Titanium plate hot continuous rolling large-scale manufacturing method

A hot continuous rolling and titanium plate technology, which is applied in the field of hot rolling, can solve problems such as easy peeling, rapid metal temperature drop, and deterioration of titanium deformation performance, and achieve the effects of ensuring surface quality, ensuring cleaning effect, and enhancing purging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

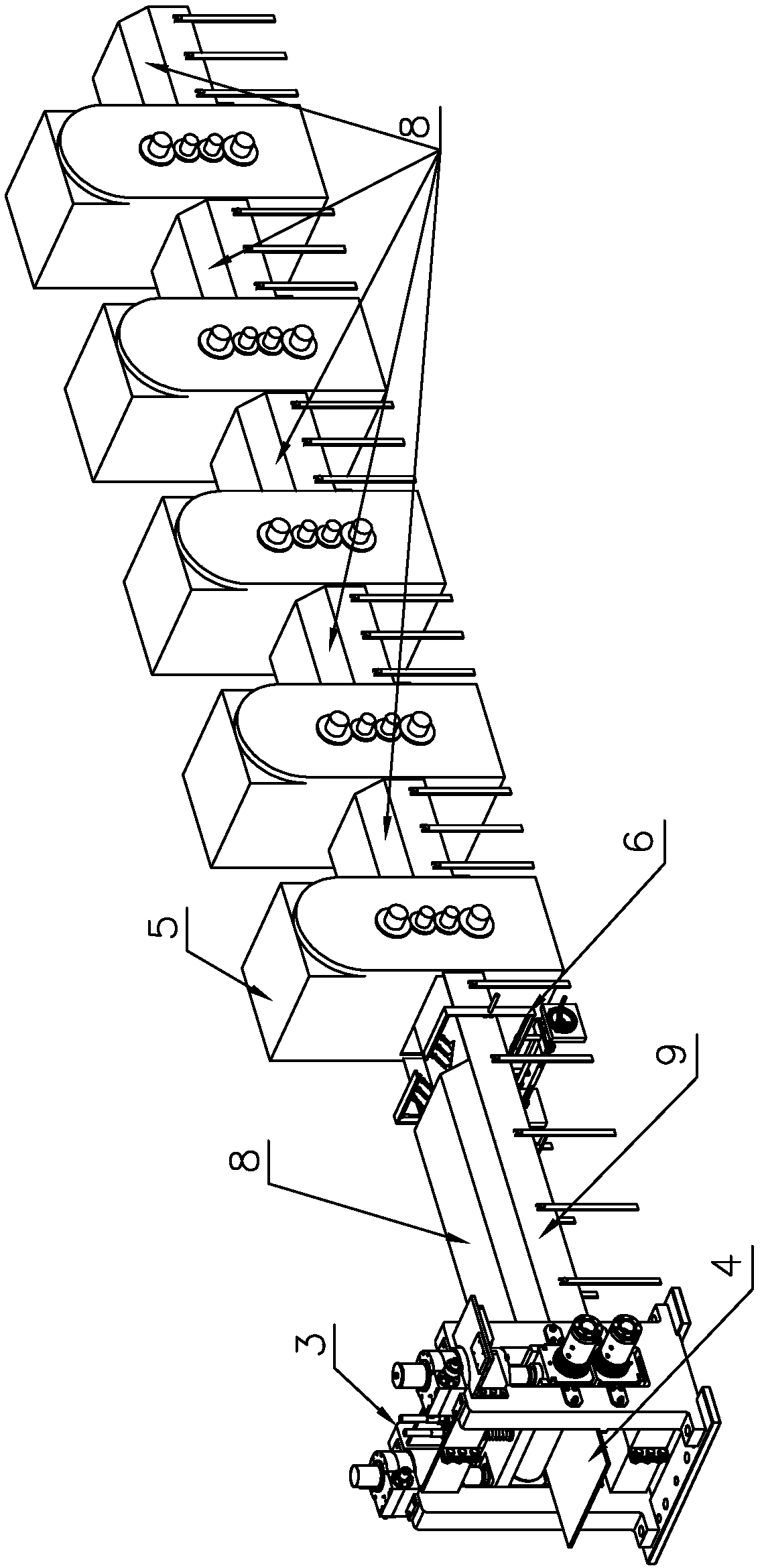

[0050] A large-scale preparation method for continuous hot rolling of titanium plates, comprising the following steps:

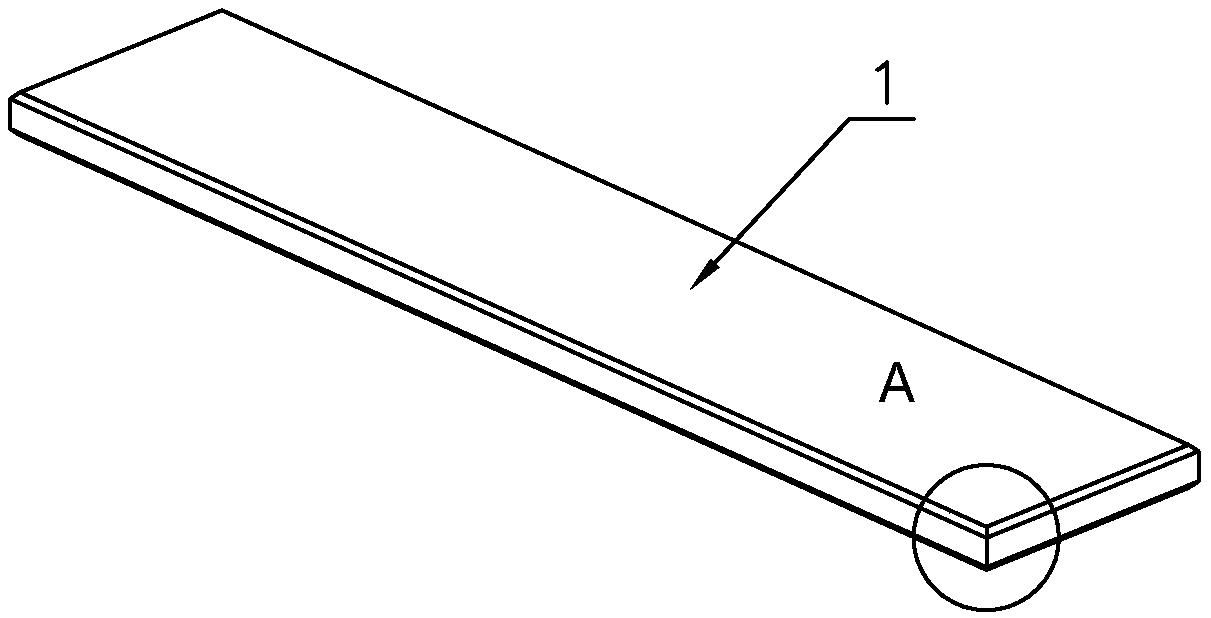

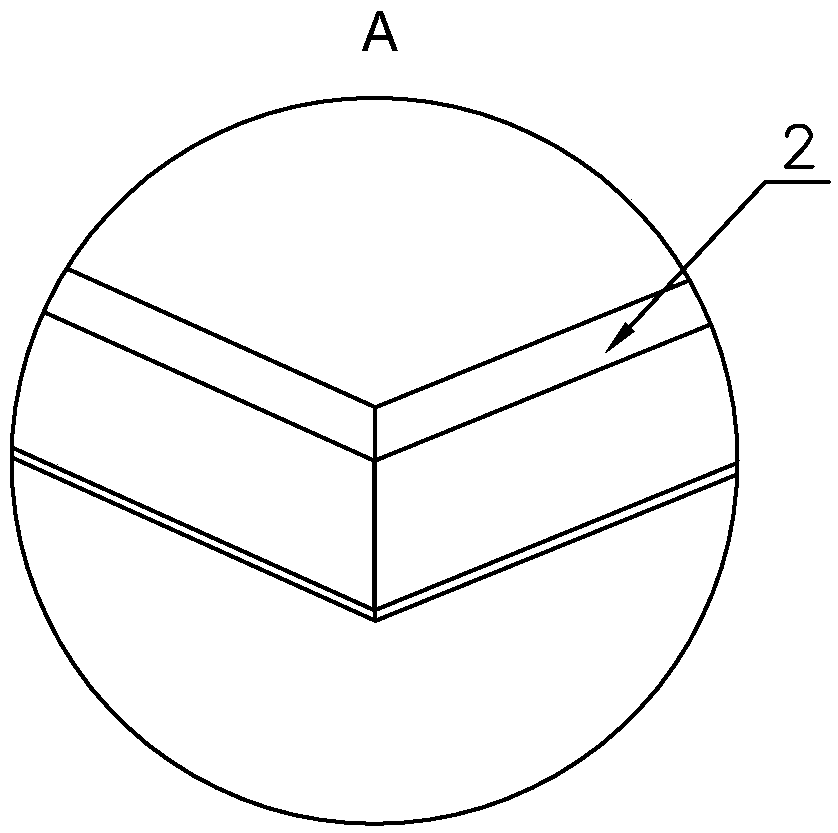

[0051] 1) heating

[0052] The brand name of the titanium ingot is TA1. Before the titanium ingot 1 is heated, the edge of the titanium ingot 1 is cut. The size of the cut corner 2 is 25mm×45°. The thickness is 200mm, and the width is 1200mm. The heating furnace adopts a continuous walking heating furnace. The temperature of the preheating section is 470°C, and the heating time is 100min. The temperature of the first heating section is 750°C, and the heating time is 45min. 950°C, the heating time is 35min, the soaking section temperature is 950°C, the heating time is 35min; the total heating time is 215min, the furnace pressure in the heating furnace is controlled at 5-15Pa, to prevent the cold air outside the heating furnace from being sucked into the furnace to cause heat Loss; the residual oxygen content of each section in the heating furnace is ≤5%, pre...

Embodiment 2

[0076] The difference from Example 1 is that the finish rolling and final rolling forming thickness is 5mm, and the TA1 titanium plate rolled in Example 2 is tested according to the inspection rules and test methods of GB / T 13810-2007, and the test results are as follows:

[0077] The surface quality of the rolled titanium plate is good, the plate shape is square, the edges are neat and free of curling, the tensile strength (Rm) is 310MPa, the yield strength (Rel) is 246MPa, the Rockwell hardness (HRB) is 70, and the elongation after fracture was 68.2%.

Embodiment 3

[0079] The difference from Example 1 is that the thickness of finish rolling and finishing rolling is 15 mm. According to the inspection rules and test methods of GB / T 13810-2007, the TA1 titanium plate rolled in Example 3 is tested, and the test results are as follows:

[0080] The surface quality of the rolled titanium plate is good, the plate shape is square, the edge is neat without curling, the tensile strength (Rm) is 309MPa, the yield strength (Rel) is 246MPa, the Rockwell hardness (HRB) is 70, and the elongation after fracture was 72.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com