressor and the high-pressure gas compressor have no mechanical connection; the controller adjusts the rotating speeds of the fan, the intermediate-pressure gas compressor and the high-pressure gas compressor in real time according to the inlet and outlet airflow pressure ratios of the fan, the intermediate-pressure gas compressor and the high-pressure gas compressor; the gas compression efficiency is high; the probability that surge happens to the gas compressors can be effectively reduced; and the structure is simple.

Owner:刘雨棣 +1

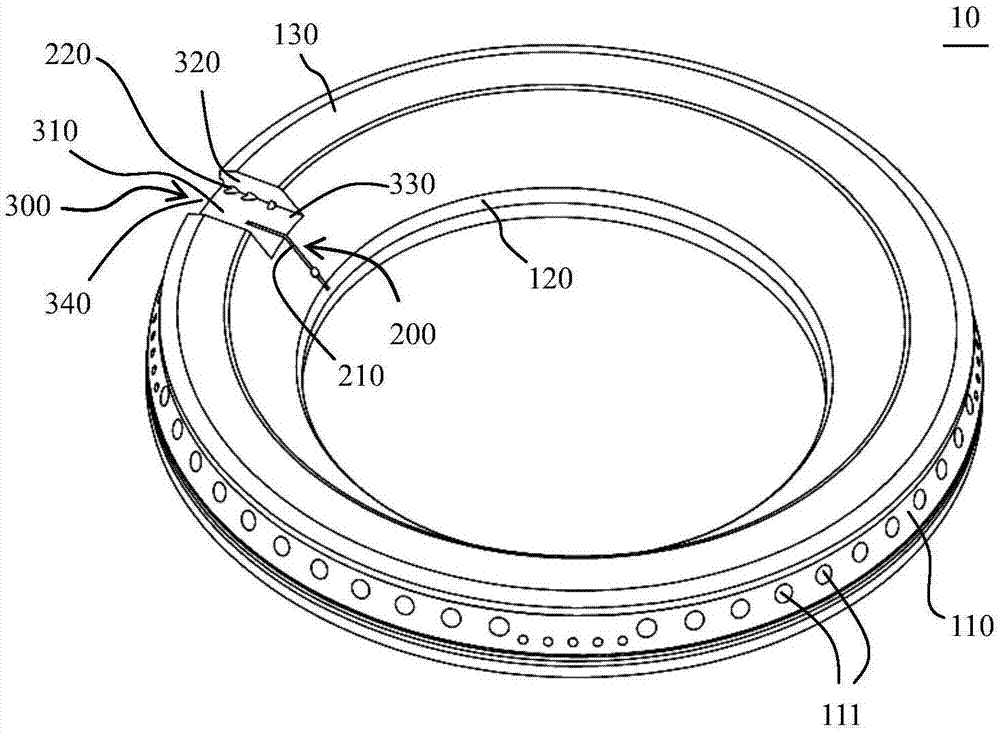

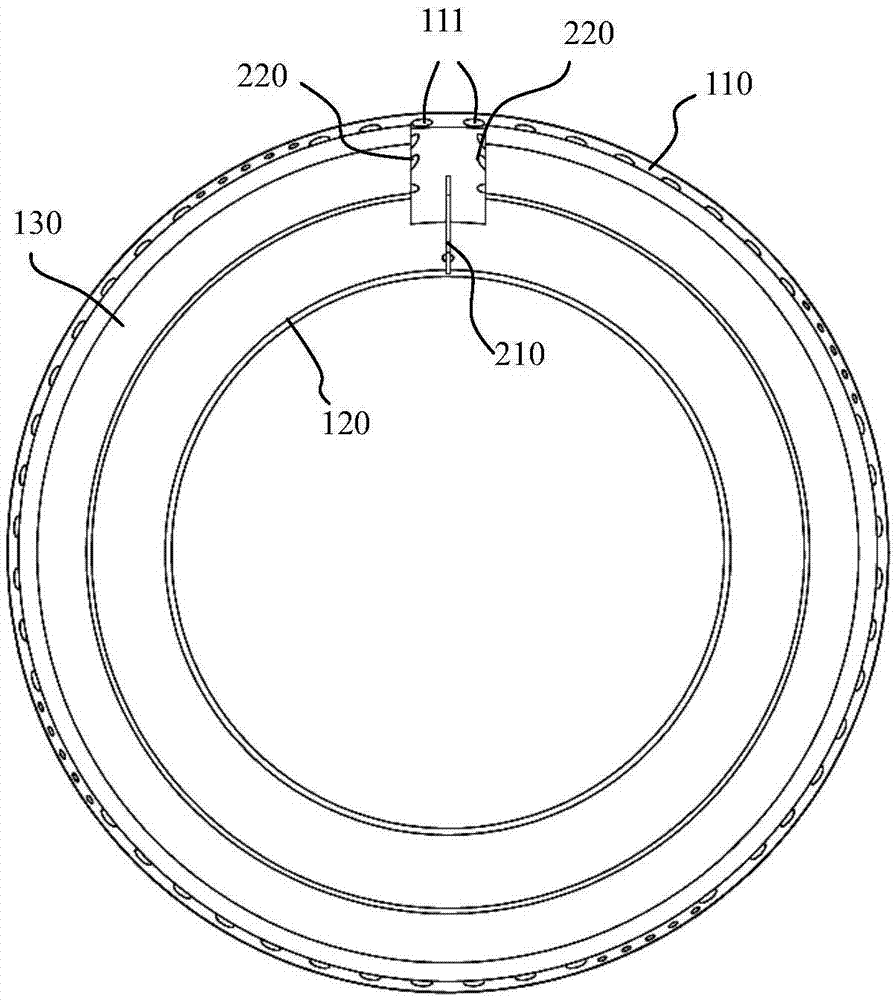

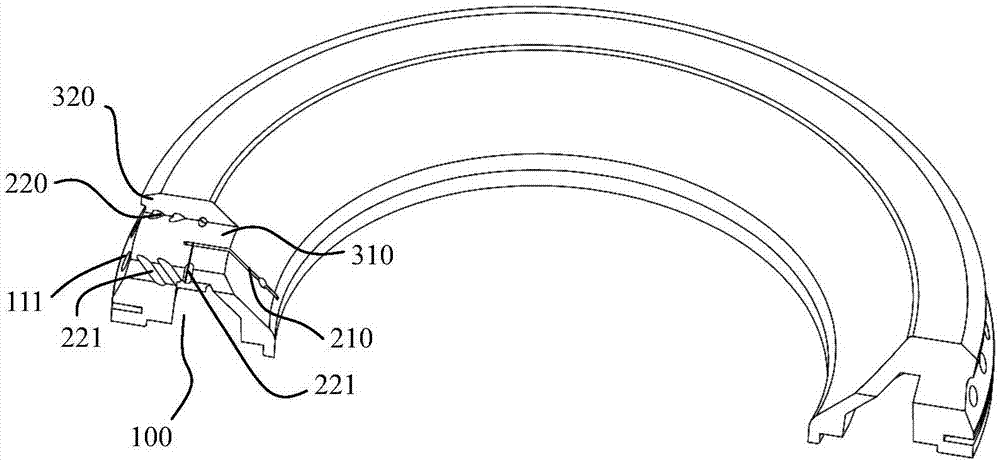

Fire cover of gas burner, gas burner and gas stove

ActiveCN106895405AIncrease combustion spaceTroubleshoot poor deliveryGaseous fuel burnerEngineeringFuel gas

The invention relates to a fire cover of a gas burner, a gas burner and a gas stove. A recessed cavity (100) is formed in the bottom of the fire cover (10) of the gas burner (2); the fire cover (10) includes a first wall surface (110) having gas outlets (111), and the gas outlets (111) communicate with the recessed cavity (100); the fire cover (10) includes a fire transmission structure (200) communicating with the recessed cavity (100); the fire transmission structure (200) extends from the other wall surface to the first wall surface (110); a groove (300) sinking toward the bottom is formed in the fire cover (10); and at least a part of the fire transmission structure (200) is positioned in the groove (300). The problem of poor flame transmission due to limited burning space can be solved.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

Hard carbon black reaction furnace

PendingCN110511599AReduce processing burdenBurn fullyPigmenting treatmentCombustion chamberWater vapor

The invention provides a hard carbon black reaction furnace. The hard carbon black reaction furnace comprises a burner, a combustion chamber, a throat pipe section, a reaction section, a reaction termination quenching section and a carbon black flue gas retention section which are connected in sequence. Through reasonable design of the length of a first straight pipe section of the combustion chamber, fuel is fully combusted, so the fuel is saved; the throat pipe section is designed with a double-row raw material oil gun, so raw materials are sprayed into a reaction furnace to be atomized better; by adoption of inclined plane reducing in the reaction section, the carbon black flue gas flow of a reaction is accelerated again, and a shearing force and the degree of cracking are increased, sothe reaction is uniform and violent, and produced carbon black particles are more uniform; the reaction termination quenching section is combined with the reaction section to expand again, so the structural degree of carbon black before the reaction is terminated is higher, and collision of crystal nucleus is more violent; meanwhile, sufficient water vapor and carbon black flue gas mixing space is provided, so the reaction can be rapidly terminated. The hard carbon black reaction furnace provided by the invention has the advantages of capability of producing and processing a plurality of varieties of carbon black series, high production capacity, stable quality, low consumption, simple and highly-efficient operation, etc., and can reach a carbon black production capacity of 6W tons per year.

Owner:山西三强新能源科技有限公司

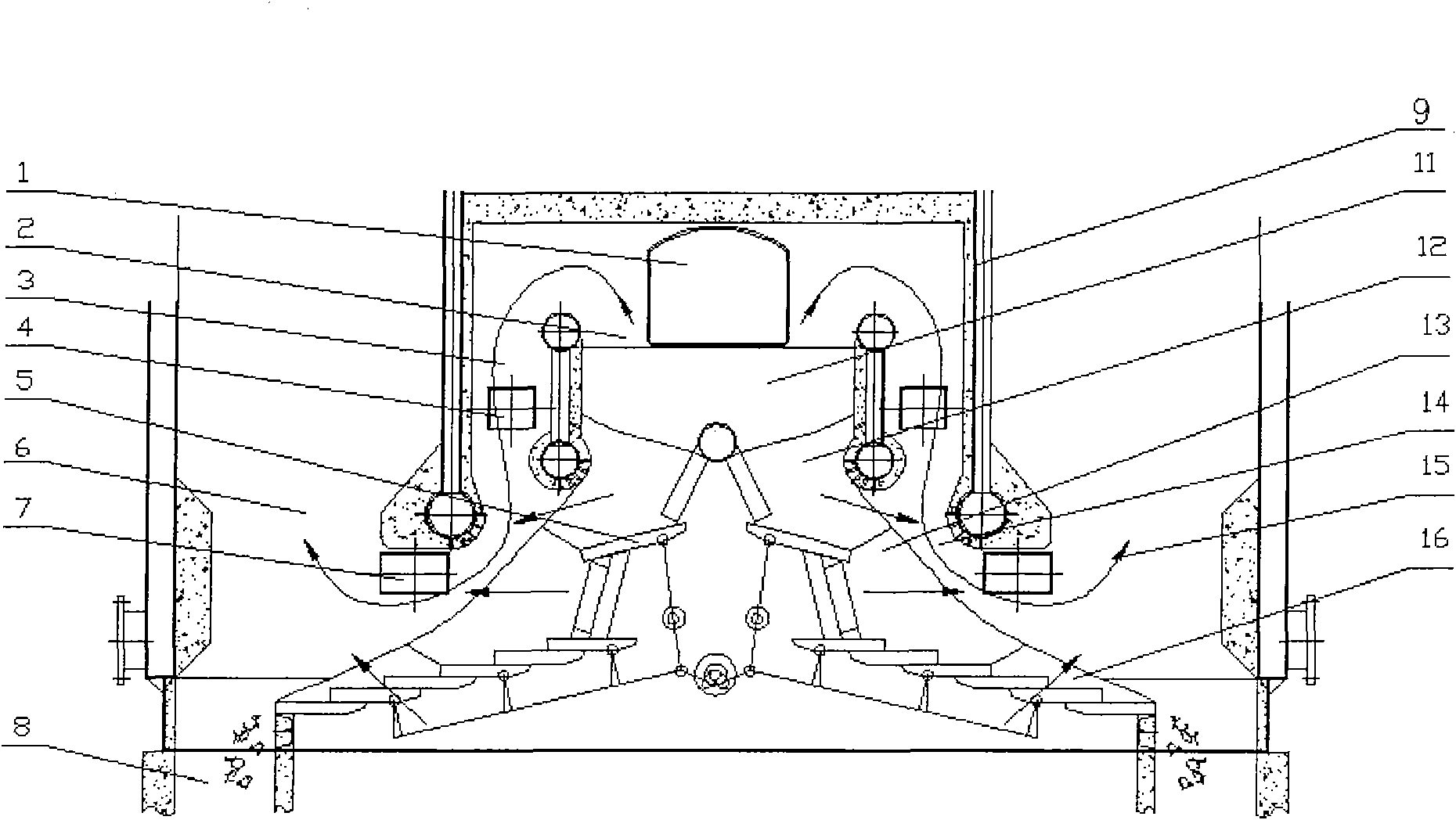

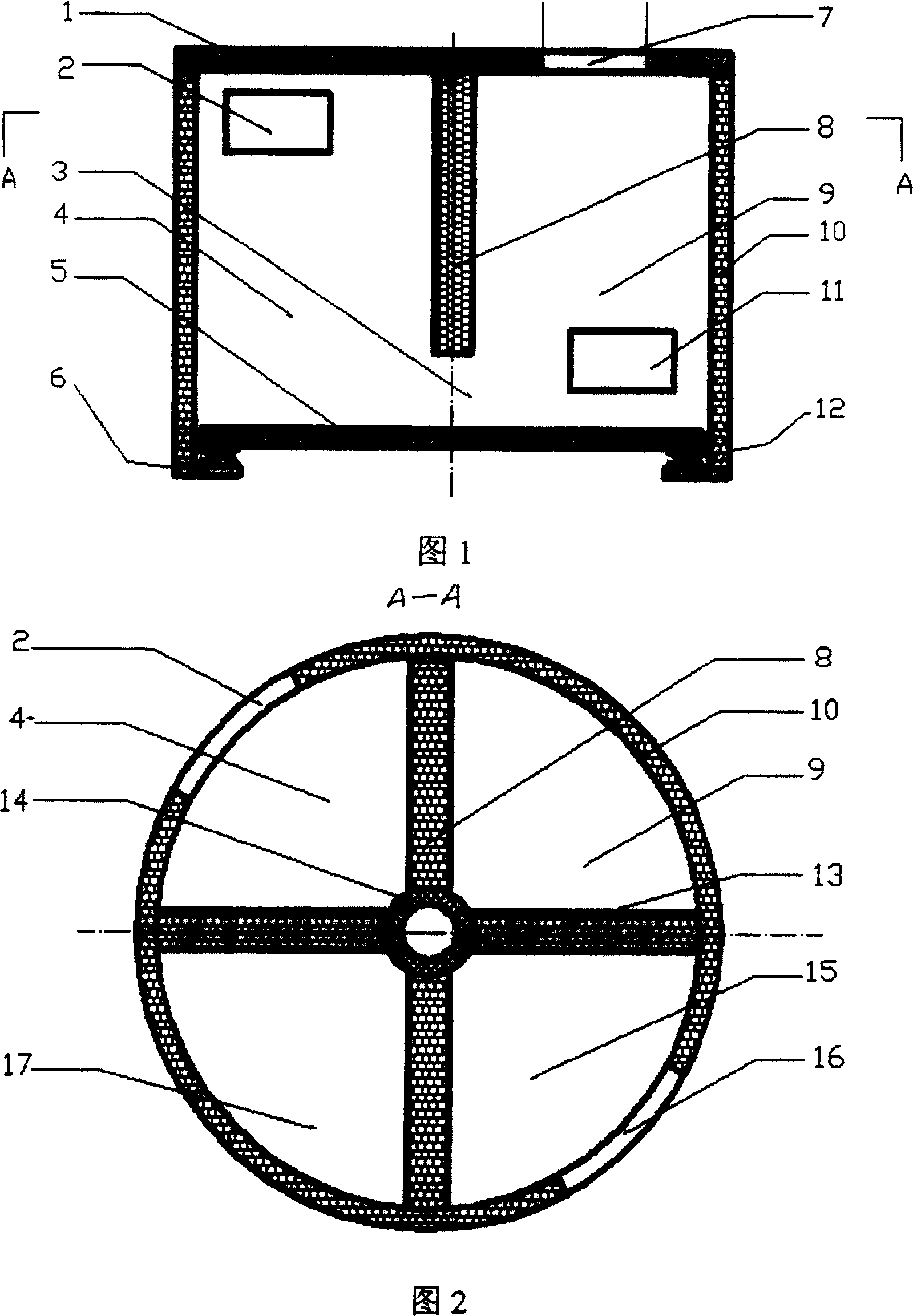

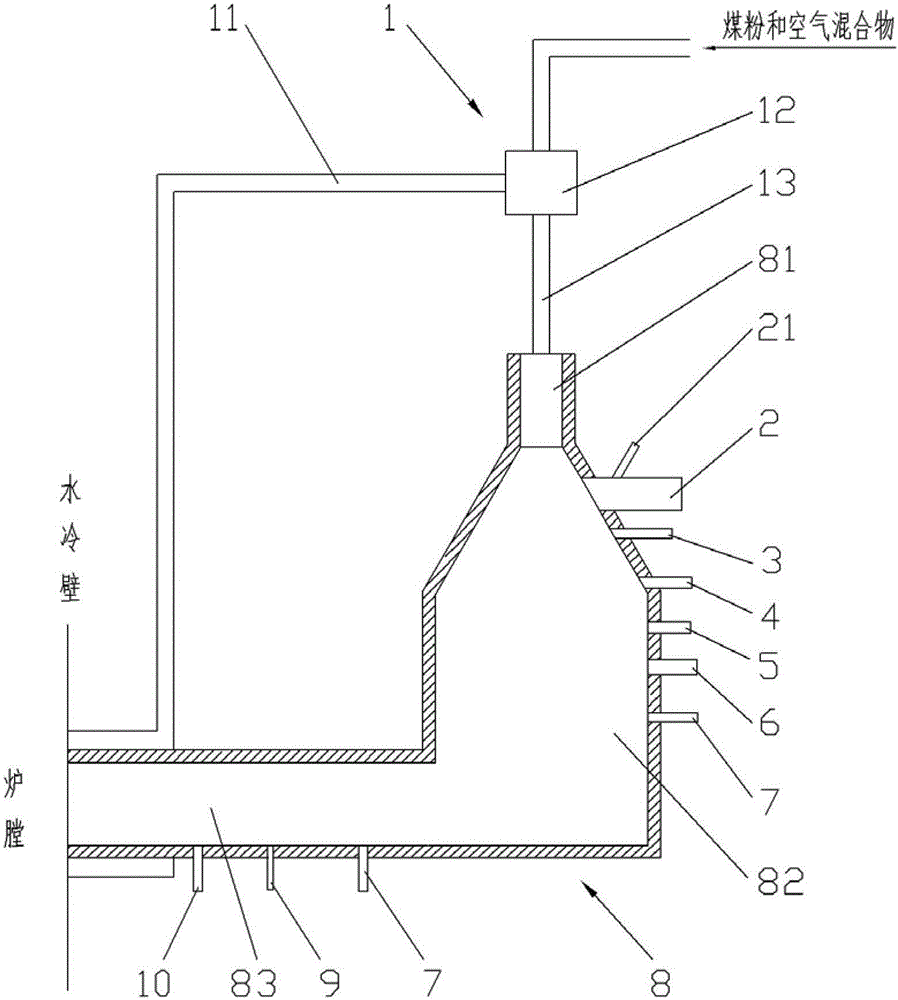

Multi-side stereo combustion boiler capable of realizing clean combustion of coal and combustion method thereof

InactiveCN1789806AEmission reductionSuppress sootSolid fuel combustionCombustion apparatusCombustion chamberNitrogen oxide

This invention relates to one multi-surface stand burst furnace and method to realize coke cleaning burst, wherein, the burst furnace comprises the following parts: column furnace with channel exit located on top cover and rotation row located on the bottom of the furnace; at least one gas chamber and one pair of burst stand symmetric cross isolation element and space burst mouth between the isolation parts down end and furnace row with gas room and burst room connected; each gas chamber top furnace wall is located with each coke adding mouth with smoke exit mouth and reside exit mouth downside as secondary mouth. The burst method is to cooperate with multiple gas rooms through rotation furnace row.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

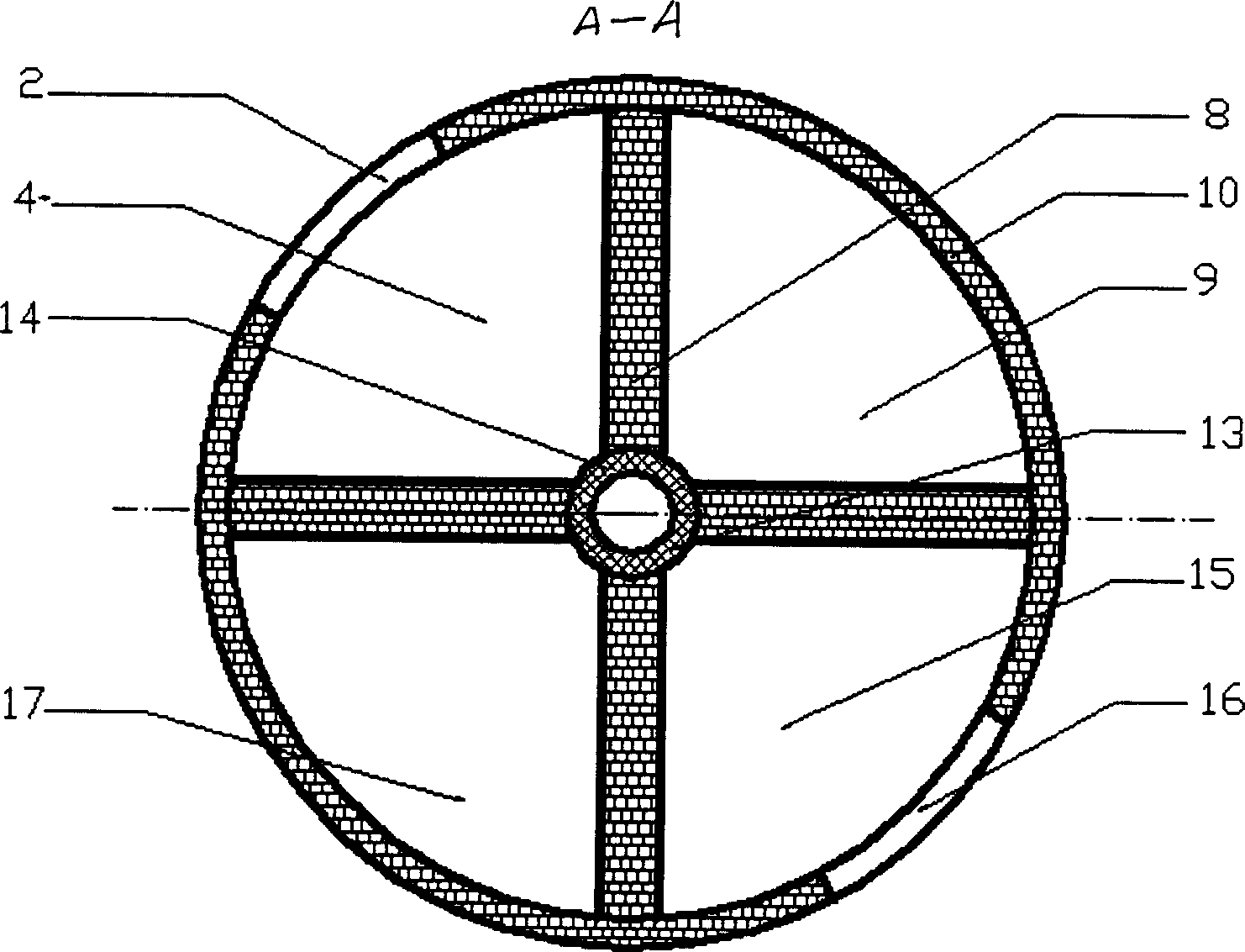

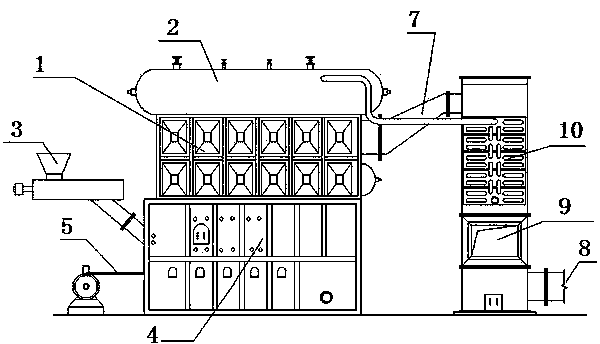

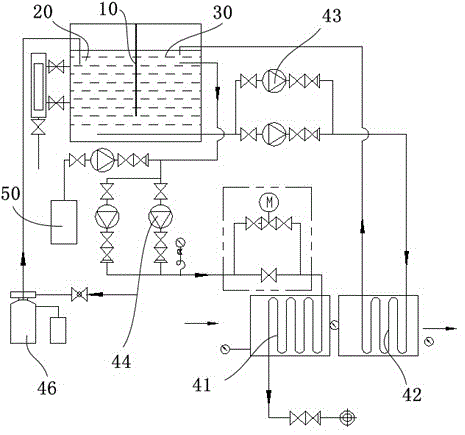

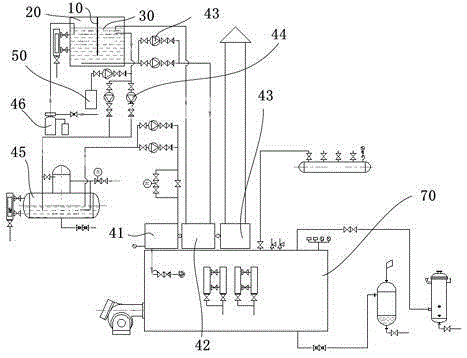

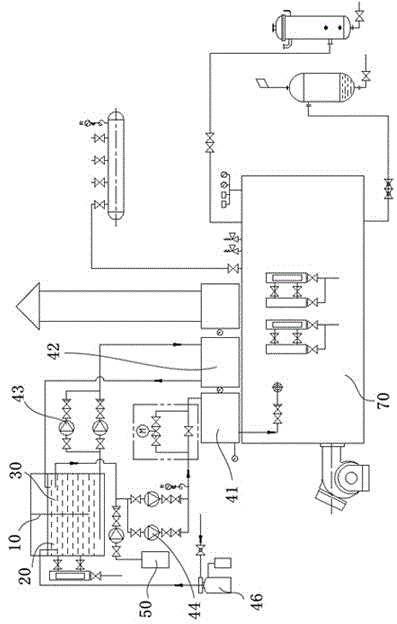

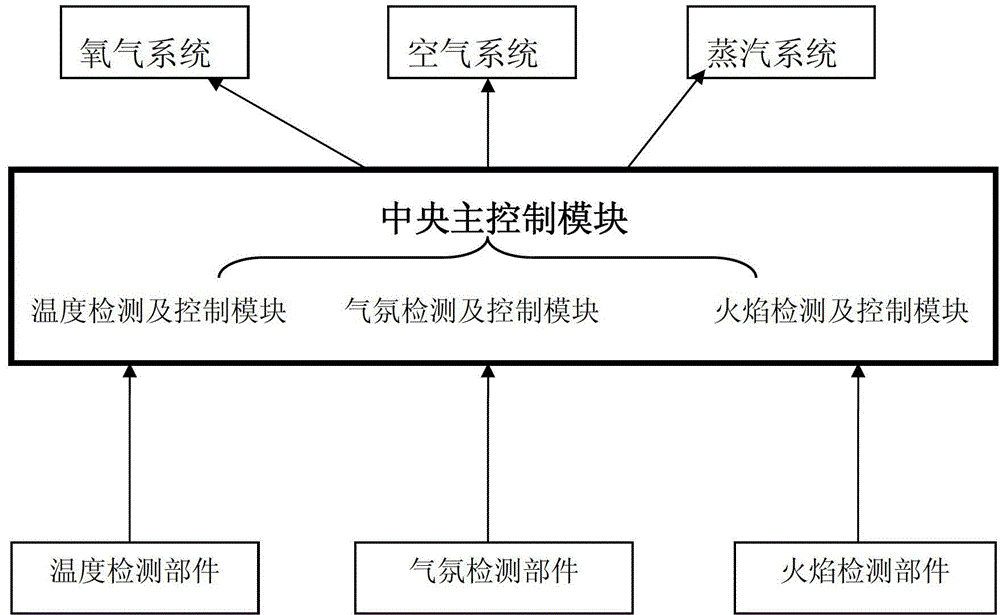

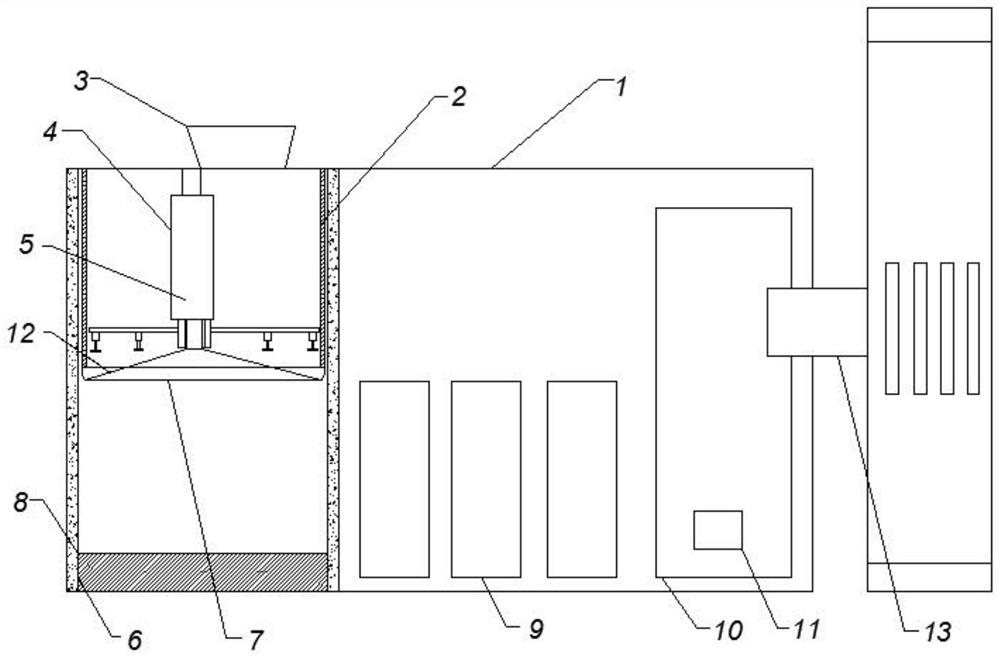

High-efficiency energy-saving biomass boiler system

ActiveCN103644561AIncrease profitDoes not affect temperatureBoiler controlSolid fuel combustionAir preheaterAutomatic control

The invention provides a high-efficiency energy-saving biomass boiler system which comprises a boiler body, a feeding system, a fire grate, a discharging device, a smoke discharging opening, a primary air inlet chamber, a secondary air inlet pipe and an air inlet chamber. A combustion chamber and a water vapor system placed above the combustion chamber are arranged in the boiler body. The feeding system is connected with the boiler body, so that biomass forming fuel is sent into the combustion chamber. The fire grate and the discharging device are placed at the bottom of the combustion chamber. The smoke discharging opening is communicated with the combustion chamber and penetrates through the water vapor system. The primary air inlet chamber is arranged below the fire grate. The secondary air inlet pipe and the air inlet chamber are arranged above the fire grate. Hot smoke discharged from the smoke discharging opening is recycled through a smoke discharging pipe and then passes through a water preheater and a secondary air preheater, wherein an outlet of the secondary air preheater is connected with a secondary air inlet chamber of the combustion chamber, inlet air is heated, and the water preheater is connected with a water inlet of a boiler, so that inlet water has certain temperature. According to the high-efficiency energy-saving biomass boiler system, burning is complete, boiler operation cost is low, feeding is convenient, heat using rate after biomass forming material burning releasing is improved, and steam production amount can be guaranteed by achieving automatic control over parameters.

Owner:浙江中吉新能源有限公司

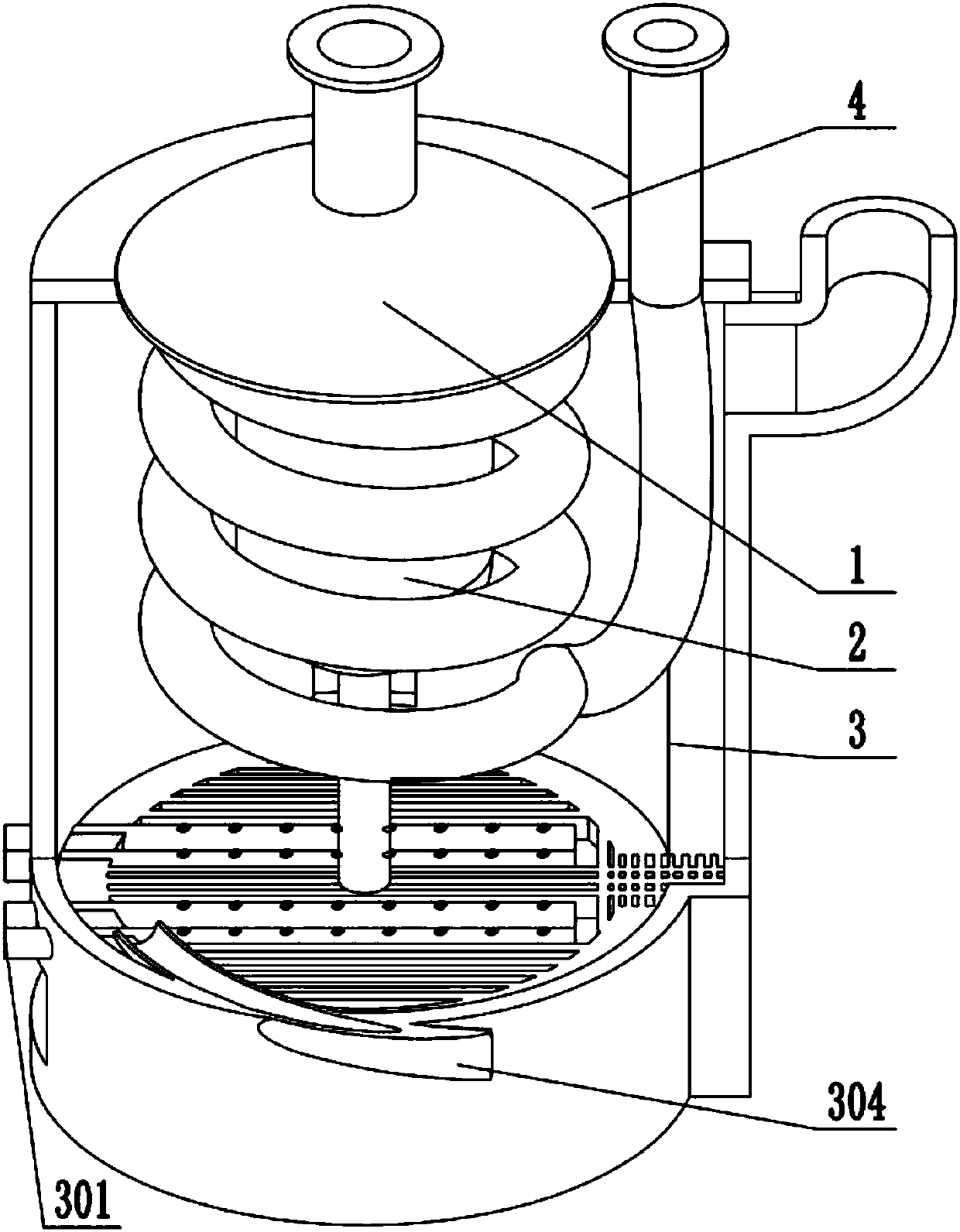

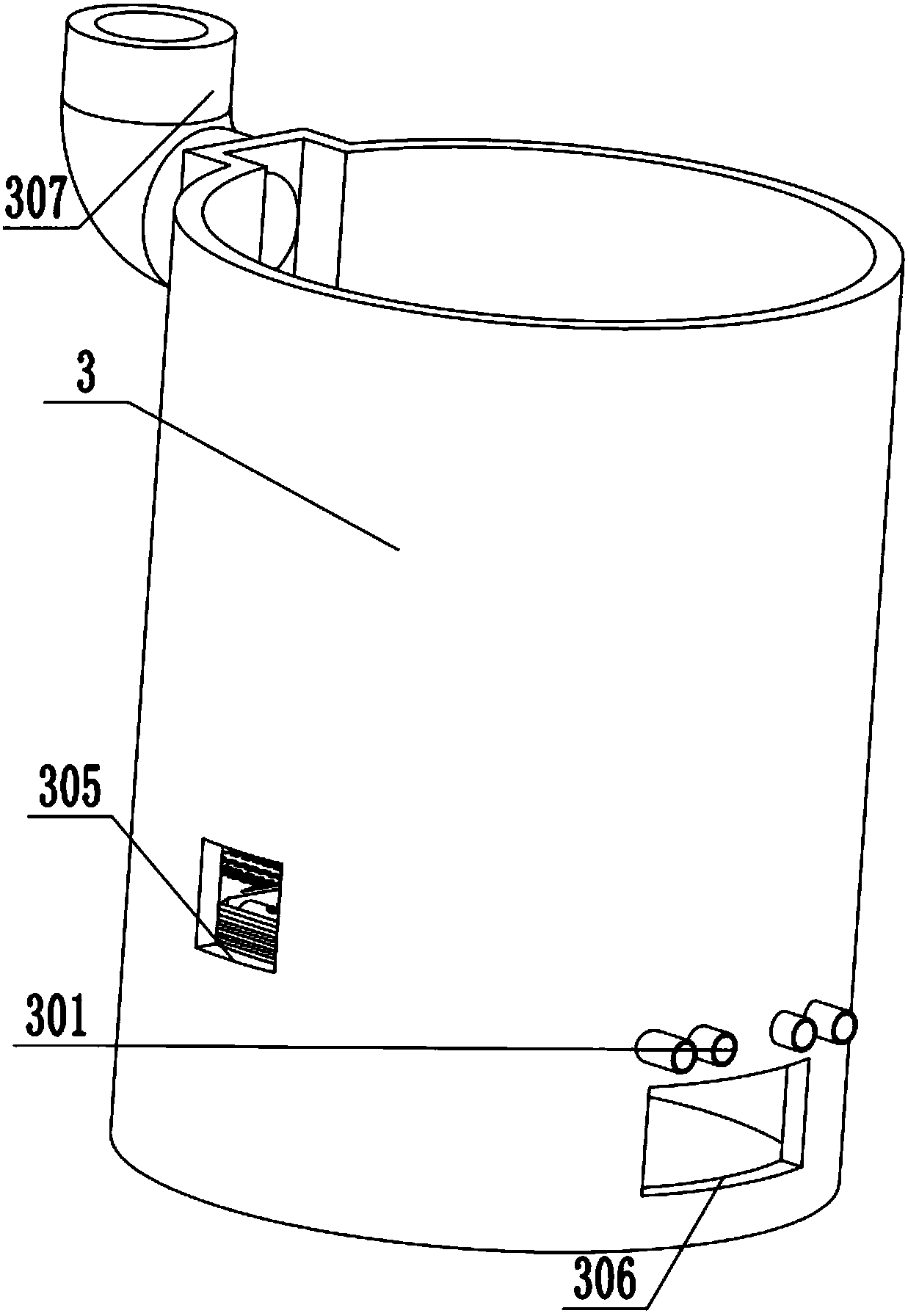

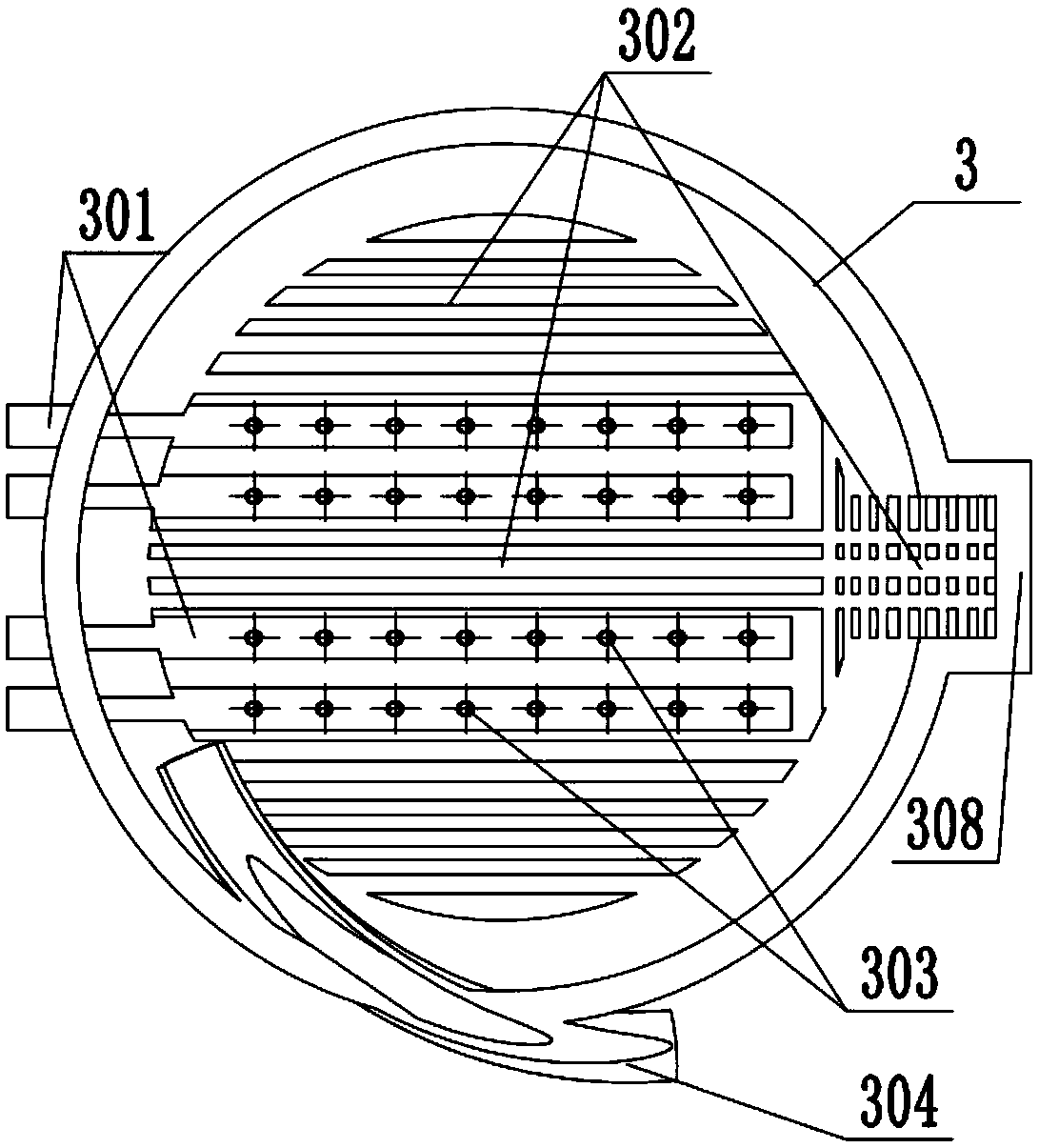

Environmental-friendly combustion furnace

InactiveCN103742920AIncrease combustion spaceFully automatic safe and reliable operationIncinerator apparatusCombustion chamberCombustor

The invention discloses an environmental-friendly combustion furnace. The environmental-friendly combustion furnace comprises a barrel-shaped combustion chamber, wherein the combustion chamber is connected with a spiral feeding mechanism through an air supply pipe; an ignition device is arranged on the combustion chamber; a fire outlet nozzle is also formed in the combustion chamber; the combustion chamber comprises a furnace body; a controller is arranged outside the furnace body; and a combustion chamber cover plate is covered on the top. Compared with the conventional furnaces and combustors, the environmental-friendly combustion furnace has the advantages that a large combustion space is formed in the structure design; a fuel oil ignition device is arranged, so that automation of ignition is realized; due to the adoption of automatic control in feeding, combustion and ignition of the combustion chamber, the environmental-friendly combustion furnace is convenient to operate; compared with the conventional furnace, the environmental-friendly combustion furnace is higher in combustion efficiency and lower in smoke exhaust temperature; due to the adoption of efficient insulation material, the surface temperature of a furnace body is low; radiation loss can be ignored; the environmental-friendly combustion furnace is capable of producing according to national norms and standards strictly, energy-saving, environmental-friendly and convenient to mount and use.

Owner:浙江华顺炉业有限公司

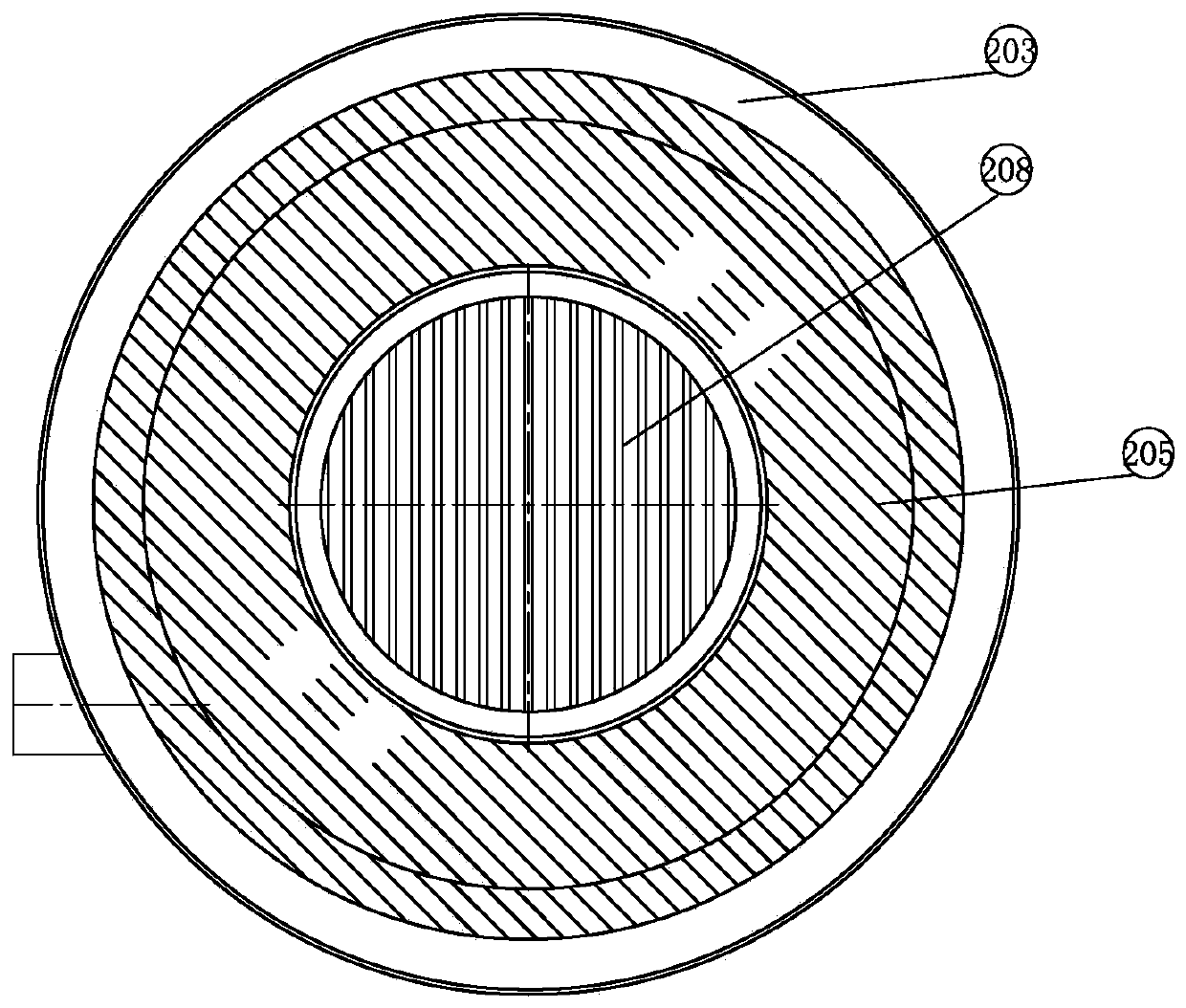

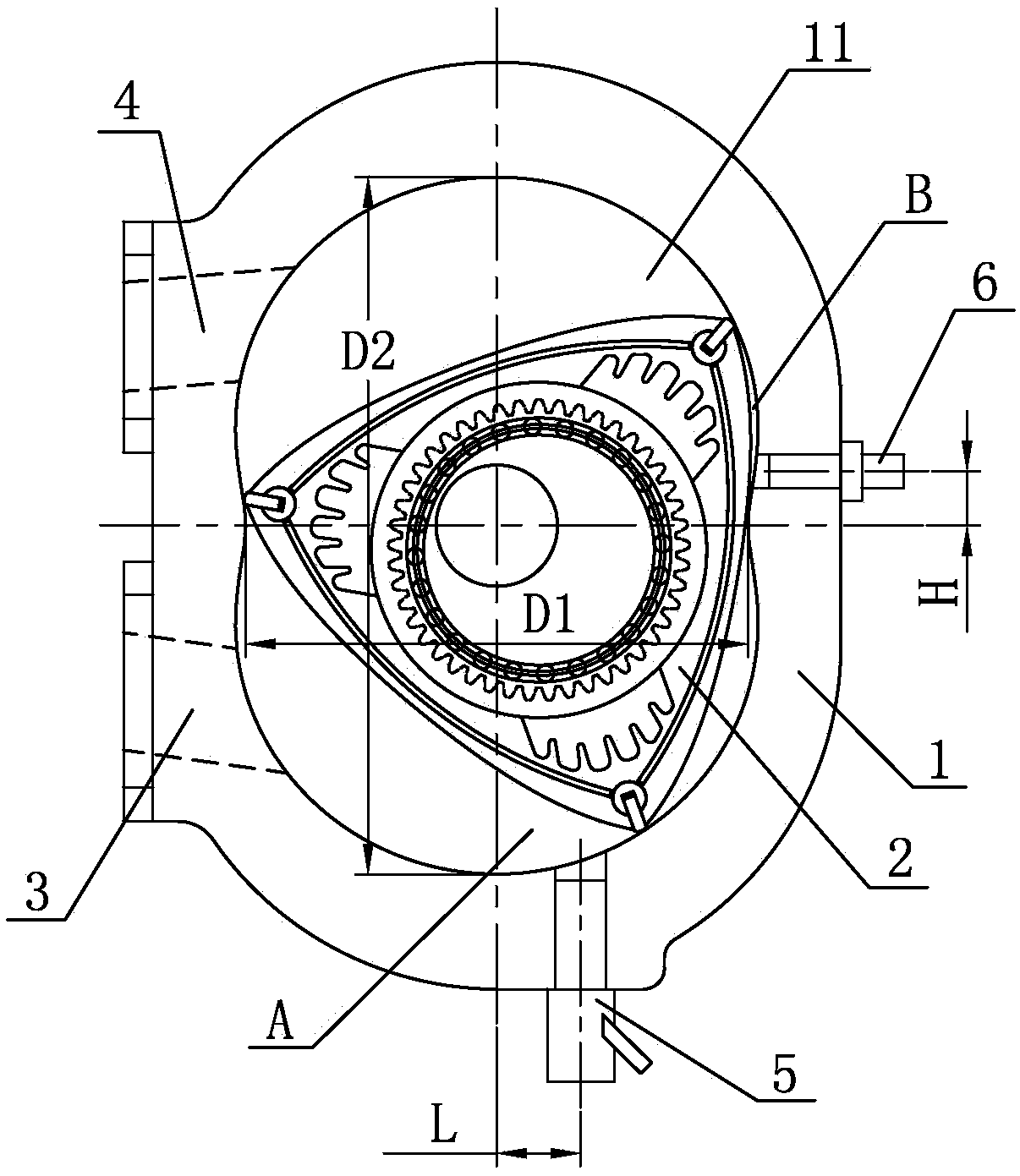

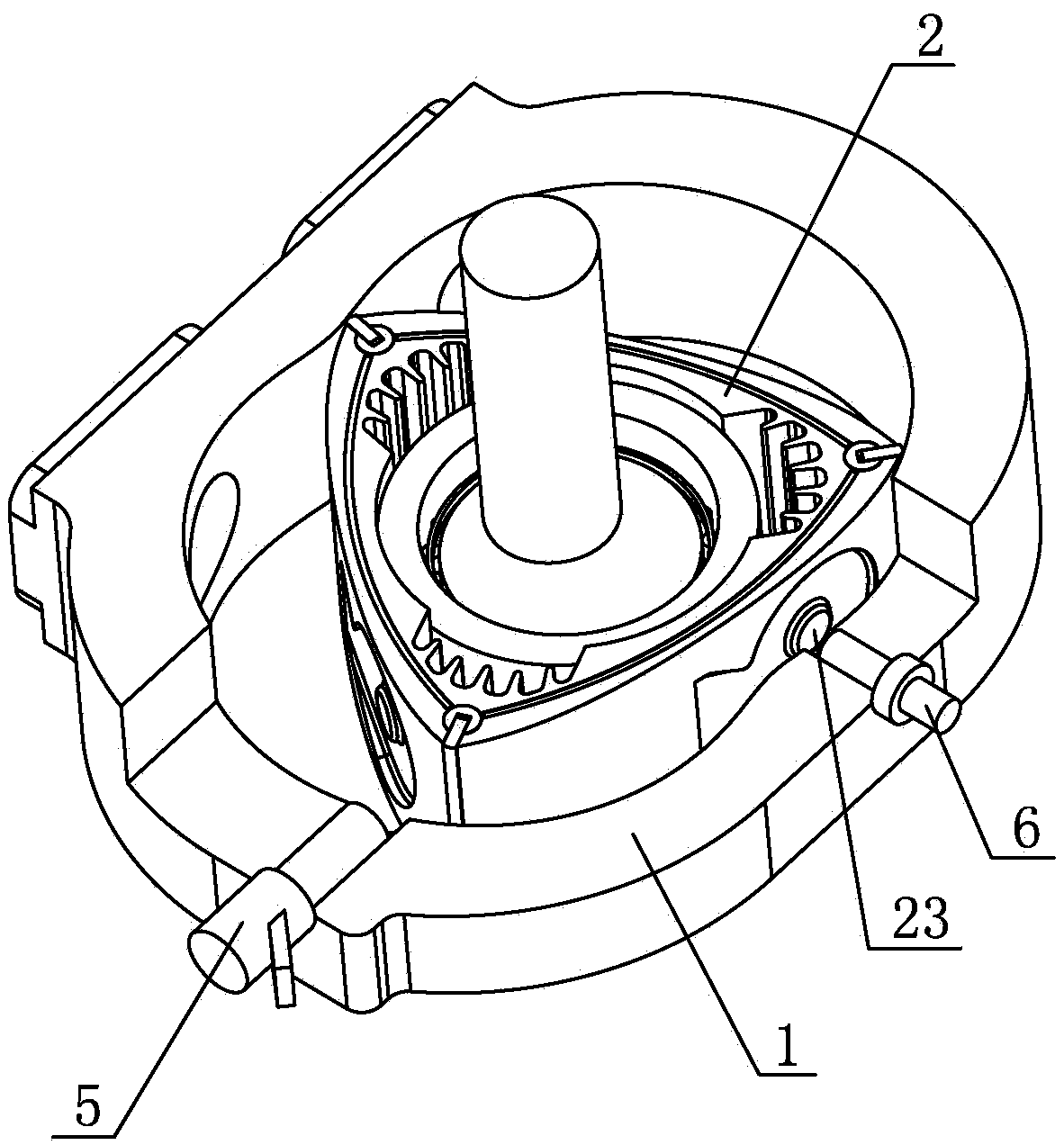

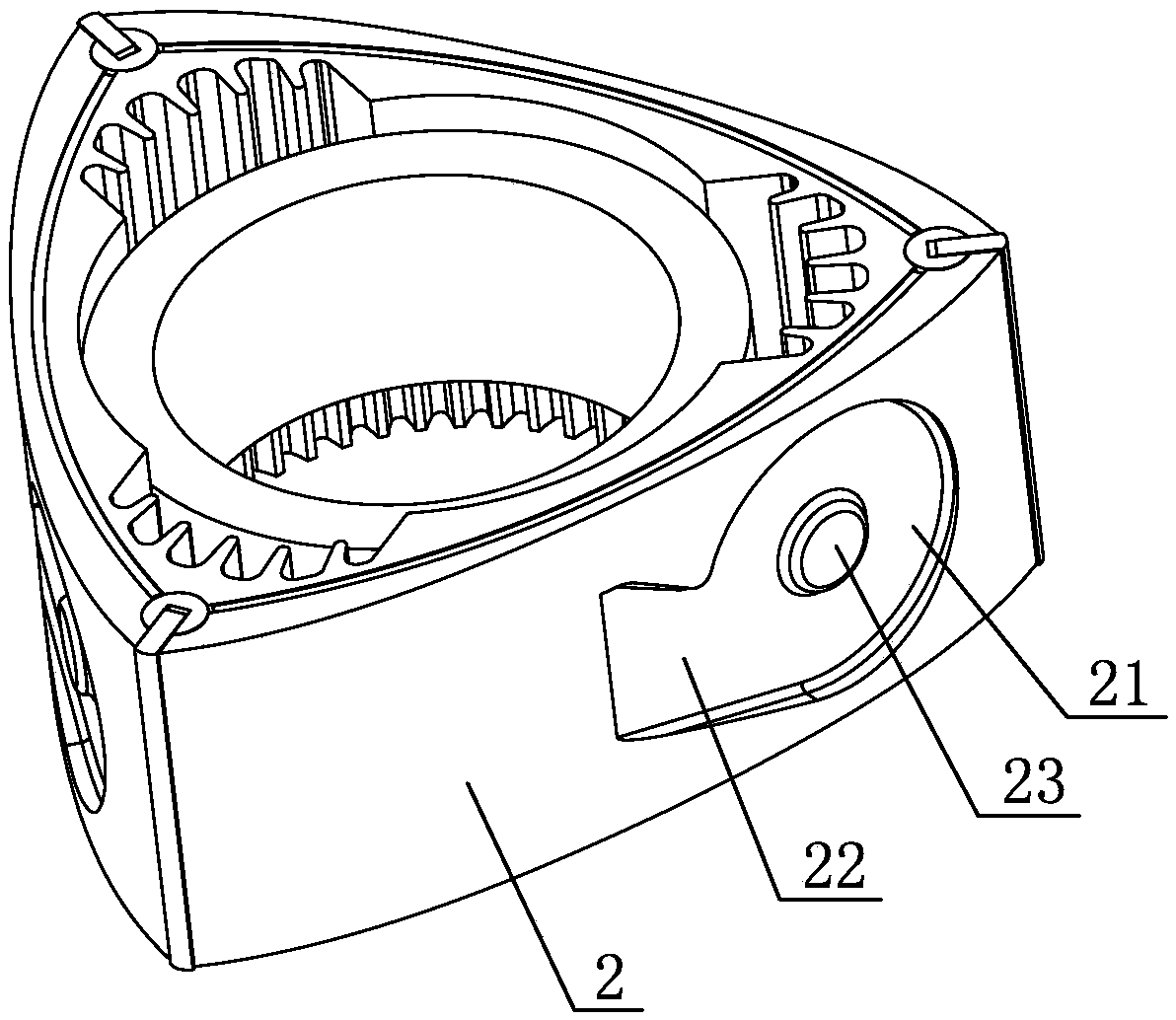

Oil-saving triangular rotor engine

InactiveCN108979849ASimple structureImprove versatilityInternal combustion piston enginesCombustion chamberCylinder block

The invention discloses an oil-saving triangular rotor engine, which comprises a cylinder body and a triangular rotor. An oil nozzle and an ignition plug are fixedly arranged on the cylinder body. Theoil-saving triangular rotor engine is characterized in that the center line of the oil nozzle is parallel to the long axis of the cylinder body, an oil spraying port of the oil nozzle is positioned in a front area of an air inlet chamber in the cylinder body, the center line of the ignition plug is parallel to the short axis of the cylinder body, and the ignition plug is positioned in a front area of a combustion chamber in the cylinder body; outer side walls of the triangular rotor are provided with circular air guide grooves and air leading grooves, the air leading grooves and the circularair guide grooves are tangential, and the center of each circular air guide groove is provided with a cylindrical boss. The oil-saving triangular rotor engine has advantages that in operation of the engine, an airflow vortex is generated on the outer lateral side of the triangular rotor, mixed gas can be easily ignited by the ignition plug, multi-point spreading of flame is accelerated by the airflow vortex, a burning route is shortened, and burning spreading speed is increased; since the mixed gas is mainly gathered in the front of the combustion chamber, complete combustion of the mixed gasis promoted, and oil consumption is reduced.

Owner:NINGBO UNIV

Full-condensation boiler

InactiveCN104990264ASolve consumptionIncrease feed water temperatureAir heatersSustainable buildingsWater vaporSoftened water

The invention discloses a full-condensation boiler. A boiler body is connected with a hot and cold water regionalized water tank and an outer circulating water path of the hot and cold water regionalized water tank; the hot and cold regionalized water tank is divided into a cold water region and a hot water region; the outer circulating water path includes an energy saving device, a condenser, a circulating pump and a feed pump; room-temperature softened water enters the cold water region, and enters the condenser through the circulating pump, and goes back to the hot water region, and enters the energy saving device through the feed pump; after the energy saving device is connected with the independent hot and cold water regionalized water tank, soft water which flows circularly under normal pressure in the energy saving device constantly to recover waste heat and store heat regardless of whether water is supplemented in the operation of the boiler; the feed-water temperature of the boiler can be improved, and big fire burning pressure-increasing time can be shortened, and fuel consumption can be reduced. The full-condensation boiler can be adopted as a boiler in which water vapor content in flue gas is high, especially adopted as a gas-fired boiler.

Owner:XIANGTAN BOILER

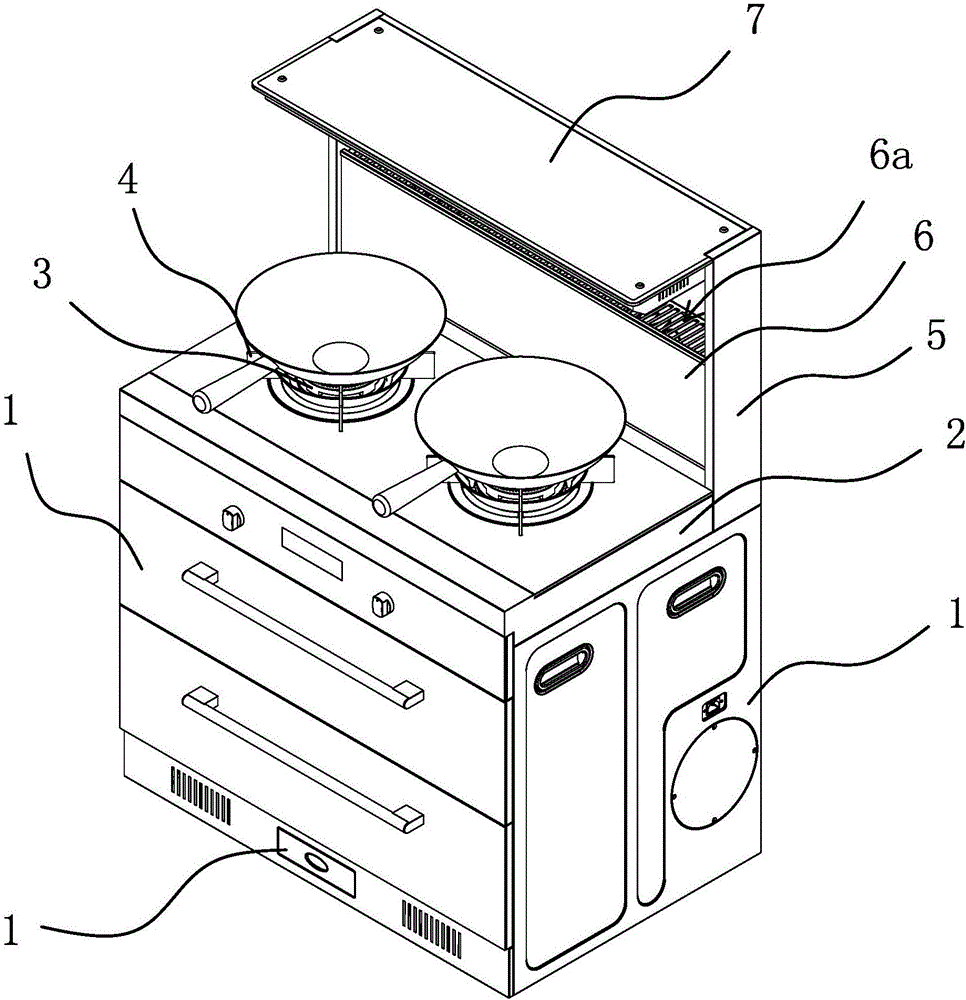

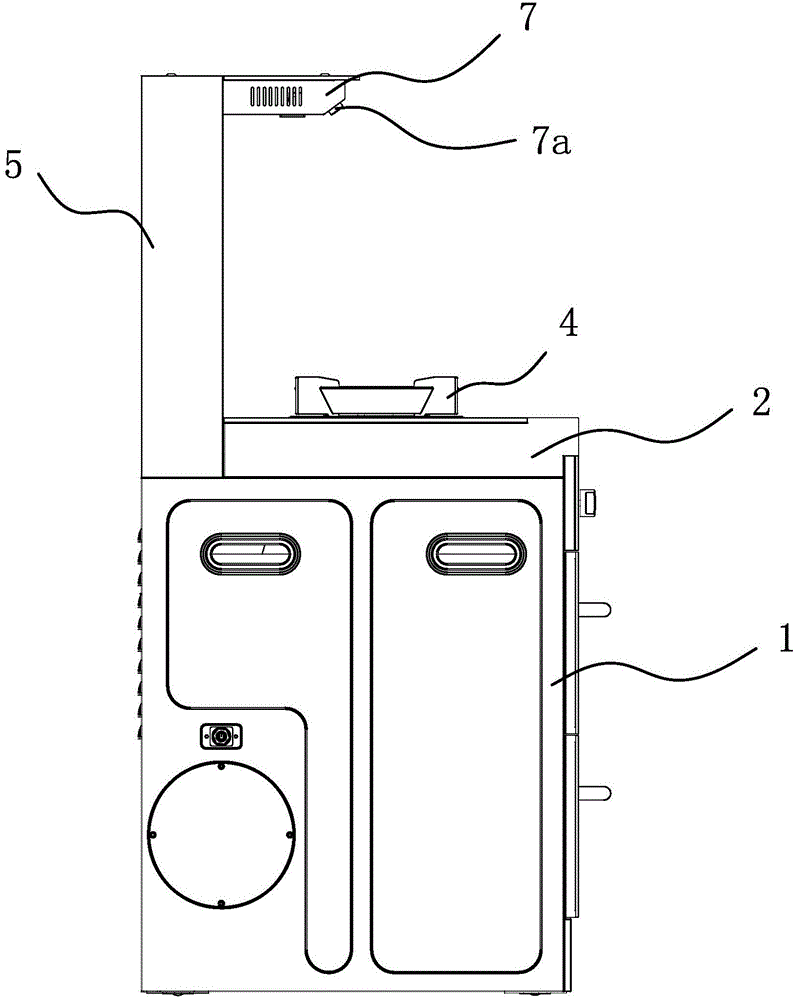

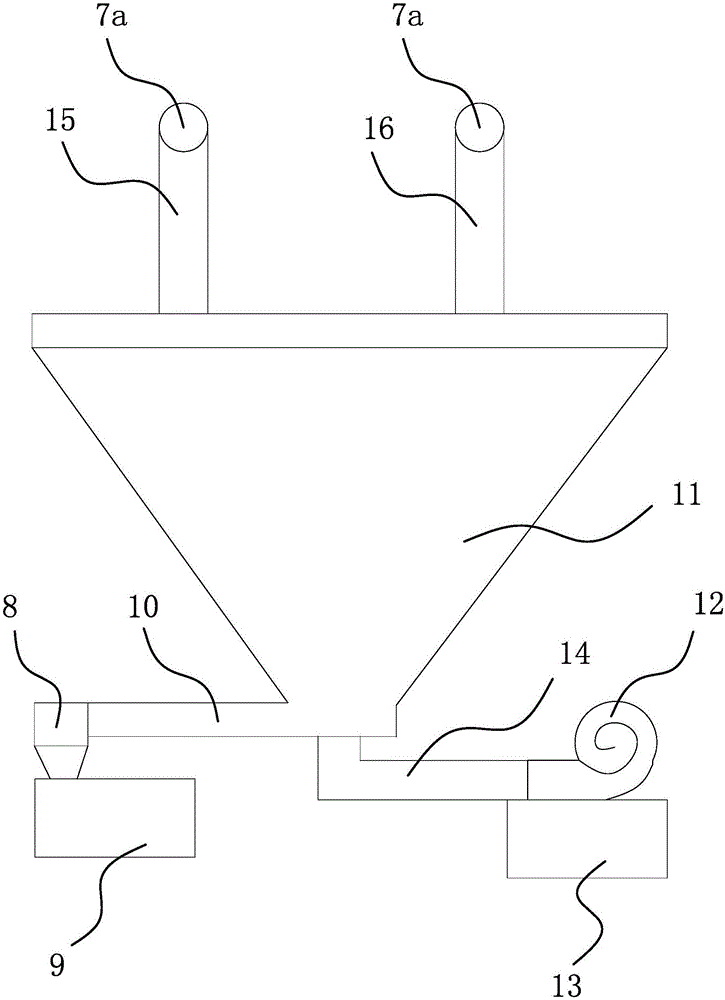

Fluid diaphragm side suction type integrated cooker

PendingCN106765336AAbsorb evenlyImprove oil absorption efficiencyDomestic stoves or rangesLighting and heating apparatusWaste management

The invention provides a fluid diaphragm side suction type integrated cooker and belongs to the technical field of integrated cookers. By means of the fluid diaphragm side suction type integrated cooker, the problem that lampblack and waste gas cannot be efficiently sucked in the prior art is solved. The fluid diaphragm side suction type integrated cooker comprises a cooker body and a cooking bench arranged on the cooker body, and is characterized in that the cooking bench is provided with burners and pot racks, a mounting plate is detachably fixed on the rear portion of the cooking bench, a lampblack sucking plate is detachably fixed on one side of the mounting plate, the height of the lampblack sucking plate is smaller than that of the mounting plate, and a lamp cover plate is detachably fixed to the upper portion of the mounting plate; and the fluid diaphragm side suction type integrated cooker further comprises a plurality of air sucking holes and a plurality of air exhausting holes, the air sucking holes are formed in the lampblack sucking plate and can suck lampblack and waste gas, the air exhausting holes are formed in the lamp cover plate and can blow out air, the air sucking holes are connected with a negative-pressure air fan capable of generating negative pressure at the air sucking holes, and the air exhausting holes are connected with an air blower capable of delivering air to an air outlet. The fluid diaphragm side suction type integrated cooker has the advantages of being high in lampblack and waste gas sucking efficiency, good in lampblack and waste gas sucking effect and the like.

Owner:浙江优格实业有限公司

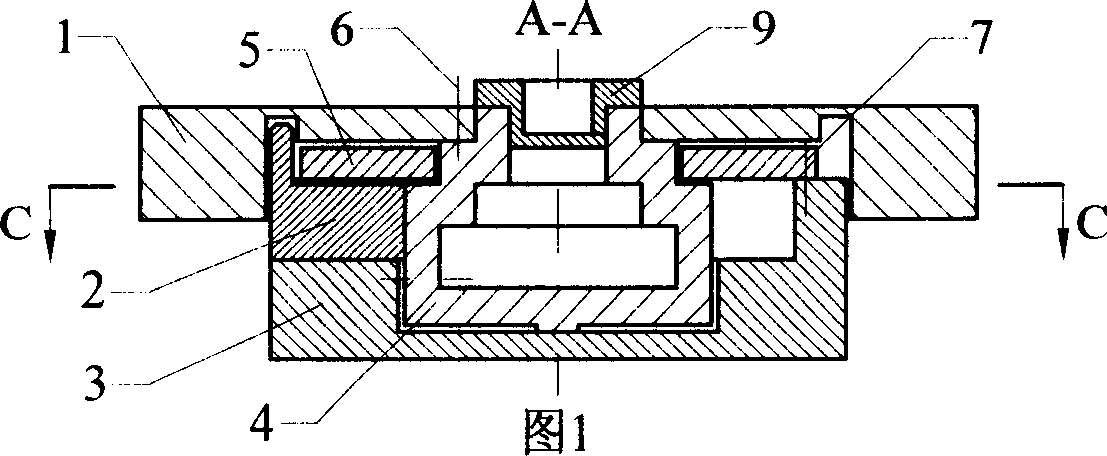

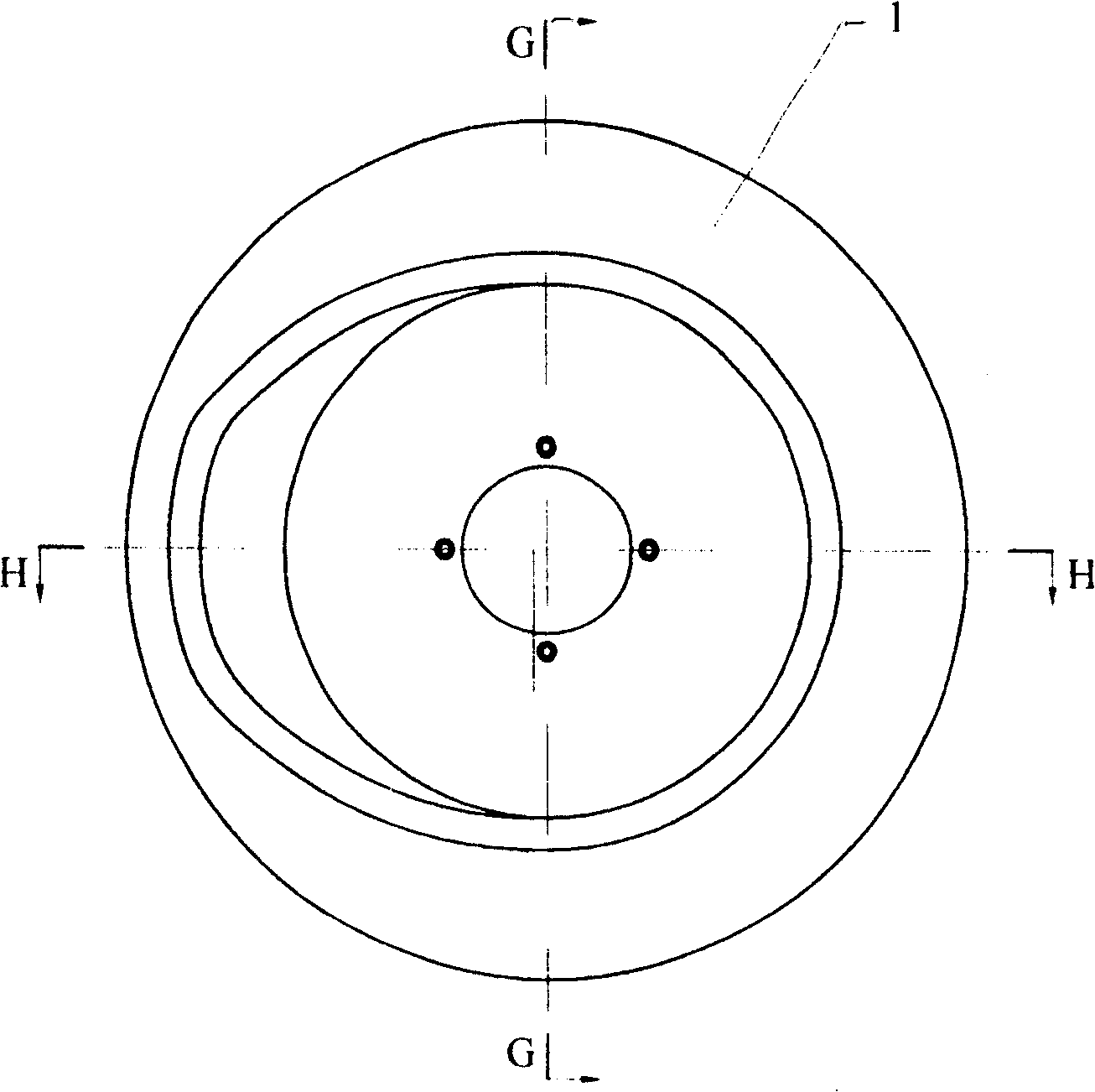

Mini-size engine

InactiveCN1815000AIncrease energy densityIncrease speedInternal combustion piston enginesCombustion chamberCam

A tiny engine, in particular a tiny engine based on quasi - forces of gas flow circulating principle makes motor outputting power reach superhigh energy density. Tiny engine includes inner cam flywheel disk, slipper, cylinder body, piston rotor shaft, cover board, gas transmission mechanism and probe type spark plug. Said space in piston rotor shaft is premixing chamber for feeding high pressure gas fuel to cylinder body firing chamber, thereby realizing the thermodynamics effect through pre-set premix high pressure gas fuel form to substitute perfect gas power cycle constant entropy adiabatic compression process. Said invention has higher output loop net work, higher energy density and more simple system structure.

Owner:CHONGQING UNIV

Method for substituting cement kiln fuel with garbage derived overtails

Owner:LINGCHUAN JINYU CEMENT

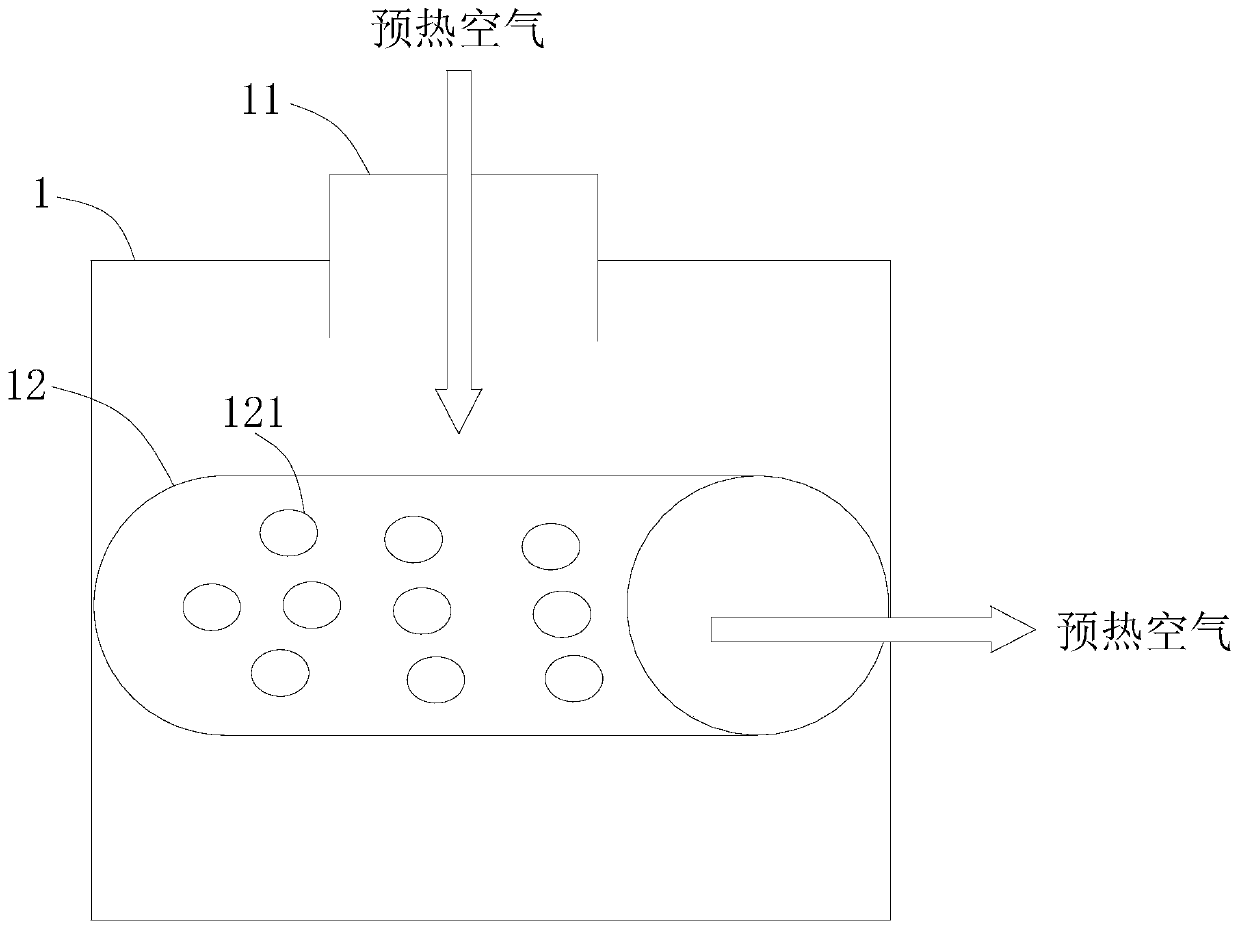

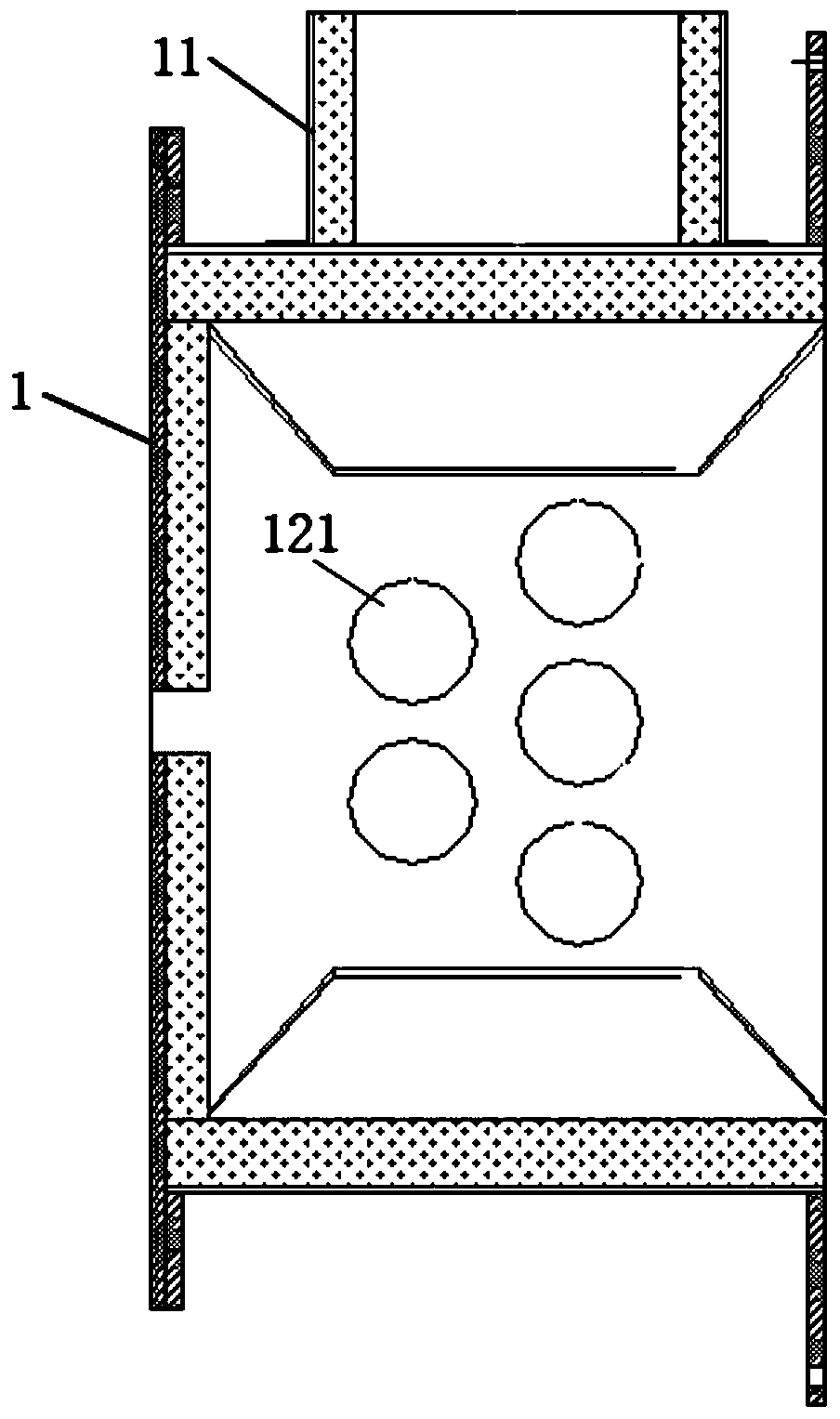

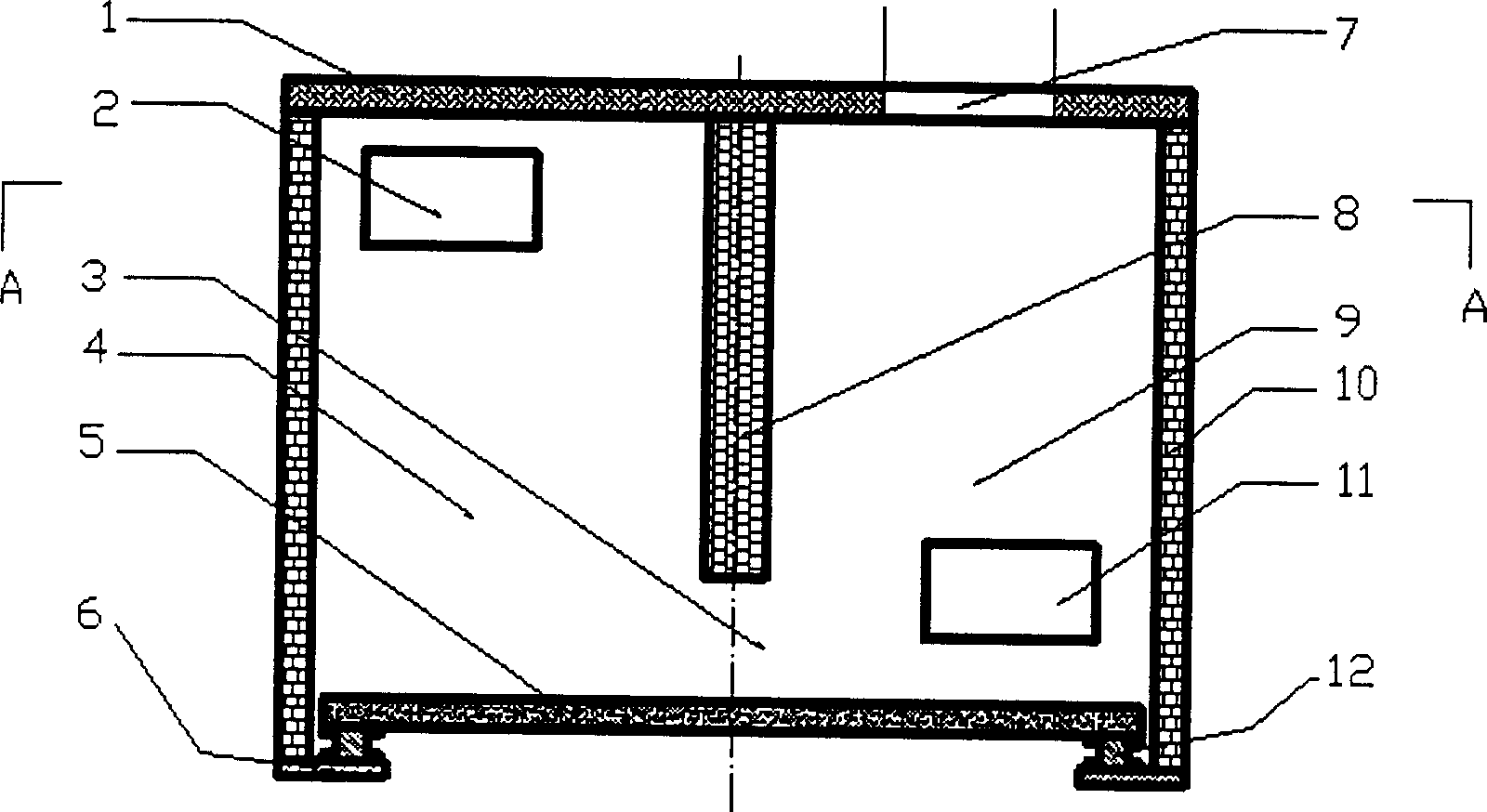

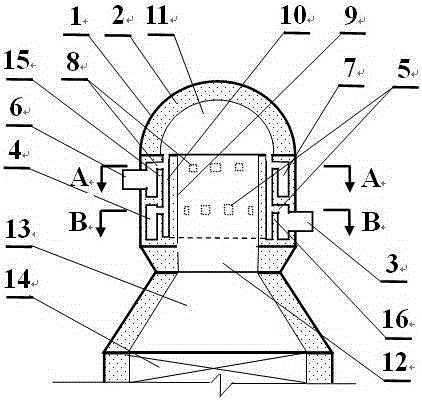

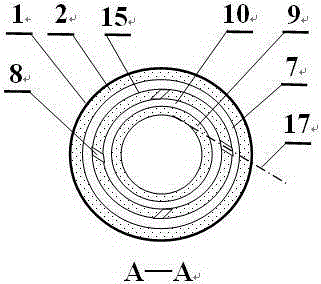

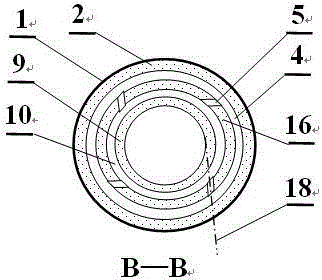

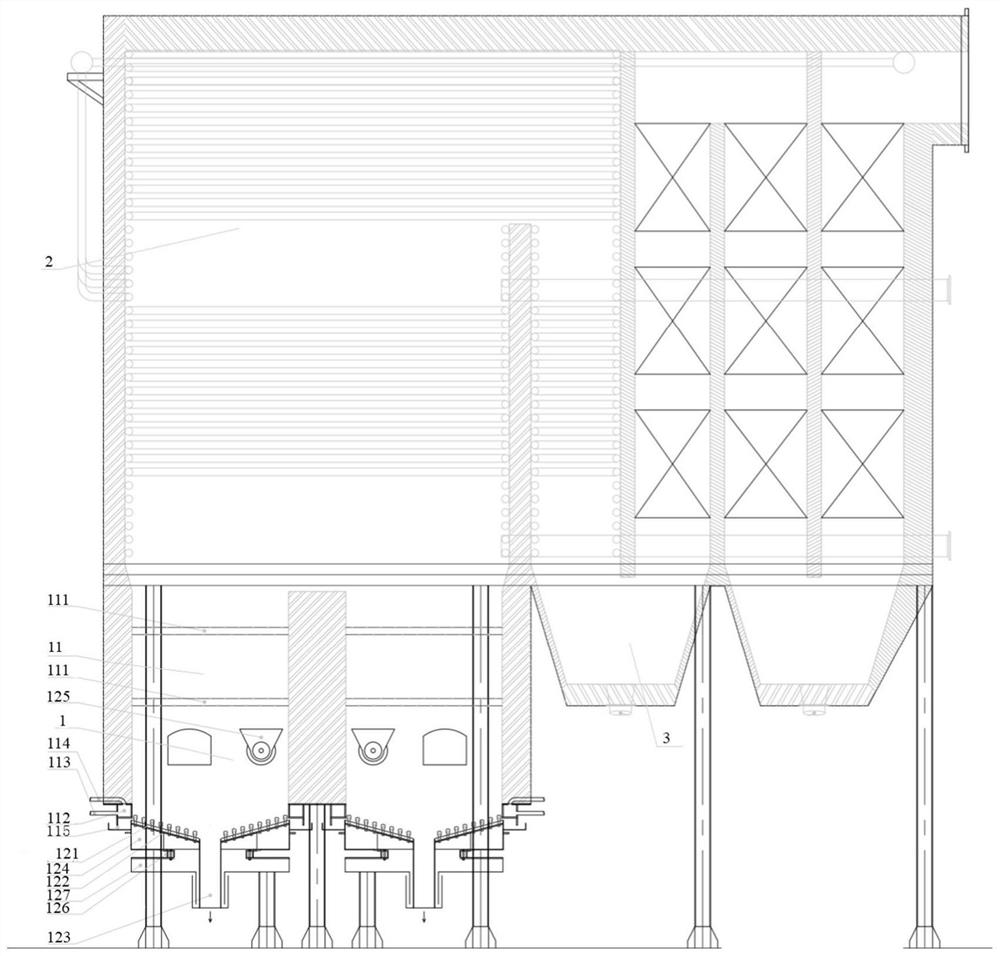

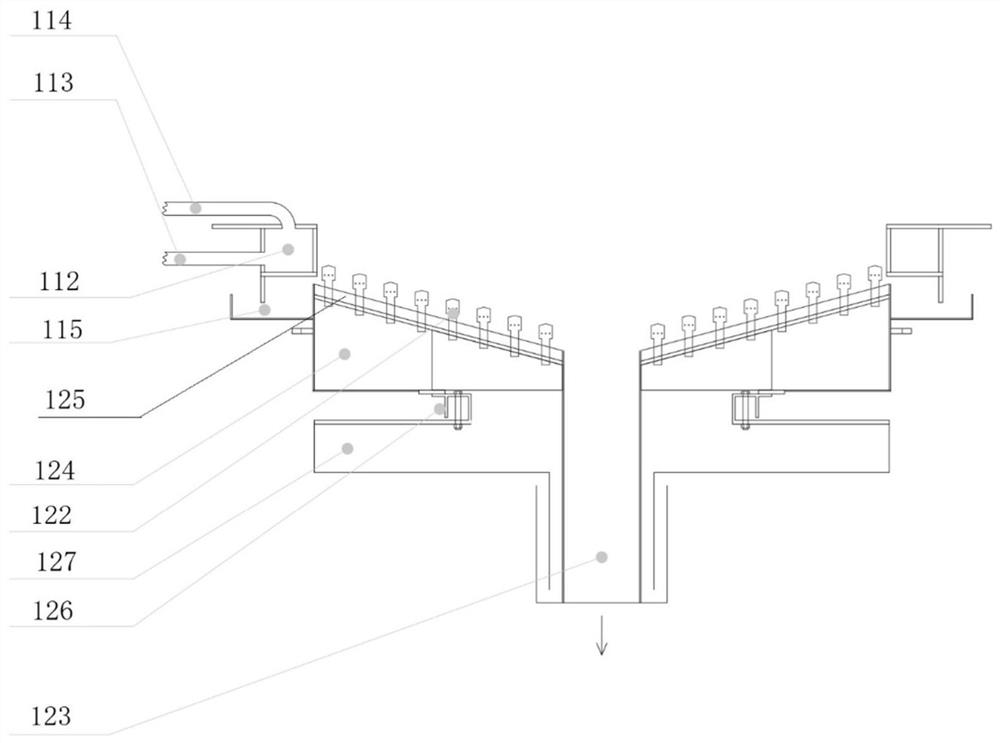

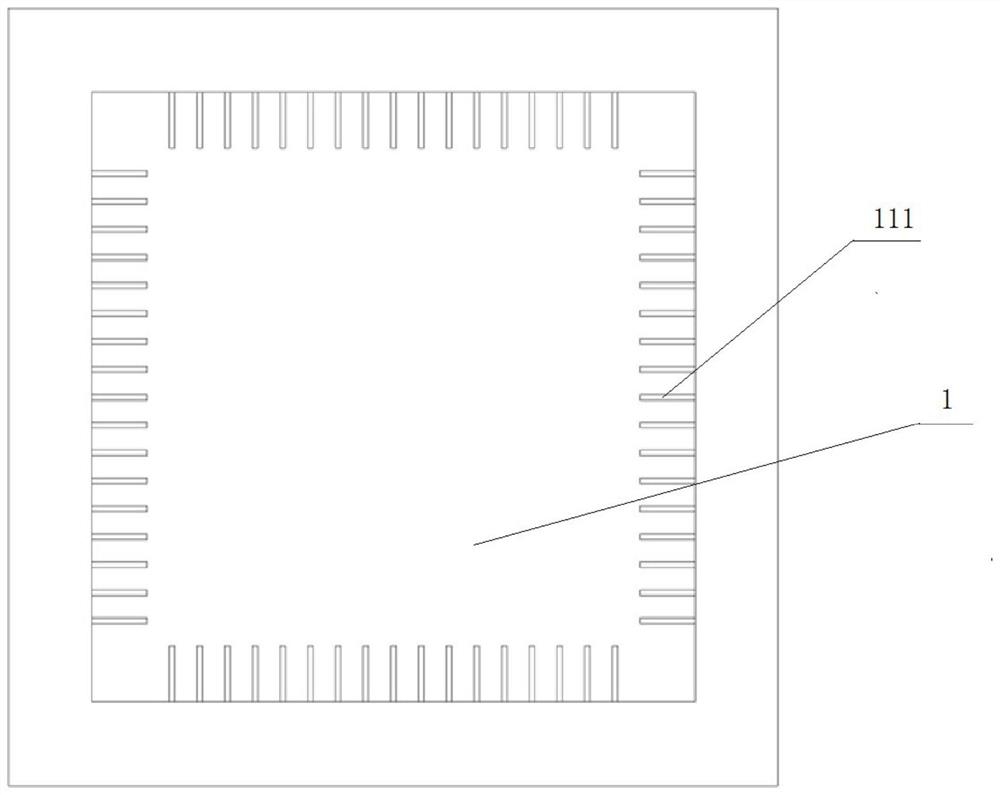

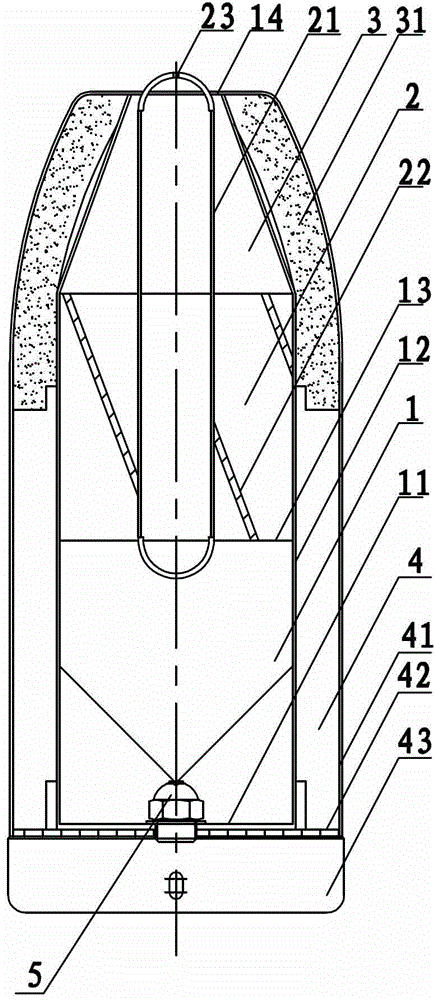

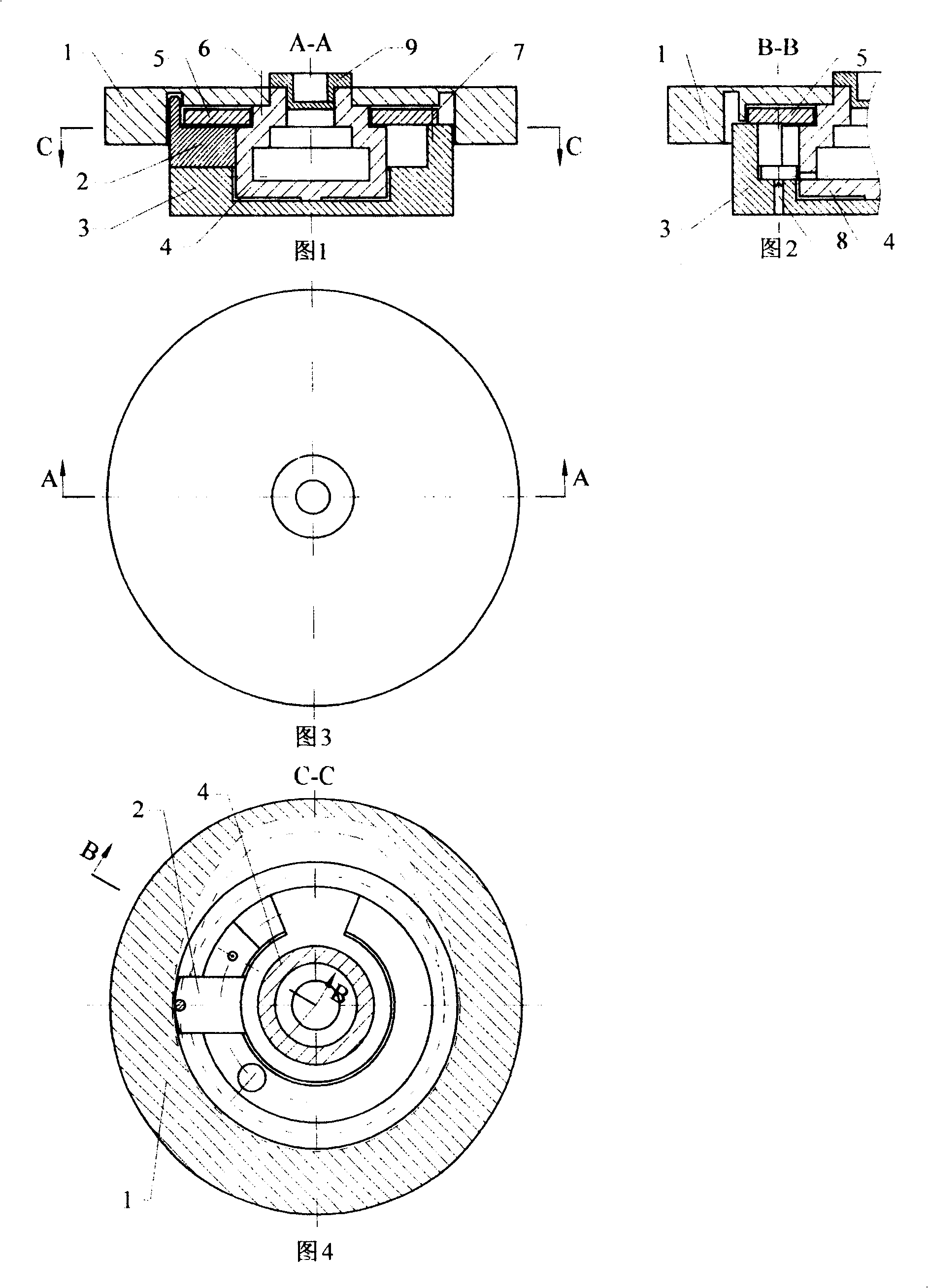

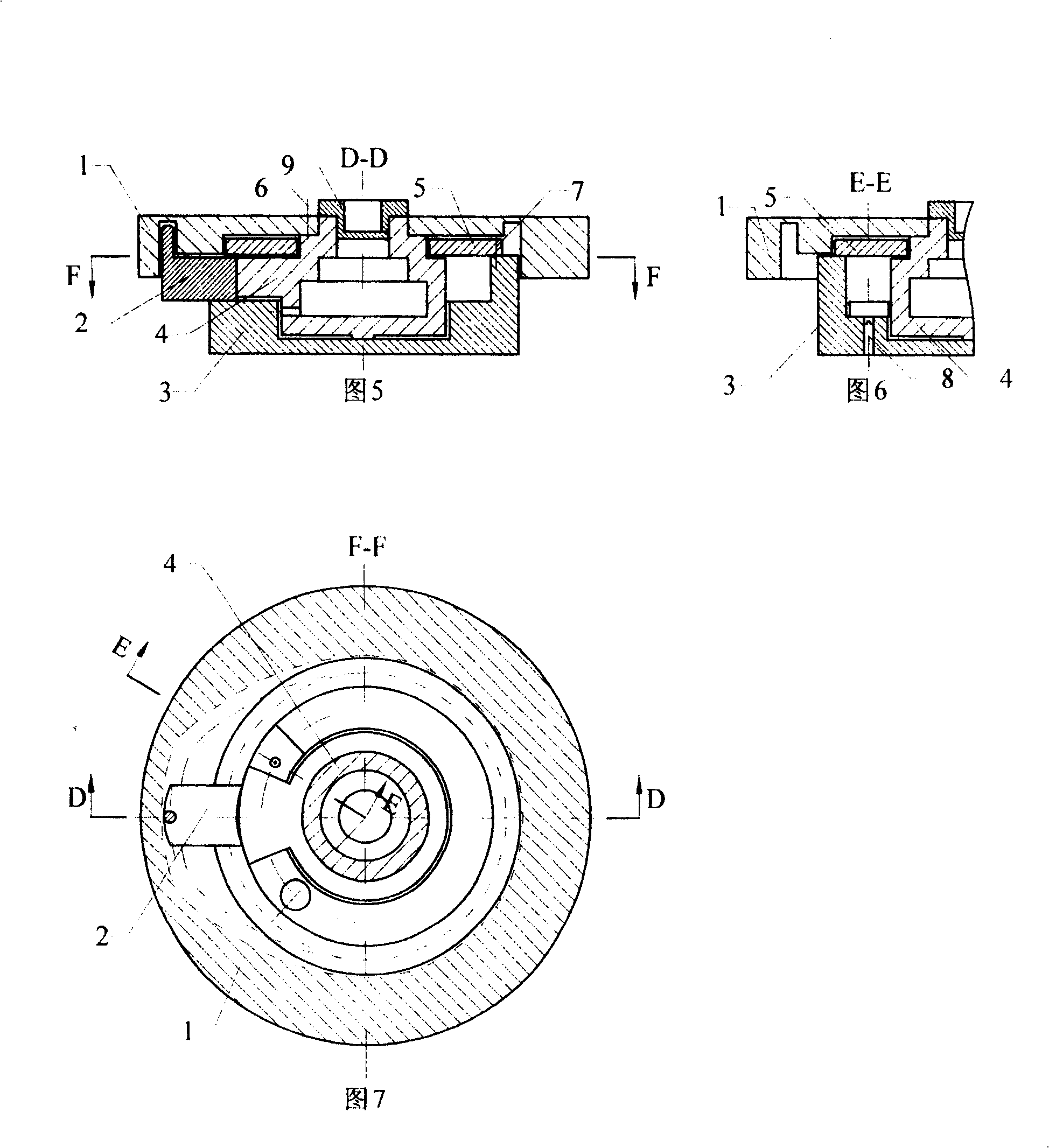

A top-fired hot blast stove burner

InactiveCN104032057BRaise the wind temperature levelSmall footprintBlast furnace detailsHeating stovesCombustorCombustion chamber

The invention provides a technical scheme of a top combustion hot blast stove combustor comprising a furnace shell, wherein the inner side of the furnace shell is provided with a refractory masonry; the furnace shell and the refractory masonry are formed into a combustion space composed of three space segments with different shapes at the upper, middle and lower ends, wherein the upper end is provided with a spherical combustion chamber segment, the middle is provided with a straight combustion chamber segment, and the lower end is provided with a tapered combustion chamber segment; the three space segments are communicated with each other; the straight combustion chamber segment is provided with a combustion air inlet, a combustion air nozzle, an annular combustion air channel, a coal gas inlet, a coal gas nozzle, an annular coal gas channel and an annular mixed channel; the inner side of the straight combustion chamber segment is provided with an annular retaining wall. According to the scheme, the top combustion hot blast stove combustor is small in whole occupied space, high in combustion temperature, very suitable for modifying hot blast stove and particularly suitable for changing an internal combustion hot blast stove into a top combustion hot blast stove. By using the top combustion hot blast stove combustor, the modification expense can be reduced, and most importantly, the blast temperature of the hot blast stove can be increased.

Owner:JIGANG GRP

Multi-side stereo combustion boiler capable of realizing clean combustion of coal and combustion method thereof

InactiveCN100375860CEmission reductionSuppress sootSolid fuel combustionCombustion apparatusCombustion chamberThermodynamics

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Power generating and heating dual-purpose boiler capable of adopting solid fuel and fuel gas

PendingCN107869840ATake advantage ofFully heatedSolid fuel combustionWater heatersThermodynamicsBoiler furnace

The invention discloses a power generating and heating dual-purpose boiler capable of adopting solid fuel and fuel gas. The power generating and heating dual-purpose boiler comprises a heating container, a boiler furnace, a boiler body, a boiler cover, a boiler grate, a heating coiled pipe, fuel gas pipelines, fuel gas holes, a fuel opening, an air door and a chimney. The fuel opening and the airdoor are formed on the wall of the boiler body, the fuel opening is formed in the upper portion of the boiler grate, and the air door is arranged on the lower portion of the boiler grate; the boiler cover covers the upper end of the boiler body, and the heating container is arranged on the boiler cover, and the heating coiled pipe is arranged on the lower portion of the heating container and stretches into the boiler body; the boiler grate is arranged on the lower portion of the boiler body; the boiler furnace is arranged at the center of the heating coiled pipe; spiral air pipes stretch to the upper portion of the boiler grate in an obliquely-upward mode along the wall of the boiler body; the fuel gas pipelines are arranged on the boiler grate, and fuel gas holes are formed in the fuel gas pipelines; a dust groove is formed in the inner wall of the boiler body, the chimney is arranged on the upper portion of the dust groove, and the lower portion of the dust groove is matched with theboiler grate; the heating container comprises a water storage tank, a water inlet and a water outlet, the water outlet is formed in the upper portion of the water storage tank, and the lower end of the heating coiled pipe is connected with the water inlet. The power generating and heating dual-purpose boiler is suitable for heating and can be also used as a power generating boiler.

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +1

Annular flame type bio-oil burner

The invention discloses an annular flame type bio-oil burner. An oil guide tube is arranged in a burner body, the bottom end of the oil guide tube is provided with a bio-oil inlet, the other end of the oil guide tube is provided with a combustion head, one side of the combustion head is provided with an igniter, a combustion cover is arranged above the combustion head, N flame passages are arranged in the combustion cover, N > / = 2, the bottom ends of the passages are connected to a flame inlet matching with the flame spraying port of the combustion head, the flame passages are in upward spiral types, and the flame sprayed from the flame passages are in an annular structure. The direction of the air flow outside the flame spraying port is divided into two or multiple directions under the effect of resistance, the annular flame is formed outside the spraying port, the combustion time of a hearth is increased, the combustion is performed completely, a smoke value is low, the combustion space is increased by the arrangement of the flame passages, vibration force is reduced, and noise is small.

Owner:XIAMEN XINYESHENG ENERGY TECH

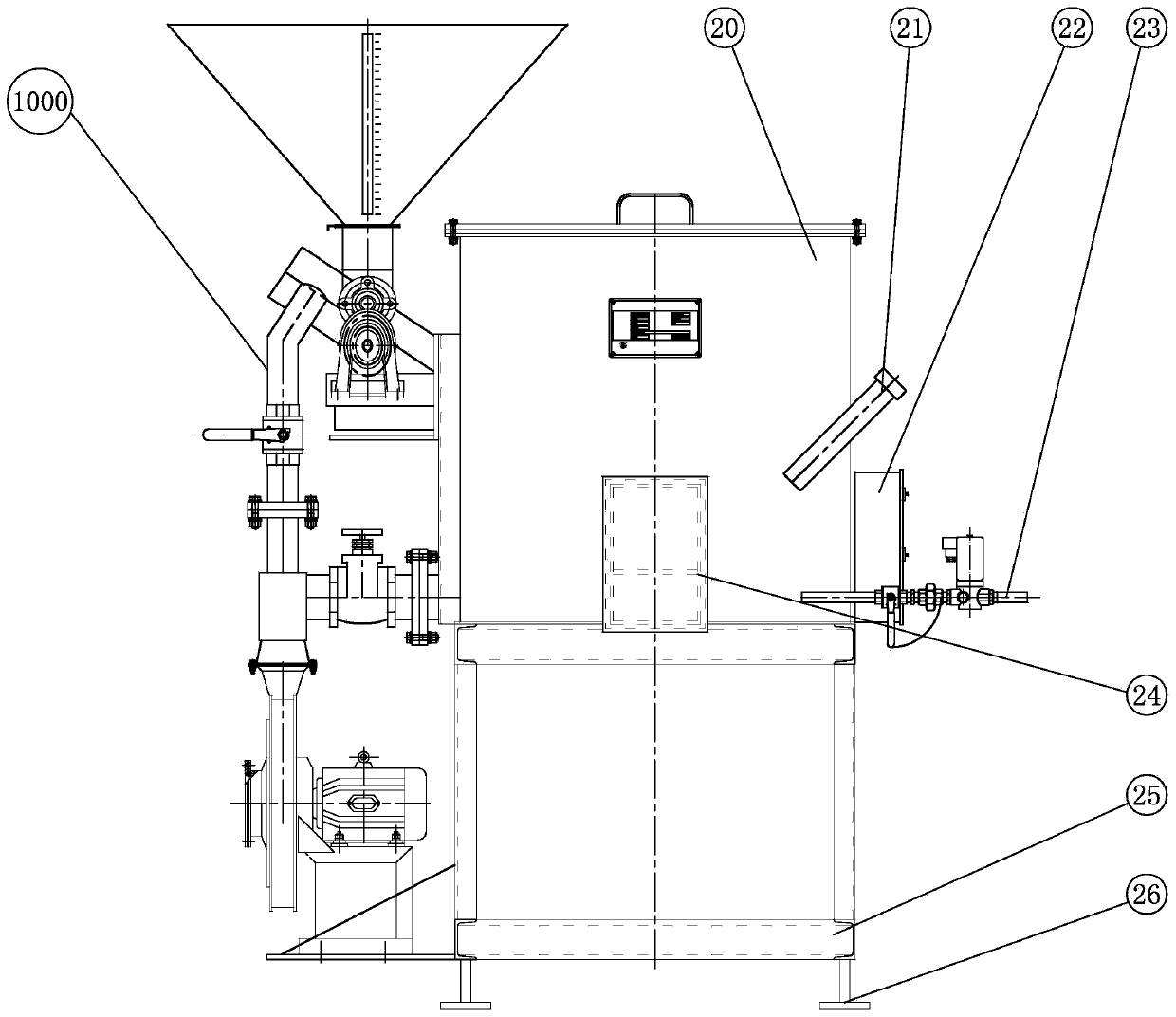

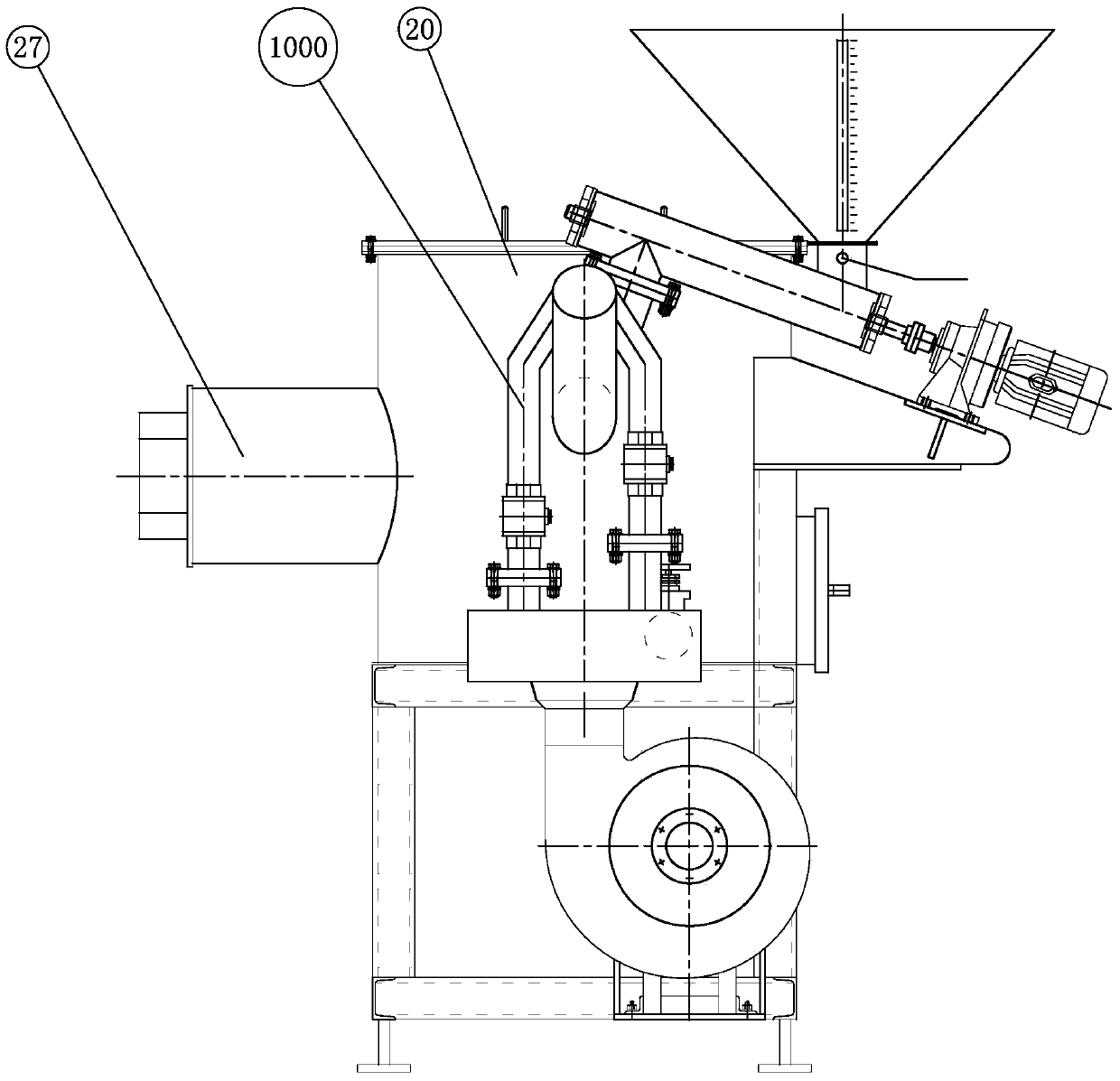

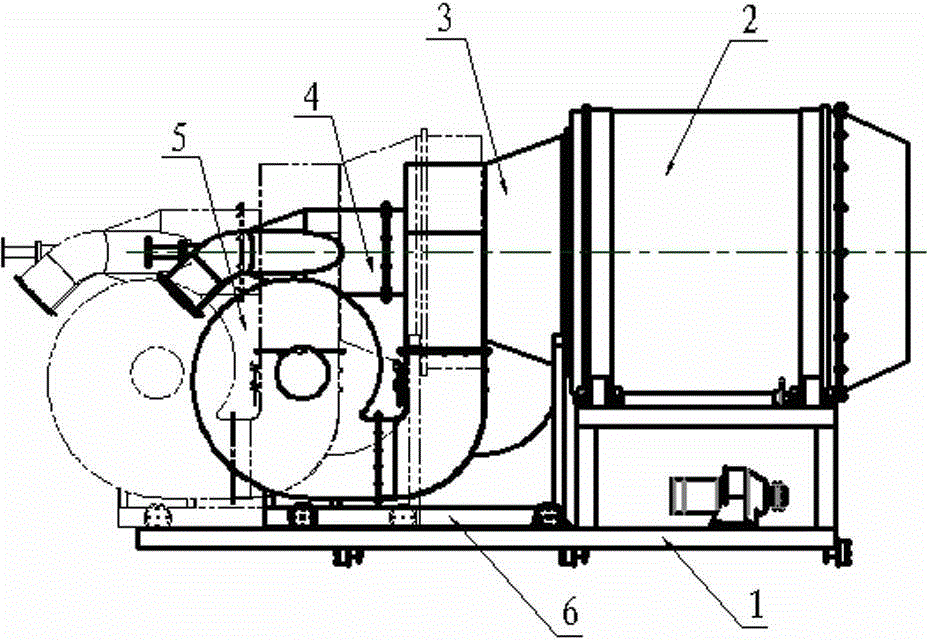

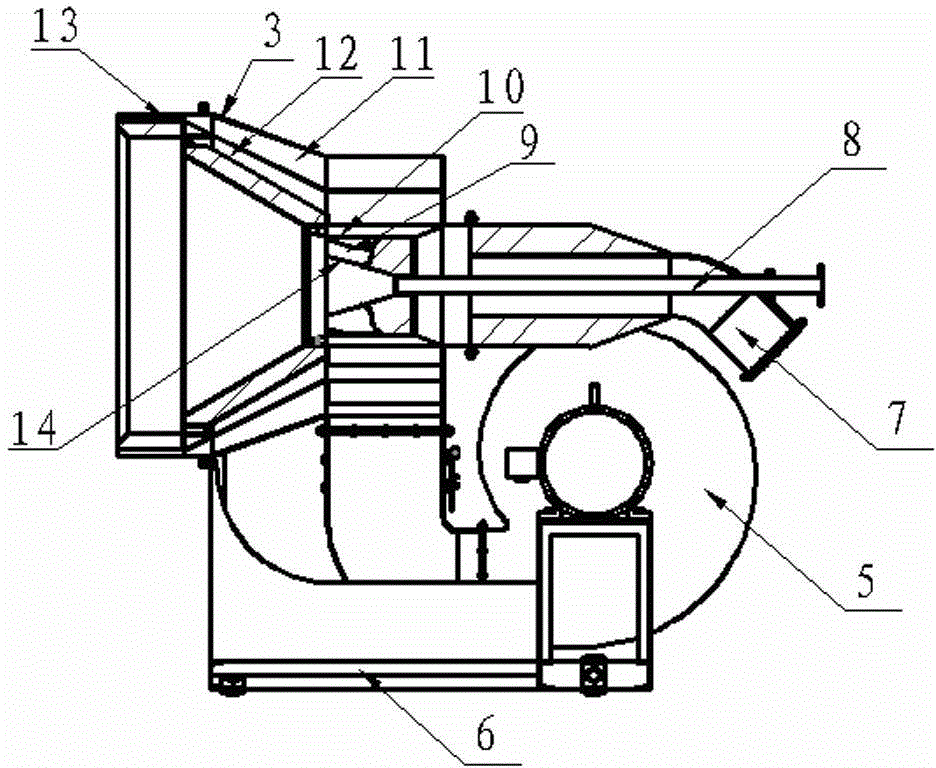

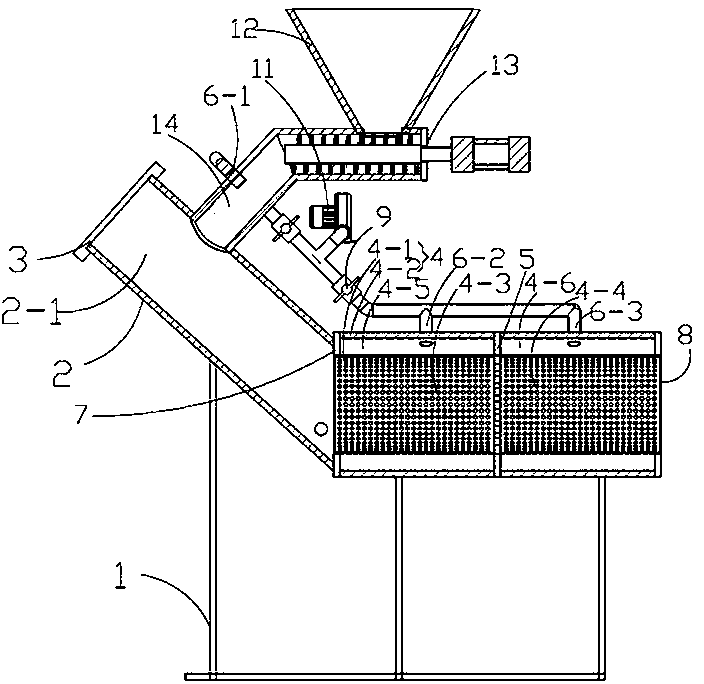

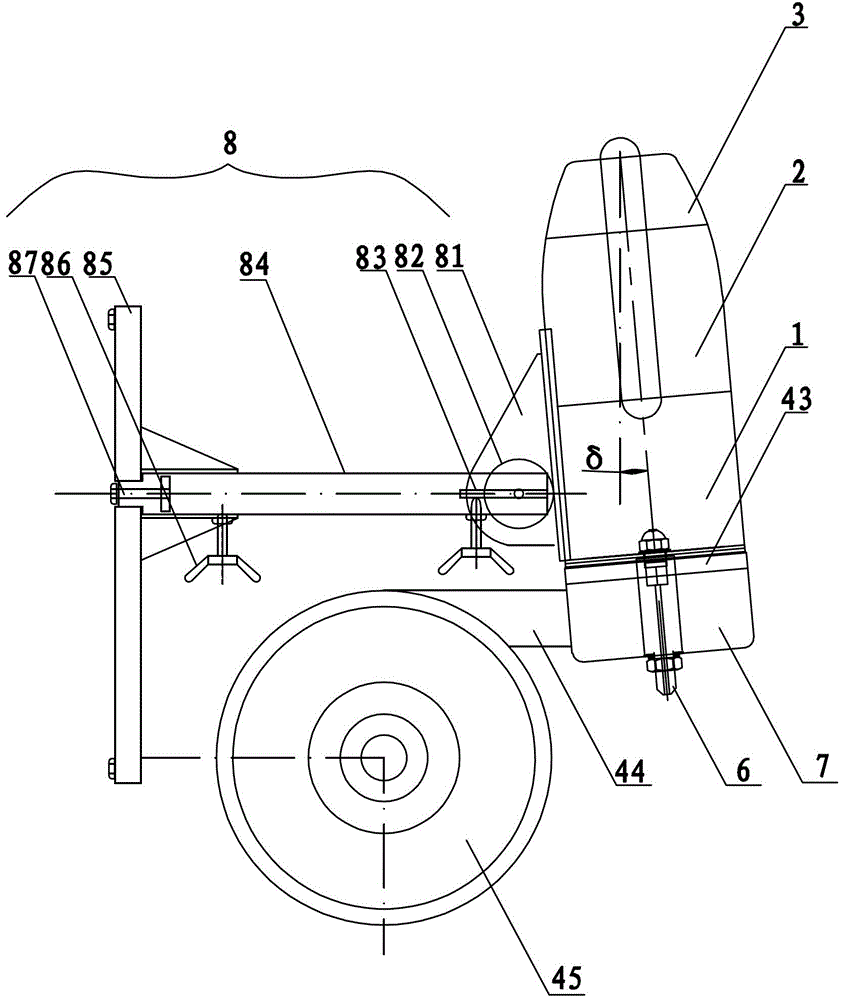

A new high-efficiency pulverized coal combustion device

InactiveCN102767824BIncrease air volumeLarge air volumeFuel supply regulationCombustion apparatusCombustion chamberThermodynamics

The invention discloses a novel efficient pulverized coal combustion device, which comprises a bottom frame, a hearth, a stable combustion chamber, an air powder adjusting mechanism, a fan, an ignition device and an electric control system, wherein the air powder adjusting mechanism is sequentially provided with an outer direct flowing air flue, a cyclone passage, an inner direct flowing air flue, a pulverized coal air flue and a central pipe from an outer layer to an inner layer; the fan is communicated with the outer direct flowing air flue, the cyclone passage and the inner direct flowing air flue; and a direct flowing blade is arranged at the outlet end of the outer direct flowing air flue, a cyclone blade is arranged in the cyclone passage, a plurality of direct flowing blades are uniformly arranged at the outlet of the inner direct flowing air flue, the central pipe is conical at the outlet position, a plurality of bent blades are uniformly arranged at the outlet of the pulverized coal air flue, and the inner edges of the bent blades are matched with the conical shape of the end of the central pipe. The device has the characteristics of compact structure, full combustion of pulverized coal, high coal adaptability, long service life and convenience in ignition, and can meet various heating requirements in the road building industry.

Owner:南阳市沧田工程机械有限公司

A detachable solid fuel suspension combustion experimental test device and test method

ActiveCN104634922BSolve the problem of not easy to igniteEasy to igniteChemical analysis using combustionData acquisitionSolid fuel

The invention discloses a detachable solid fuel suspension combustion experiment testing device and a detachable solid fuel suspension combustion experiment testing method, belonging to the technical field of a solid fuel combustion experiment. The testing device comprises a suspension combustion mechanism, a combustion data acquisition mechanism, a gas supply mechanism and an ignition mechanism; a base is arranged on a base bracket; the lower end hole of a primary combustion pipe is communicated and in detachable connection with the upper end hole of an inner pipe of the base; the lower end hole of a secondary combustion pipe is communicated and in detachable connection with the upper end hole of the primary combustion pipe; two porous metal plates are respectively arranged at the upper end hole of the inner pipe of the base and the upper end hole of the primary combustion pipe. The testing method comprises the steps of placing fuel; enabling the fuel to suspend; burning; acquiring combustion data; finishing the experiment. The device and the method mainly have the functions of realizing visualization of a combustion state, realizing uniform combustion at a suspended state, carrying out a combustion test on multiple samples for once and enabling the large-particle samples to be easily ignited.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Circulation Flame Biomass Oil Burner

The invention discloses an annular flame type bio-oil burner. An oil guide tube is arranged in a burner body, the bottom end of the oil guide tube is provided with a bio-oil inlet, the other end of the oil guide tube is provided with a combustion head, one side of the combustion head is provided with an igniter, a combustion cover is arranged above the combustion head, N flame passages are arranged in the combustion cover, N > / = 2, the bottom ends of the passages are connected to a flame inlet matching with the flame spraying port of the combustion head, the flame passages are in upward spiral types, and the flame sprayed from the flame passages are in an annular structure. The direction of the air flow outside the flame spraying port is divided into two or multiple directions under the effect of resistance, the annular flame is formed outside the spraying port, the combustion time of a hearth is increased, the combustion is performed completely, a smoke value is low, the combustion space is increased by the arrangement of the flame passages, vibration force is reduced, and noise is small.

Owner:XIAMEN XINYESHENG ENERGY TECH

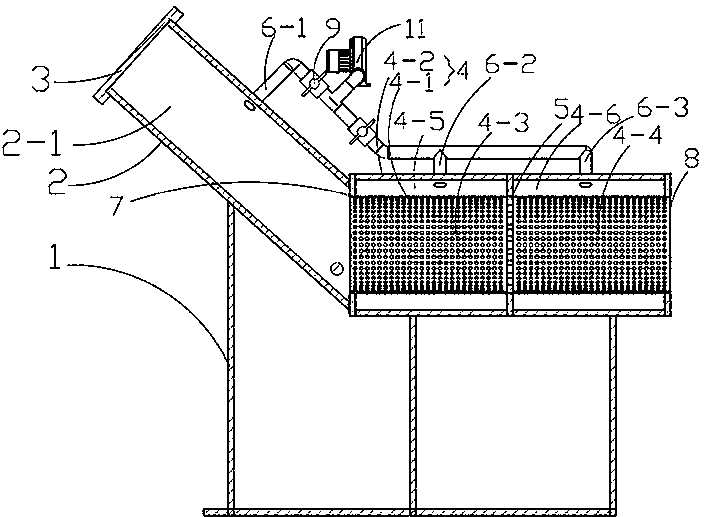

Integrated biomass gasification low-nitrogen oxygen-deficient combustion boiler

PendingCN111720815AEasy to installIncrease spacingGratesSolid fuel combustionThermodynamicsCombustion chamber

The invention discloses an integrated biomass gasification low-nitrogen oxygen-deficient combustion boiler. The low-nitrogen oxygen-deficient combustion boiler comprises a gasification combustion area, a heat exchange area and an ash deposition area which are arranged in the same combustion boiler body. The gasification combustion area comprises a combustion chamber and a rotary combustion bed layer, the rotary combustion bed layer is arranged below the gasification combustion area, the rotary combustion bed layer comprises a rotary combustion bed, a fixed gear is arranged on the outer ring ofthe rotary combustion bed, and a motor drives the rotary combustion bed to rotate through the fixed gear; the rotary combustion bed is a conical plate, and the air cap is arranged on the conical plate; the central position of the conical plate is hollow and is connected with the ash falling pipe; a primary air duct is arranged below the conical plate, a fixed air duct is arranged below the primary air duct, and the fixed air duct is connected with a primary fan air outlet; the combustion chamber is a cylindrical cavity connected with the rotary combustion layer, an air pipe surrounding the inner wall of the cavity is arranged in the cavity, the heat exchange area is arranged above the gasification combustion area, a heat exchange layer is arranged in the heat exchange area, and the heat exchange layer is formed by evenly arranging heat conduction oil pipelines or steam pipelines; and the ash deposition area is communicated with the heat exchange area.

Owner:TAICANG XINRUI ENERGY SAVING EQUIP +1

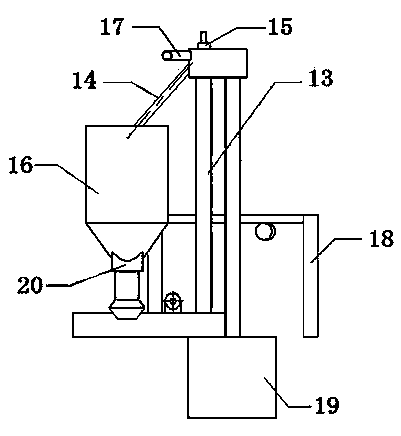

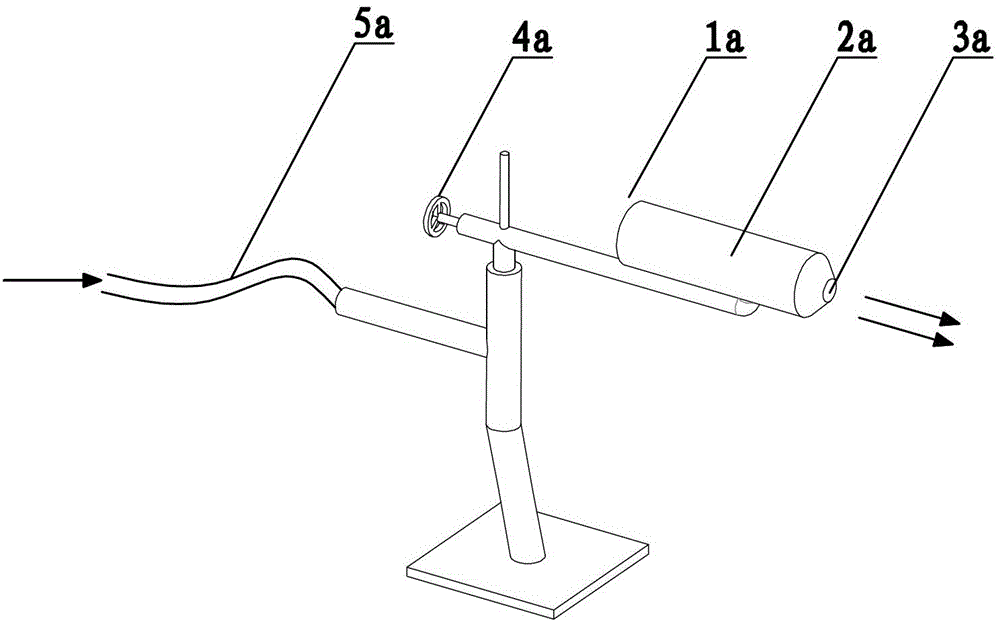

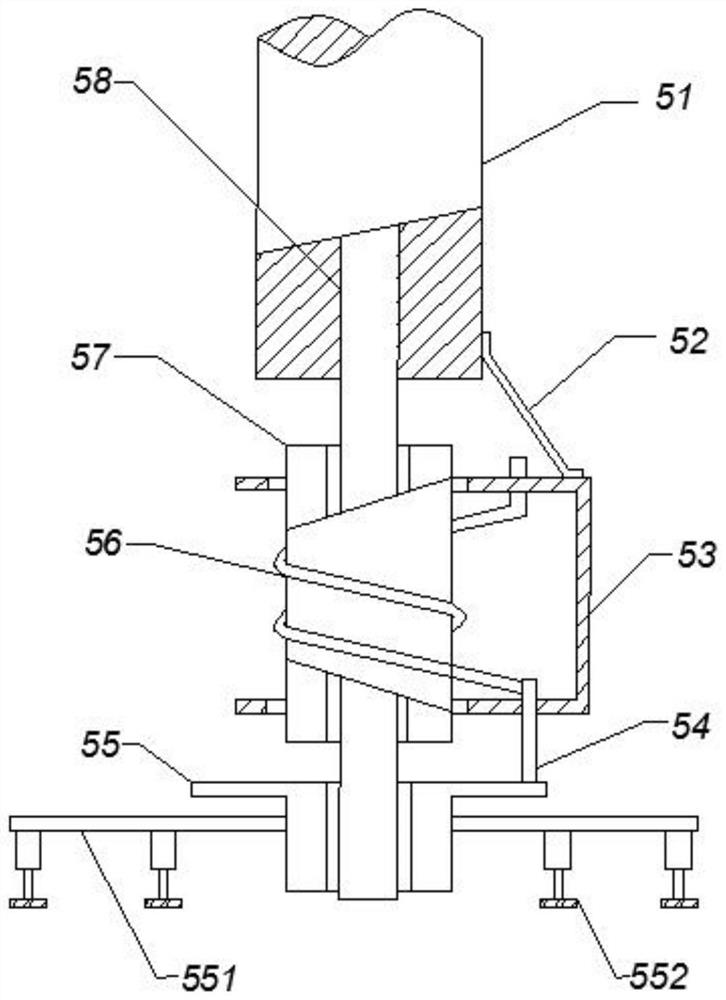

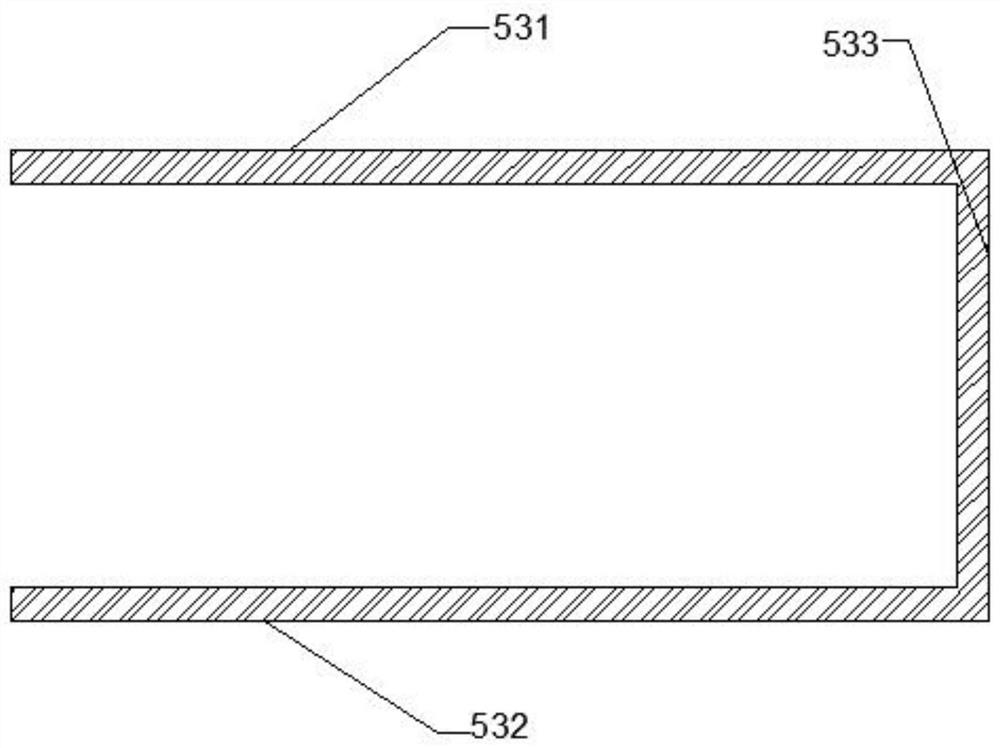

Biomass gasification burner

PendingCN108692310APrevent overflowPrevent backchannelingSolid fuel combustionAir/fuel supply for combustionCombustionProcess engineering

The invention provides a biomass gasification burner. The biomass gasification burner comprises a bracket, and a primary combustion tube is fixedly mounted at the top of the bracket. The nozzle at oneend of the primary combustion tube is a fuel inlet, and the other end of the primary combustion tube communicates with a secondary combustion tube. The secondary combustion tube comprises a secondarycombustion inner tube and a secondary combustion outer tube. A cracking disk arranged in the secondary combustion tube separates the secondary combustion inner tube into a gasification chamber and aflaming cavity, and the gasification chamber communicates with the flaming cavity through flame outlet holes in the cracking disk. The secondary combustion inner tube, the secondary combustion outer tube and the primary combustion tube enclose an annular cavity, and the cracking disk separates the annular cavity into a secondary oxygen supply chamber and a tertiary oxygen supply chamber. The secondary oxygen supply chamber communicates with the gasification chamber through vent holes, and the tertiary oxygen supply chamber communicates with the flaming cavity through the vent holes. A secondary oxygen supply tube and a tertiary oxygen supply tube separately communicate with the secondary oxygen supply chamber and the tertiary oxygen supply chamber. The biomass gasification burner can fullyburn biomass fuel, has high thermal efficiency and high gasification rate, and is beneficial to environmental protection.

Owner:雷连净

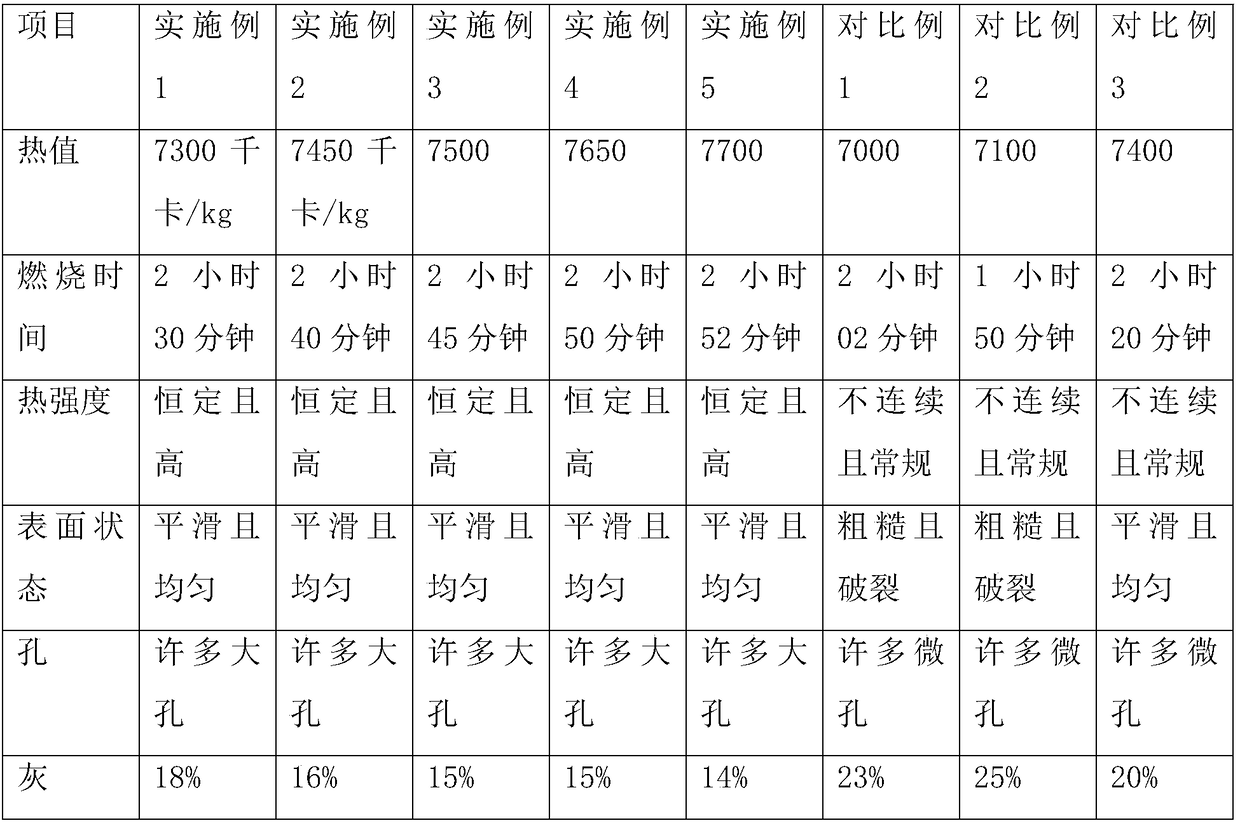

Energy-saving and environmental-protection charcoal and preparation method thereof

InactiveCN109294605AImprove combustion performanceImprove combustion efficiencyProductsReagentsTarWood waste

The invention discloses energy-saving and environmental-protection charcoal, which comprises the following raw materials: rubber wood waste, crop straw, carbon powder, a clinker combustion improver, roasting siderite, plant fiber particles, potassium permanganate, an oxygen supply agent, methanol, copper oxide, and a wood tar binder. According to the present invention, the prepared energy-saving and environmental-protection charcoal can substantially improve the burning performance of charcoal, reduce the amount of the unburned charcoal, improve the burning efficiency of the burning charcoal,greatly reduce the cost, and save the resources.

Owner:HEFEI FANTENG ENVIRONMENTAL PROTECTION TECH CO LTD

Combustor for industrial furnace

InactiveCN103267283BImprove effective utilizationIncrease temperatureGaseous fuel burnerCombustorCombustion chamber

The invention relates to a combustor for an industrial furnace, and belongs to the technical field of combustors. The combustor for the industrial furnace comprises a combustion chamber defined by a bottom cover, a lateral wall and an opening, wherein the bottom cover is connected to fuel through a fuel pipe, a flame outlet is formed in the top end of the lateral wall and is located above the opening, a heat preservation cover covers the upper portion of the lateral wall, the heat preservation cover forms a heat preservation chamber between the opening and the flame outlet, an air cover is arranged outside the heat preservation cover, the air cover, the heat preservation cover and the lateral wall form an air chamber at the lower portion of the lateral wall, and the air chamber is communicated with the combustion chamber through the lateral wall with an air hole, and is connected to an air source through a poroid air plate and an air inlet pipe at the bottom of the air chamber. The combustor for the industrial furnace has the advantages of being high in combustion efficiency, convenient and fast to apply and the like, and can be applied to existing industrial furnaces.

Owner:浙江绍兴世纪能源有限公司

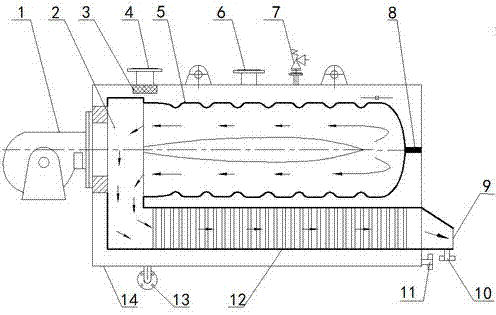

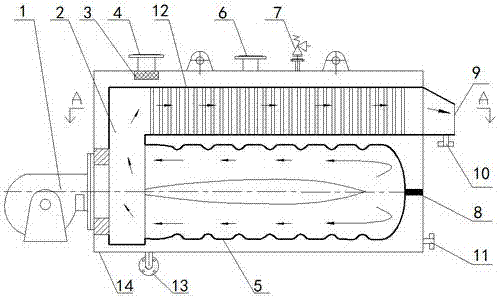

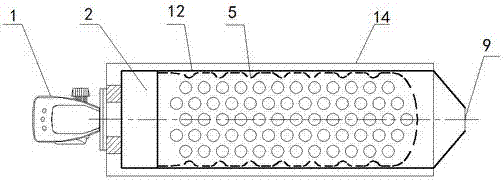

Horizontal flushing water tube type central back-firing boiler

The invention discloses a central back combustion boiler with water pipes being transversely scoured. The central back combustion boiler with the water pipes being transversely scoured mainly comprises a combustor, a shell, a boiler furnace, a smoke transferring chamber and a box type heat exchanger. The central back combustion boiler with the water pipes being transversely scoured is characterized in that the boiler shell is a cuboid, the upper boiler furnace is arranged on the upper portion of the interior of the boiler shell, and the lower box type heat exchanger is arranged on the lower portion of the interior of the boiler shell; the boiler furnace is wavy, the internal combustion mode is central back combustion; the front end of the boiler furnace is welded to the smoke transferring chamber, and an oval sealing head is welded to the rear end of the boiler furnace; the multiple vertical heat exchange water pipes are arranged in the box type heat exchanger, an inlet of the box type heat exchanger is welded to the smoke transferring chamber, and an outlet of the box type heat exchanger is connected with a chimney or an economizer; the boiler furnace, the smoke transferring chamber and the box type heat exchanger are all immersed in boiler water, and a smoke heat exchange surface is a totally-wet back structure. During operation, high-temperature smoke is discharged from the front end of the boiler furnace, passes through the smoke transferring chamber and then enters the box type heat exchanger, the smoke transversely scours the heat exchange water pipes arranged in a staggered mode and heats water in the water pipes, and hot water rises and is discharged from a water outlet pipe on the upper portion of the boiler after being heated again through the boiler furnace. The central back combustion boiler is simple in structure, the heat exchange effect is good due to the fact that the smoke transversely scours pipe bundles, and the heat efficiency of the boiler is high.

Owner:ZHENGZHOU UNIV

Mini-size engine

InactiveCN100445529CIncrease energy densityIncrease speedInternal combustion piston enginesProbe typeCombustion chamber

A tiny engine, in particular a tiny engine based on quasi - forces of gas flow circulating principle makes motor outputting power reach superhigh energy density. Tiny engine includes inner cam flywheel disk, slipper, cylinder body, piston rotor shaft, cover board, gas transmission mechanism and probe type spark plug. Said space in piston rotor shaft is premixing chamber for feeding high pressure gas fuel to cylinder body firing chamber, thereby realizing the thermodynamics effect through pre-set premix high pressure gas fuel form to substitute perfect gas power cycle constant entropy adiabatic compression process. Said invention has higher output loop net work, higher energy density and more simple system structure.

Owner:CHONGQING UNIV

Self-cleaning heating stove

InactiveCN106288364AIncrease combustion spaceAchieve the purpose of purificationWater heatersCombustion chamberEngineering

The invention relates to a self-cleaning heating stove, which comprises a main stove body, wherein the main stove body comprises an outer chamber, a combustion chamber and a purification chamber; the combustion chamber and the purification chamber are arranged in the outer chamber; a water sandwich layer is arranged between the combustion chamber and the purification chamber; the combustion chamber and the purification chamber are separated by a spacer with air holes; the upper end of the spacer is connected with the top of the combustion chamber and the top of the purification chamber; the lower end of the spacer is connected with the bottom of the combustion chamber and the bottom of the purification chamber; the spacer inclines towards the purification chamber; the top of the purification chamber is connected with a separation blade; the bottom of the separation blade is in hollow connection of the bottom of the purification chamber; an angle is formed between the separation blade and the spacer; a feeding port is formed in the top of the combustion chamber; an air supply outlet is formed in the side of the combustion chamber; a water storehouse is arranged at the bottom of the combustion chamber; a water outlet pipe is connected on the water storehouse and is connected to a water inlet in the top of the purification chamber; the bottom of the purification chamber is connected with a water outlet; and a gas outlet is formed in the upper part of the purification chamber. The self-cleaning heating stove has the advantage that water is heated by the combustion chamber and the temperature of heating installation is not influenced, so the normal use of the heating installation is guaranteed.

Owner:全爱军

Hot blast stove for grain dryer

PendingCN113124417AAvoid damageSolve the accumulationDrying gas arrangementsMagnetic separationTemperature controlCold air

The invention discloses a hot blast stove for a grain dryer. The grain dryer communicates with the hot blast stove through a pipeline. The hot blast stove comprises a combustion chamber and a circulation chamber, the combustion chamber comprises a feeding device, a conveying device and a combustion device from top to bottom in sequence, and a settling chamber and a temperature control chamber are arranged in the circulation chamber. Through cooperative use of parts such as a transmission shaft, a cam, a mandrel, a support, an operating rod, a pressing plate, a spring and the like, the conveying device can accurately convey fuel in the vertical direction and also solves the problem that a spiral feeder is prone to material blocking; meanwhile, the pressing plate crushes granular biomass fuel, so that the granular biomass fuel can be combusted more sufficiently and are flammable; through cooperation of the feeding device, the conveying device, the combustion device and the circulation chamber, hot air in the combustion device is mixed with cold air after being subjected to multi-layer gravity dust removal, and the conveyed hot air is cleaner.

Owner:合肥三伍机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com