Current assisted vacuum rolling method for preparing metal composite plate

A technology of metal composite plate and rolling composite, which is applied in metal rolling, auxiliary arrangement, metal rolling, etc., can solve the problems of long heating time, cumbersome preparation process, poor processing plasticity, etc., and improve the formation of internal microstructure , Improve the distribution of ductile and plastic tissues, and reduce the effect of deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

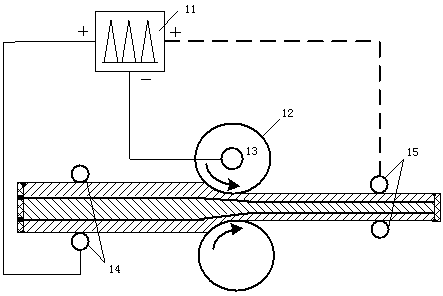

[0028] Fabrication of Titanium-Al-Titanium Composite Plates by Vacuum Electroplastic Rolling

[0029] Specifically include the following steps:

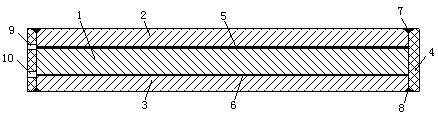

[0030] Select two titanium plates with a thickness of 0.5mm and one aluminum plate with a thickness of 3mm, and cut them so that the width of the plates is 100mm and the length is 500mm;

[0031] Clean the titanium plate with a solution of 1:3:10=hydrofluoric acid: nitric acid: hot water, clean the aluminum plate with 10% sulfuric acid aqueous solution, and then perform mechanical polishing to completely remove the surface oxide layer;

[0032] Sand the deoxidized titanium and aluminum plates with sandpaper to expose the fresh metal on the surface, then clean them with alcohol and acetone solution to remove the surface oil and put them in a ventilated place to dry for later use;

[0033] The treated metal plates are aligned and stacked in the order of titanium / aluminum / titanium to form a composite panel blank, and the composite pane...

Embodiment 2

[0041] Fabrication of Nickel-Titanium Composite Plates by Vacuum Electroplastic Rolling

[0042] Specifically include the following steps:

[0043] Select a titanium plate with a thickness of 1.5mm and a nickel plate with a thickness of 2mm, respectively, and cut them so that the width of the plate is 50mm and the length is 300mm;

[0044] Clean the titanium plate with 1:3:10=hydrofluoric acid: nitric acid: hot water solution, clean the nickel plate with 15% hydrochloric acid aqueous solution, and then, carry out mechanical grinding to completely remove the surface oxide layer;

[0045] Sand the deoxidized titanium and nickel plates with sandpaper to expose the fresh metal on the surface, then clean them with alcohol and acetone solution to remove the surface oil and put them in a ventilated place to dry for later use;

[0046] The processed titanium / nickel metal plates are aligned and stacked to form a composite plate blank, and the sealing welding plate is welded around the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com