Lubricating method between melting cup and injection punch of die casting machine

A technology of injection punch and die-casting machine, which is applied in the field of injection lubrication of die-casting machines, can solve problems affecting the internal quality of die-casting parts, etc., and achieve the effects of improving service life, sufficient lubrication, and reducing the amount of gas and impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

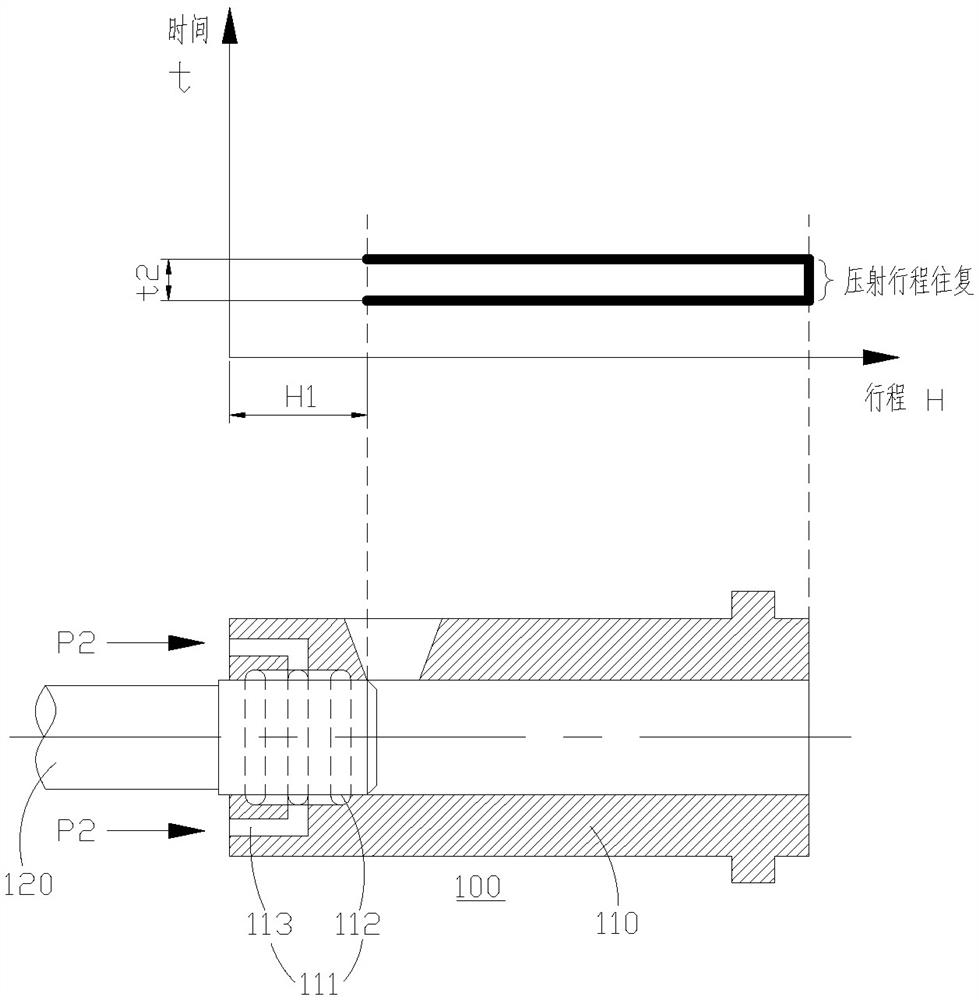

[0044] Example 1: Please refer to figure 2 and Figure 4 , a method for lubricating between a melting cup and an injection punch of a die-casting machine, the die-casting machine includes an injection device, the injection device includes a melting cup and an injection punch that are slidably fitted to each other, and the melting cup The side wall is provided with a lubricating oil passage, and the lubricating oil passage includes a lubricating oil groove located on the inner wall of the melting cup. A starting position is set in the melting cup, and the injection punch covers all the lubricating oil when it is at the starting position. oil tank;

[0045] Described lubricating method comprises the following steps:

[0046] S11. Control the injection punch to be at the initial position, and at this time, all the lubricating oil grooves are covered by the injection punch;

[0047] S12. Lubricating oil is pressurized and delivered to the injection punch through the lubricatin...

Embodiment 2

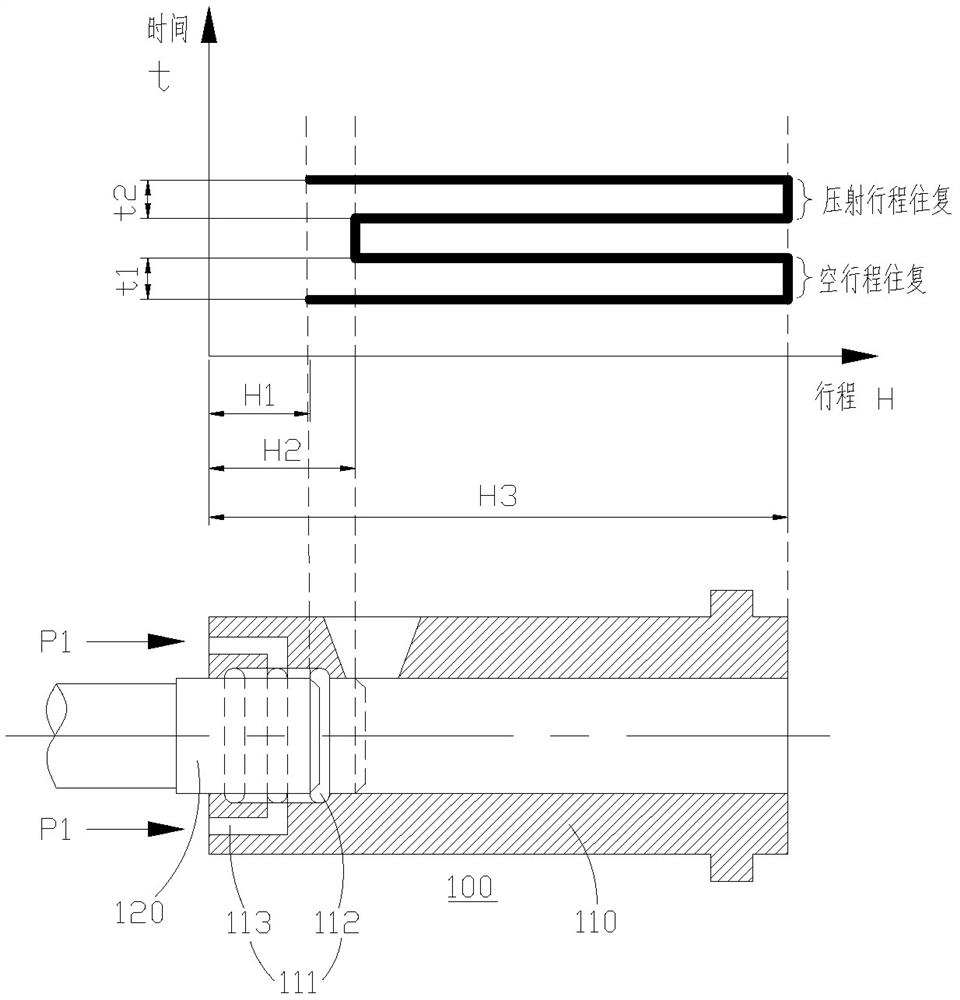

[0055] Example 2: Please refer to figure 1 and image 3 , a method for lubricating between a melting cup and an injection punch of a die-casting machine, the die-casting machine includes an injection device, the injection device includes a melting cup and an injection punch that are slidably fitted to each other, and the melting cup The side wall is provided with a lubricating oil passage, and the lubricating oil passage includes a lubricating oil groove located on the inner wall of the melting cup. The first starting position, the second starting position and the ending position are arranged in the melting cup in sequence. The injection When the punch is in the first initial position, part of the lubricating oil groove (such as one of the multiple lubricating oil grooves) is exposed, and the injection punch covers all the lubricating oil grooves when it is in the second initial position;

[0056] Described lubricating method comprises the following steps:

[0057] S11, cont...

Embodiment 3

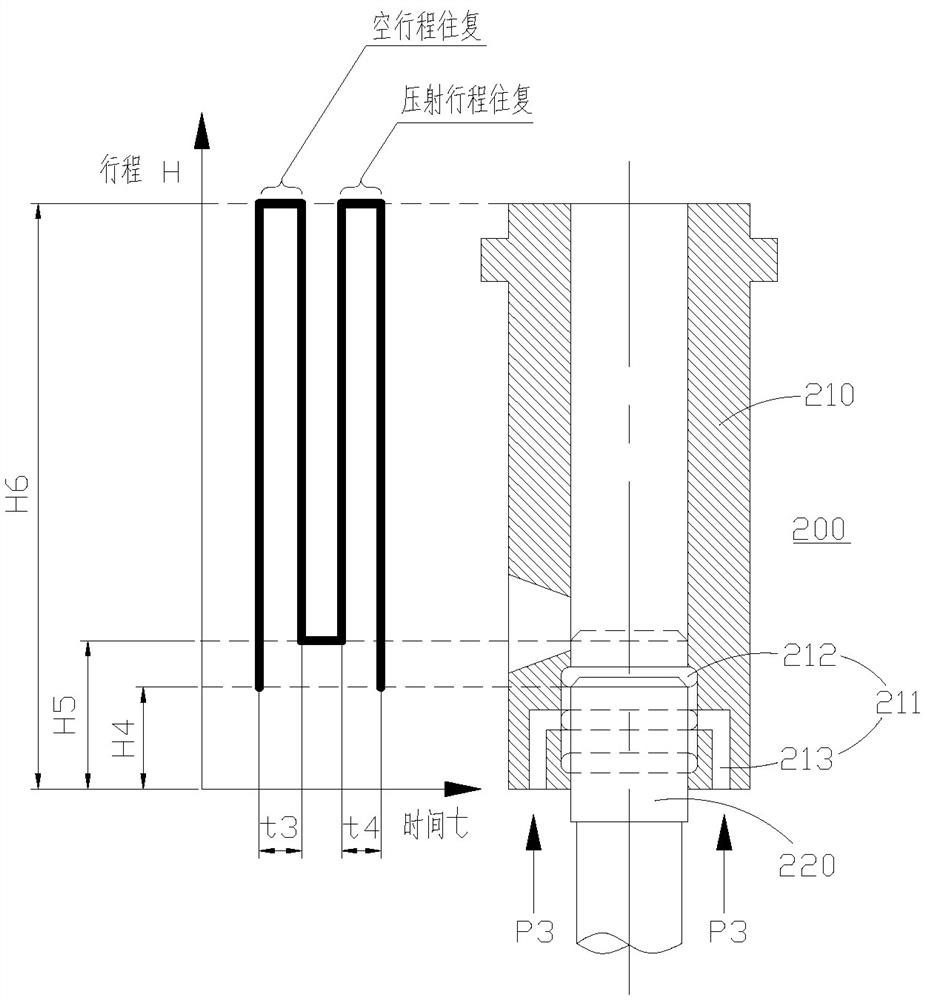

[0070] Example 3: Please refer to Figure 1 to Figure 4 , a lubrication method for a double-pressure shot cold chamber die-casting machine,

[0071] The double-shot cold chamber die-casting machine includes a horizontal injection device 100 and a vertical injection device 200;

[0072] The horizontal injection device 100 includes a horizontal melting cup 110 and a horizontal injection punch 120 that are slidingly fitted with each other, and the lubrication method between the horizontal melting cup 110 and the horizontal injection punch 120 adopts the above-mentioned implementation Any one of the two lubricating methods of example one and embodiment two;

[0073] The vertical injection device 200 includes a vertical melting cup 210 and a vertical injection punch 220 that are slidably fitted to each other, and the lubrication method between the vertical melting cup 210 and the vertical injection punch 220 adopts the above-mentioned implementation Any one of the two lubricating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com