Full-condensation boiler

A technology of condensing boilers and condensers, applied in the field of boilers, can solve the problems of reducing fuel consumption, low efficiency, shortening the boosting time of high-fire combustion, etc., and achieve the effects of reducing fuel consumption, easy manufacture, and shortening the boosting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

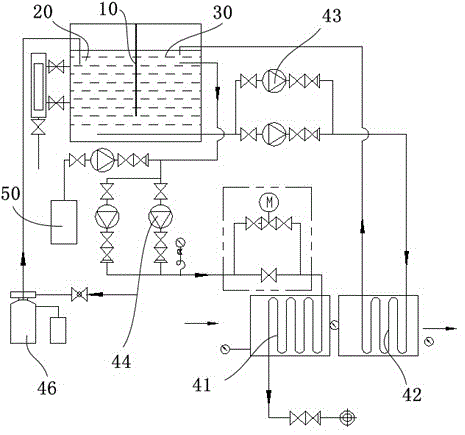

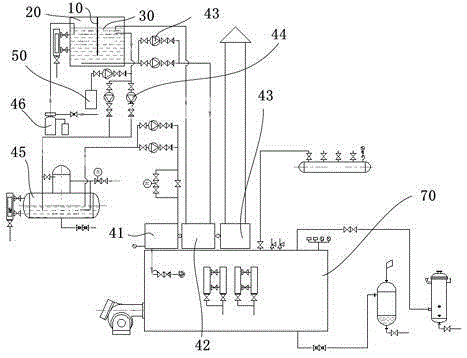

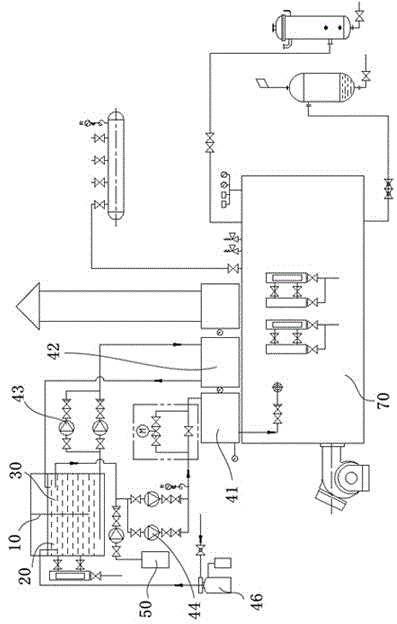

[0016] see Figure 1 to Figure 3 , the boiler body 70 of the present invention is made up of a steam drum and its accessories, each heating surface, header and connecting pipes thereof, steam-water system pipes and accessories, combustion equipment, flue air pipes, a framework comprising a platform, an escalator, and a furnace wall.

[0017] The boiler body 70 is connected to the hot and cold zoned water tank and its external circulation waterway, the cold and hot zoned water tank is divided into a cold water zone 20 and a hot water zone 30, and the external circulation waterway includes an economizer 41, a condenser 42, a circulation pump 43, and a feed water pump 44 , softened water at room temperature enters the cold water zone 20, enters the condenser 42 through the circulation pump 43, then returns to the hot water zone 30, and then enters the economizer 41 through the feed water pump 44, and then enters the boiler body 70 to maximize the exhaust gas temperature limit red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com