Prevention and collection method for oil and gas fire disasters

A technology of oil and gas and fire, which is applied in fire rescue and other fields, and can solve problems such as shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

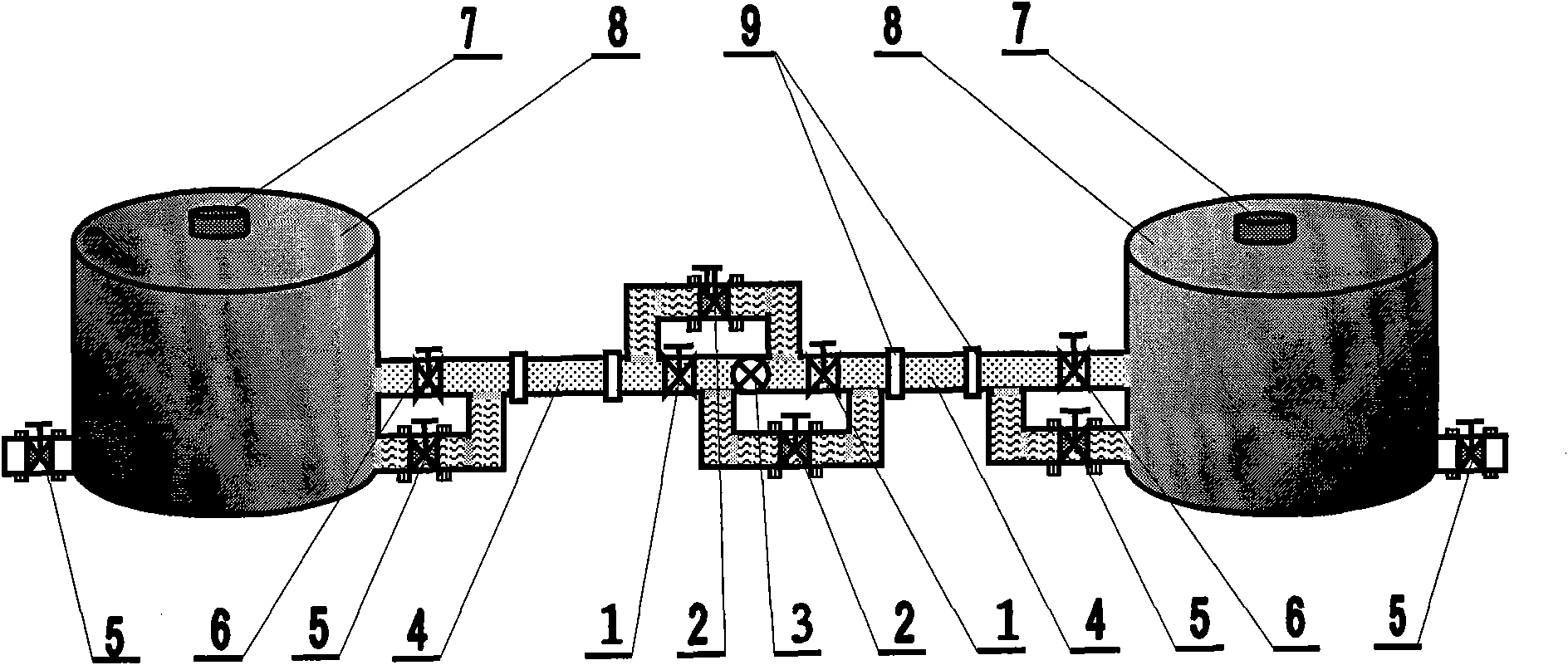

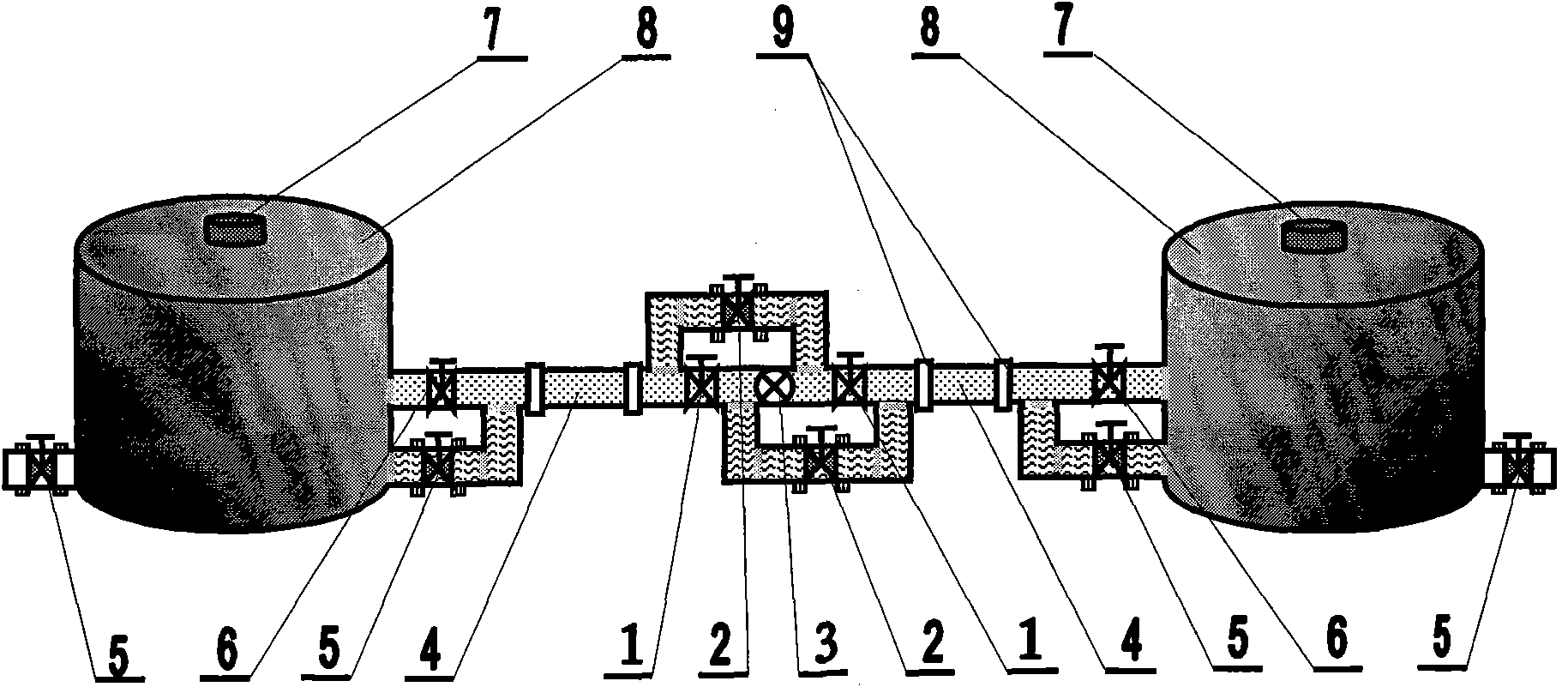

[0005] The present invention will be described in further detail below in conjunction with the accompanying drawings embodiment, a kind of petroleum and natural gas fire prevention and control collection method as illustrated in the accompanying drawings can safely and effectively collect the petroleum and natural gas in combustion, can prevent the fire from continuing to burn and explode, it is characterized in that: The top of the tank body 8 is equipped with a ventilated anti-tempering pressure relief safety device 7. When a fire occurs, the ventilated anti-tempering pressure relief safety device 7 is opened to prevent the internal explosion of the tank and reduce the pressure of the internal explosion of the tank. Pressure; the oil inlet and outlet at the bottom of the tank body 8 are installed horizontally in parallel with the cooling type anti-backfire valve device 5 and the tank body valve 6, and connected in series with the oil pipeline 4; the oil pipeline valve 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com