Hot-stamping automobile part with flexibly-distributed intensity and control method thereof

A technology of hot stamping forming and auto parts, which is applied in the field of manufacturing hot stamping forming parts. It can solve the problems of large contrast in tissue composition and strength, no smooth transition, and increased weld seam, and achieve ideal performance, smooth transition, and improved performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

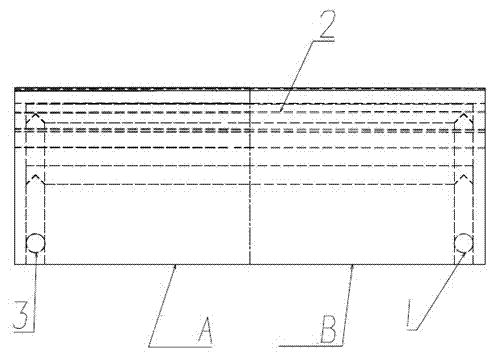

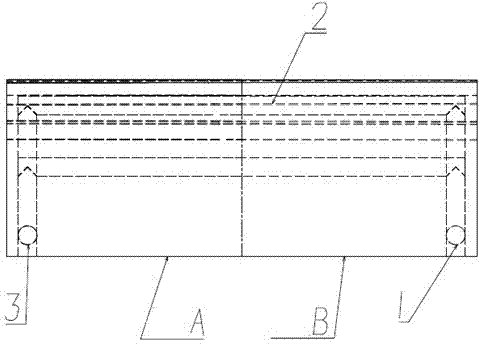

Image

Examples

Embodiment

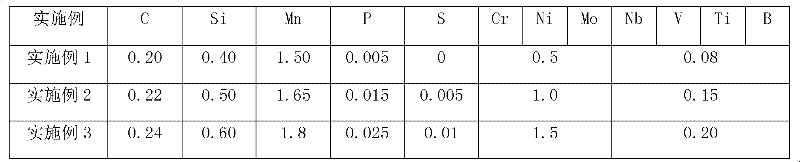

[0018] Table 1 is the chemical composition of the rolled plate used to manufacture the hot stamping formed auto parts of strength flexible distribution in the present invention;

[0019] Table 1 Chemical composition of rolled sheets used in the manufacture of hot stamped automotive parts with flexible distribution of strength

[0020]

[0021] Table 2 shows the strength flexibility distribution of the hot stamping auto parts control method and the mechanical properties of the resulting parts. Among them, the mechanical performance test is carried out according to GB6397-86.

[0022] The steel billet containing the composition of Example 2 in Table 1 is produced by conventional metallurgical technology, according to the control method shown in Example 2 of Table 2, heating at 1220 ° C, starting rolling at 1100 ° C, finishing rolling temperature 870 ° C, coiling after rolling Air cooling to form a slab; uncoiling the hot-rolled plate, and cutting it into heat-treated parts s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com