Natural gas hydrogen production plant and method

A hydrogen production device and natural gas technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve problems such as high energy consumption, high cost, complex system, etc., achieve increased reaction temperature, compact equipment design, and reduced energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

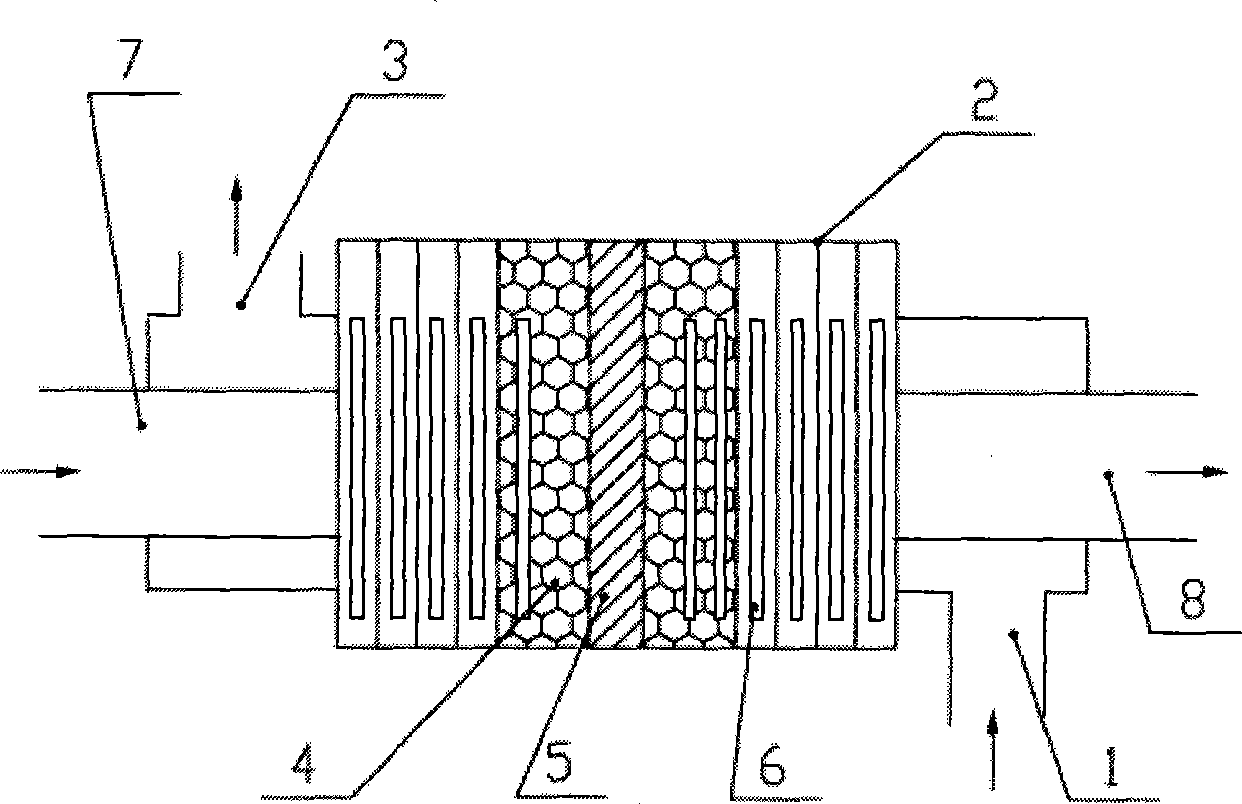

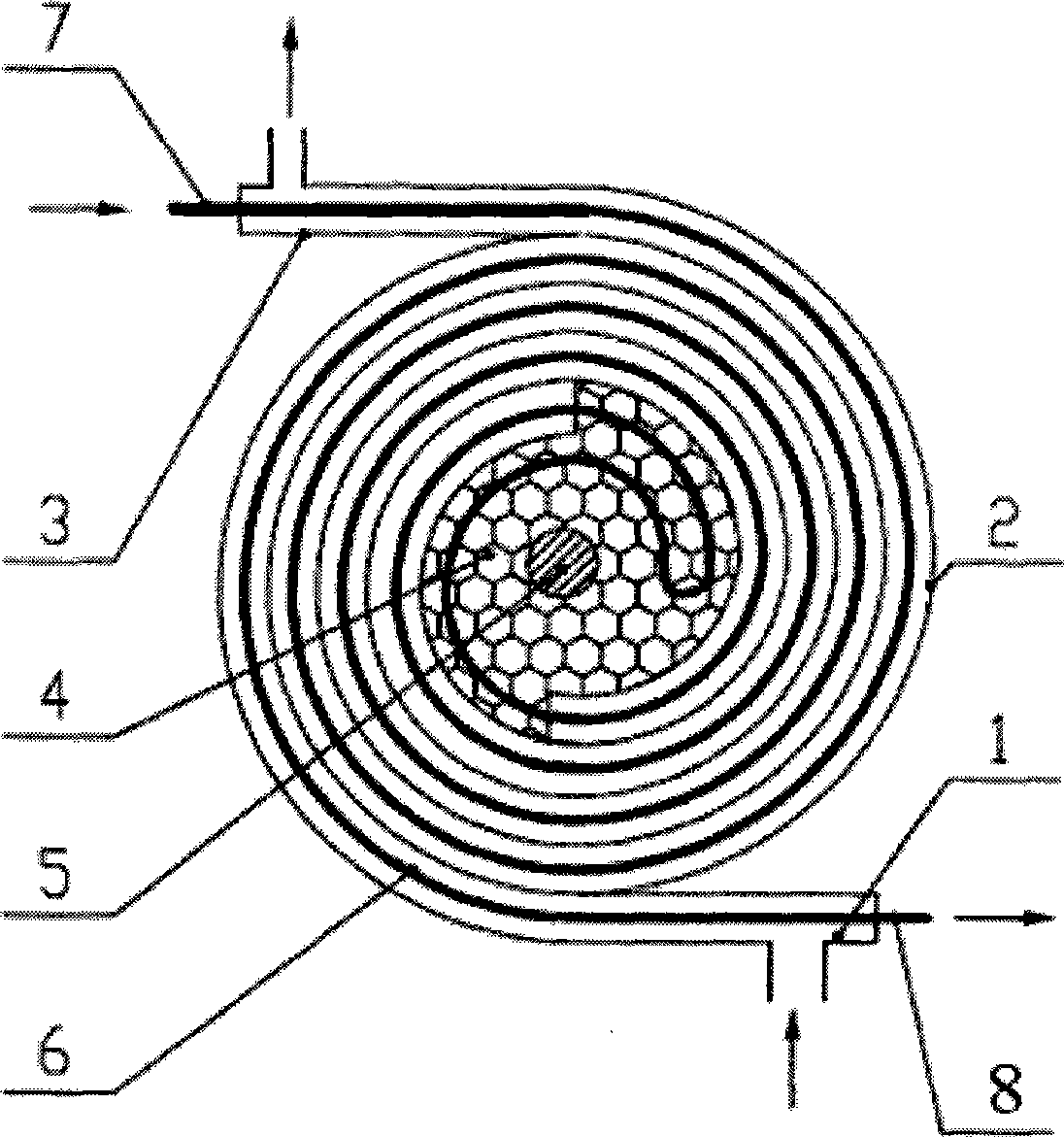

[0020] The specific implementation of the natural gas on-site hydrogen production device and method of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] A kind of natural gas site hydrogen production device and method of the present invention such as figure 1 , figure 2 As shown, it mainly includes a tangential inlet 1, a reverse heat exchanger 2, a tangential outlet 3, a porous medium 4, an electrically heated silicon carbide rod 5, and a reaction coil 6. The surface of the inner layer of the center of the reverse heat exchanger 2 is plated with high-temperature resistant ceramic materials, and the material of the low-temperature heat exchange area of the other outer ring layers is made of stainless steel. The reaction coil 6 is made of materials with excellent thermal conductivity and heat resistance, and is placed in the reverse heat exchanger 2 . The porous medium 4 is formed by stacking ceramic balls with hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com