Self-cleaning heating stove

A heating stove and self-cleaning technology, applied in lighting and heating equipment, fluid heaters, water heaters, etc., can solve problems such as human injury, damage to heating stoves and radiators, and impact on service life, to ensure normal use, The effect of increasing the running path and increasing the combustion space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

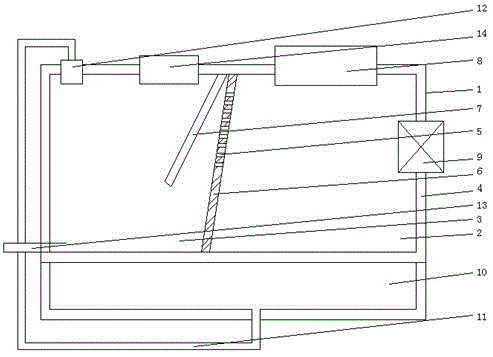

[0016] Such as figure 1 As shown, the self-cleaning heating furnace of the present invention includes a main furnace body, and the main furnace body includes an outer chamber 1, a combustion chamber 2 and a clean room 3, and the outer chamber 1 is provided with a combustion chamber 2 and a clean room 3, and the combustion chamber 2 A water trap 4 is provided between the combustion chamber 2 and the purification chamber 3, and the combustion chamber 2 and the purification chamber 3 are separated by a partition 6 with a vent hole 5, and the upper end of the partition 6 is connected to the top of the combustion chamber 2 and the purification chamber 3, The lower end of spacer 6 connects the bottom of combustion chamber 2 and clean room 3, spacer 6 is inclined to clean room 3, and the top of clean room 3 is connected with baffle plate 7, and the bottom of baffle plate 7 is hollowly connected with the bottom of clean room 3, There is an angle between the baffle piece 7 and the spac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com