Patents

Literature

44results about How to "Burn less" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

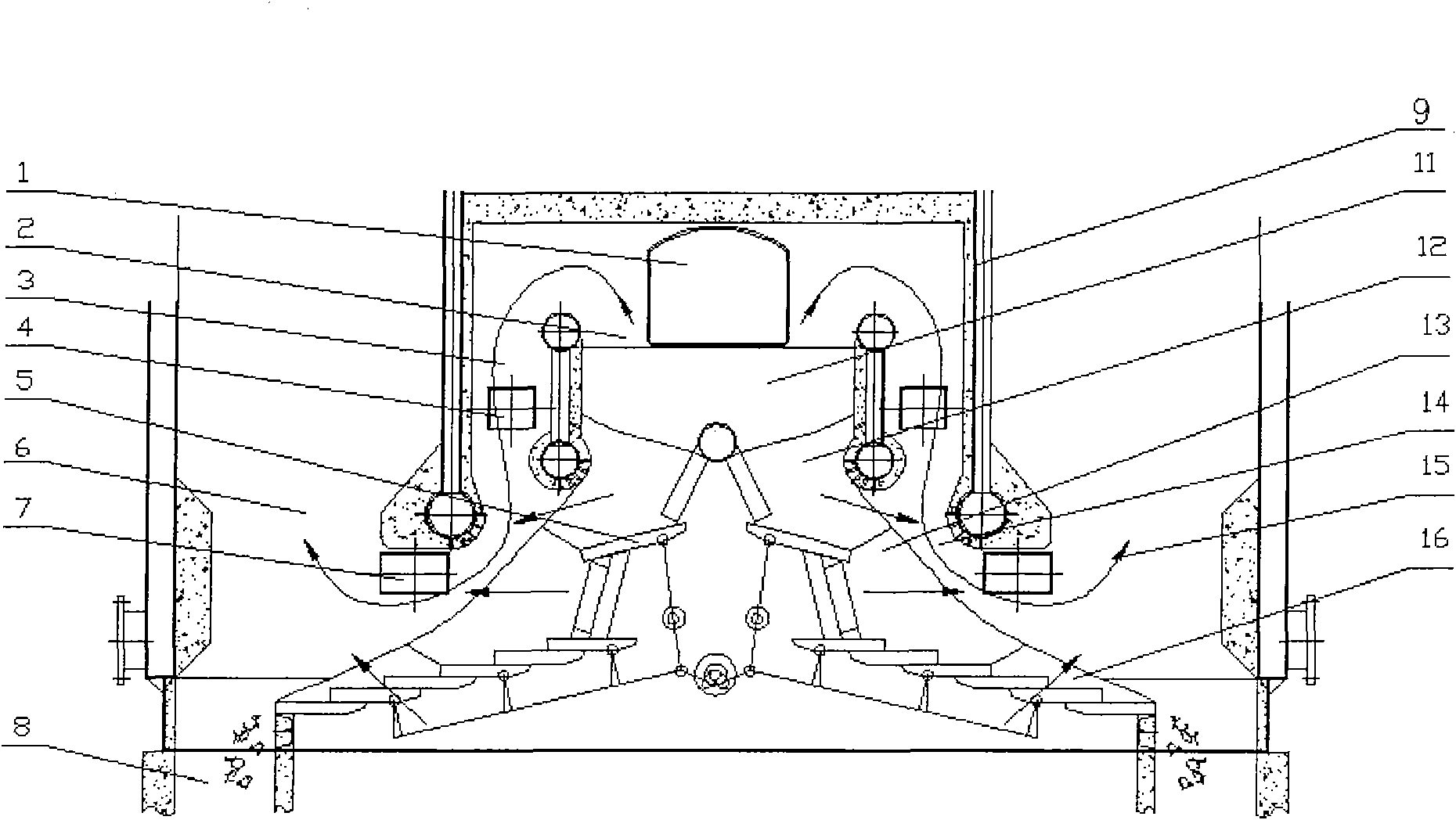

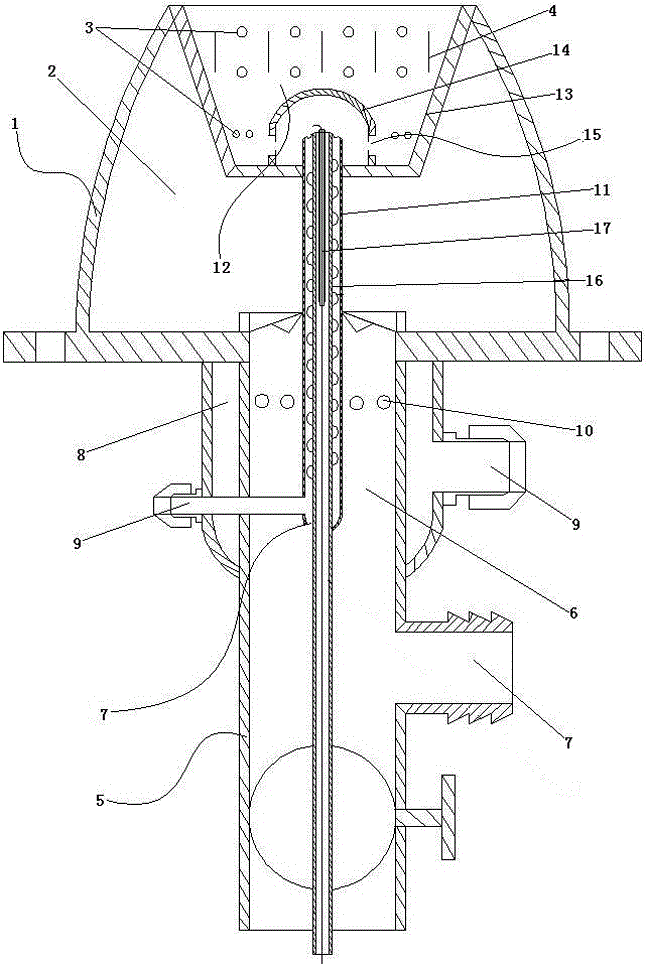

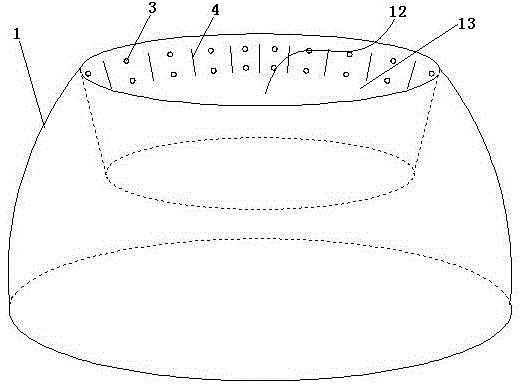

Decoupling combustion furnace and decoupling combustion method

ActiveCN101650025AIncrease combustion spaceImprove combustion intensityAir supply regulationCarburetting by solid carbonaceous material pyrolysisCombustionProcess engineering

The invention provides a decoupling combustion method, which comprises the following steps: a) firstly, performing pyrolysis and gasification of fuels to generate semicoke and gas; b) secondly, combusting part of gas and semicoke to perform oxidation reaction and reduction reaction to generate coke, and applying the generated heat to the pyrolysis and gasification in step a); c) thirdly, combusting the coke and the left gas generated in step a) under the condition that an excess air coefficient is less than 1, and simultaneously generating smoke in the combustion; and d) finally, performing full secondary combustion of the smoke and the remained gas after the steps. The decoupling combustion method can increase the decoupling combustion space and intensity with a smaller floor area; the increase of the gasification zone and the gasification intensity greatly improve the load increasing capability of a decoupling combustion furnace; and in addition, because the high-temperature smoke strongly heats the fuels in the upper part of a pyrolysis and gasification chamber and has higher pyrolysis and gasification intensity, the gas output is increased and the combustion amount of solid semicoke is reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

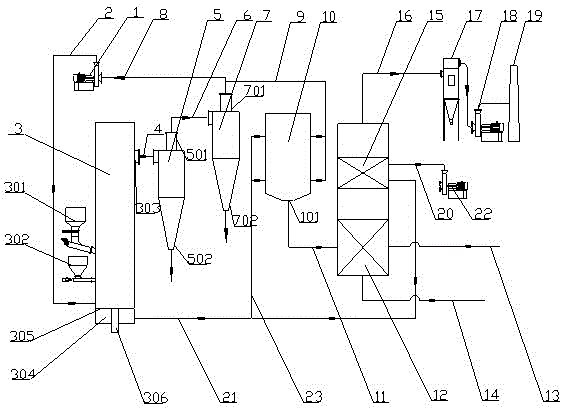

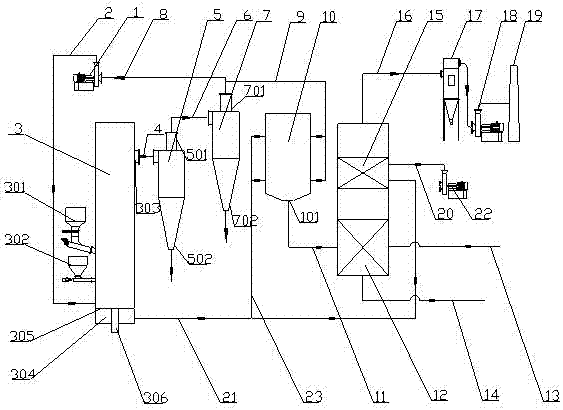

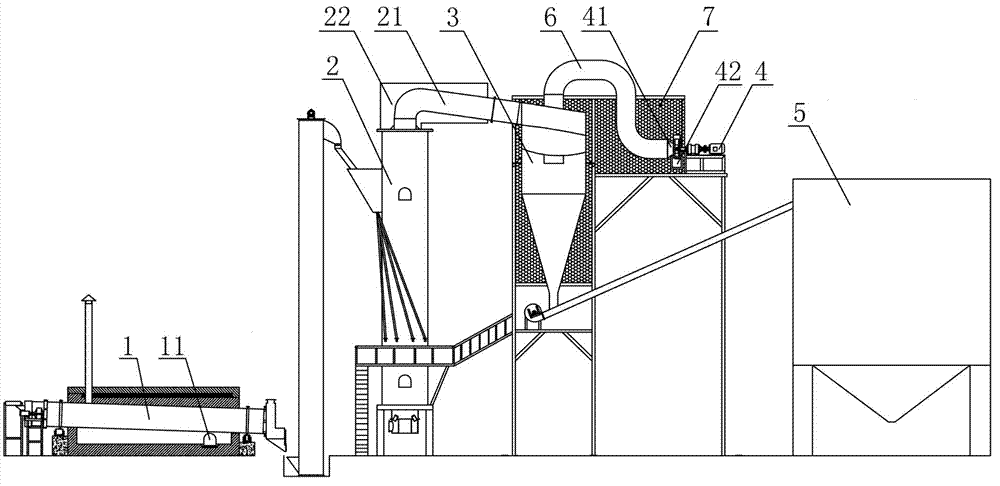

Biocarbon/steam co-production device and technology through biomass pyrolysis, gasification, and combustion sectional conversion

ActiveCN104830377ABurn lessReduce manufacturing costCombustion processEnergy inputAir preheaterCyclone

The invention discloses a biocarbon / steam co-production device and technology through biomass pyrolysis, gasification, and combustion sectional conversion. The co-production device comprises a fluidized-bed pyrolysis and gasification furnace, a low thermal value gas combustion chamber, a primary separation device, a secondary cyclone separator, an air preheater, a steam generator, and a flue gas processing facility. The technology comprises the following steps: making biomass raw materials carry out pyrolysis and gasification reactions in the fluidized-bed pyrolysis and gasification furnace so as to generate biocarbon and high-temperature low thermal value fuel gas, separating the biocarbon and fuel gas by the two grade separation devices to obtain high quality biocarbon, transferring the separated high temperature fuel gas into the low thermal value gas combustion chamber, burning, and transferring the high temperature flue gas generated by the combustion into the steam generator to generate steam. The provided technology is advanced, the production equipment is simple and reliable, the production cost can be effectively reduced, and the production benefit is improved.

Owner:HEFEI DEBO BIOENERGY SCI & TECH

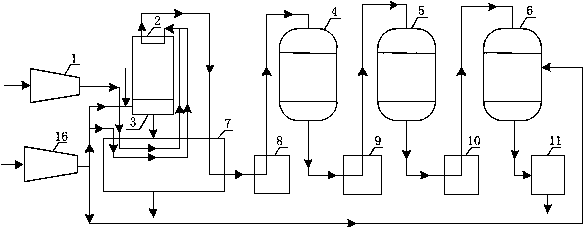

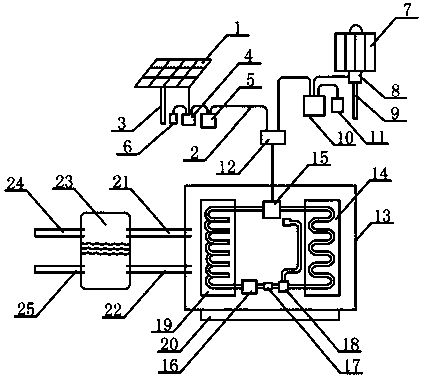

Natural gas autothermal reforming proton exchange membrane fuel cell distributed cogeneration system and method

PendingCN110544785ARealize cogeneration of heat and powerSolve the bottleneck problem of large-scale applicationFuel cell heat exchangeElectrochemical responseSteam reforming

The invention relates to a natural gas autothermal reforming proton exchange membrane fuel cell distributed cogeneration system and method. The system includes a natural gas autothermal reforming module, a proton exchange membrane fuel cell module, an autothermal reforming exhaust gas heat utilization module, a fuel cell waste heat utilization module, and a connection pipeline. The system inputs anatural gas, air, and working water, and outputs power and multistage heat to achieve high-efficiency cogeneration. The natural gas comes directly from an existing urban pipe network. By autothermalsteam reforming, a coupled endothermic steam reforming reaction and an exothermic partial oxidation reaction, self heat supply is achieved in the system. High and low temperature steam conversion andpreferential oxidation technology is used to product a hydrogen-rich gas for fuel cells, which electrochemical reacts with a pressurized self-humidified air entering a fuel cell stack system to outputelectricity. In addition, the waste heat of the system is used in multiple stages to form a clean and efficient natural gas autothermal reforming proton exchange membrane fuel cell distributed cogeneration system.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

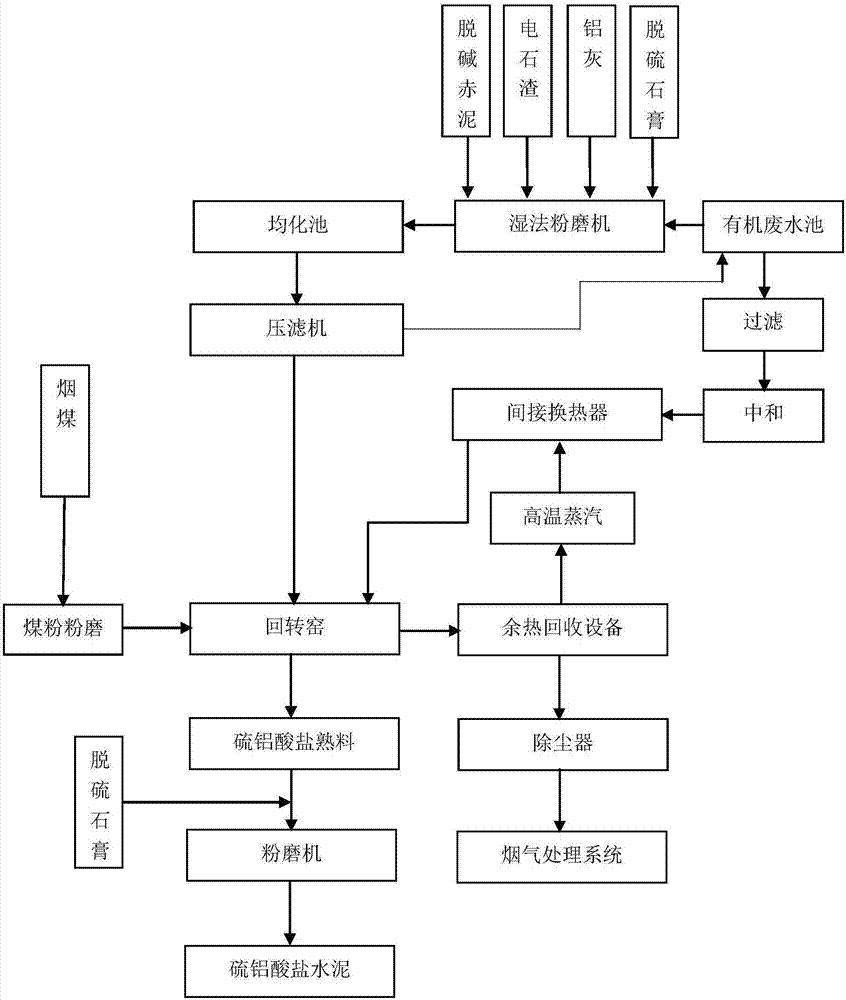

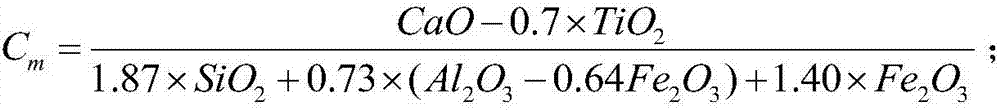

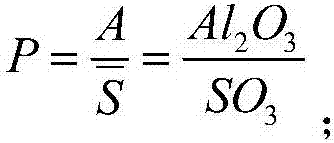

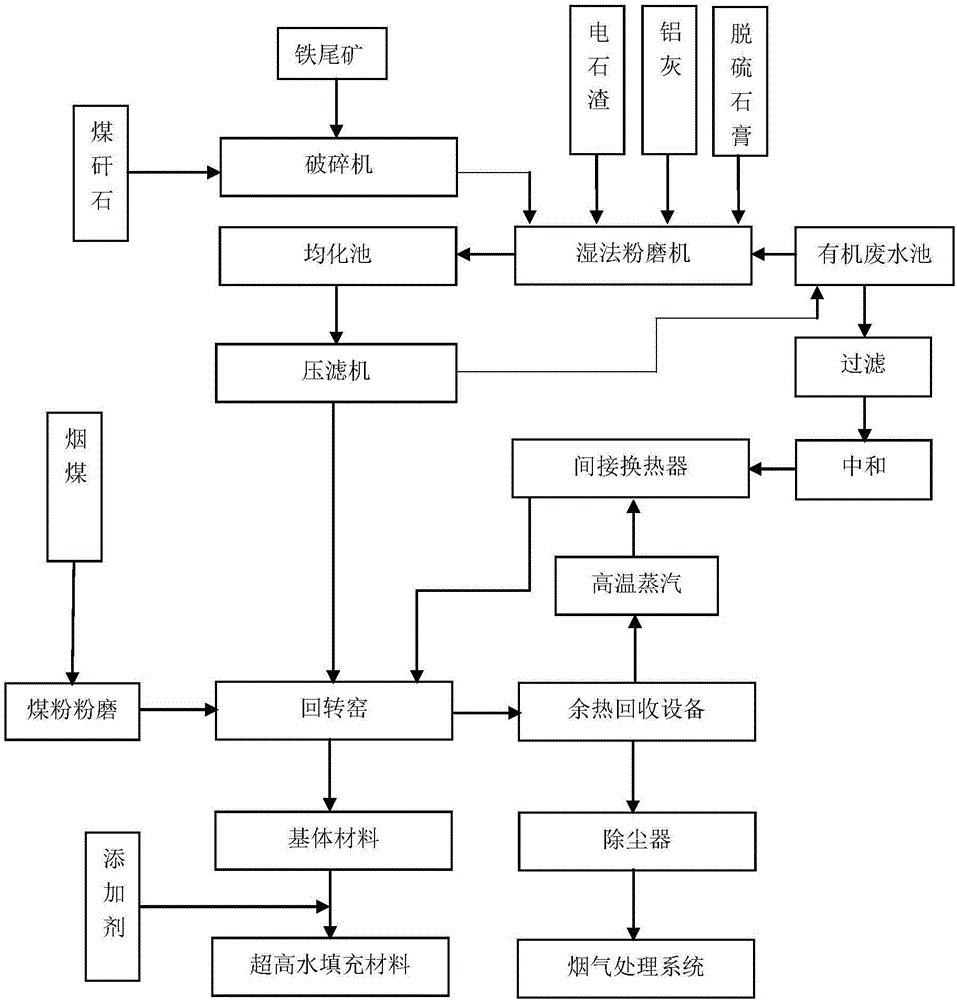

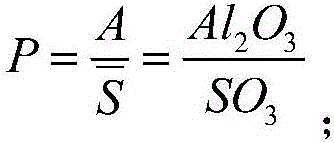

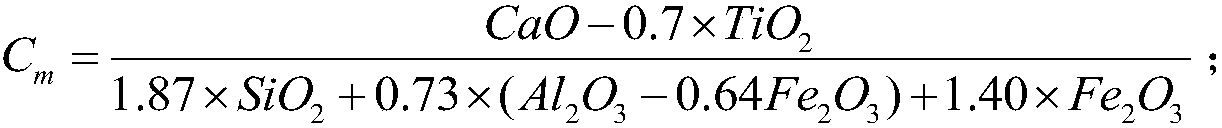

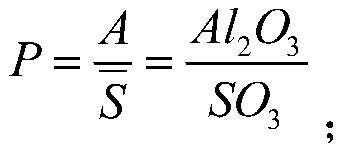

System and method for preparation of sulphoaluminate cement through collaboration of organic wastewater and industrial solid waste

ActiveCN106866006ASolve the shortcomings of productionSolve the problem of difficult utilization of solid wasteClinker productionFiltrationRed mud

The invention discloses a system and a method for preparation of sulphoaluminate cement through collaboration of organic wastewater and industrial solid waste. The system consists of an organic wastewater pool, a homogenizing pool, a wet powder mill, a pressure filter, a rotary kiln and an indirect heat exchanger. The method includes: mixing dealkalized red mud, carbide slag, aluminum ash, desulfurized gypsum and a part of organic wastewater to obtain a mixed solution, which has a water content of 60%-70% (mass), then conducting wet pulverizing on the mixed solution, and subjecting the wet pulverized material to homogenizing treatment so as to obtain a slurry, and performing mechanical pressure filtration dehydration to obtain a slurry, concentrating another part of organic wastewater, then sending the concentrated organic wastewater and the slurry into the rotary kiln and performing high-temperature calcination to obtain a sulphoaluminate clinker, and spraying pulverized coal into the rotary kiln during high-temperature calcination to combust organic waste in the pulverized coal and slurry and organic waste in the concentrated wastewater. The system and method realize comprehensive utilization of industrial solid waste and organic wastewater and zero-pollution emission.

Owner:SHANDONG UNIV

Inorganic precoated sand and preparation method thereof

InactiveCN106424535AEmission reductionImprove production environmentFoundry mouldsFoundry coresInorganic phosphateOrganic compound

The invention discloses inorganic precoated sand. The inorganic precoated sand is prepared from raw materials in parts by weight as follows: 80-90 parts of crude sand, 0.3-3 parts of a curing agent, 0.01-0.1 parts of a polyacrylamide modifying agent, 2-10 parts of a binder and 0.04-0.6 parts of calcium stearate. The invention further discloses a preparation method of the inorganic precoated sand. The method comprises steps as follows: (1) the crude sand and the curing agent are mixed; (2) the polyacrylamide modifying agent is added for a reaction; (3) the binder is added and mixed for a reaction; (4) the calcium stearate is added and mixed for a reaction. The prepared inorganic precoated sand is high in strength and good in collapsibility, according to the preparation method, inorganic phosphate of a basic metal replaces organic resin of traditional precoated sand to be used as the binder, intake of organic compounds is avoided, discharge of toxic and hazardous gases is reduced, and the production environment of workers is greatly improved.

Owner:HEFEI RENCHUANG CASTING MATERIAL CO LTD

Complete processing equipment of coal gas expanded perlite

The invention provides complete processing equipment of coal gas expanded perlite, comprising a coal gas device, a preheating furnace, an expansion furnace, a cyclone dust collector, a material bin, a high-temperature induced-draft fan, a high-temperature discharging pipe and a high-temperature induced-draft pipe, wherein the preheating furnace is provided with a high-temperature hot-air inlet; one end of the high-temperature discharging pipe is communicated with a discharging port of the expansion furnace, and the other end of the high-temperature discharging pipe is communicated with a feeding port of the cyclone dust collector; one end of the high-temperature induced-draft pipe is communicated with the top part of the cyclone dust collector, and the other end of the high-temperature induced-draft pipe is communicated with an air inlet of the high-temperature induced-draft fan; and an air outlet of the high-temperature induced-draft fan is communicated with the high-temperature hot air inlet. The complete processing equipment has the advantages that high-temperature hot air in the cyclone dust collector is introduced to the preheating furnace for preheating ore sand by the high-temperature induced-draft fan, so that not only is the burning amount of coal gas in the preheating furnace reduced, but also the problem that the energy is wasted for nothing is solved.

Owner:信阳市四通机械制造有限公司

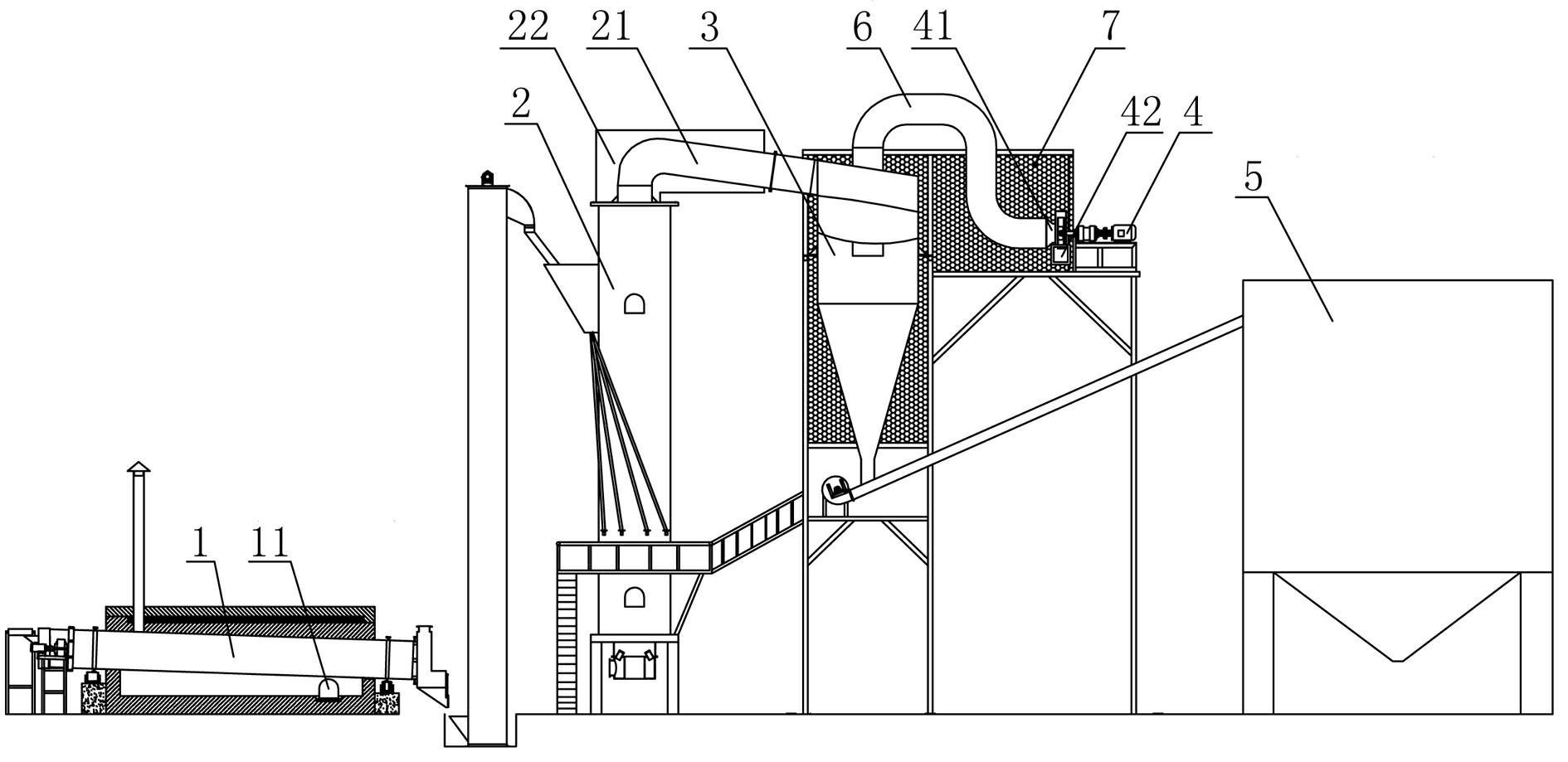

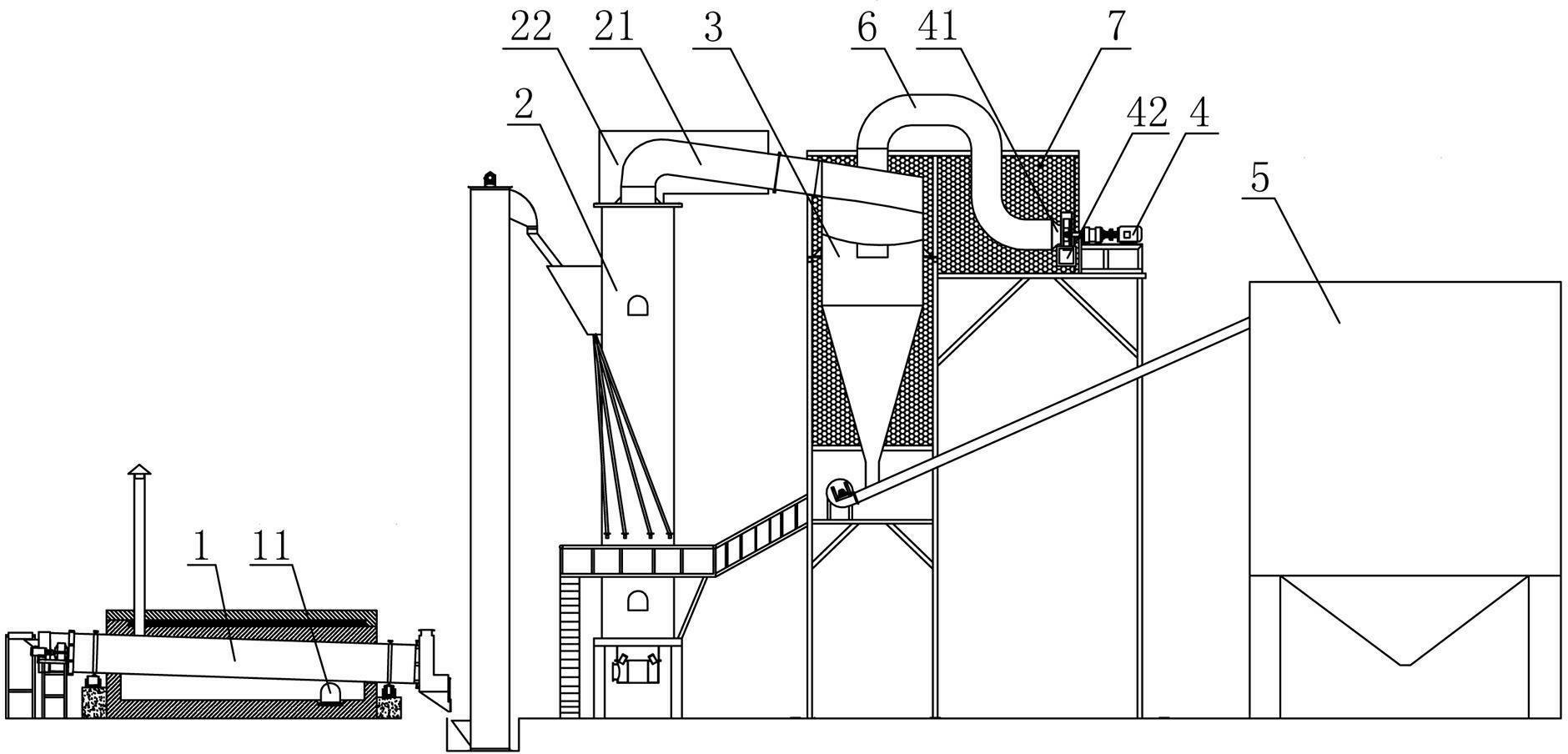

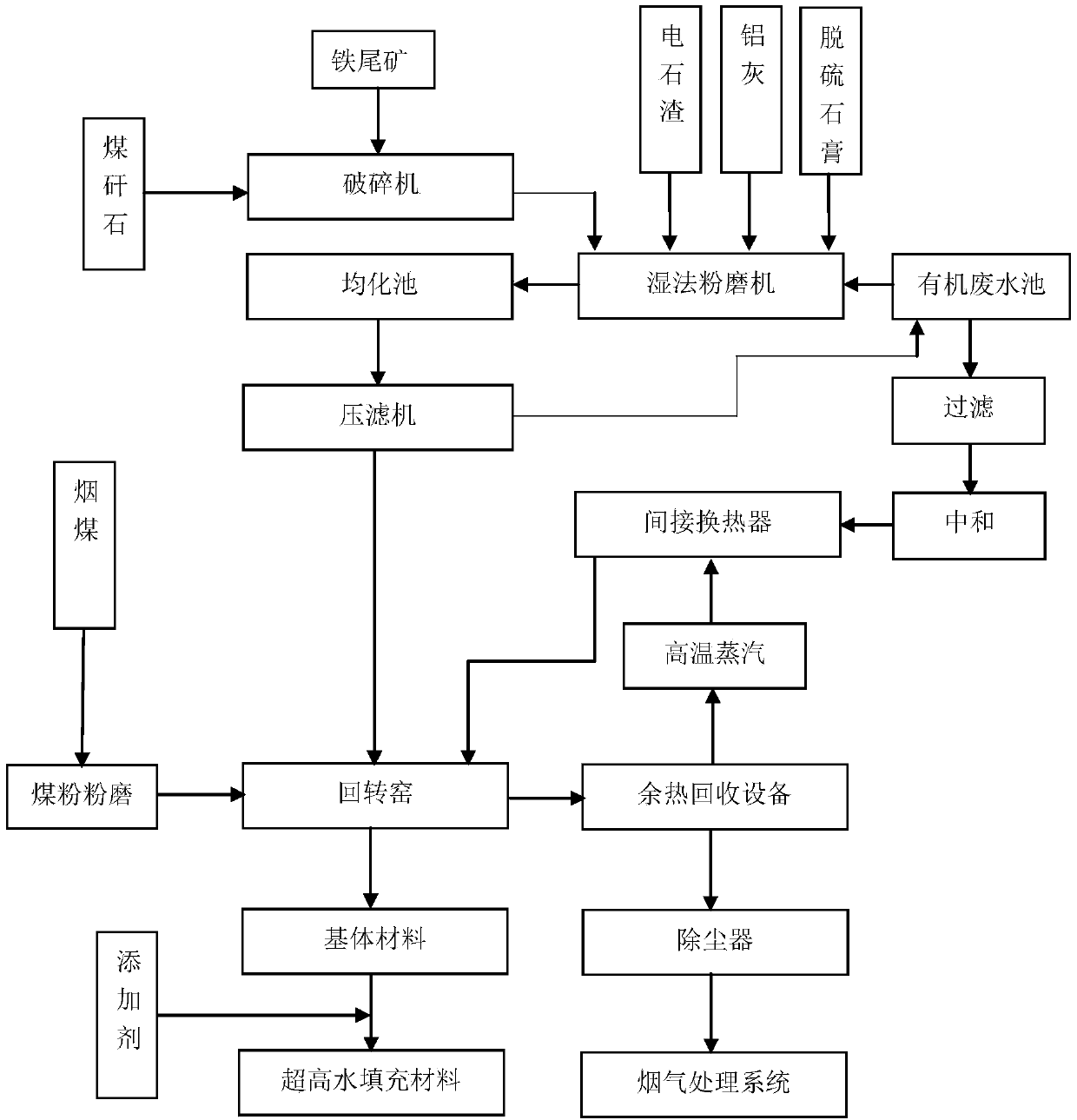

System and method for preparing ultra-high water filling materials by organic wastewater and industrial solid waste

The invention discloses a system and a method for preparing ultra-high water filling materials by organic wastewater and industrial solid waste. The system comprises a wet pulverizer, a pressure filter, an equalizing basin, a rotary kiln and an indirect heat exchanger. Desulfurized gypsum, aluminum ash, carbide slag, coal gangue, iron tailings and part of the organic wastewater are mixed to obtain mixed solution, the water content of the mixed solution is 60%-70% (mass), the mixed solution is pulverized by a wet process, wet pulverized materials are equalized to obtain slurry, the slurry is mechanically pressed, filtered and dewatered to obtain paste, the other part of the organic wastewater is concentrated, then enters the rotary kiln together with the paste and calcined at high temperature to obtain base materials, pulverized coal is sprayed into the rotary kiln in the high-temperature calcining process, so that the pulverized coal and organic matters in the mixed paste are burnt, and finally, the base materials, accelerators, dispersants, expanding agents and water are prepared into the ultra-high water filling materials. The system and the method can be used for preparing the novel ultra-high water filling materials by reusing the industrial solid waste.

Owner:SHANDONG UNIV

Method of producing biogas through Chinese medicine residues

ActiveCN103290060AReduce dependenceEmission reductionWaste based fuelFermentationRural landBiomass c

The invention discloses a method of producing biogas through Chinese medicine residues, relating to application of Chinese medicine residues and belonging to the field of utilization of biomass energy sources. The method is characterized by comprising the following steps of: crushing the Chinese medicine residues to 40 meshes, filling methane bacteria accounting for 10% of total amount of the Chinese medicine residues, adjusting the carbon-nitrogen ratio to be (20-25):1, and treating at 53-55 DEG C for 10 days; and performing an anaerobic digestion reaction to prepare biogas. The method has the beneficial effects that biogas preparation and combustion equipment is simple, the equipment is conveniently used and managed, rely of urban residents on fossil energy and emission of greenhouse gases are reduced, and the biogas contains no such poisonous gases as CO, thereby being more beneficial to human body health and excellent in environmental effect; the straw combustion quantity is reduced to create conditions for straw application and realizing sustainable utilization of rural lands; and the biogas is used for replacing the straws to greatly improve the living environment of farmers and improving the living standard of the farmers, thereby having excellent social benefit and ecological benefit.

Owner:甘肃富民生态农业科技有限公司

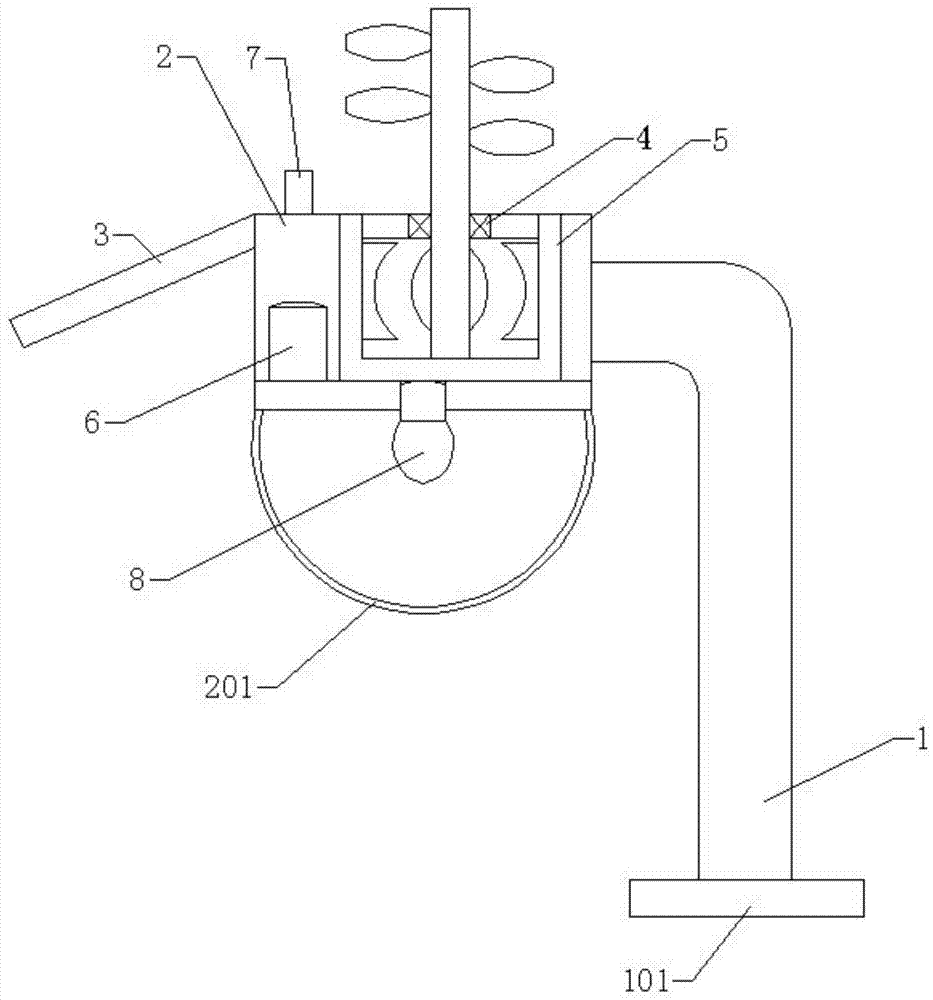

Air-source heat pump water heater powered by wind-solar complementary power generation system

InactiveCN103776165ATake advantage ofReduce power consumptionFluid heatersPV power plantsWind drivenThermal energy

The invention relates to an air-source heat pump water heater powered by a wind-solar complementary power generation system, and belongs to the technical field of clean energy application. Sunlight irradiates a solar battery to generate current which is inputted to a junction station through a conductor wire, a photovoltaic controller and a photovoltaic inverter, wind power blows blades to rotate, a wind driven generator is driven to generate current which is inputted to the junction station through a conductor wire and a wind power controller, the current outputted from the junction station is inputted to a compressor through a conductor wire to serve as driving power, rotation of the compressor drives refrigerants to continuously circulate in a system, the refrigerants evaporate and absorb heat energy in air in an evaporator, so that liquid refrigerants are changed into gaseous refrigerants, the gaseous refrigerants enter a condenser, then release high-temperature heat energy to heat water and are cooled into the liquid refrigerants, and photovoltaic current and wind power current are collected in the junction station to serve as the driving power for driving the air-source heat pump water heater to generate a large amount of hot water supplied to users. The air-source heat pump water heater generates the hot water without burning coal, so that the environments are protected, and energy is saved.

Owner:湖北开日空气能源研究院有限公司

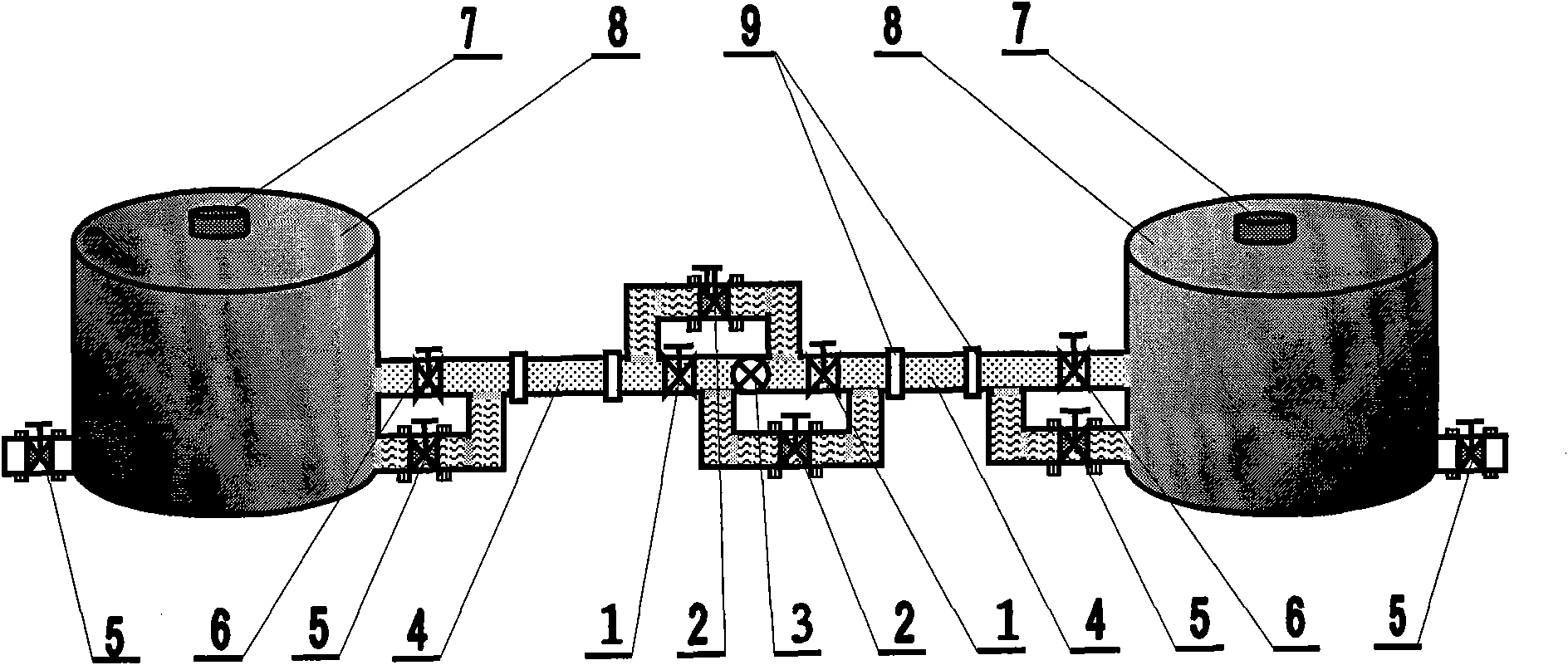

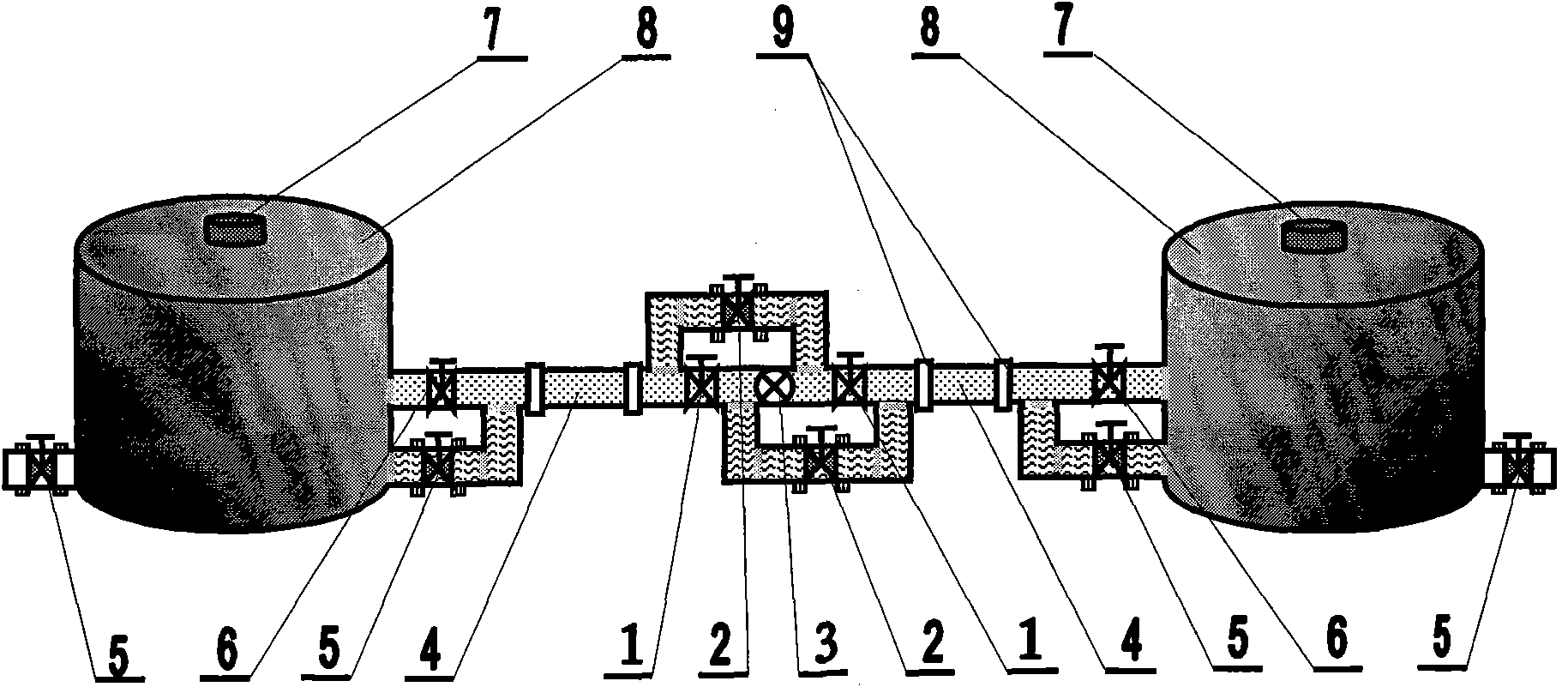

Prevention and collection method for oil and gas fire disasters

ActiveCN101912673AAvoid reactionSafe and efficient collectionFire rescueFire - disastersCollection methods

The invention relates to a prevention and collection method for oil and gas fire disasters, which is characterized in that a ventilating anti-backfire decompression safety device 7 is arranged on the top of a tank body 8, the oil inlet port and the oil outlet port at the bottom of the tank body 8 are horizontally equipped with a radiation-type anti-backfire valve gear 5 and a tank body valve 6 in parallel and are connected with an oil pipeline 4 in series; oil delivery pipeline valves 1 are horizontally connected with a pipeline radiation-type anti-backfire valve gear 2 in parallel, and an oil delivery pump 3 is arranged between the two oil delivery pipeline valves 1 so as to collect oil and gas burning in the tank body 8 or the pipeline 4 in time and transmits the oil and gas into the safe tank body 8 or the safe pipeline 4. The method is as follows: closing the valves 1 and 6, and opening the radiation-type anti-backfire valve gears 2 and 5 to delivery the oil and gas towards the direction of the safe tank body 8 and the safe pipeline 4, wherein the radiation-type anti-backfire valve gears 2 and 5 in the pipeline are characterized by preventing backfire phenomenon in the pipeline and simultaneously reducing the temperature when oil and gas passes the valve gears.

Owner:阳泉新宇岩土工程有限责任公司

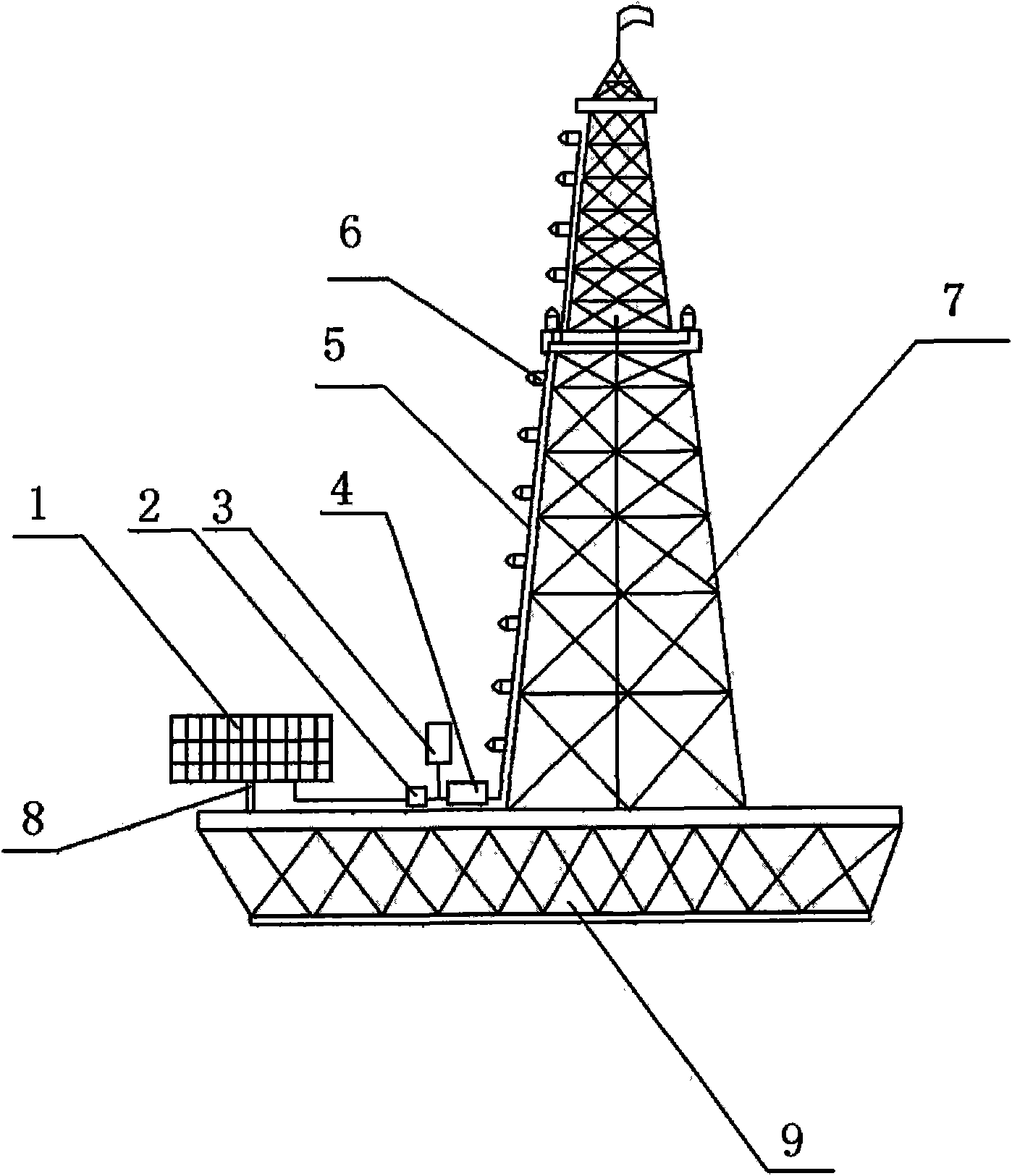

Power-supply device of solar photovoltaic generating system applied to petroleum boring tower

InactiveCN101608765ABurn lessEmission reductionLighting applicationsBatteries circuit arrangementsNew energyAlternating current

The invention relates to a power-supply device of a solar photovoltaic generating system applied to a petroleum boring tower, which pertains to the technical filed of new energy application. Bright sunlight shines on a plurality of petroleum boring towers standing on an overland drilling platform. On the overland drilling platform and petroleum boring towers, solar panels are arranged for receiving solar radiation. Optical energy is transformed into electric energy on the surfaces of solar panels. Direct current is input into a controller for regulation through electric leads, and then input into an inverter; and in this way, the direct current is transformed into alternative current to supply power for alternative current loads arranged on the overland drilling platform and petroleum boring towers. Current can also enter a lithium ion battery for storage after being regulated by the controller. The new energy supplied by the solar photovoltaic generating system can be served for saving energy and reducing emission for exploiting traditional petroleum.

Owner:WUXI MEICUN TONGCHUN SOLAR ENERGY PV TECH AGRI PLANTATION

Biomass Pyrolysis Gasification Combustion Staged Conversion Biochar/Steam Cogeneration Process

ActiveCN104830377BBurn lessReduce manufacturing costCombustion processEnergy inputAir preheaterCyclone

The invention discloses a biocarbon / steam co-production device and technology through biomass pyrolysis, gasification, and combustion sectional conversion. The co-production device comprises a fluidized-bed pyrolysis and gasification furnace, a low thermal value gas combustion chamber, a primary separation device, a secondary cyclone separator, an air preheater, a steam generator, and a flue gas processing facility. The technology comprises the following steps: making biomass raw materials carry out pyrolysis and gasification reactions in the fluidized-bed pyrolysis and gasification furnace so as to generate biocarbon and high-temperature low thermal value fuel gas, separating the biocarbon and fuel gas by the two grade separation devices to obtain high quality biocarbon, transferring the separated high temperature fuel gas into the low thermal value gas combustion chamber, burning, and transferring the high temperature flue gas generated by the combustion into the steam generator to generate steam. The provided technology is advanced, the production equipment is simple and reliable, the production cost can be effectively reduced, and the production benefit is improved.

Owner:HEFEI DEBO BIOENERGY SCI & TECH

Energy-saving and environment-friendly LED lamp

InactiveCN104748051ABurn lessAchieve energy saving and environmental protection functionsPoint-like light sourceElectric circuit arrangementsEngineeringSolar power

The invention discloses an energy-saving and environment-friendly LED lamp which comprises a support rod, a mounting base, a solar power conversion plate, a bearing, a wind driven generator, a storage battery, a photosensitive resistor and a bulb. According to the energy-saving environment-friendly LED lamp, the structure is simple, the function is powerful, electric energy is supplied for the bulb through solar power generation and wind power generation instead of thermal power generation is replaced, the coal burning quantity is reduced, and the energy-saving and environment-friendly effects are achieved.

Owner:ANHUI ZHAOLI OPTO ELECTRONICS TECH

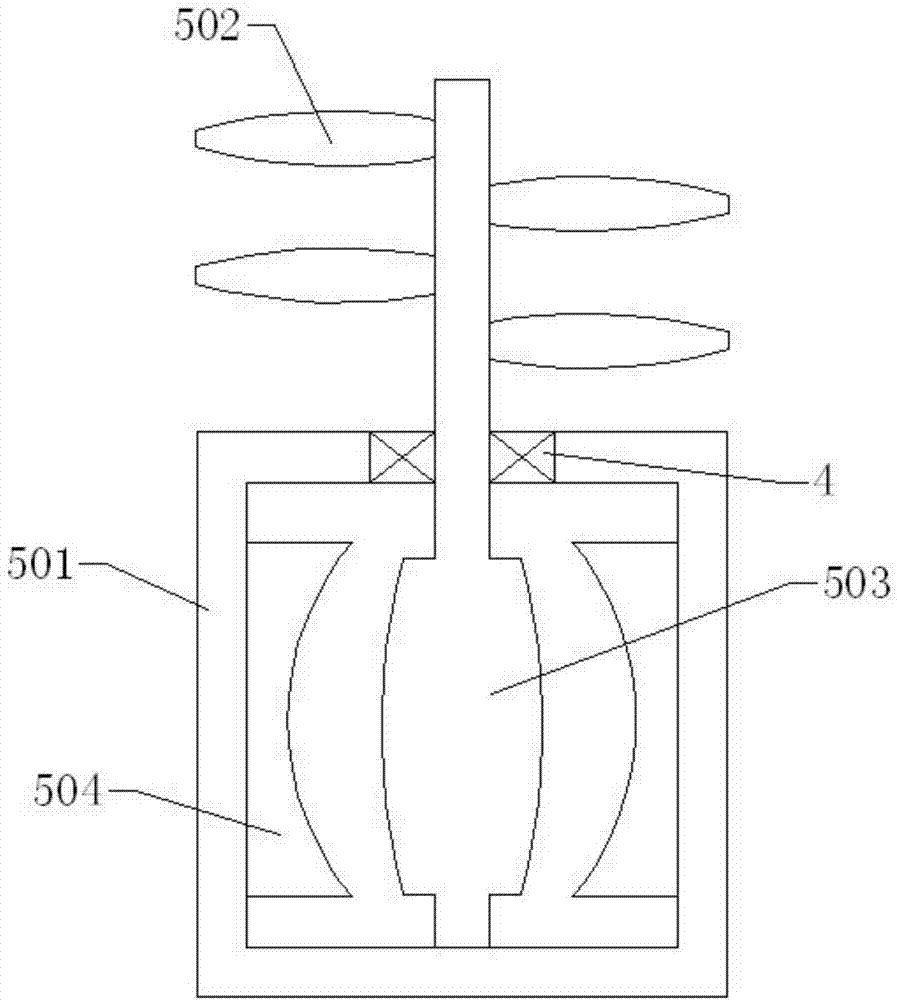

Energy-saving gas stove core with fire spit out of side wall

InactiveCN105627314AUnobstructed air outletAvoid blockageGaseous fuel burnerForeign matterBottom ash

The invention relates to an energy-saving gas stove core with fire spit out of a side wall. The energy-saving gas stove core comprises a cooking range with a mixing cavity and a combination pipe communicated with the mixing cavity. One end of the cooking range is provided with a plurality of gas nozzles, and the other end of the cooking range is connected with the combination pipe. A tank is arranged at the end, with the gas nozzles, of the cooking range and is concaved into the cooking range in the axis direction of the cooking range. The tank is provided with the side wall surrounding the axis of the cooking range by a circle. The gas nozzles are formed in the side wall in a penetrating manner. The mixing cavity is communicated with the tank through the gas nozzles. The gas nozzles are formed in the side wall of the tank, and the horizontally and obliquely upward gas injection direction of the gas nozzles is formed. By means of the direction of the gas nozzles, the situation that in the prior art, gas nozzles are upwards, and consequently the gas nozzles are likely to be blocked by fallen pan bottom ash or foreign matter in the prior art is avoided, gas output of the gas nozzles is smooth, and foreign matter nearby the gas nozzles of the cooking range hardly needs to be scrubbed. The beveling direction of the gas nozzles in the side wall is located between the tangent direction and the radial direction of a round, and therefore the condition that spinning fire is jointly spit by the multiple gas nozzles is formed, and flame distribution is evener.

Owner:SUZHOU LONGRONG INFORMATION TECH CO LTD

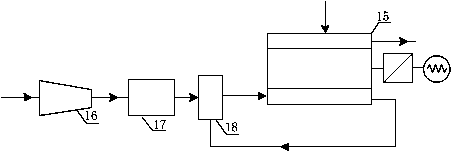

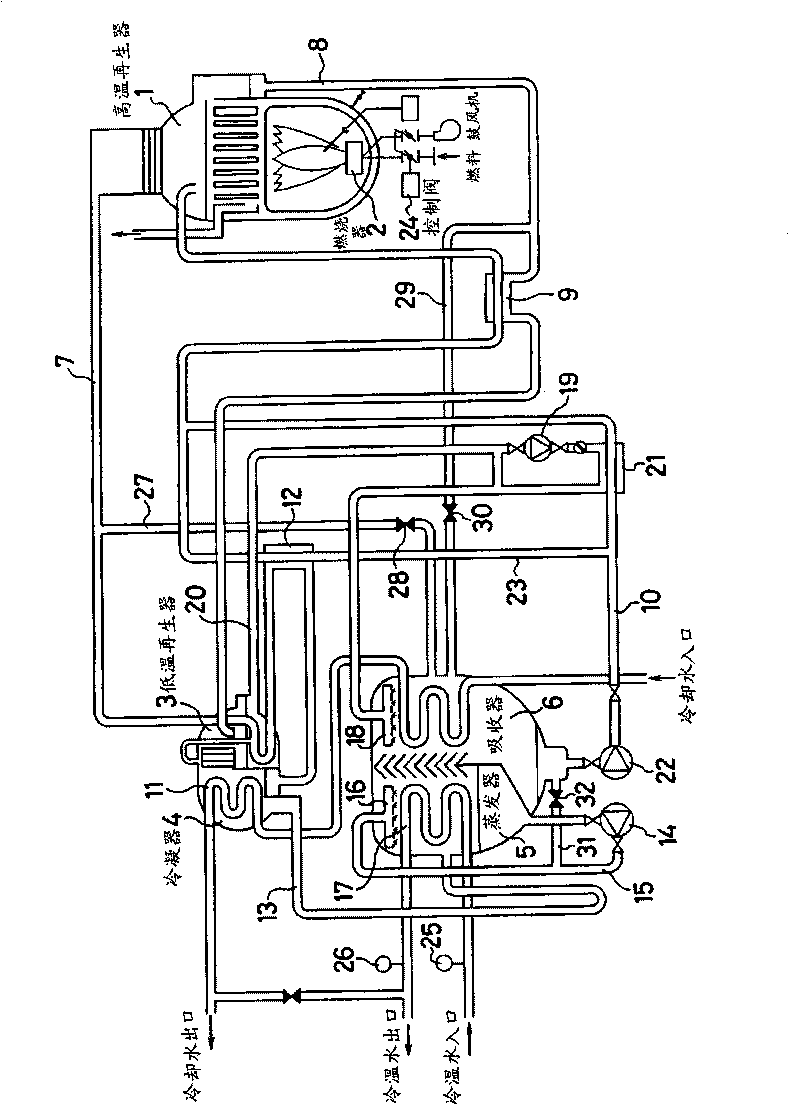

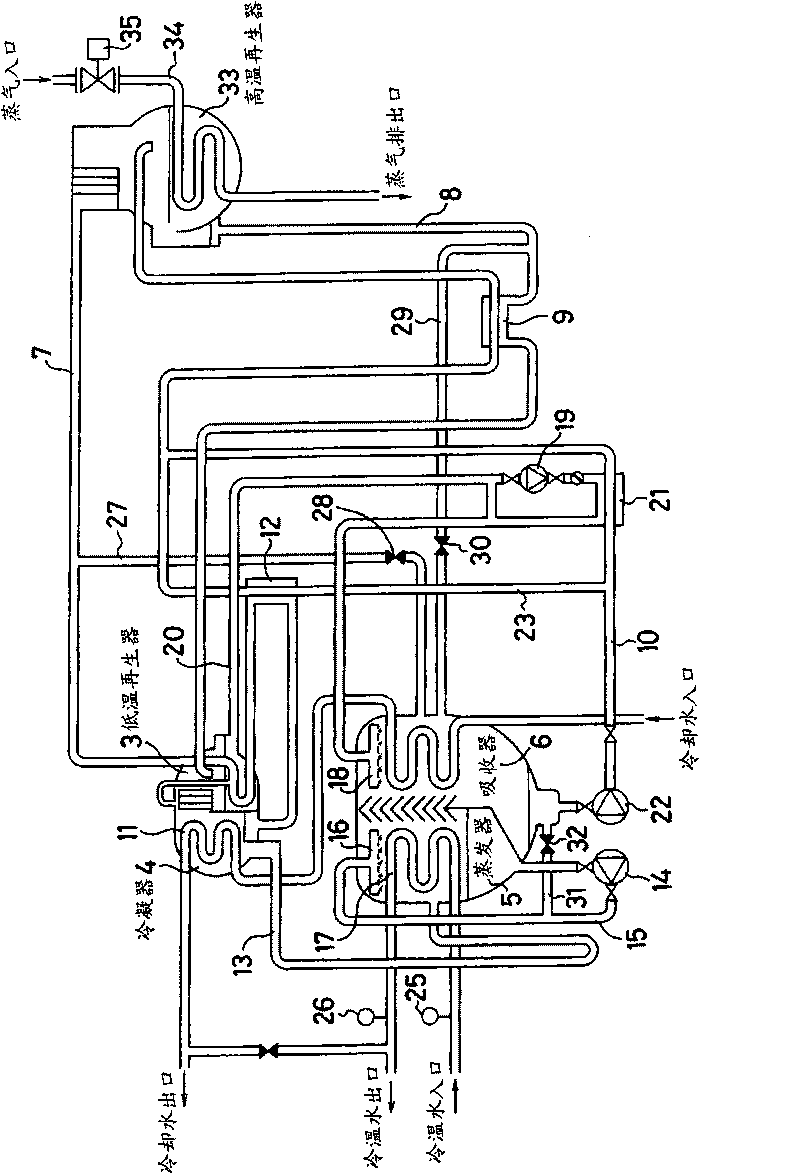

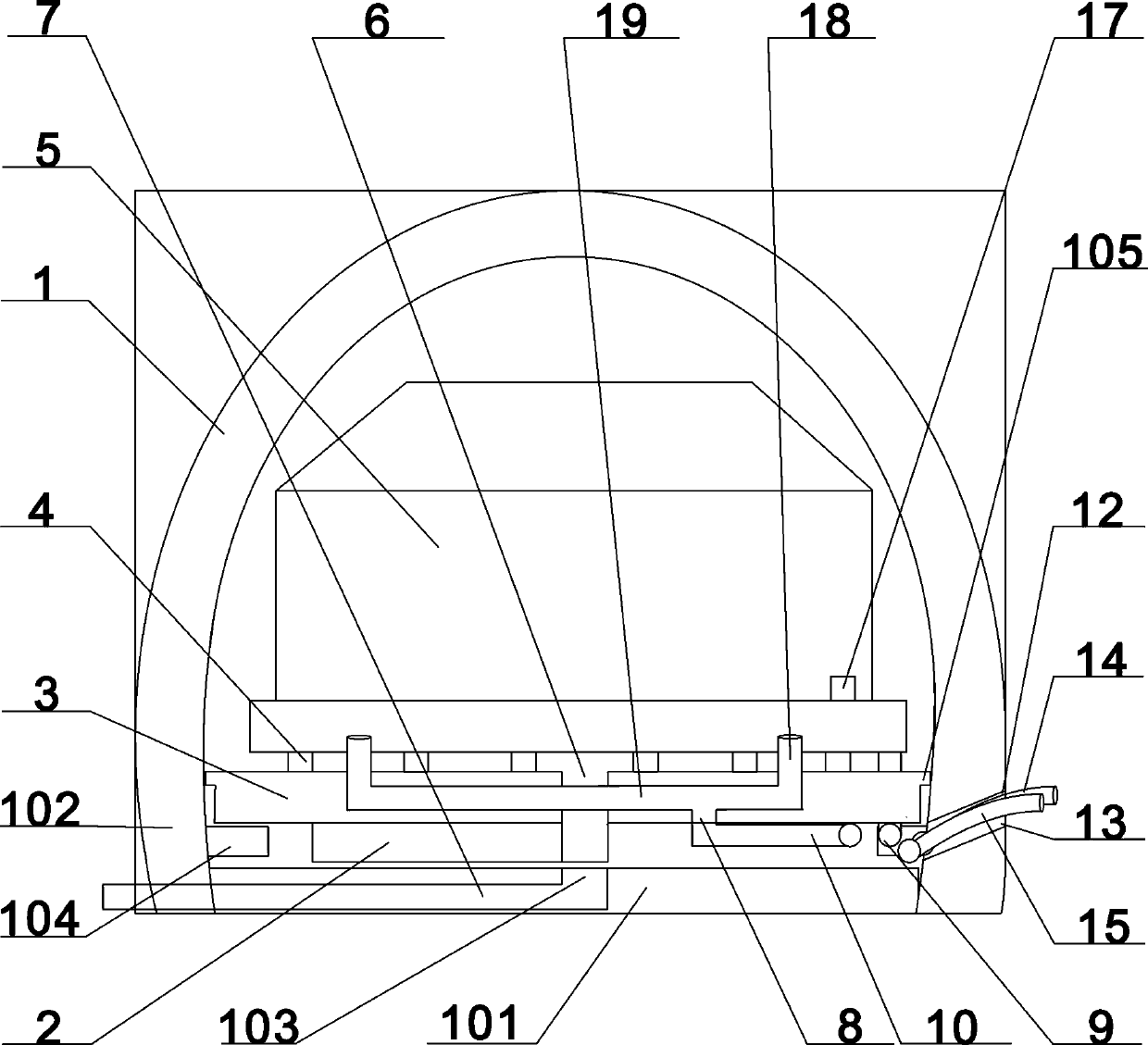

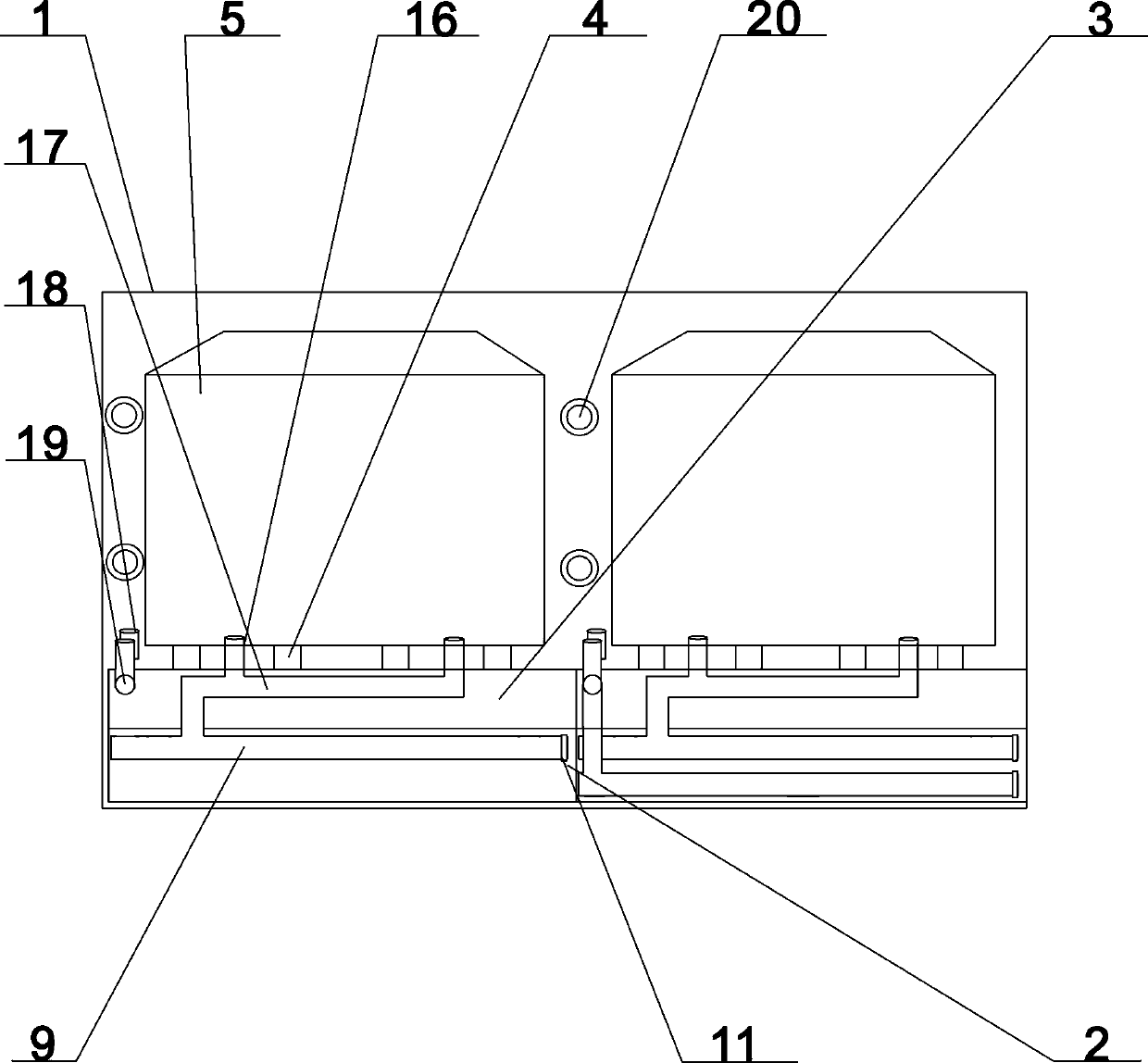

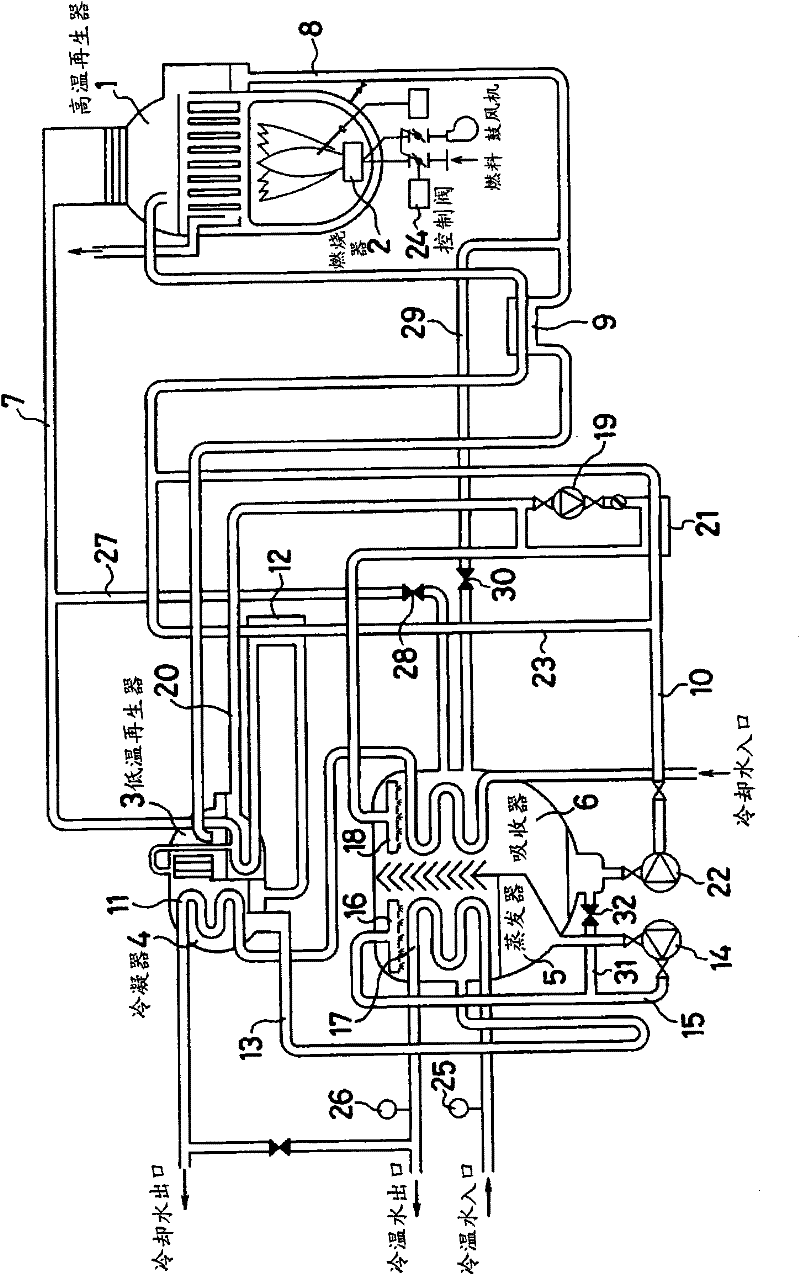

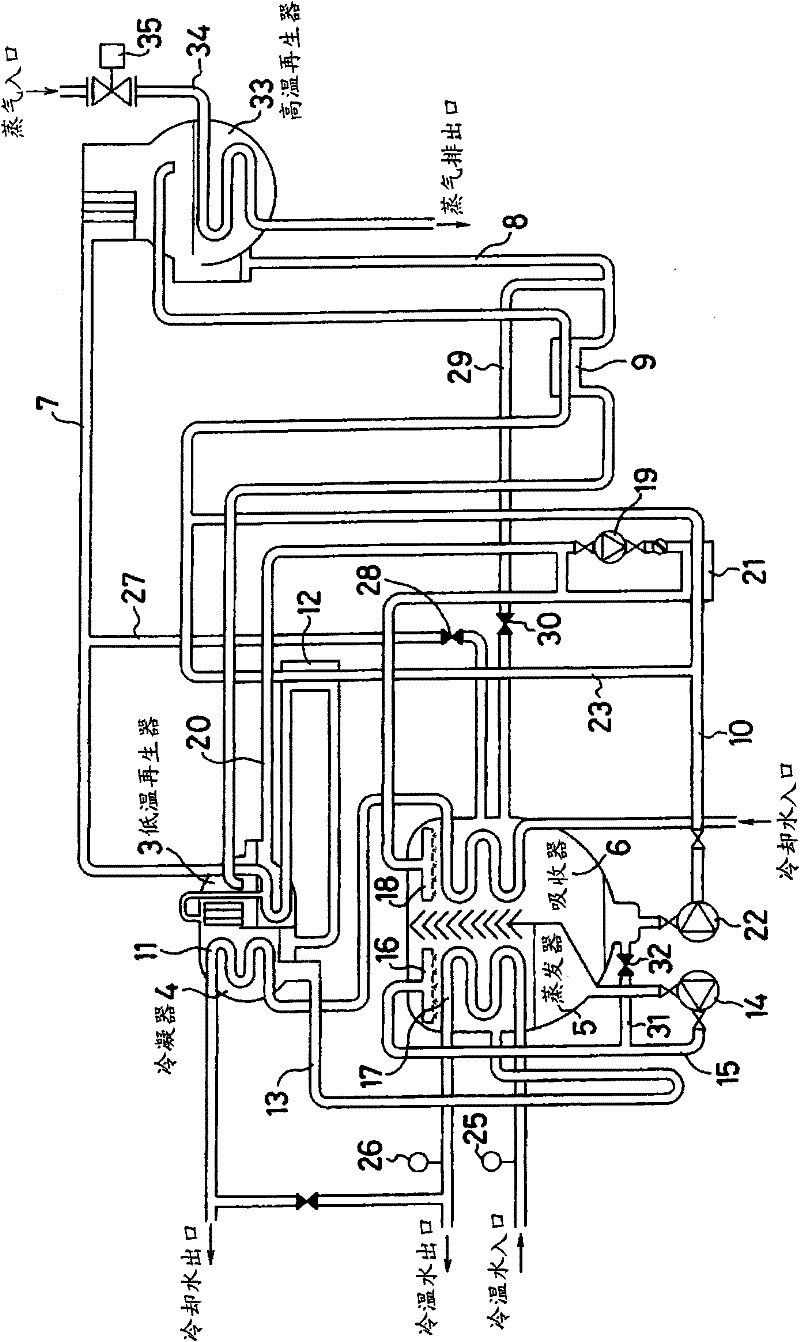

Absorption refrigerating machine

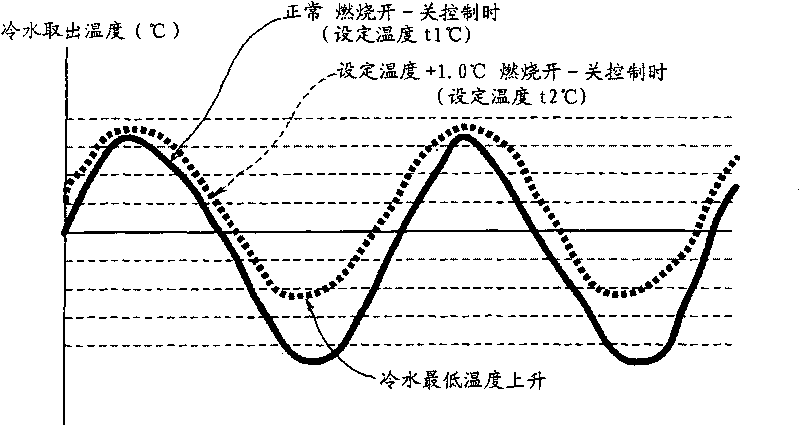

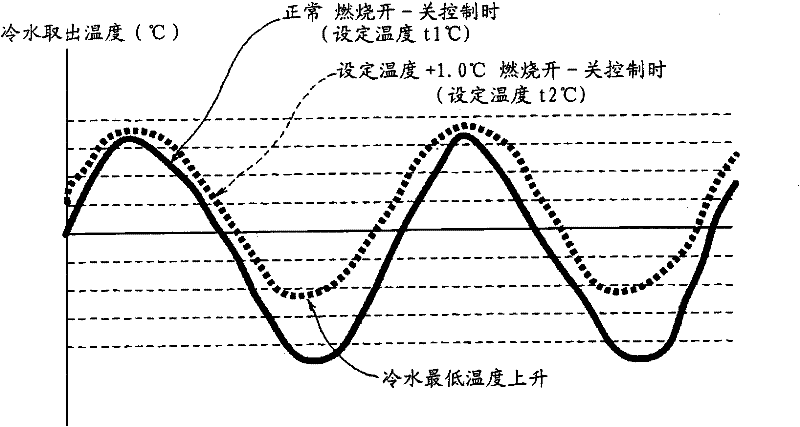

InactiveCN101713597APrevent the temperature from dropping too muchImprove average COPClimate change adaptationEnergy efficient heating/coolingEvaporatorLow load

The invention provides an absorption refrigerating machine that can seek improving average COP based on a low load less than 20%. The absorption refrigerating machine at least comprises the follow components: a high temperature regenerator (1), a low temperature regenerator (3), a condensator (4); and comprises an evaporator (5), an absorption device (6), a refrigerant pump (14) and an absorption liquid pump (20, 22), through which lukewarm water supplied to a load bypassing a lukewarm water tube (17). When operating low load by refrigeration, set temperature of cold water to a principled temperature that higher than preset temperature when switching combustion of a burner (2) of the high temperature regenerator (1) closed; when operating low load by heating, , set temperature of warm water to a principled temperature that lower than preset temperature when switching combustion of a burner (2) of the high temperature regenerator (1) closed.

Owner:SANYO ELECTRIC CO LTD

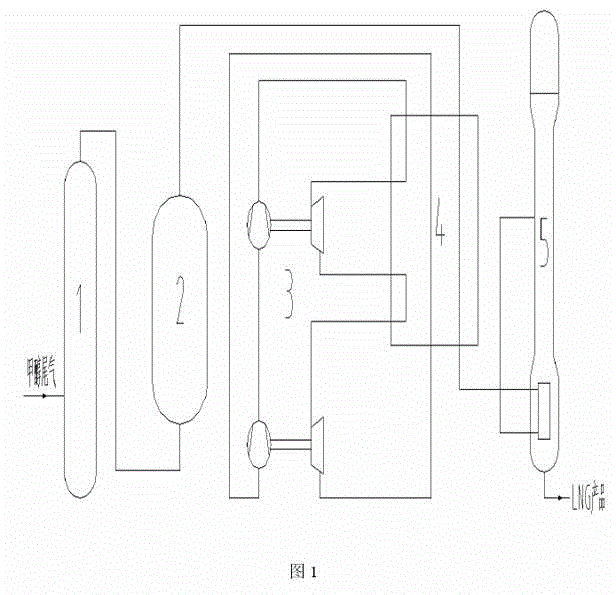

Method for preparing LNG (Liquefied Natural Gas) by recycling methanol tail gas

The invention relates to a method for preparing LNG (Liquefied Natural Gas) by recycling methanol tail gas. Devices adopted in the method comprise a carbon removal tower, a molecular sieve, a high-low-temperature expansion machine, a heat exchanger and a rectifying tower, wherein the carbon removal tower is connected with the molecular sieve. The method comprises the following steps of removing carbon dioxide in the methanol tail gas by virtue of the carbon removal tower so that the content of carbon dioxide in the tail gas reaches below 30ppm, feeding the carbon-dioxide-removal methanol tail gas into the molecular sieve to remove heavy hydrocarbons and the moisture so that the dew point of the tail gas is less than -70 DEG C, exchanging heat with the purified and qualified methanol tail gas to -174 DEG C by virtue of the heat exchanger and feeding the methanol tail gas subjected to heat exchange to the low-temperature rectifying tower for rectifying and carrying out cryogenic liquefaction, separation and extraction to prepare LNG and obtain a LNG product of which the purity is 99.8%, wherein the tail gas discharged from the top of the rectifying tower is adopted as a cool source of a subcooler for cryogenic liquefaction of LNG, a small part of the tail gas is used as a regeneration gas of the molecular sieve and the other part of the tail gas is used as a fuel gas. By the method, the problem of environmental pollution caused by the burning of exhaust gas is reduced and meanwhile, the high value-added LNG is produced.

Owner:呼伦贝尔东能化工有限公司

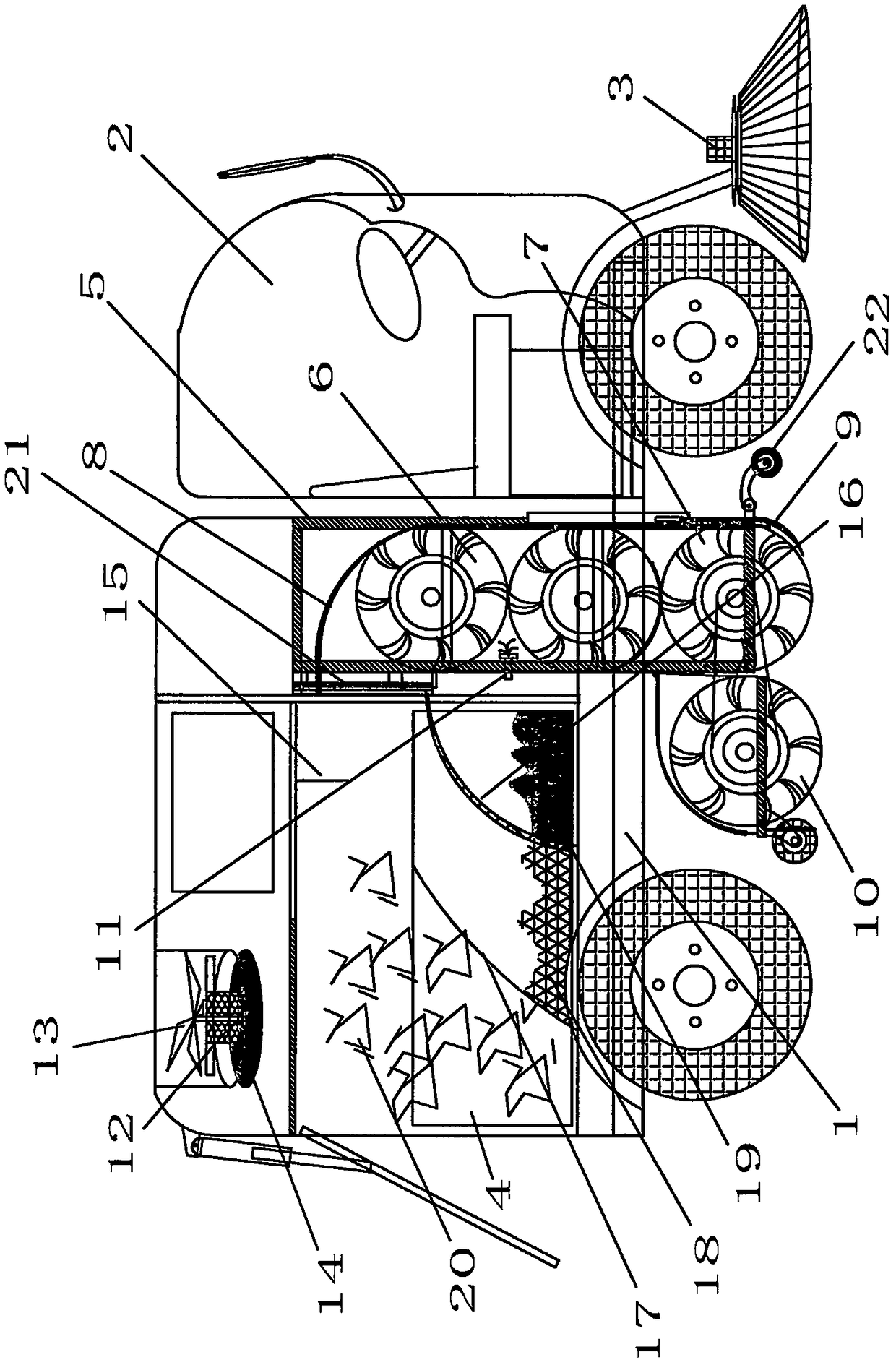

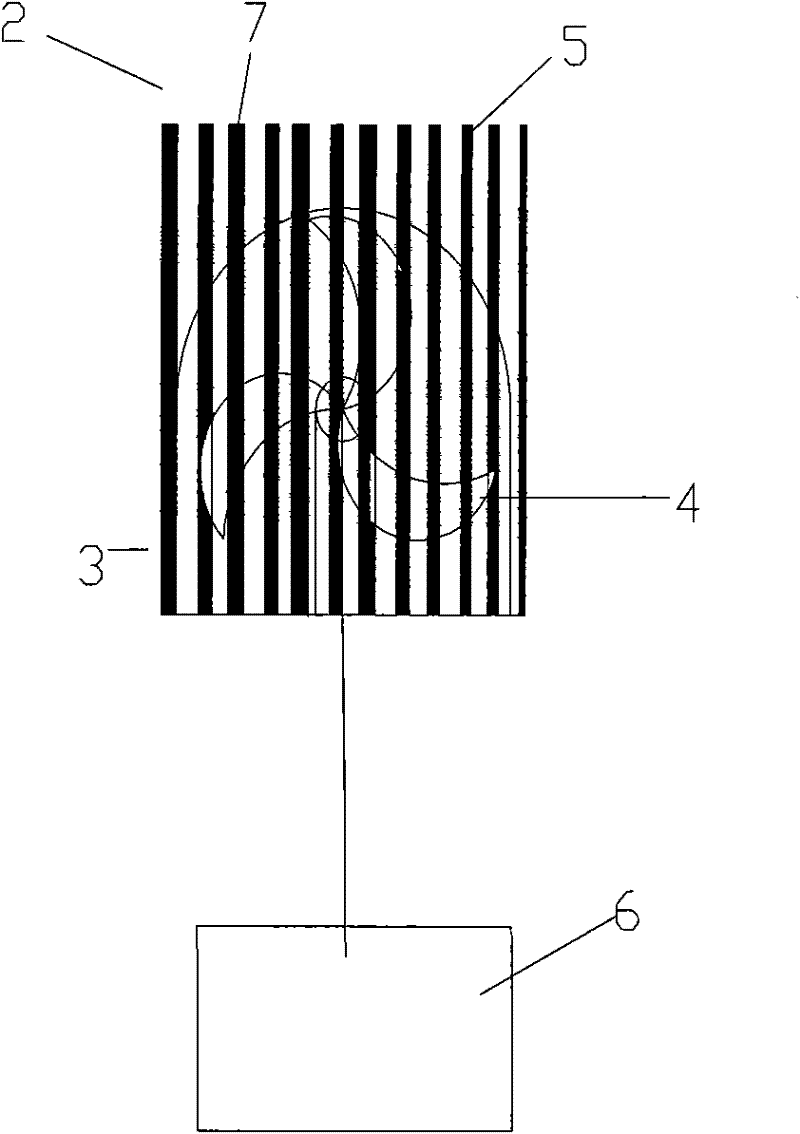

Multifunctional street sweeper

The invention relates to a multifunctional street sweeper. The multifunctional street sweeper comprises a vehicle body and is characterized in that an air handler is arranged between a cab and a garbage bin; multiple garbage conveying rolling brushes are arranged in the air handler, and the garbage conveying rolling brushes and a floor sweeping rolling brush underneath perform reverse rotation simultaneously and are matched with each other; an elastic garbage guide plate is installed under the front of the air handler, and the elastic garbage guide plate is capable of controlling opening and closing of a garbage inlet in an up and down sliding and lifting mode or controlling a forward-rotation small rolling brush which can press the ground and leave the ground to be matched with the floorsweeping rolling brush in a tangent mode; aground sweeping rolling brush is additionally arranged at the rear of the floor sweeping rolling brush to be matched with the floor sweeping rolling brush; multiple water spraying heads are installed at an appropriate position of the air handler to be matched with the rotating rolling brushes; a high-speed dust suction fan is installed at a suitable position at the top of the garbage bin; dust suction fan blades are arranged above the dust suction fan, and a rotary dust filter net is arranged under the dust suction fan in a matched mode; a garbage baffle is installed at a suitable position at the top of the garbage bin; and a movable partition plate is arranged at about two-thirds of the lower rear part of an entrance of the garbage bin.

Owner:张珉

Complete processing equipment of coal gas expanded perlite

The invention provides complete processing equipment of coal gas expanded perlite, comprising a coal gas device, a preheating furnace, an expansion furnace, a cyclone dust collector, a material bin, a high-temperature induced-draft fan, a high-temperature discharging pipe and a high-temperature induced-draft pipe, wherein the preheating furnace is provided with a high-temperature hot-air inlet; one end of the high-temperature discharging pipe is communicated with a discharging port of the expansion furnace, and the other end of the high-temperature discharging pipe is communicated with a feeding port of the cyclone dust collector; one end of the high-temperature induced-draft pipe is communicated with the top part of the cyclone dust collector, and the other end of the high-temperature induced-draft pipe is communicated with an air inlet of the high-temperature induced-draft fan; and an air outlet of the high-temperature induced-draft fan is communicated with the high-temperature hot air inlet. The complete processing equipment has the advantages that high-temperature hot air in the cyclone dust collector is introduced to the preheating furnace for preheating ore sand by the high-temperature induced-draft fan, so that not only is the burning amount of coal gas in the preheating furnace reduced, but also the problem that the energy is wasted for nothing is solved.

Owner:信阳市四通机械制造有限公司

Technique for producing synthetic ammonia gas by inputting nitrogen-rich air into two-stage converter in membrane method

ActiveCN101580234BBurn lessIncrease productionNitrogen purification/separationEnergy inputAir preheaterEngineering

Owner:DALIAN UNIV OF TECH +1

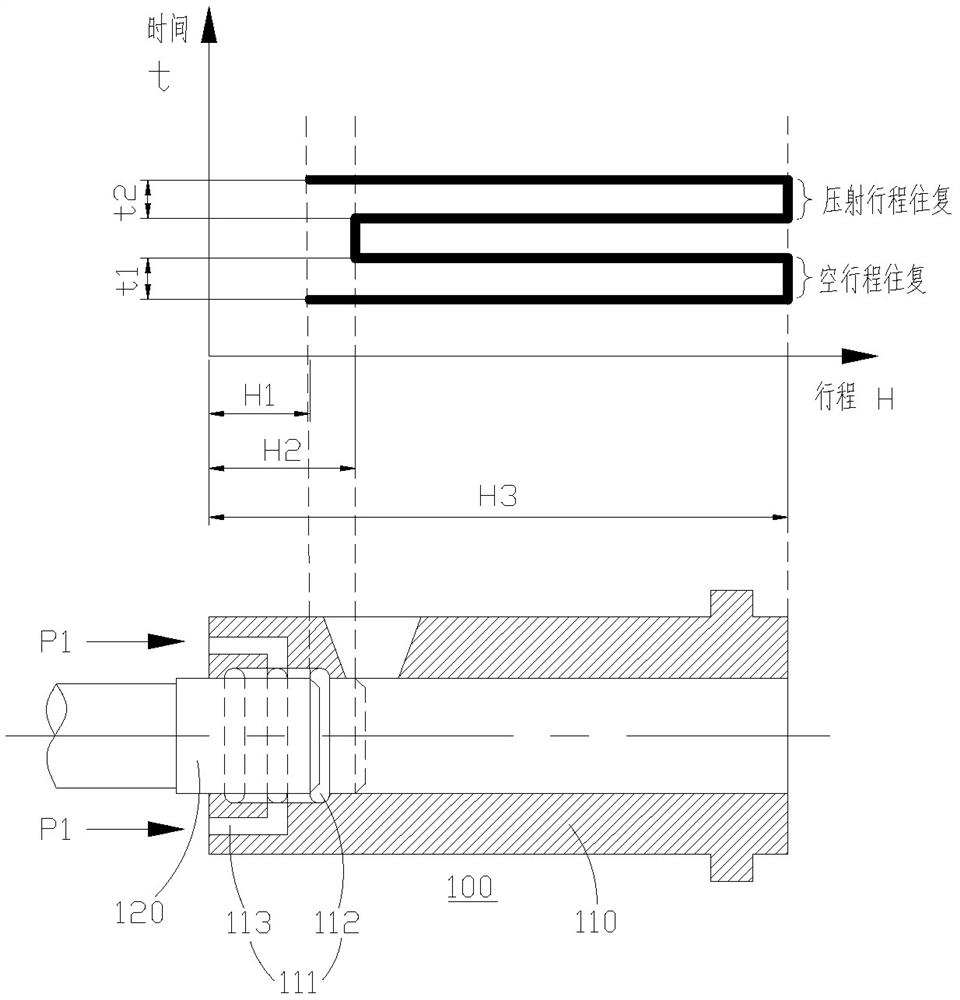

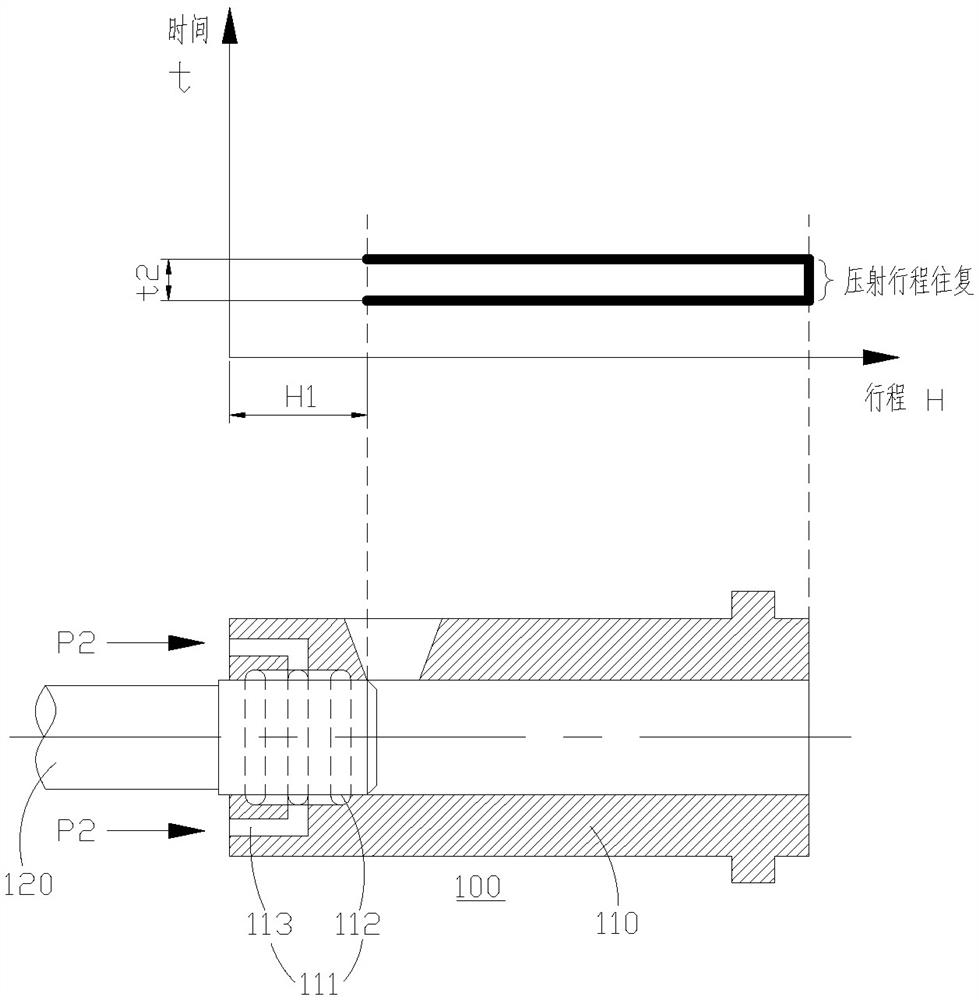

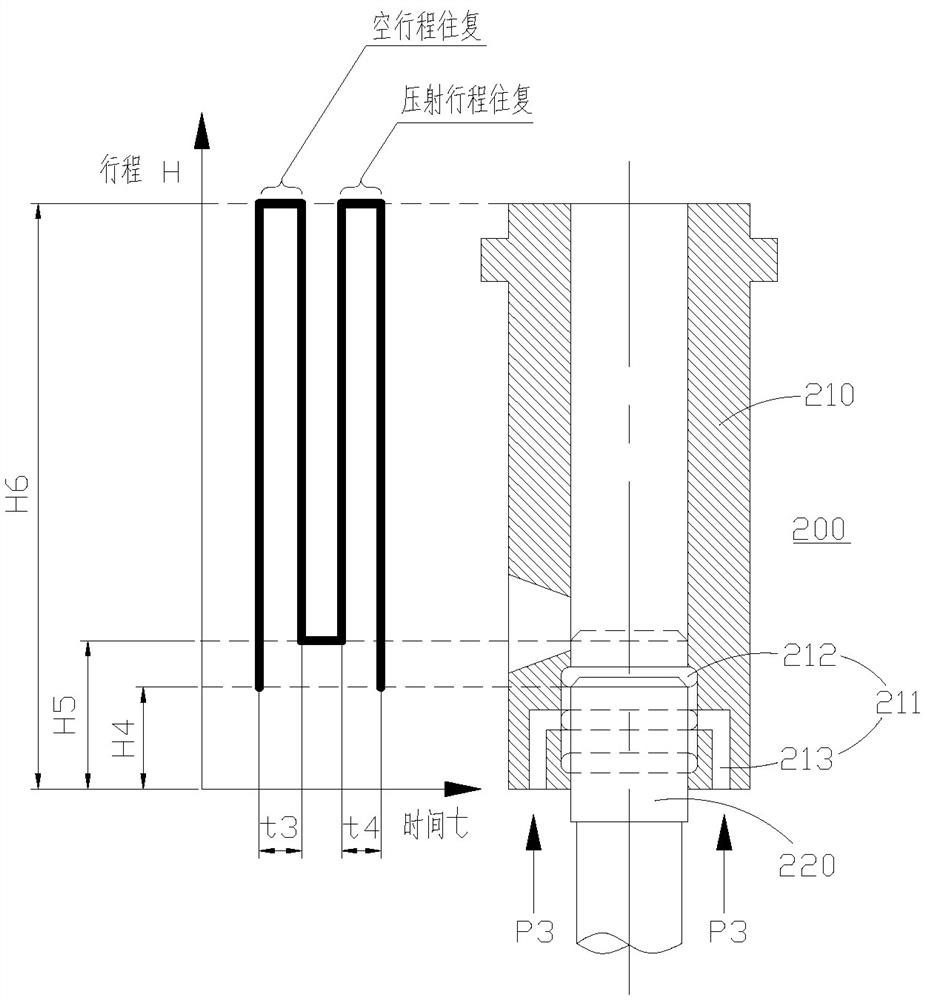

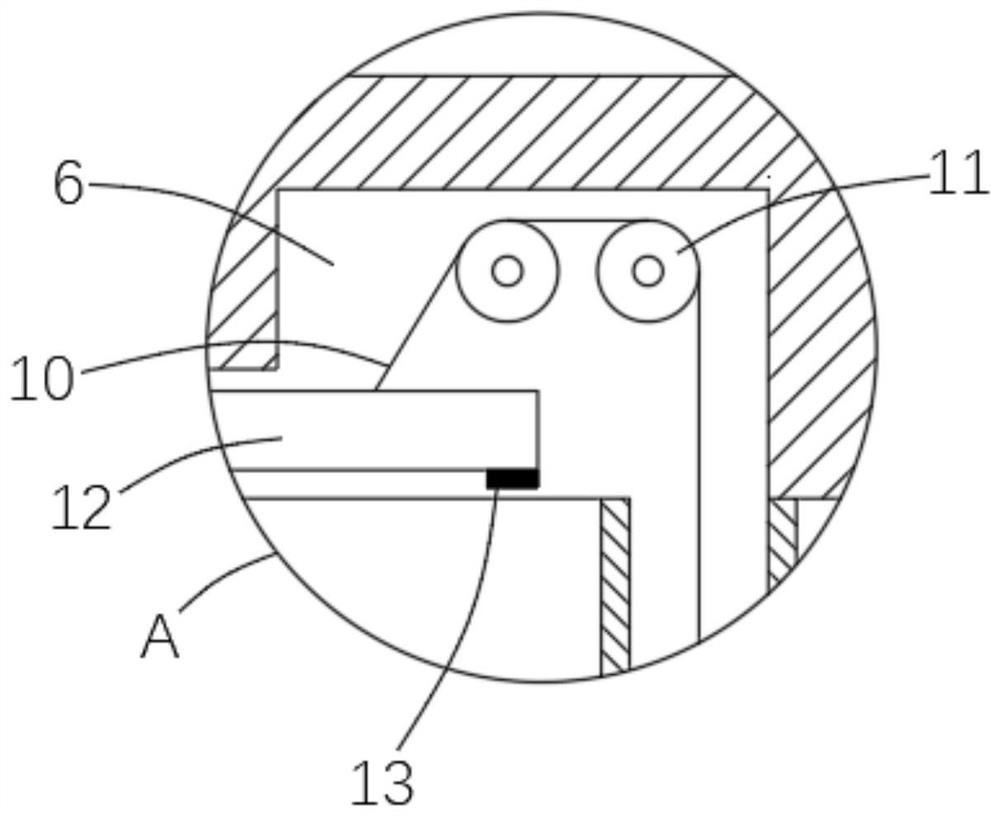

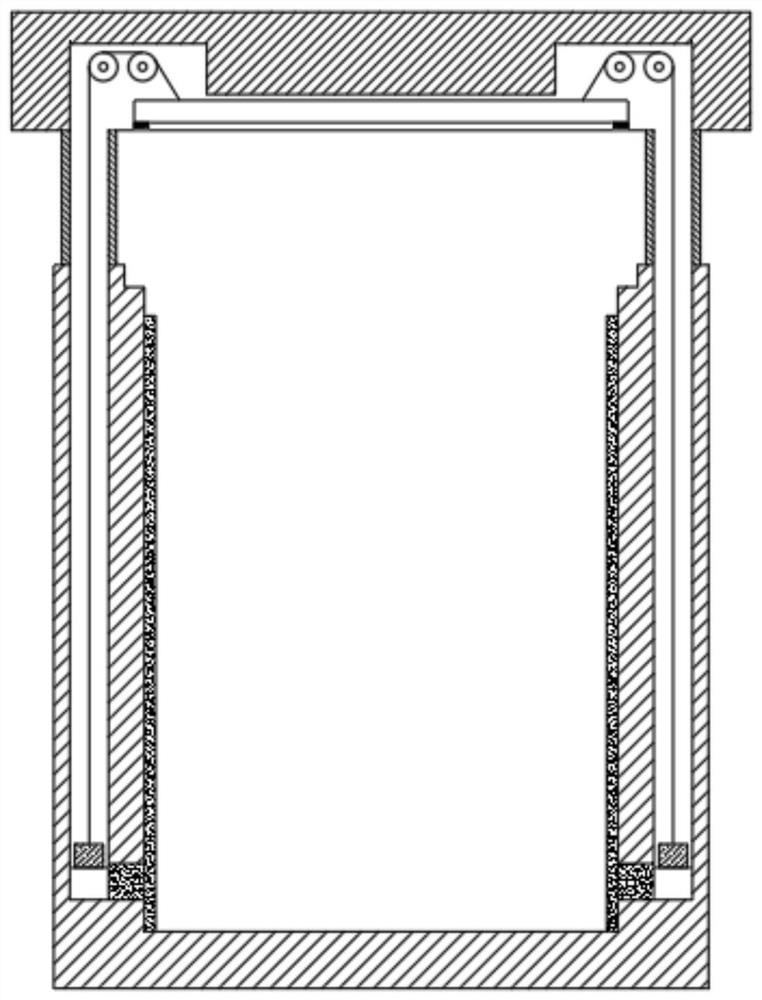

Lubricating method between melting cup and injection punch of die casting machine

The invention discloses a lubricating method between a melting cup and an injection punch of a die casting machine. The lubricating method comprises the following steps that S11, the injection punch is controlled to be positioned at an initial position, and all lubricating oil grooves are covered by the injection punch at the moment; S12, lubricating oil is pressurized and conveyed to the injection punch through a lubricating oil channel, and the lubricating oil overflows to the movement front of the injection punch through a gap between the outer peripheral wall of the injection punch and the inner peripheral wall of the melting cup; S13, molten metal is poured into the melting cup; S14, the injection punch is controlled to perform injection action, and the metal liquid in the melting cup is injected out, so that the lubricating oil lubricates the inner peripheral wall of the melting cup and the outer peripheral wall of the injection punch when the injection punch injects the molten metal; and S15, the injection punch is controlled to return to the initial position. According to the lubricating method, the lubricating effect is good, the service life of the melting cup and the injection punch is prolonged, the tendency that gas and impurities generated by combustion of the lubricating oil are mixed into molten metal can be reduced, and the quality of die castings is improved.

Owner:PUTIAN RONGXING MECHANICAL

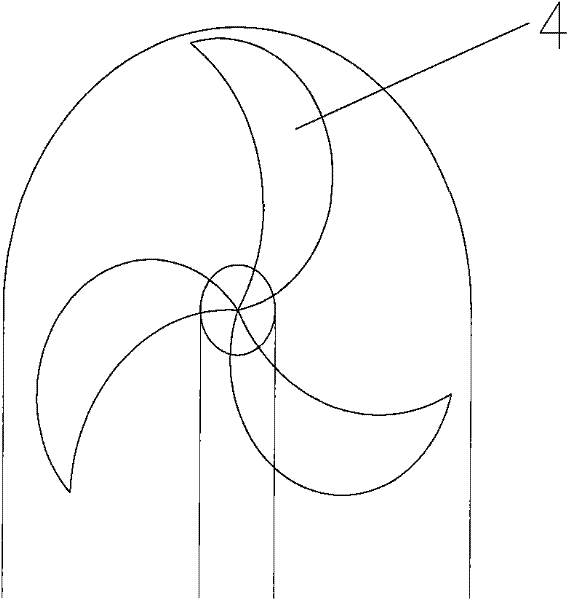

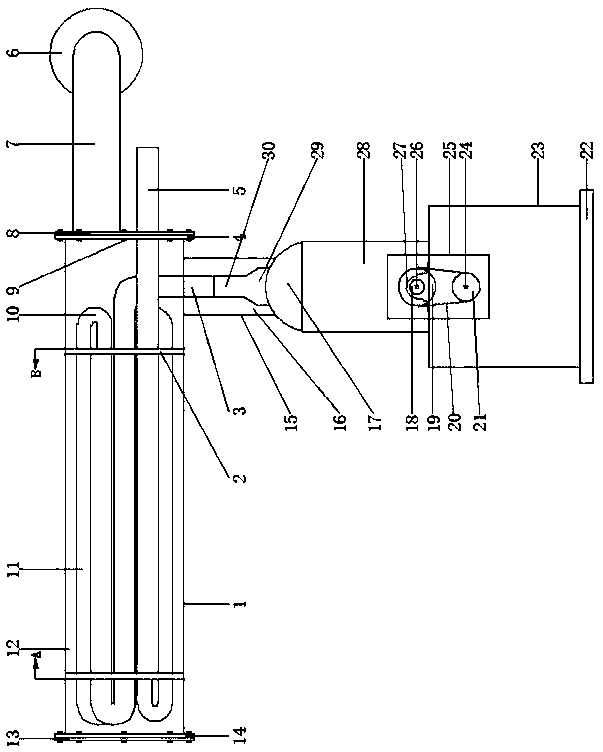

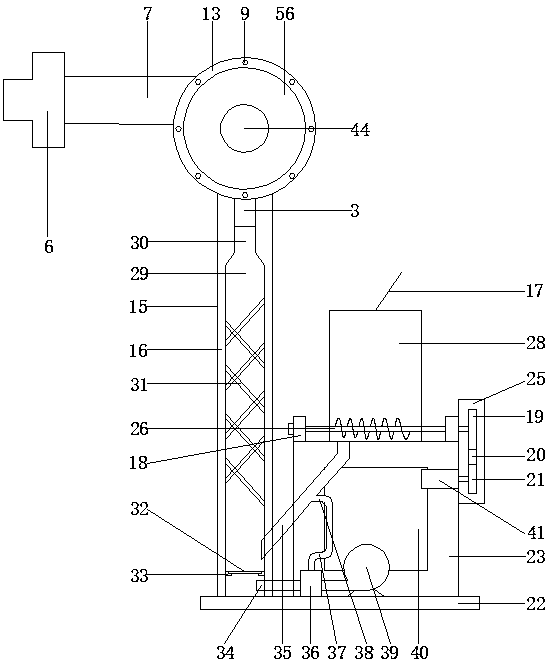

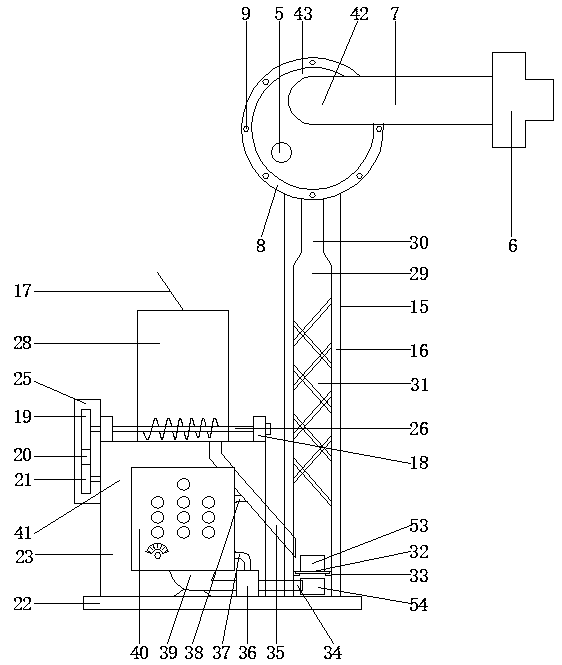

car wind engine

InactiveCN102294959AReduce usageReduce the burden onAuxillary drivesMachines/enginesWind drivenCombustion

A kind of automobile wind power generator, comprises common automobile starting device, wherein, described automobile wind power generator also comprises windmill generator; Said windmill generator comprises windmill and electromagnetic conversion device; Said windmill and electromagnetic conversion device are fixedly connected; The windmill generator is connected to the storage battery of the car through wires. The wind generator of the automobile wind starter of the present invention can convert wind energy into electric energy, provide energy for the start of the car, not only reduce the burden on the storage battery but also reduce the amount of power provided after the engine starts, and indirectly reduce the amount of fuel burned. Moreover, after the car is started, it continues to work, converting wind energy into electrical energy, providing energy for the operation of the car, and reducing the amount of non-renewable energy used.

Owner:SHANGHAI JINYUAN SENIOR HIGH SCHOOL

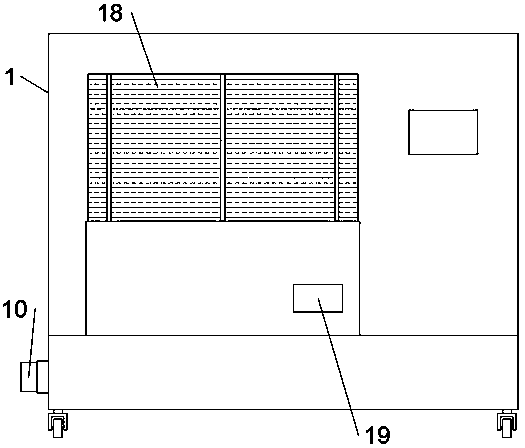

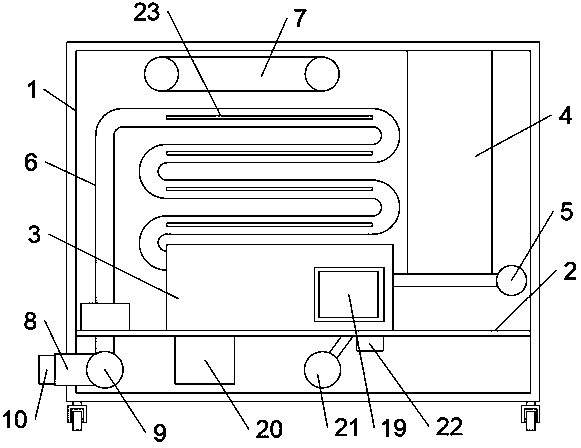

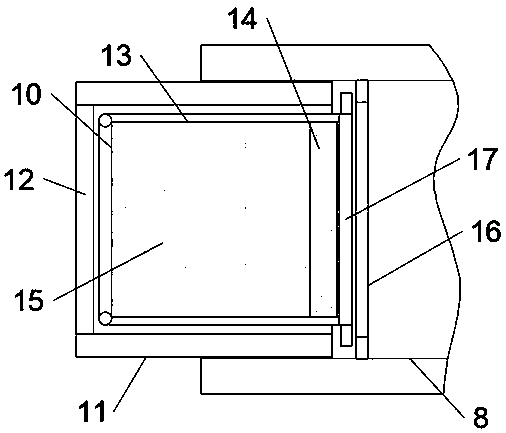

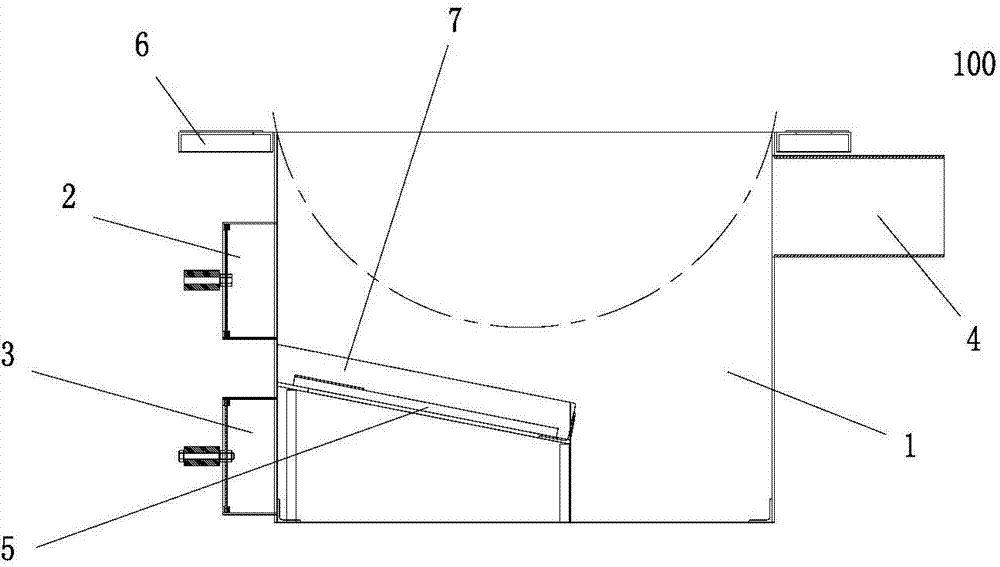

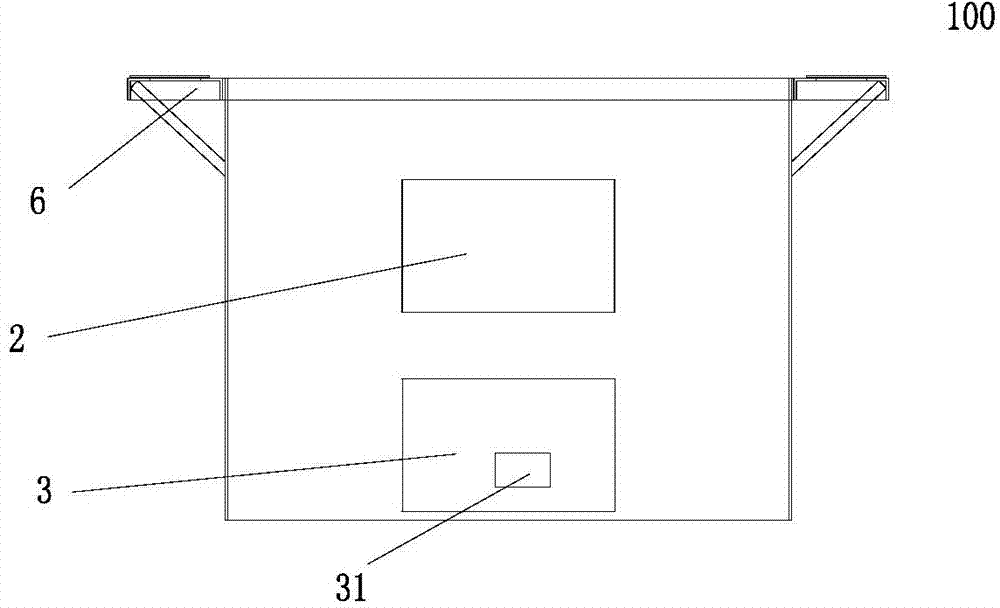

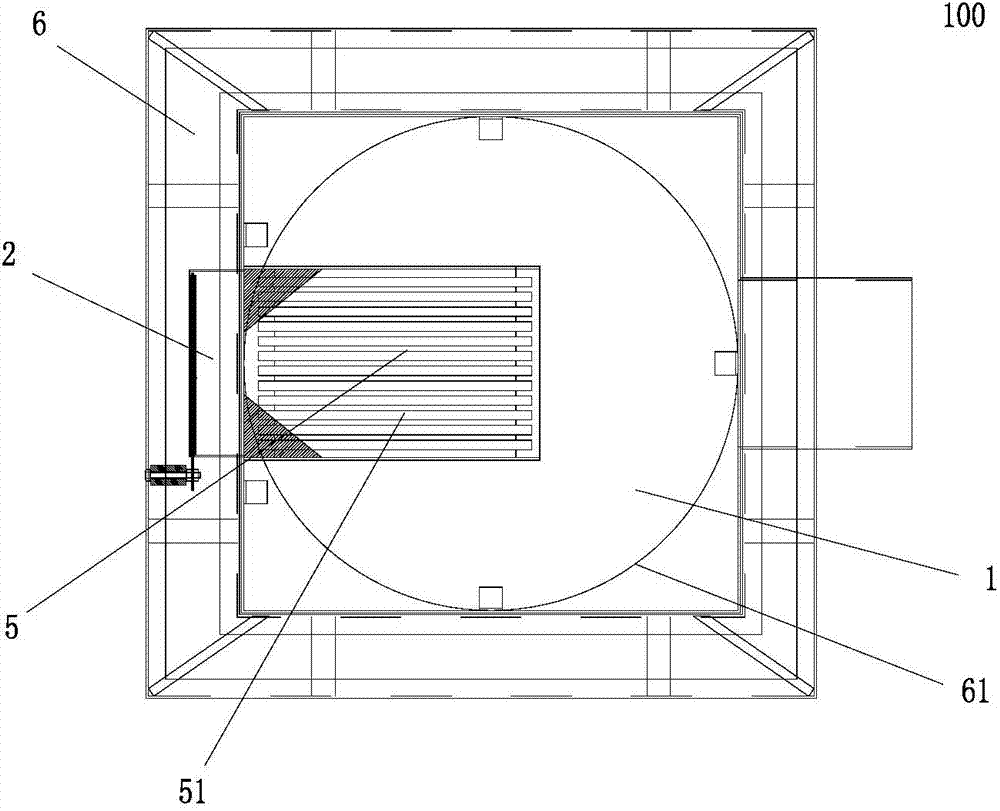

Biomass particle temperature-increasing and freeze-proofing system for heliogreenhouse

PendingCN108684396ARealize the collectionDiffuse fullyClimate change adaptationSolid fuel combustionGreenhouseProcess engineering

The invention discloses a biomass particle temperature-increasing and freeze-proofing system for a heliogreenhouse. The system comprises a fuel feeding machine, a combustion machine and a heat exchange device, and the fuel feeding machine, the combustion machine and the heat exchange device are integrally formed. According to the system, feeding, air blowing and air inducing equipment can be adjusted, and heat can be sufficiently collected and diffused under the condition of low energy consumption; hot air collection and circulation with small-load combustion, large-area heat exchange, multi-point-location collection and full-coverage circulation is achieved so that heat dissipated by combustion, exchange and circulation devices can all be collected into a circulating system and quickly diffused to all directions of the heliogreenhouse; the utilization rate of the heat is effectively increased, the loss amount of the heat is reduced, a new way for standardized and routinized application of biomass particle fuel in temperature-increasing and freeze-proofing procedures of the heliogreenhouse is put forward, organic combination of ecology, environmental protection and circulation of modern facility agriculture is achieved, and the advancement level takes the lead in China.

Owner:酒泉中天新能源科技有限公司

Energy-saving and environment-friendly device for burning organic matter in nitriding kiln

PendingCN110094969ASimple structural designSolve the pollution of the environmentFurnace typesGas emission reductionTunnel kilnDirect combustion

The invention belongs to the technical field of combustion of organic matter in a nitriding kiln, and discloses an energy-saving and environment-friendly device for burning the organic matter in the nitriding kiln. The device is characterized in that an air blowing hose hole and an air suction hose hole are through holes penetrating through the right side wall of a tunnel kiln, two binding agent discharging holes are horizontally and symmetrically arranged at the left and the right of the front of the inner bottom of a sagger respectively, a discharge porcelain tube penetrates through the twobinding agent discharge holes to extend to the inner bottom of the sagger, the discharge porcelain tube is arranged inside a refractory material layer, combustion porcelain tubes extend to the upper part of the refractory material layer, and the two combustion porcelain tubes fixedly communicate with a transverse ceramic tube transversely arranged in the refractory material layer. According to theenergy-saving and environment-friendly device for burning the organic matter in the nitriding kiln, direct combustion of a binding agent on a burner is realized, the combustion heat is increased, thecombustion amount of natural gas passing through the burner is saved, the heat energy consumption is reduced, and the environment is protected.

Owner:REFRACTORY MATERIAL OF SINOSTEEL CORP

Absorption refrigerating machine

InactiveCN101713597BReduce the temperatureBurn lessClimate change adaptationEnergy efficient heating/coolingCombustorWarm water

The invention provides an absorption refrigerating machine that can seek improving average COP based on a low load less than 20%. The absorption refrigerating machine at least comprises the follow components: a high temperature regenerator (1), a low temperature regenerator (3), a condensator (4); and comprises an evaporator (5), an absorption device (6), a refrigerant pump (14) and an absorptionliquid pump (20, 22), through which lukewarm water supplied to a load bypassing a lukewarm water tube (17). When operating low load by refrigeration, set temperature of cold water to a principled temperature that higher than preset temperature when switching combustion of a burner (2) of the high temperature regenerator (1) closed; when operating low load by heating, , set temperature of warm water to a principled temperature that lower than preset temperature when switching combustion of a burner (2) of the high temperature regenerator (1) closed.

Owner:SANYO ELECTRIC CO LTD

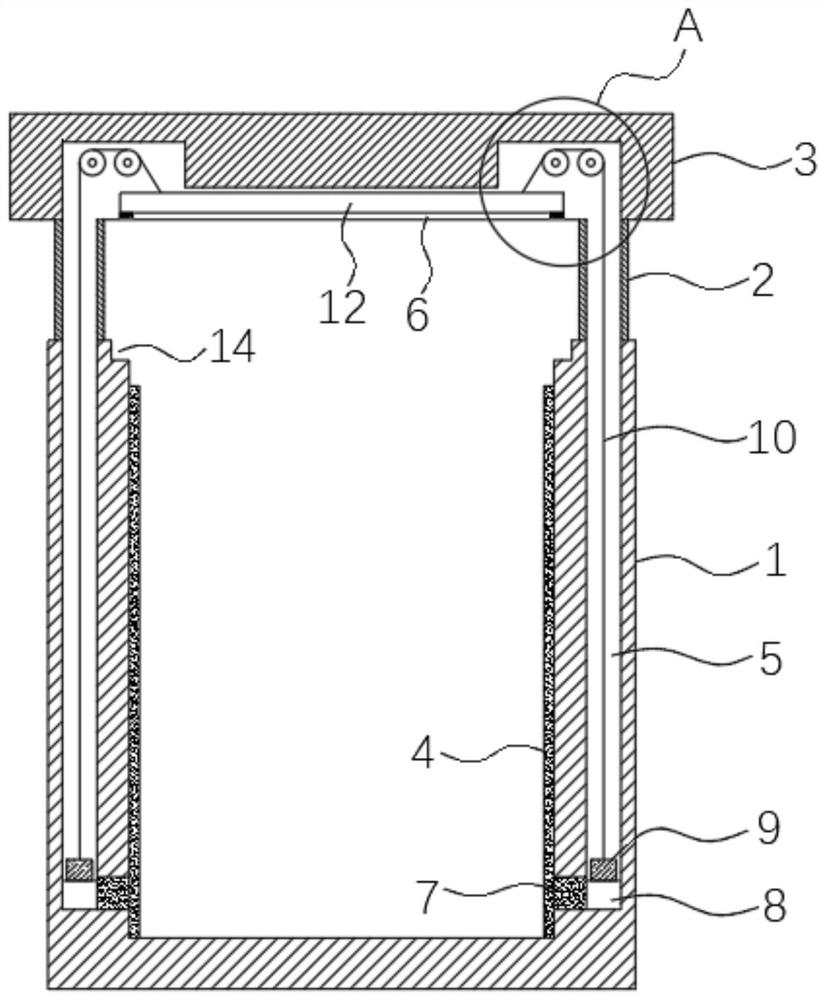

Energy-saving particle heating stove with heat recovery function

InactiveCN111219737AReduce the temperatureBurn lessStoves/ranges with convection heatingLighting and heating apparatusAir filtrationThermodynamics

The invention discloses an energy-saving particle heating stove with a heat recovery function. The energy-saving particle heating stove comprises a shell, wherein a screen board is fixedly connected to the front surface of the shell; and a radiating fan is fixedly arranged in the middle of the inner wall of the upper end of the shell. A concentric square-shaped smoke exhaust pipe is arranged at the upper part of a flame box, the radiating fan is arranged on the inner wall of the upper end of the shell, the radiating fan is rotated to generate downward airflow to allow outside air to enter theshell from the upper end of the shell, after absorbing heat of the smoke exhaust pipe and the flame box, the air is exhausted out of the shell through the screen board into the external environment for recycling and heat recovery, therefore, under the premise of guaranteeing indoor heating temperature, the required temperature of the heating stove is reduced, the combustion amount of bio-particlesis reduced, and the energy-saving effect is achieved; and a filter device is arranged at the left end of the smoke exhaust pipe, so that the discharged smoke is filtered by PPS filter felt and air filtering cotton, and a filter element is convenient to replace and filtered substances are convenient to remove while the smoke is filtered.

Owner:大连世茂机械有限公司

Large stove and application method thereof

InactiveCN104713135ABig hearthEasy to cookDomestic stoves or rangesLighting and heating apparatusFlueExhaust gas

The invention discloses a large stove and an application method thereof. The large stove comprises a hearth encircled by the side wall of a stove body and used for combusting fuels, wherein a fire hole capable of being positioned at the bottom of a pot is arranged above the hearth; a flue outlet for leading out combustion tail gas is formed in the side wall of the stove body; a feed port and an ash cleaning port leading to the insideof the hearth are formed in the side wall of the furnace body; the feed port is higher than the ash cleaning port; a grate is arranged in the hearth corresponding to the feed port, and is provided with a stacking area for concentrating particle-shaped biomass fuels; the area of the stacking area is smaller than the area of the fire hole; and an air supply grille is formed below the grate. The large stove and the application method thereof are suitable for concentrated combustion of the particular-shaped biomass fuels, prevent the atmospheric pollution, and improve the combustion efficiency.

Owner:车战斌

A kind of preparation method of using traditional Chinese medicine dregs to produce biogas

The invention discloses a method of producing biogas through Chinese medicine residues, relating to application of Chinese medicine residues and belonging to the field of utilization of biomass energy sources. The method is characterized by comprising the following steps of: crushing the Chinese medicine residues to 40 meshes, filling methane bacteria accounting for 10% of total amount of the Chinese medicine residues, adjusting the carbon-nitrogen ratio to be (20-25):1, and treating at 53-55 DEG C for 10 days; and performing an anaerobic digestion reaction to prepare biogas. The method has the beneficial effects that biogas preparation and combustion equipment is simple, the equipment is conveniently used and managed, rely of urban residents on fossil energy and emission of greenhouse gases are reduced, and the biogas contains no such poisonous gases as CO, thereby being more beneficial to human body health and excellent in environmental effect; the straw combustion quantity is reduced to create conditions for straw application and realizing sustainable utilization of rural lands; and the biogas is used for replacing the straws to greatly improve the living environment of farmers and improving the living standard of the farmers, thereby having excellent social benefit and ecological benefit.

Owner:甘肃富民生态农业科技有限公司

A suffocating fire-retardant trash can

The invention discloses a suffocating flame-retardant garbage can, which comprises a garbage can with a cylindrical structure, a switch door is installed on the outer wall of the garbage can, and the upper edge of the garbage can takes its own central axis as the center of the circle, etc. The corners are fixedly connected with three connecting plates, and the upper end surfaces of the three connecting plates are jointly fixedly connected with a top cover. The advantage is that: under normal conditions, the magnetic attraction between the permanent magnet and the ferromagnet is used to store the suffocation plate into the storage tank. In the fire extinguishing state, the heat is conducted to the ferromagnet through the heat conducting ring plate and the heat conducting block, and the internal temperature of the ferromagnet gradually rises Until it reaches the Curie temperature and turns into paramagnetism, the permanent magnet will no longer generate magnetic attraction to the ferromagnet, and the suffocation plate will move vertically downward under the action of its own gravity until it reaches the steps, forming a sealed space and isolating the outside air to complete the fire extinguishing , reduce the amount of combustibles burned and the harmful gases generated by the combustion, and protect the health of pedestrians.

Owner:湖南金世达城市公共设施有限公司

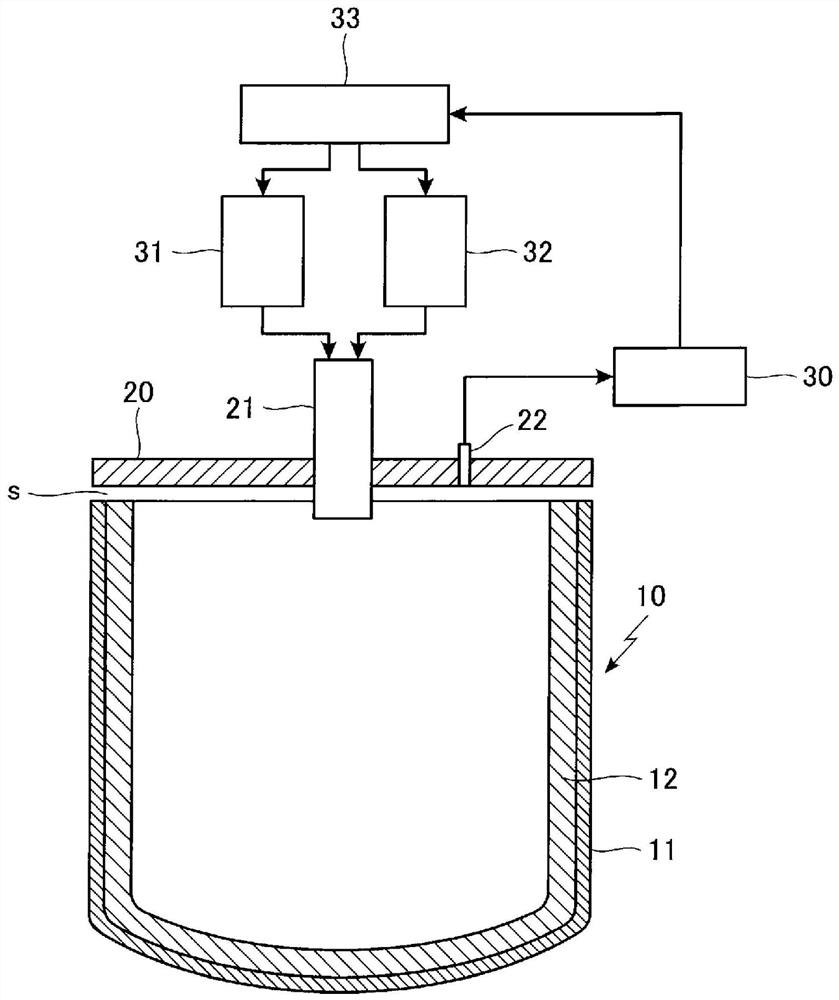

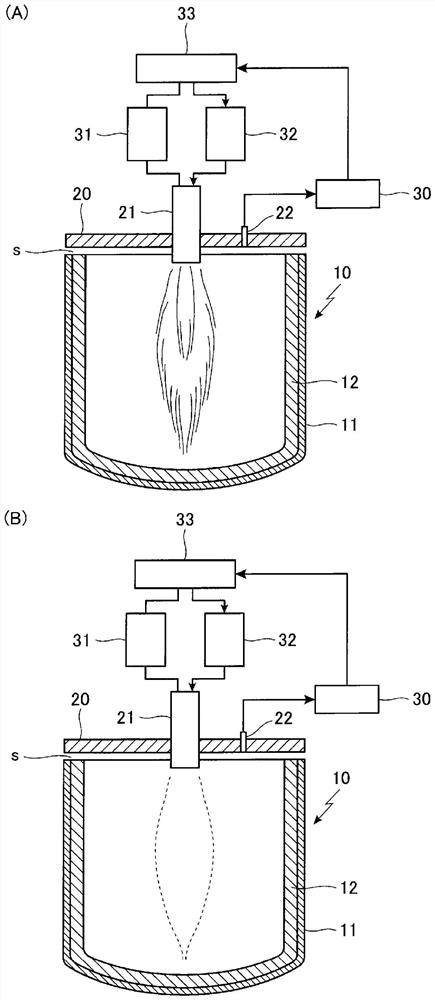

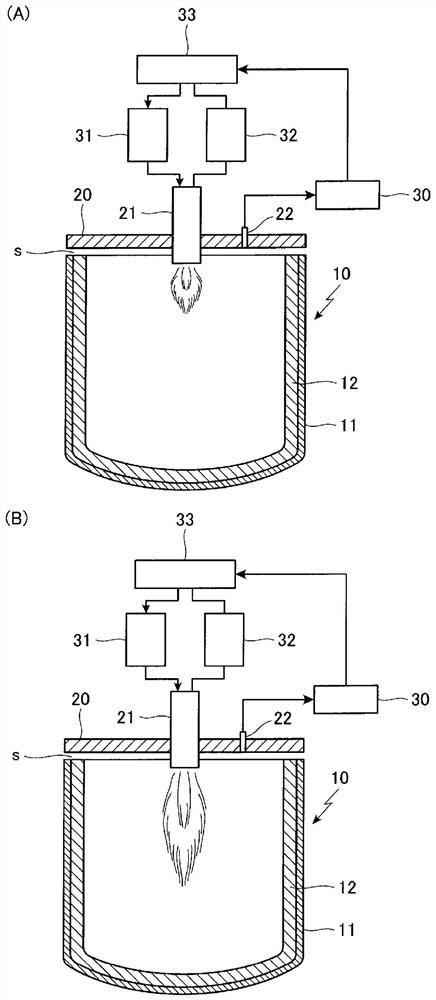

Heating device and heating method inside refractory container

ActiveCN110249195BTemperature controlControl temperature riseMelt-holding vesselsLinings repairCombustorEngineering

The cover is disposed so as to cover at least the opening of the upper surface of the refractory container made of refractory on the inner surface side through a gap, and when the inside of the refractory container is heated by a burner installed to penetrate the cover, The burner is provided with a continuous combustion control mechanism that adjusts the amount of combustion while continuously burning fuel with the burner, and an on / off combustion control mechanism that adjusts the switching time of burning and stopping of fuel by the burner and the amount of combustion. A switching device for switching combustion of the burner between said continuous combustion control mechanism and said on / off combustion control mechanism.

Owner:CHUGAI RO CO LTD

System and method for preparing ultra-high water filling materials with organic wastewater and industrial solid waste

ActiveCN106830722BSolve the shortcomings of productionSolve the problem of difficult utilization of solid wasteCement productionSlagSlurry

The invention discloses a system and a method for preparing ultra-high water filling materials by organic wastewater and industrial solid waste. The system comprises a wet pulverizer, a pressure filter, an equalizing basin, a rotary kiln and an indirect heat exchanger. Desulfurized gypsum, aluminum ash, carbide slag, coal gangue, iron tailings and part of the organic wastewater are mixed to obtain mixed solution, the water content of the mixed solution is 60%-70% (mass), the mixed solution is pulverized by a wet process, wet pulverized materials are equalized to obtain slurry, the slurry is mechanically pressed, filtered and dewatered to obtain paste, the other part of the organic wastewater is concentrated, then enters the rotary kiln together with the paste and calcined at high temperature to obtain base materials, pulverized coal is sprayed into the rotary kiln in the high-temperature calcining process, so that the pulverized coal and organic matters in the mixed paste are burnt, and finally, the base materials, accelerators, dispersants, expanding agents and water are prepared into the ultra-high water filling materials. The system and the method can be used for preparing the novel ultra-high water filling materials by reusing the industrial solid waste.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com