Decoupling combustion furnace and decoupling combustion method

A combustion furnace and decoupling technology, applied in the field of raw coal combustion equipment, can solve the problems of difficulty in realizing large-scale decoupling combustion furnaces, decoupling combustion can only occur on one side, and space to increase the speed of pyrolysis and gasification, etc. Achieve the effect of increasing the decoupling combustion space and intensity, improving the ability to increase the load, and increasing the intensity of pyrolysis and gasification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

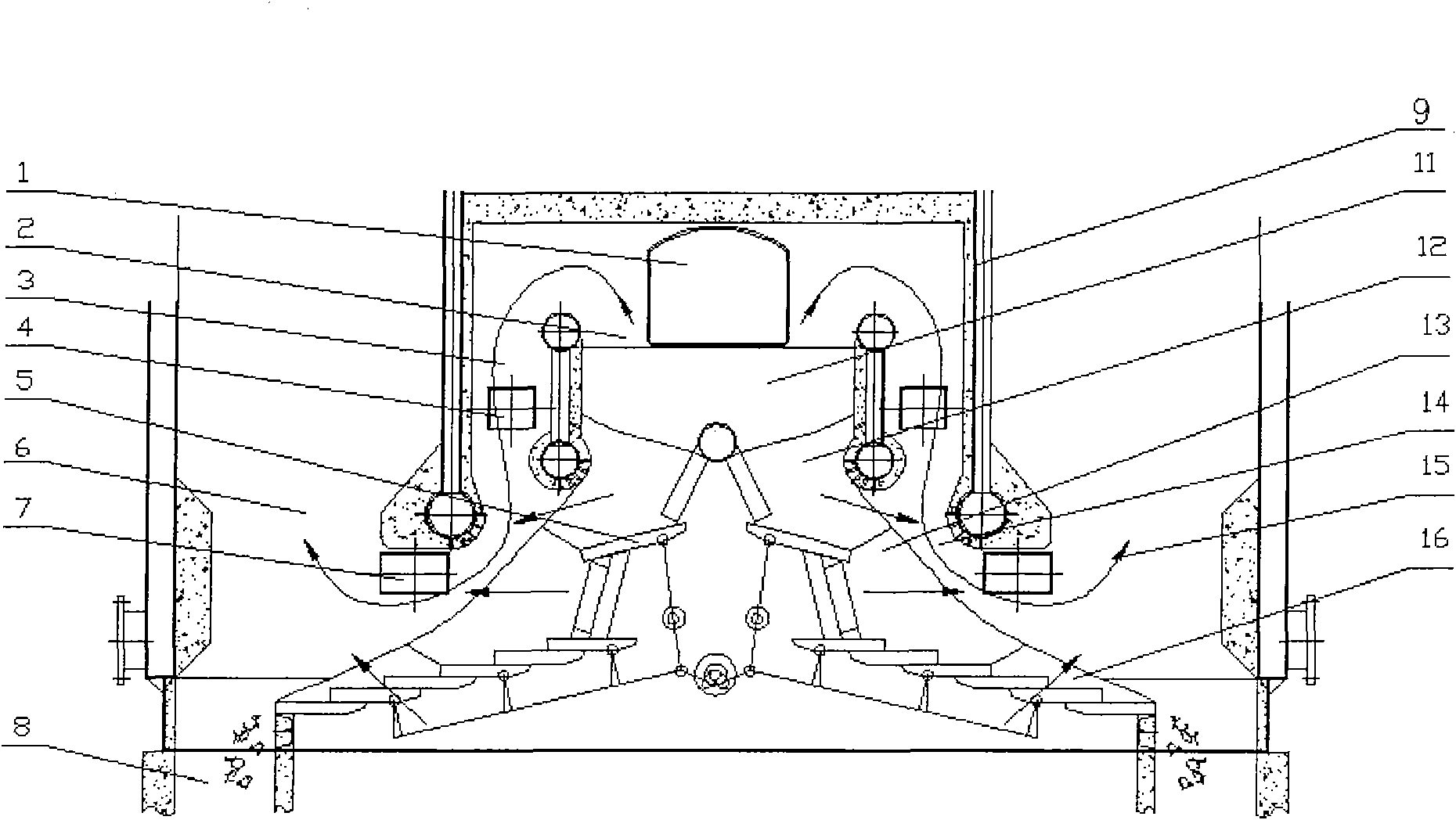

Image

Examples

Embodiment Construction

[0026] Due to the existence of fuel nitrogen inherent in coal, the coal gas produced by pyrolysis gasification contains certain nitrogen-containing substances, including NH 3 , HCN, etc. If the pyrolysis gasification gas is burned in an oxidizing atmosphere, these nitrogen-containing substances will be converted into nitrogen oxides. If the pyrolysis gasification gas is used as the reburning gas, the nitrogen-containing substances will x The reduction plays a promoting role. If the coal gas produced in the pyrolysis gasification chamber in the decoupling combustion furnace enters the semi-coke combustion zone, an appropriate amount of air is added to the appropriate position for premixing, so that the mixed gas can be burned under the condition that the excess air coefficient is less than 1, so that the main combustion NO produced in an oxidizing atmosphere x Reduction, the combusted mixed gas is mixed with the incoming secondary air and burned up, so that the emission of ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com