Circulation Flame Biomass Oil Burner

A biomass oil and burner technology, which is used in burners, lighting and heating equipment, etc., can solve the problems of inability to achieve stable biomass oil, full combustion, single flame-spraying airflow, and insufficient combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

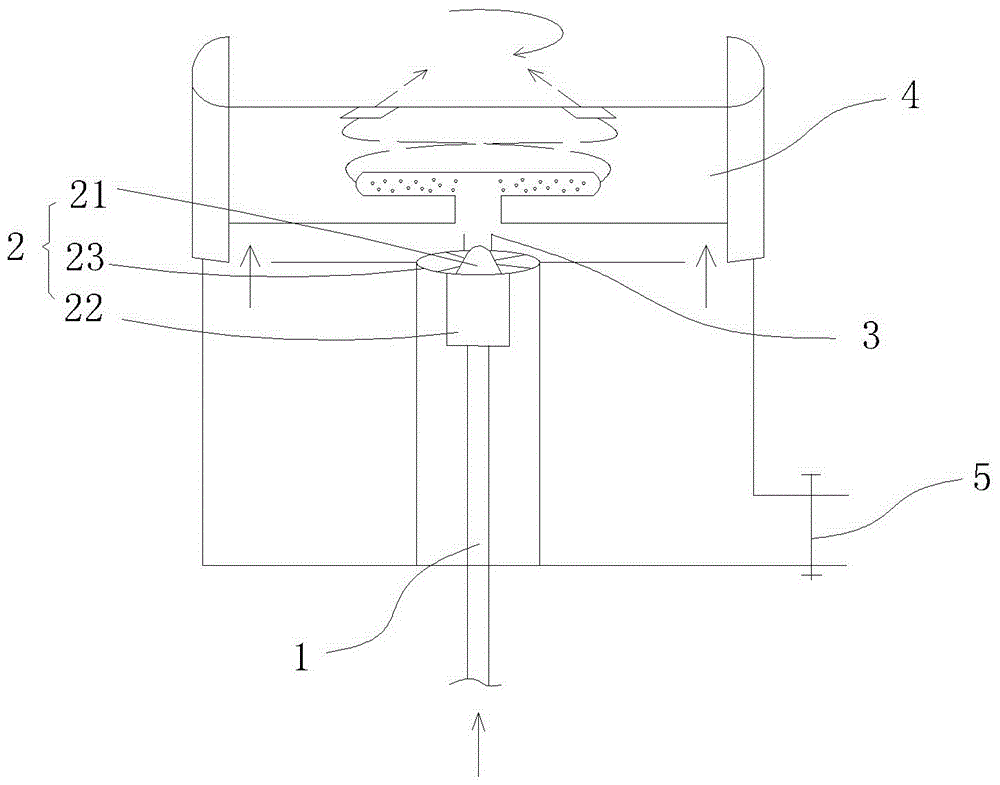

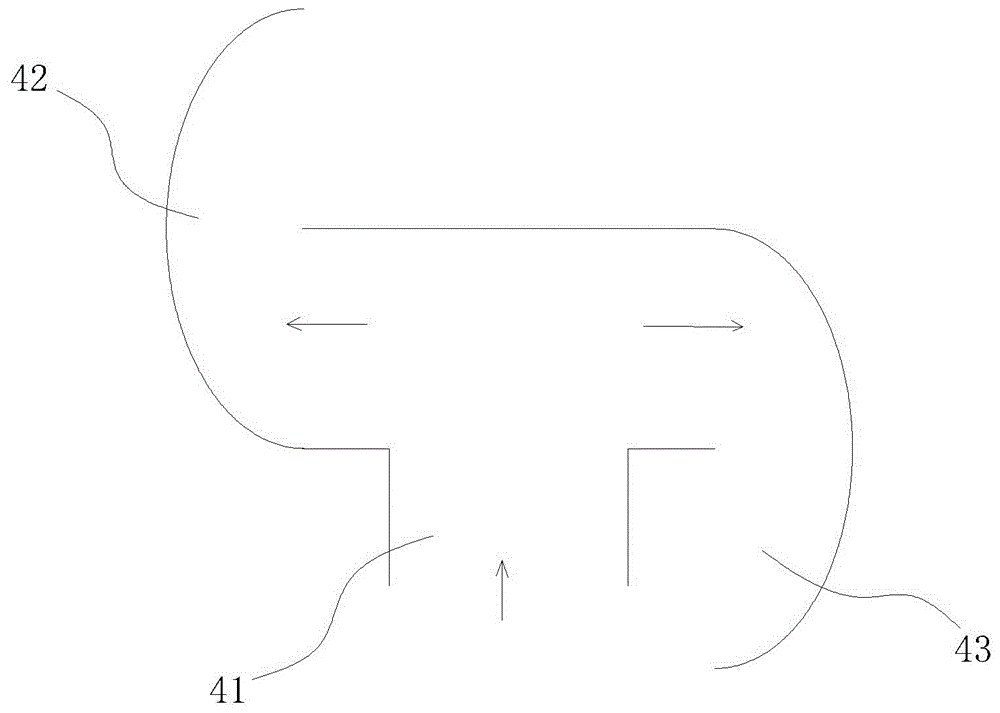

[0020] Example: see figure 1 , a circulating flame type biomass oil burner, the burner is provided with an oil guide pipe 1, the bottom end of the oil guide pipe 1 is the inlet of biomass oil, the other end of the oil guide pipe is connected to the combustion head 2, and an igniter 3 is provided on one side of the combustion head , a combustion hood 4 is provided on the combustion head 2, and N flame flow channels are arranged in the combustion hood 4, wherein N≥2, and the bottom end of each flow channel is connected to a flame inlet 41, and the flame inlet matches the flame nozzle of the combustion head Each flame channel is a spiral ascending channel, and the flames sprayed from the outlets of each channel are sprayed to the central axis of the combustion hood and crossed and split to form a ring structure. The cylinder wall side of this burner is provided with air inlet 5. Combustion head 2 comprises oil nozzle 21 and oil nozzle seat 22 and steady flame dish 23, and steady...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com