Steel plate surface treatment method and device

A surface treatment device and surface treatment technology, applied in the direction of workpiece surface treatment equipment, workpiece cleaning device, metal rolling, etc., can solve the problems of failure to meet requirements, inability to flexibly control roughness, and decrease of roll surface roughness, and achieve reduction Effect of load and its equipment section length, control of strip surface roughness, and improvement of strip mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

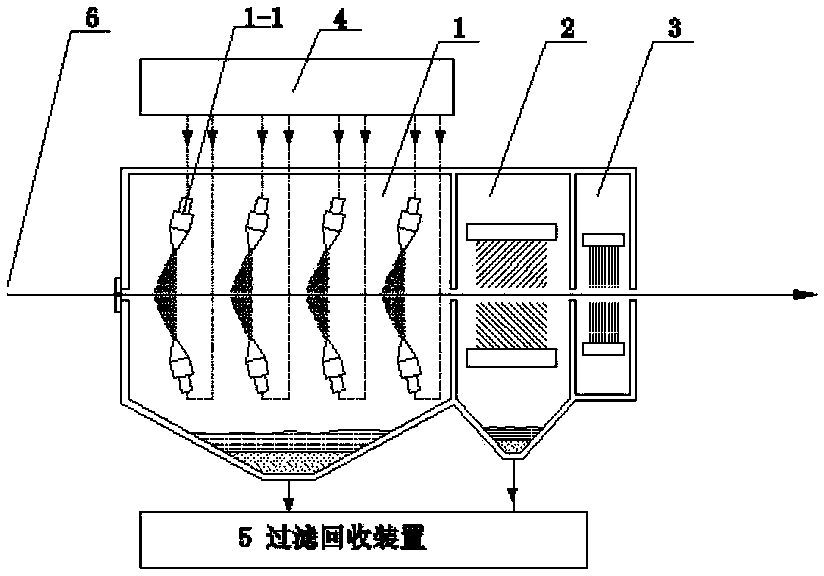

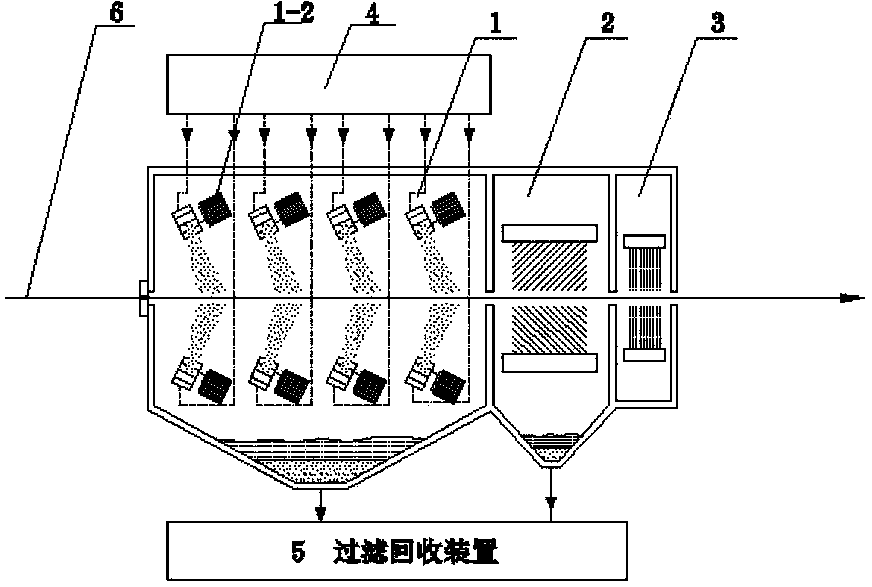

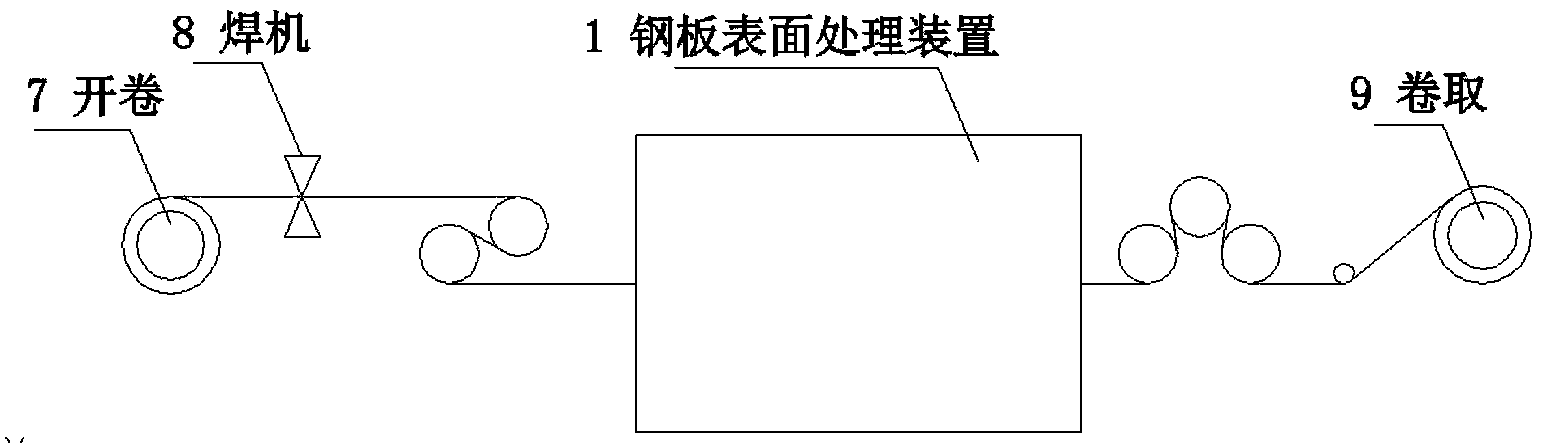

[0103] Take the technology when the strip surface treatment device described in the present invention is set on the independent degreasing unit as an example, refer to image 3 , the specific implementation is as follows:

[0104] The steel strip in this embodiment is a cold-rolled steel strip with a width of 700-1300 mm and a thickness of 0.2-3 mm. At this time, various dirt generated during the rolling process remains on the surface of the strip, including rolling oil and slag in the rolling oil, iron powder generated during the cold rolling process, accumulated dust, and dust generated during the welding process. Welding slag etc. The surface roughness of the strip after cold rolling is 0.7-0.8 μm, and the user requires a surface roughness of 1.5 μm.

[0105] The steel strip 6 is welded by the welding machine 8 after being decoiled by the uncoiler 7, and then enters the steel plate surface treatment device 1 through the tension roller, and the steel plate pretreatment dev...

Embodiment 2

[0108] Take the process when the strip surface treatment device described in the present invention is set on the continuous annealing unit as an example, refer to Figure 4 , the specific implementation is as follows:

[0109] The steel strip in this embodiment is a cold-rolled steel strip with a width of 700-1300 mm and a thickness of 0.2-3 mm. At this time, various dirt generated during the rolling process remains on the surface of the strip, including rolling oil and slag in the rolling oil, iron powder generated during the cold rolling process, accumulated dust, and dust generated during the welding process. Welding slag etc. The surface roughness of the strip after cold rolling is 0.7-0.8 μm, and the user requires a surface roughness of 1.5 μm.

[0110]The steel strip 6 is welded by the welder 8 after being decoiled by the uncoiler 7, and then enters the steel plate surface treatment device 1. The technology in the steel plate surface treatment device is the same as tha...

Embodiment 3

[0112] Take the process when the strip surface treatment device described in the present invention is set on the continuous hot-dip galvanizing unit as an example, refer to Figure 5 , the specific implementation is as follows:

[0113] After the steel strip 6 is uncoiled by the uncoiler 7, it enters the inlet looper 10 through the welding machine 8, and then enters the steel plate surface treatment device 1. The strip steel surface treatment process in the steel plate pretreatment device 1 is similar to that of Example 1. After the steel strip processed by the pretreatment device 1 is annealed in the annealing furnace 12, it is then subjected to hot-dip galvanizing treatment, thereby completing the entire hot-dip galvanizing process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com