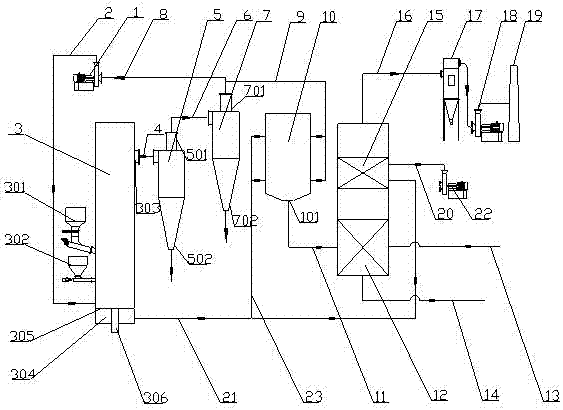

Biomass Pyrolysis Gasification Combustion Staged Conversion Biochar/Steam Cogeneration Process

A technology of pyrolysis gasification and biomass, which is applied in the direction of combustion method, steam generation, steam generation device, etc., and can solve the limitation of raw material range, low calorific value, low calorific value of gas, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023]Wood chips with a water content of 33% and a particle size of 5 cm are fed into the fluidized bed pyrolysis gasifier 3 by a biomass feeding device 301, and ceramic balls with a particle size of 4 mm are fed into the fluidized bed by a bed material feeding device 302 Pyrolysis gasification furnace 3, the air is preheated to 300°C by air preheater 15, and part of the air is sent into fluidized bed pyrolysis gasification furnace 3, and the other part is sent into low calorific value gas combustion chamber 10 in stages, and fluidized bed pyrolysis The reaction temperature in the gasification furnace 3 is 700°C. Wood chips undergo pyrolysis and gasification reactions in the fluidized bed pyrolysis gasification furnace 3 to generate high-temperature biomass gas and biomass charcoal. The high-temperature biomass gas carries biochar through the The primary separation device 5 and the secondary cyclone separator 7 separate the biomass charcoal, which contains 81% fixed carbon cont...

Embodiment 2

[0025] Rice husks with a water content of 38% and a particle size of 0.5 cm are fed into the fluidized bed pyrolysis gasifier 3 by a biomass feeding device 301, and ceramic balls with a particle size of 5 mm are fed into the fluidized bed by a bed material feeding device 302. In the fluidized bed pyrolysis gasification furnace 3, the air is preheated to 380°C by the air preheater 15, and part of the air is sent into the fluidized bed pyrolysis gasification furnace 3, and the other part is sent into the low calorific value gas combustion chamber 10 in stages, and the fluidized bed The reaction temperature in the pyrolysis gasification furnace 3 is 730°C. The rice husk undergoes pyrolysis and gasification reactions in the fluidized bed pyrolysis gasification furnace 3 to generate high-temperature biomass gas and biomass charcoal. The high-temperature biomass gas carries biomass The charcoal is separated from the biomass charcoal through the primary separation device 5 and the sec...

Embodiment 3

[0027] The wood chips with a water content of 45% and a particle size of 0.1 cm are fed into the fluidized bed pyrolysis gasifier 3 by the biomass feeding device 301, and alumina balls with a particle size of 3 mm are fed into the fluidized bed by the bed material feeding device 302. In the fluidized bed pyrolysis gasification furnace 3, the air is preheated to 280°C by the air preheater 15, and part of the air is sent to the fluidized bed pyrolysis gasification furnace 3, and the other part is sent to the low calorific value gas combustion chamber 10 in stages, and the fluidized bed The reaction temperature in the pyrolysis gasification furnace 3 is 680°C. The wood chips undergo pyrolysis and gasification reactions in the fluidized bed pyrolysis gasification furnace 3 to generate high-temperature biomass gas and biomass charcoal. The high-temperature biomass gas carries biochar The biomass charcoal is separated through the primary separation device 5 and the secondary cyclone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com