A top-fired hot blast stove burner

A hot blast stove and burner technology, which is applied in furnaces, blast furnaces, heating furnaces, etc., can solve the problems that limit the transformation process of small and medium-sized blast furnace hot blast stoves, and achieve the effects of small space occupation, high combustion temperature and improved air temperature level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

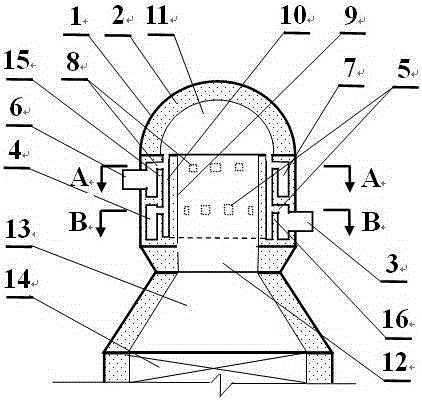

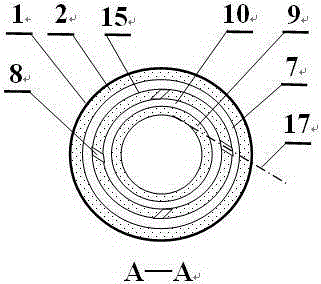

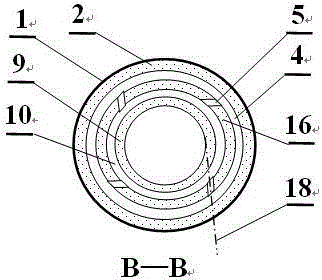

[0017] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0018] As can be seen from the accompanying drawings, a top-combustion hot blast stove burner of the present invention has a furnace shell 1, a refractory masonry 2, a combustion air inlet 3, a combustion air annular passage 4, a combustion air nozzle 5, and a gas inlet 6. Gas annular channel 7, gas nozzle 8, annular retaining wall 9, annular mixing channel 10, combustion chamber spherical section 11, combustion chamber straight section 12, combustion chamber conical section 13; there is a refractory masonry inside the furnace shell 1 2. In the refractory masonry 2 around the straight section 11 of the combustion chamber, there are combustion air annular channels 4, combustion air nozzles 5, gas annular channels 7, gas nozzles 8 and annular mixing channels 10, and the combustion air a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com