Heated wall surface cooling structure and gas turbine impeller vane with the same

A gas turbine blade and cooling structure technology, which is applied to blade support components, mechanical equipment, engine components, etc., can solve problems such as uneven cooling, material fatigue failure, and limited cooling capacity, so as to provide cooling efficiency and avoid thermal stress The effect of continuous increase and decrease of wall temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

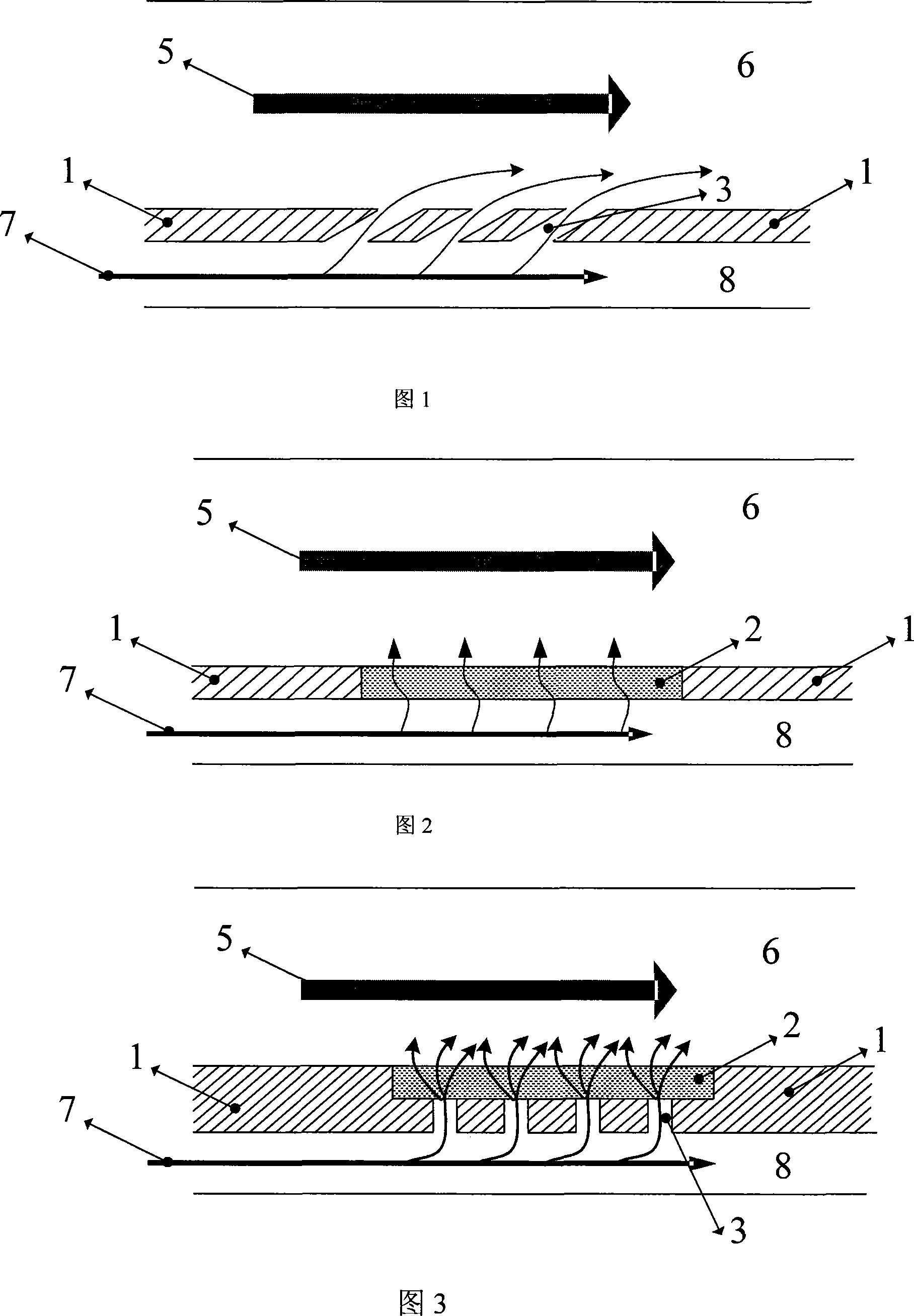

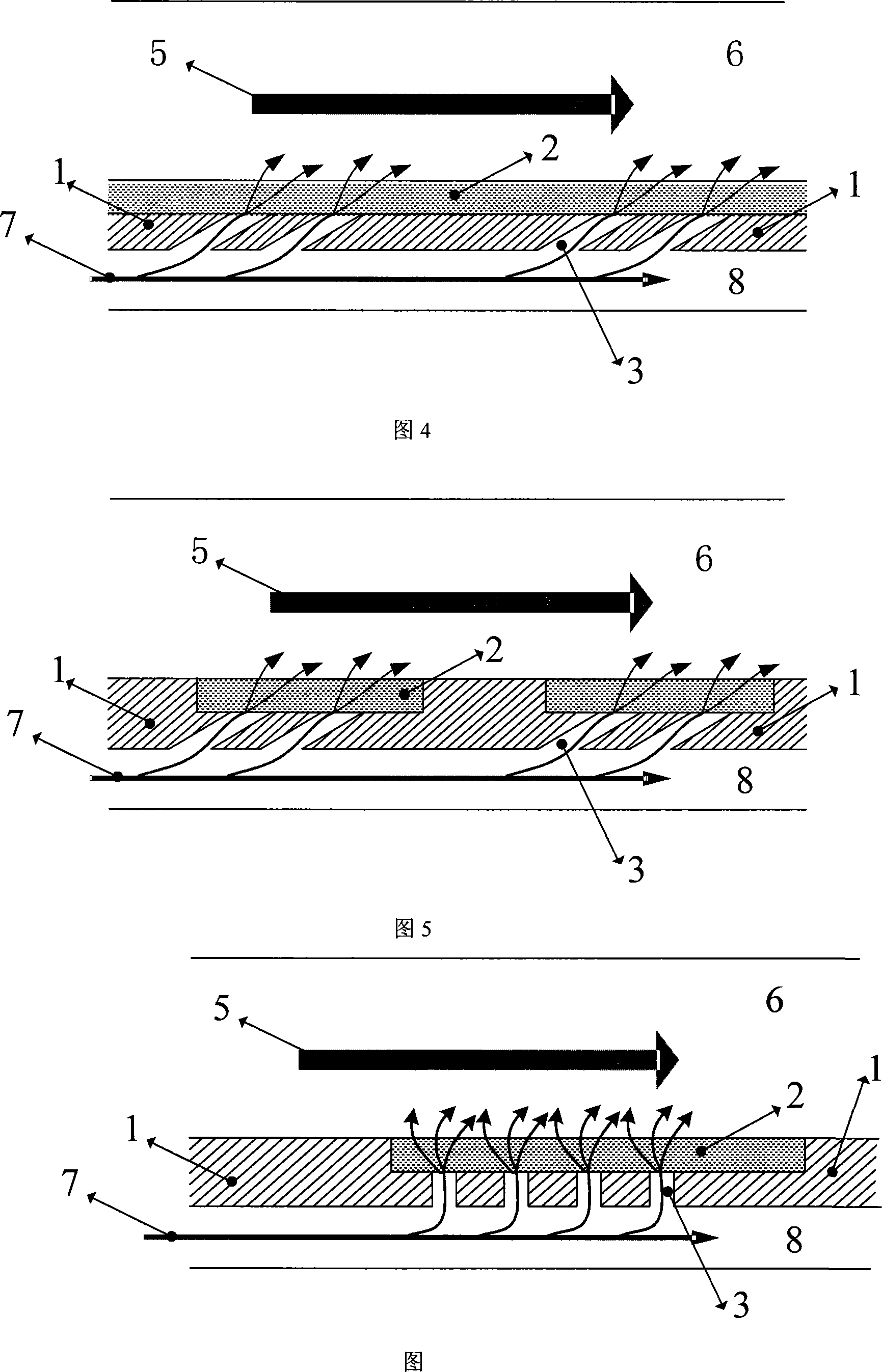

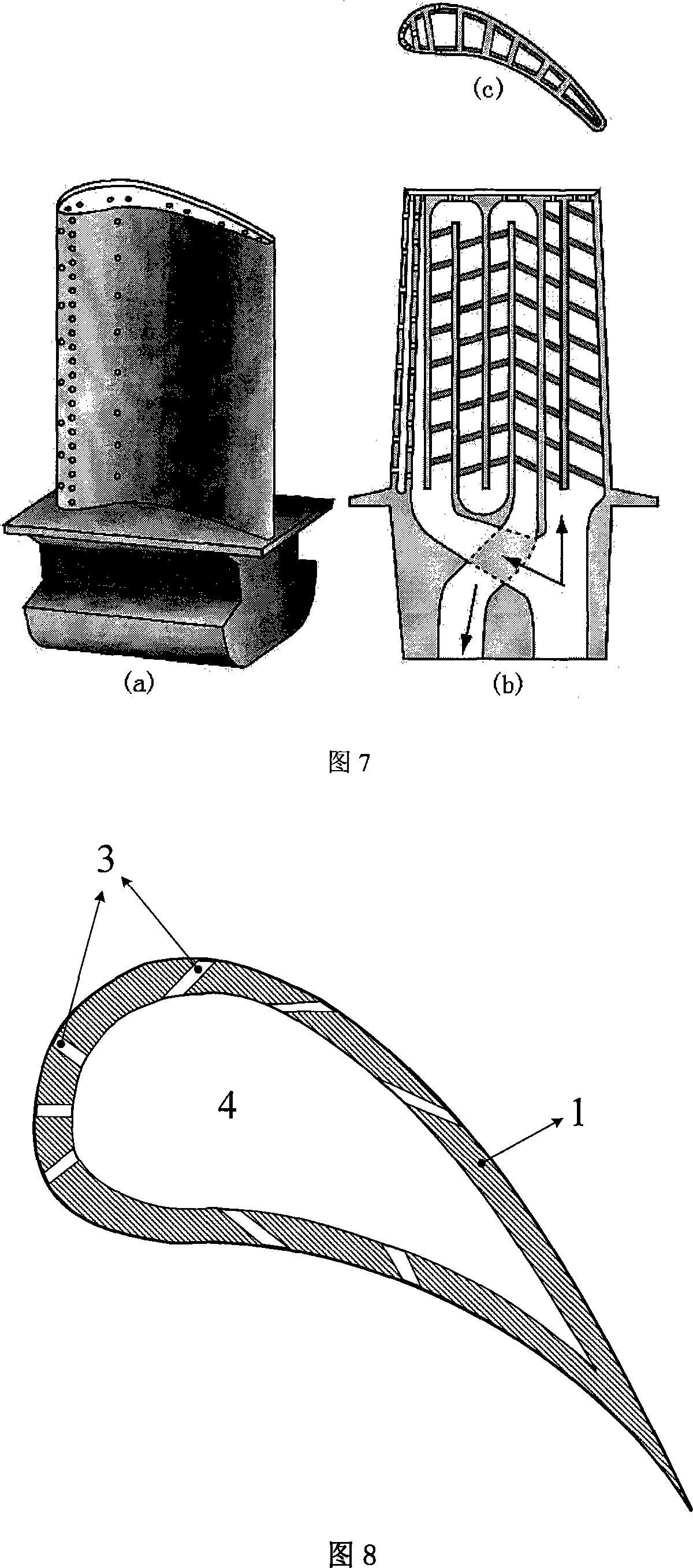

[0031] The principle and specific structure of the present invention will be further described below.

[0032] The heated wall surface cooling structure provided by the present invention has a dense wall surface layer 1, and the dense wall surface layer 1 is provided with a plurality of discrete through holes 3 for coolant to pass through, and the heated side of the dense wall surface layer 1 is covered with a porous medium layer 2, Thereby the porous medium layer 2 and the dense wall surface layer 1 having a plurality of discrete through-holes 3 form a double-layer stacked structure, and the described porous medium layer 2 covers the outlets of all the discrete through-holes 3; the described porous medium layer 2 is A whole piece of continuous distribution is continuously and completely covered on the heated side of the dense wall surface layer 1, so that the outlets of all the discrete through holes 3 are covered by the whole piece of porous medium layer 2; or the porous medi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com