System and method for preparing ultra-high water filling materials by organic wastewater and industrial solid waste

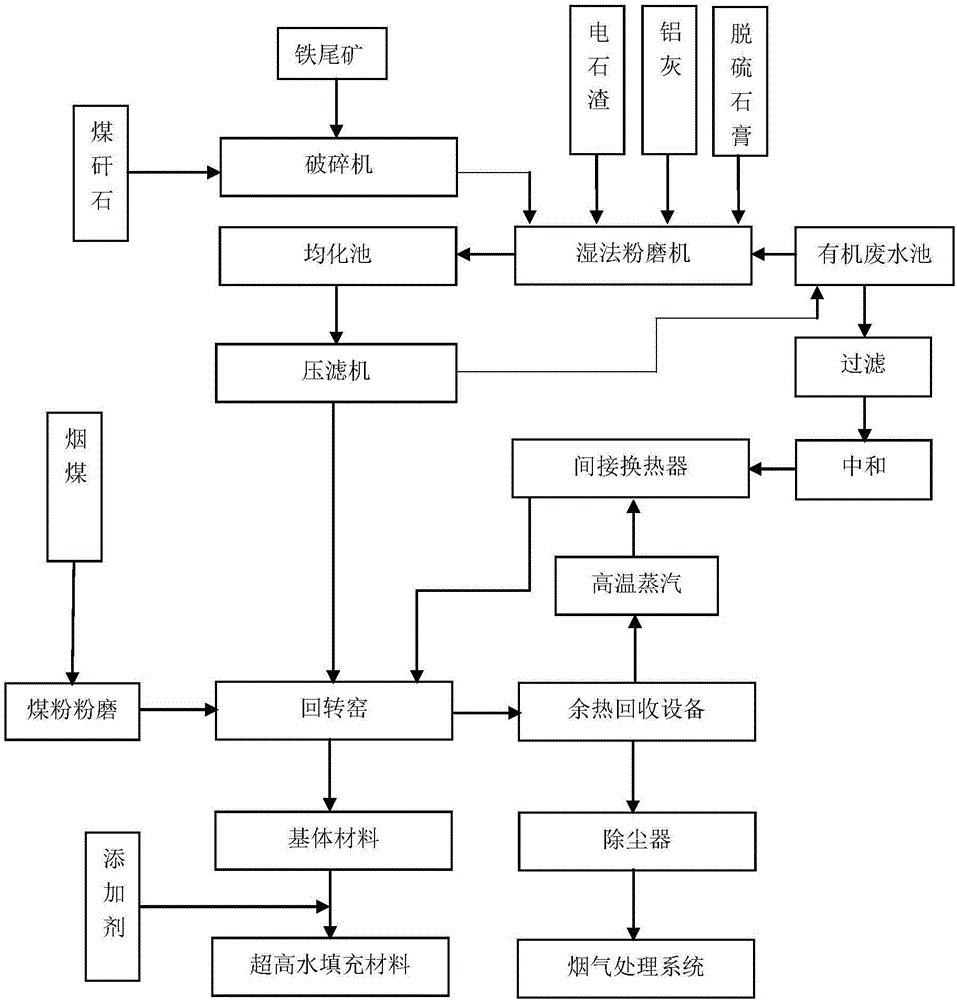

A technology of organic wastewater and filling materials, which is applied in cement production, etc., can solve the problems of large investment in incineration equipment, difficulty in applying incineration to organic wastewater, and high treatment costs, so as to achieve energy utilization, avoid occupation and pollution, and improve economic efficiency. benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

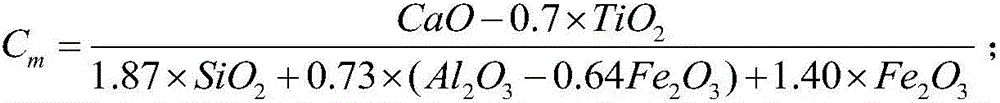

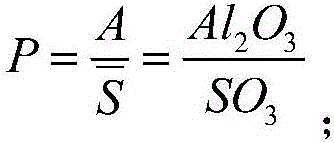

[0089] Prepare according to the above-mentioned system and the above-mentioned process, and its specific parameters are as follows: pulverize the coal gangue, and carry out batching with aluminum ash, carbide slag, and desulfurized gypsum. In terms of solid matter, the coal gangue accounts for 25 parts by weight, and the desulfurized gypsum accounts for 17 parts by weight. parts, calcium carbide slag accounts for 40 parts by weight, aluminum ash accounts for 18 parts by weight, and iron tailings accounts for 8 parts by weight. After the materials are blended, they are ground and homogenized. After being filtered, they are directly transported into the rotary kiln for calcination. The calcination temperature is 1270°C and the calcination time is 80 minutes. The main phases of the clinker after firing are calcium sulfoaluminate and dicalcium silicate. Take the above base material, add 1.0% of the mass of the base material as quick-setting agent, 1.5% of expansion agent, and 1.5%...

Embodiment 2

[0091] Prepare according to the above-mentioned system and the above-mentioned process, and its specific parameters are as follows: crush the coal gangue, and carry out batching with aluminum ash, carbide slag, and desulfurized gypsum. In terms of solid matter, the coal gangue is 23 parts by weight, and the desulfurized gypsum is 22 parts by weight. parts, calcium carbide slag is 35 parts by weight, aluminum ash is 20 parts by weight, and iron tailings is 11 parts by weight. After the materials are blended, they are ground and homogenized. After being filtered, they are directly transported into the rotary kiln for calcination. The calcination temperature is 1350°C and the calcination time is 80 minutes. Take the above base material, add 0.5% of the mass of the base material as quick-setting agent, 1.5% of expansion agent, and 1.0% of dispersant, and take another 97 parts of water, the quality of each 2 parts of water is the same as that of the above-mentioned base material, an...

Embodiment 3

[0093] Prepare according to the above-mentioned system and the above-mentioned process, and its specific parameters are as follows: crush the coal gangue, and carry out batching with aluminum ash, carbide slag, and desulfurized gypsum. In terms of solid matter, the coal gangue is 21 parts by weight, and the desulfurized gypsum is 20 parts by weight. parts, calcium carbide slag is 37 parts by weight, aluminum ash is 15 parts by weight, and iron tailings is 15 parts by weight. After the materials are blended, they are ground and homogenized. After being filtered, they are directly transported into the rotary kiln for calcination. The calcination temperature is 1350°C and the calcination time is 75 minutes. Take the above base material, add 1.0% quick-setting agent, 0.5% expansion agent, and 1.5% dispersant of the base material mass, and take another 97 parts of water, the quality of every 2 parts of water is the same as that of the above base material, and mix thoroughly Prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com