Efficient graphene-based cooling coating as well as preparation method and application thereof

A graphene-based, heat-dissipating coating technology, applied in anti-corrosion coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of inability to exhibit the excellent characteristics of graphene, poor dispersibility, and increased difficulty in post-processing, etc. Achieve the effect of promoting the development of miniaturization, stable performance and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

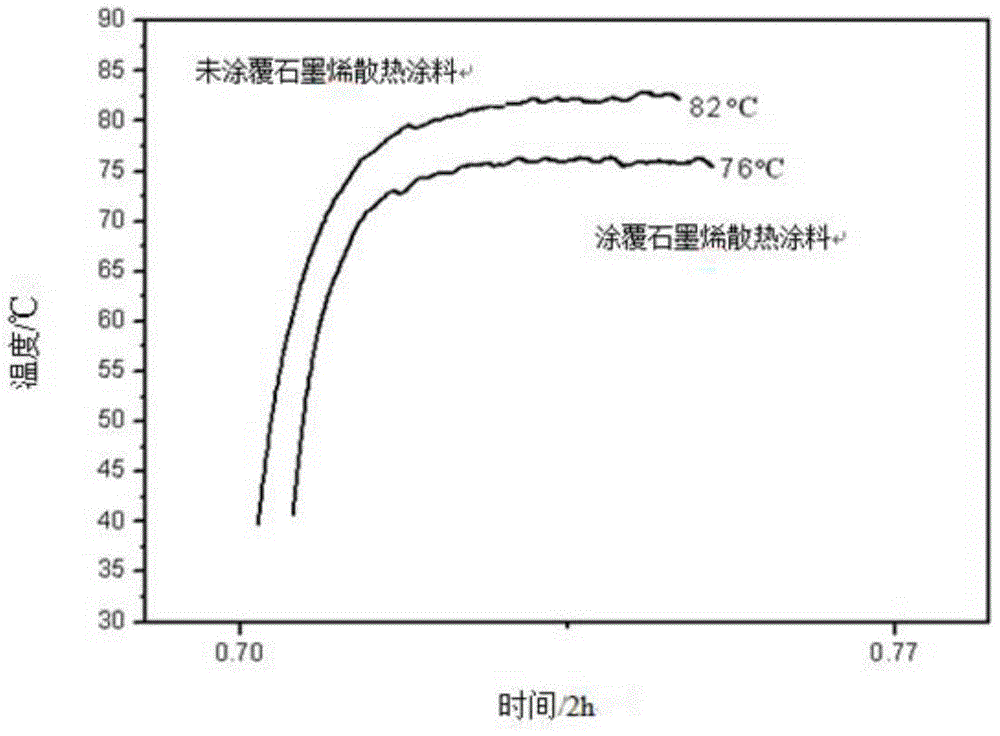

[0031] Example 1 Take 5 parts of graphene powder with an average radial size of about 20 μm and an average thickness of about 5 nm (all parts by weight unless otherwise specified below), and 10 parts of carbon black with an average particle diameter of about 30 nm in diacetone alcohol Ultrasonic for 1 h, and dried at 90°C to obtain graphene carbon black composite powder. Then mix with 5 parts of 325 mesh graphite and 10 parts of nano-silica in a high-speed disperser, and then mix with 60 parts of epoxy resin, 10 parts of ethyl acetate, 20 parts of N, N-dimethylformamide, Stir and disperse in a planetary mixer (3000rpm, 1h), and then grind on a three-roller machine for 3 hours, 2000rpm, to obtain the final heat-dissipating coating. See the heat-dissipating effect figure 1 .

[0032] When this heat dissipation paint is coated on the CPU radiator, it can be seen that the CPU operating temperature coated with graphene heat dissipation paint (refer to figure 1 The lower curve in ...

Embodiment 2

[0033] Example 2 Take 10 parts of graphene powder with an average radial size of about 50 μm and an average thickness of about 10 nm, and 5 parts of carbon black with an average particle size of about 30 nm, ultrasonically in N,N-dimethylformamide for 1 hour, and dry to obtain Graphene carbon black composite powder. Then mix evenly with 5 parts of 325 mesh graphite and 10 parts of activated carbon in a high-speed disperser, then mix with 60 parts of polyurethane, 10 parts of acetone, 20 parts of N, N-dimethylformamide, vacuum planetary stirring (3000rpm, 1h), Then grind for 3 hours with a three-roll machine at 2000 rpm to obtain the final heat-dissipating coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com