Combustor for industrial furnace

A technology for burners and industrial furnaces, applied in burners, gas fuel burners, combustion methods, etc., can solve the problems of insufficient mixing of air and fuel, failure to use reasonably, insufficient fuel combustion, etc., and achieve convenient application. , avoid radiation loss, the effect of improving the effective utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

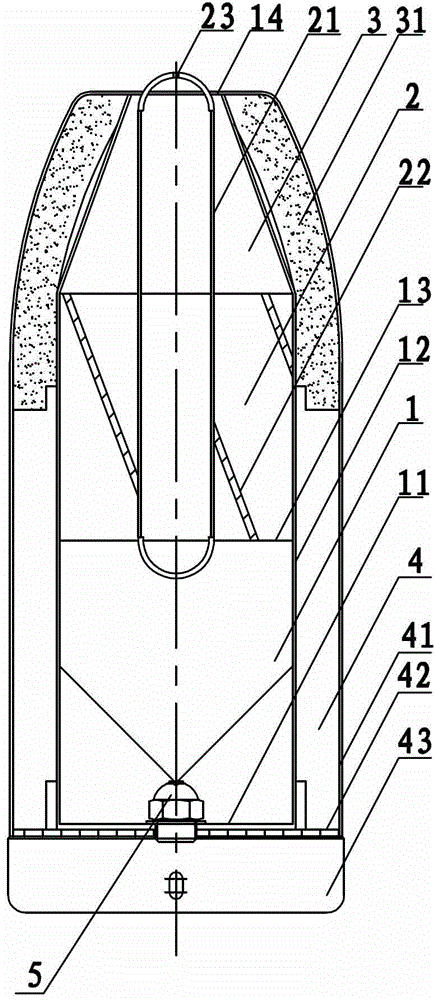

[0022] The present embodiment industrial furnace burner, combines image 3 , including the combustion chamber 1 surrounded by the bottom cover 11, the side wall 12 and the opening 13, the bottom cover 11 is connected to the fuel through the fuel pipe 6; the top of the side wall 12 forms a fire outlet 14, and the fire outlet 14 is located above the opening 13, and the side wall 12. The upper part is provided with a thermal insulation cover 31, and the thermal insulation cover 31 forms the thermal insulation chamber 3 between the opening 13 and the fire outlet 14; The lower part of 12 forms the air chamber 4, and the air chamber 4 is connected with the combustion chamber 1 through the side wall 12 provided with air holes. 44 connect the wind source provided by blower 45; be provided with heating chamber 2 between combustion chamber 1 and heat preservation chamber 3, heat chamber 2 is the space between heat preservation chamber 3 and combustion chamber 1, and guide pipe 21 is arr...

Embodiment 2

[0026] The working principle and setting of this embodiment are the same as those in Embodiment 1, the difference being that the angle of inclination θ of the guide blades 22 is 35°, 6 pieces are evenly arranged, the increase of the angle of inclination increases the quantity of the guide blades 22 simultaneously, The contact area between the flame and the guide vane 22 can be increased, thereby increasing the heating surface of the heat conducting air plate 22, which can better heat the passing fuel and further improve the combustion efficiency.

Embodiment 3

[0028] The working principle and setting of this embodiment are the same as those in Embodiment 1, the difference is that the inclination angle θ of the guide vanes 22 is 20°, and there are 10 uniformly arranged, and the increase of the number of guide vanes 22 can increase the flame and the guide vanes. 22, so that the actual heating surface of the heat-conducting air plate 22 also increases, which can better heat the passing fuel and further improve the combustion efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com