Preheating method and device for sintering mixture

A technology for sintering mixture and mixture, which is applied in the field of ferrous metallurgy sintering process and steam preheating process of sintering mixture, can solve the problems of over-humidity of the mixture, insufficient heat exchange, large heat energy consumption of sintered ore, etc., and achieve preheating. The effect of uniform temperature, high heat conduction efficiency and full utilization of waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

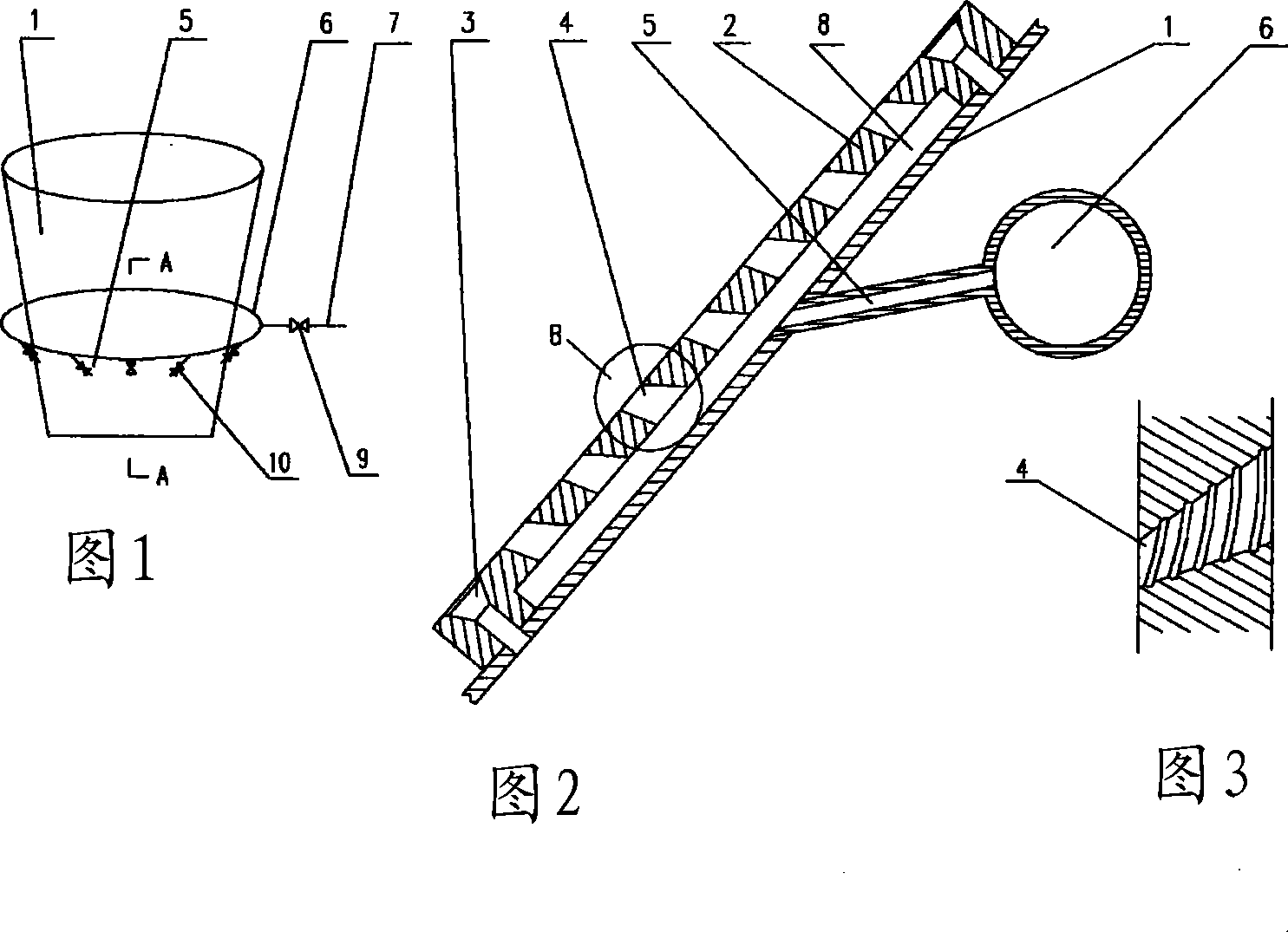

Image

Examples

Embodiment Construction

[0018] Realize the preferred mode of the present invention, according to the following examples, illustrate: 70 square meters of sintering machine ring coolers are equipped with waste heat boilers to produce superheated steam, through superheated steam pipelines with heat preservation and control facilities thereof, steam-water separator, flow rate Gauge, regulating valve and pressure gauge control the superheated steam main pipe, ring pipe and branch pipe sent to the mixture mine tank. Each branch pipe passes through the mine tank wall and connects to the steam chamber cavity in the mine tank to form the steam chamber plate of the steam chamber cavity The combined connection surrounds the ore tank to form a preheating zone with heat exchange function of double heat conduction by spraying steam and steam chamber plate heat conduction, heating the mixture, and raising its temperature to above 62°C or 67°C, implementing the present invention method, according to the following ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com