Power generating and heating dual-purpose boiler capable of adopting solid fuel and fuel gas

A solid fuel and gas technology, applied in the field of dual-purpose boilers for power generation and heating, can solve the problems of excessive emission pollution and low thermal efficiency, and achieve the effects of promoting full combustion, large heating area, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

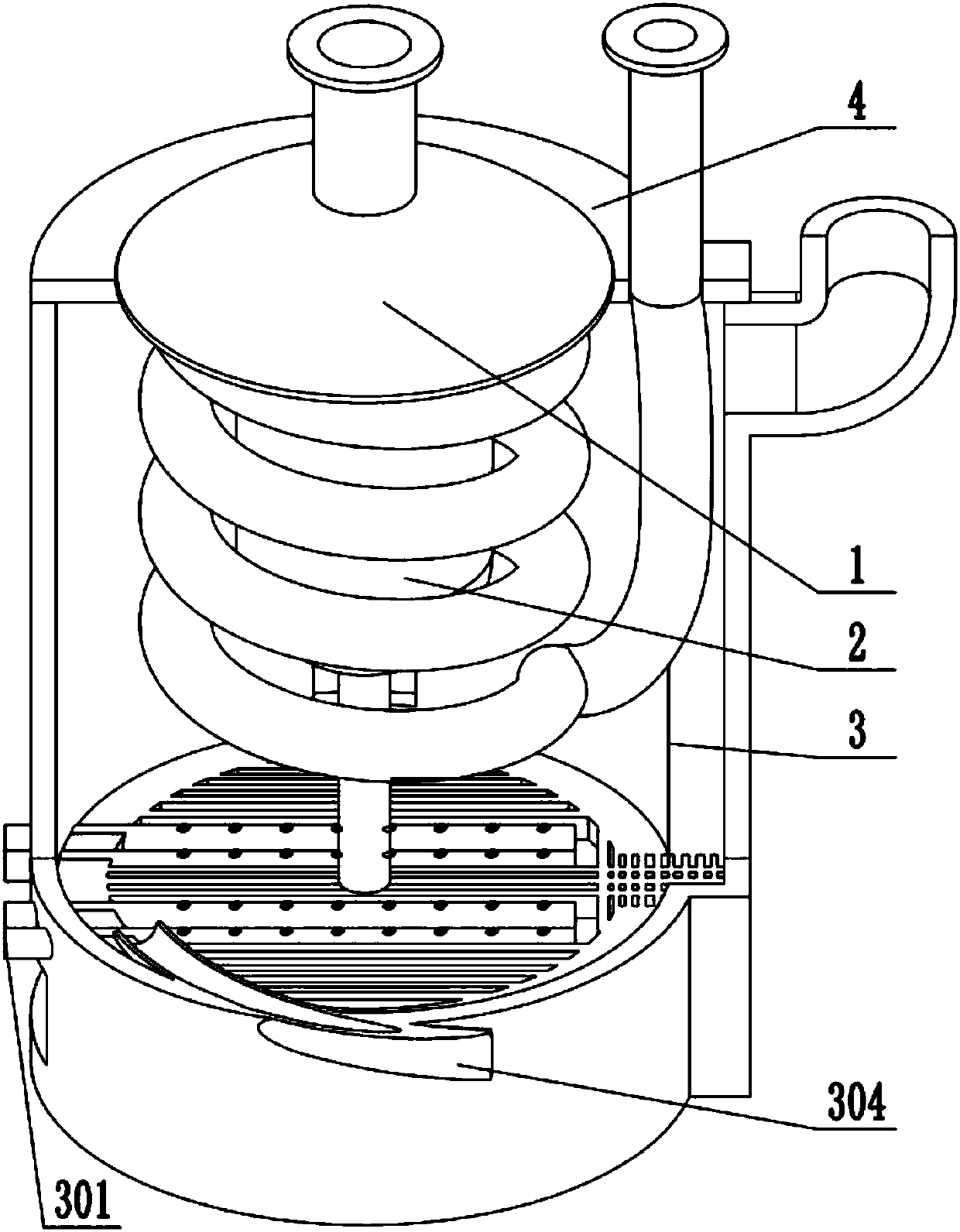

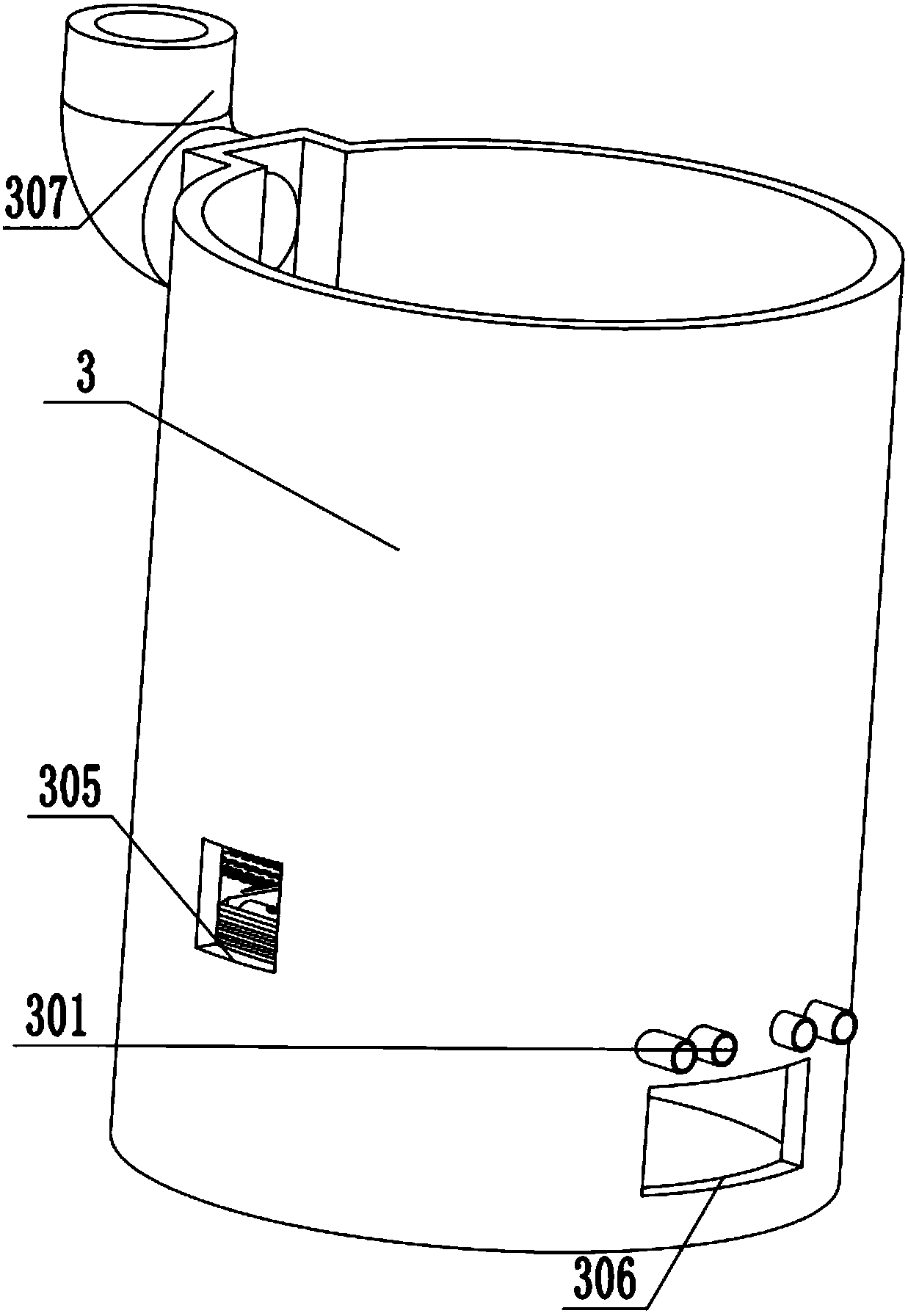

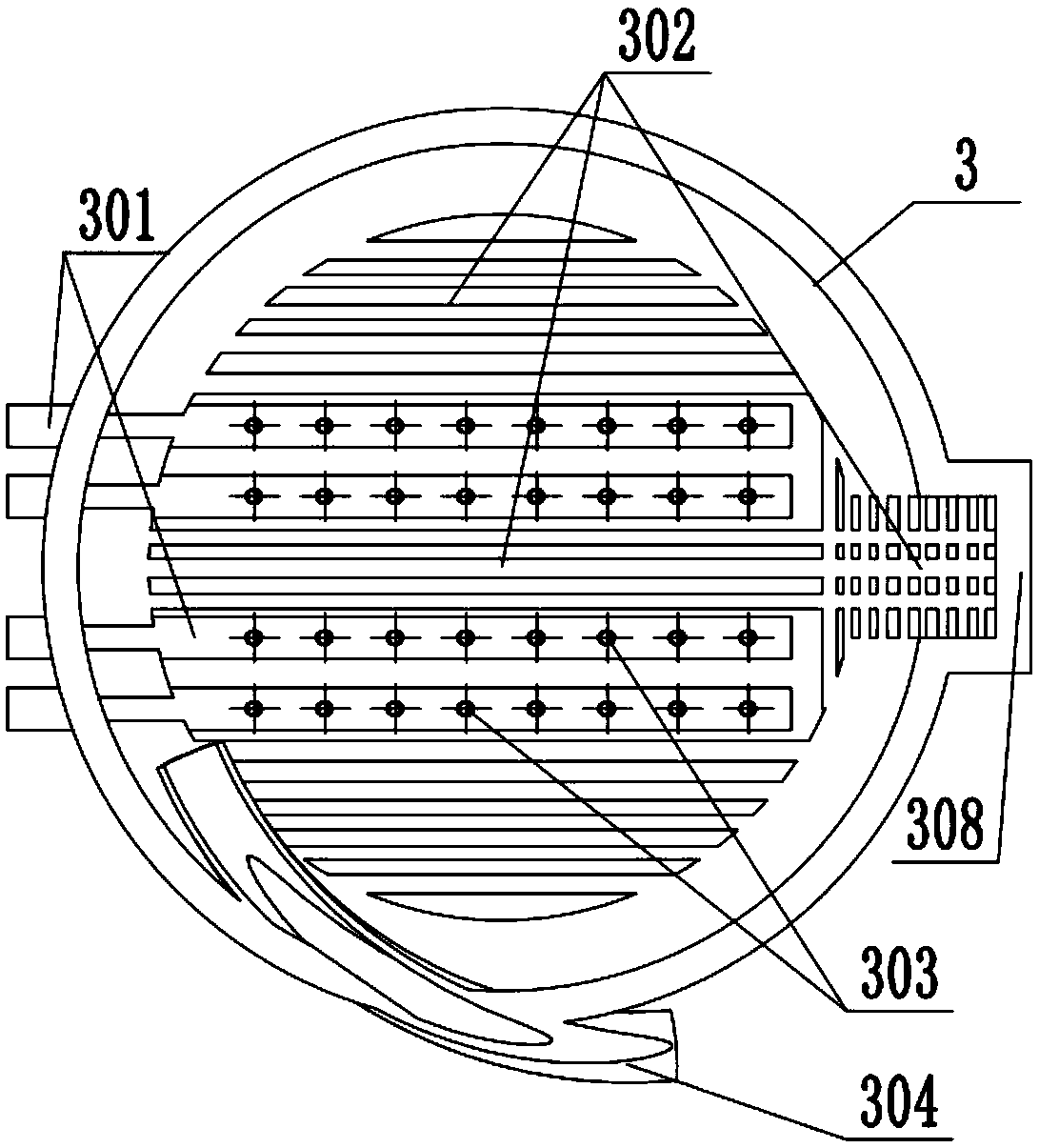

[0024] Such as Figure 1 to Figure 6 As shown, a dual-purpose boiler for power generation and heating that can use solid fuel and gas includes a heating container 1, a furnace 2, a furnace pole 201, a furnace body 3, a furnace cover 4, a grate 302, a heating coil 103, Spiral air duct 304, gas pipeline 301, gas hole 303. A furnace cover 4 covers the upper end of the furnace body 3 , and the heating vessel 1 is arranged on the furnace cover 4 . The water storage tank 102 of the heating vessel 1 and the water inlet 104 cooperate with the furnace cover 4, and the sealing method is used to seal the water storage tank seal 401 and the water inlet seal 402, forming an airtight top except the chimney 307 at the upper end of the body of heater 3, and the water storage tank 102 The heating area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com