Waste heat recovery device for ascending pipe of coke oven

A waste heat recovery device and coke oven technology, which is applied in the heating of coke ovens, coke ovens, carbonization gas discharge devices, etc., can solve problems such as large ammonia water, waste of water resources and electricity, and increase sewage discharge, so as to ensure safety Operation, avoid coking, reduce the effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

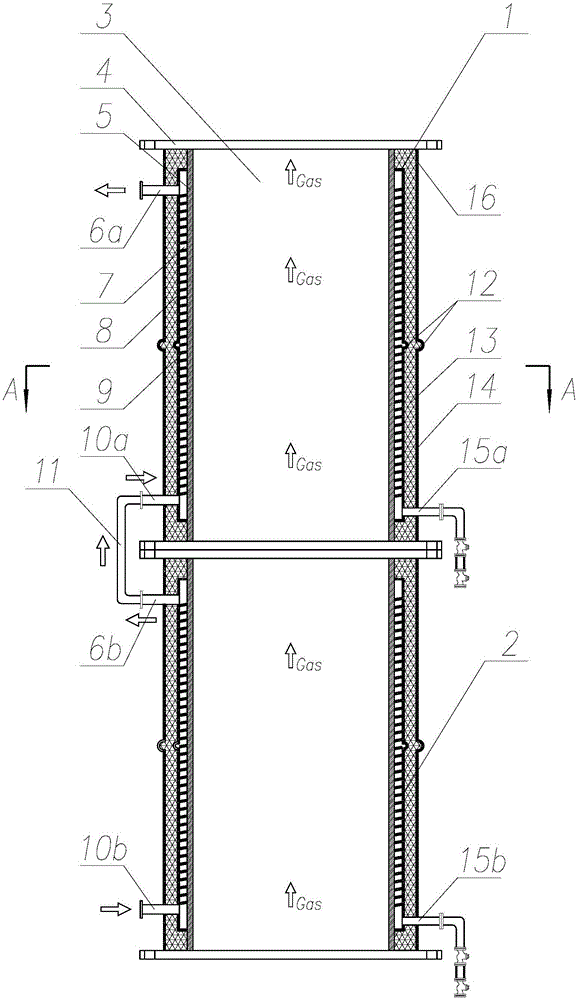

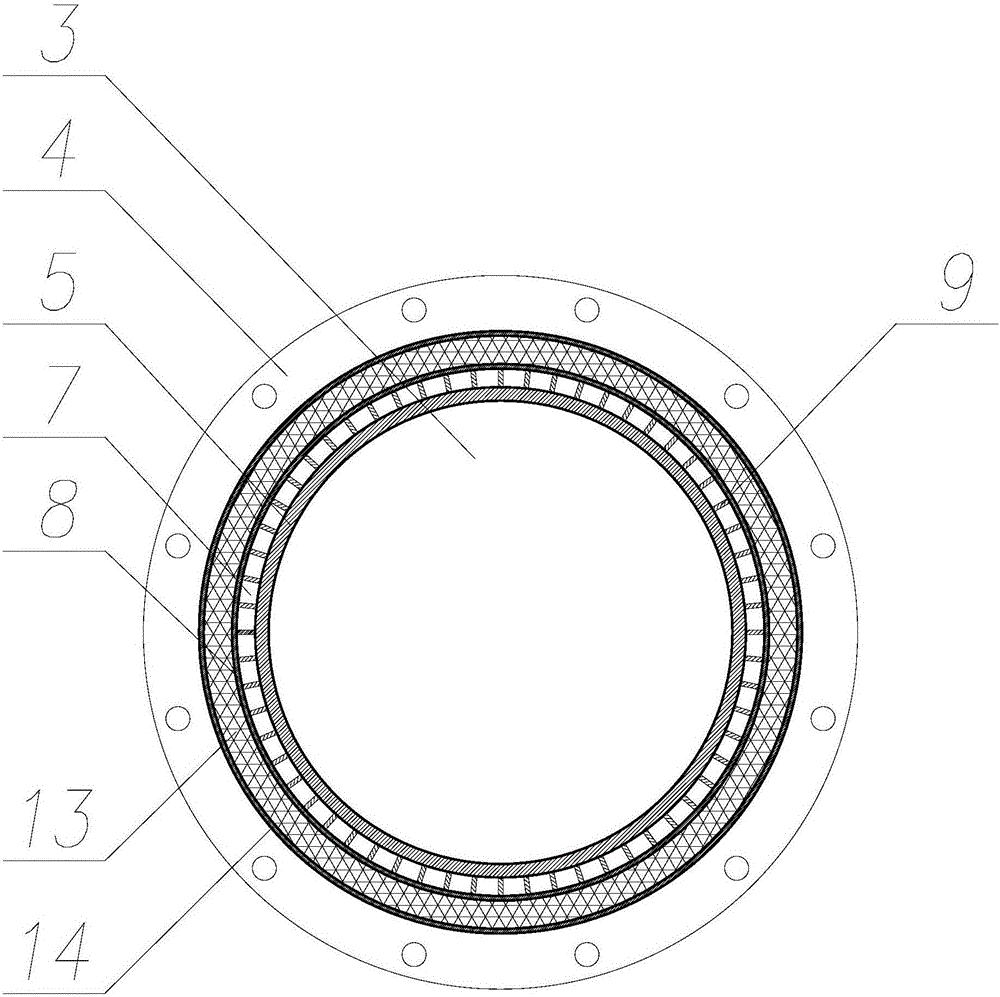

[0025] Such as Figure 1-2 As shown, the present embodiment provides a coke oven riser gas waste heat recovery device, the device includes two coke oven riser evaporators 1, 2; wherein the coke oven riser evaporator 1 adopts a jacket structure, It is composed of coke oven raw gas channel 3, inner pipe 5, steam water channel 7, inner casing 8, insulation layer 13, outer jacket 14, etc. The central tube is a cylindrical raw gas channel 3, and the inner pipe wall 5 is coated Layer to prevent coking, and at the same time as the main heating surface.

[0026] The pipe wall jacket is a steam-water channel 7, and the steam drum feedwater absorbs the heat of the rising tube evaporator in the jacket to generate a steam-water mixture; the inside of the rising tube evaporator is provided with a cooling water diversion structure 9, which can make the inside of the jacket The soda flow field is evenly distributed.

[0027] The inner tube 5 and the inner casing 8 of the riser tube evapora...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that corrugated compensators 12 are provided on the outer wall 8 of the inner casing and the outer jacket 14 respectively. A balance hole 16 is provided on the upper side of the outer jacket.

[0032] Since the inner pipe 5, the inner sleeve 8, and the outer jacket 14 have different heating degrees and different materials, a corrugated compensator is provided on the inner sleeve 8 and the outer jacket 14 in this embodiment to Compensate for the deformation difference caused by the expansion and contraction ratio among the three, and avoid damage to the riser heat exchanger.

Embodiment 3

[0034] On the basis of the above-mentioned embodiments, each spoiler 9 is arranged in a spiral in the soda channel, and the spoilers 9 are arranged at intervals between two adjacent spoilers 9 , and the spoilers 9 on two adjacent spiral tracks are arranged alternately.

[0035] The setting method of the spoiler 9 in this embodiment can make the heat exchange medium spontaneously select the flow mode according to its temperature. If the temperature of the medium is high and the rising ability is strong, it will rise directly from the space between the spoiler 9. If The temperature of the medium is relatively low, and its rising ability is weak. It will flow along the spiral channel and extend the heat exchange path, so as to ensure the sufficient heat exchange of the medium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com