Ammonia distillation method for waste heat of coke-oven flue gas and equipment

A flue gas waste heat and coke oven technology, applied in ammonia preparation/separation, climate sustainability, degassed water/sewage treatment, etc., can solve the problems of flue gas heat waste, energy consumption, and large energy consumption. Reach the effect of reducing sewage discharge, increasing power consumption and reducing discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

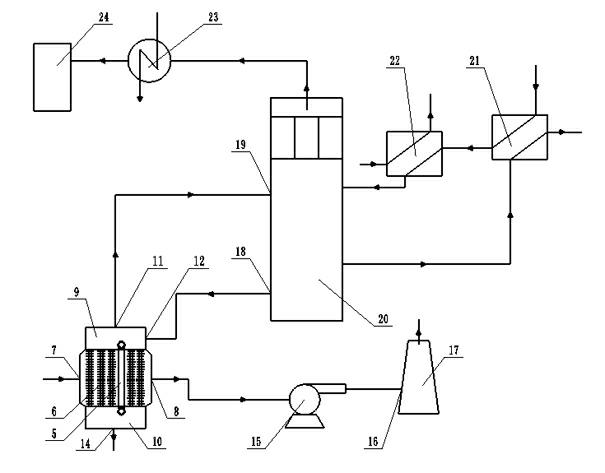

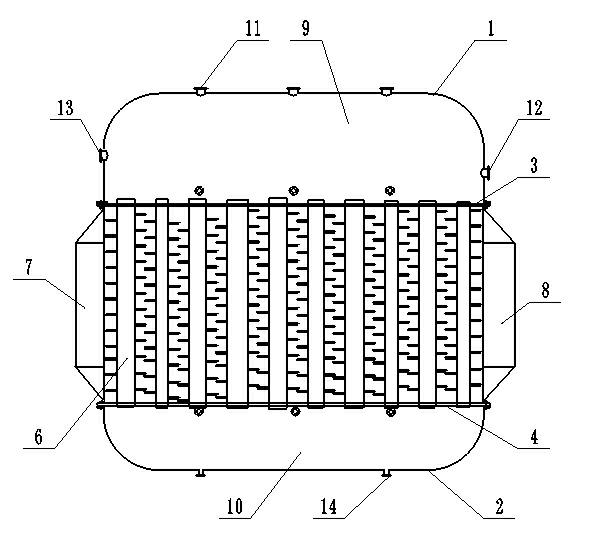

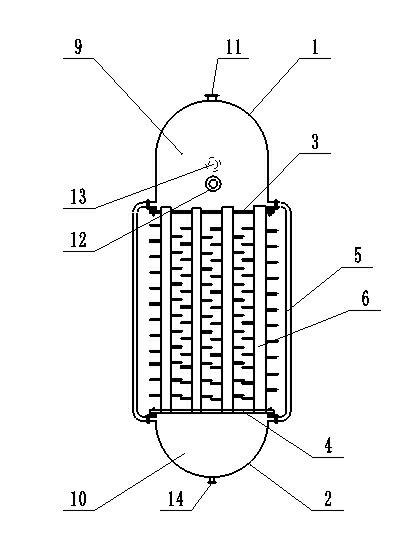

[0037] Such as figure 1 , figure 2 with image 3 Shown, coke oven flue gas residual heat ammonia steaming method, carry out according to the following steps:

[0038] The first step, inject water

[0039] Ammonia distillation waste water enters the vapor-liquid separation chamber 9 of the reboiler from the ammonia distillation waste water outlet 18 of the ammonia distillation tower through the water inlet 12 of the reboiler, and the ammonia distillation waste water flows into the reboiler through the circulation downcomer 5 by the difference in vapor-liquid specific gravity The water settling chamber 10;

[0040] The second step, settling solid impurities

[0041] The ammonia distillation waste water is settled in the water settling chamber 10, and the settled solid impurities are discharged from at least one sewage outlet 14 at the bottom of the water settling chamber 10, and the settled ammonia distillation waste water enters the evaporation pipe 6 on the top of the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com