Patents

Literature

38results about "Cantilevered roll stands" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

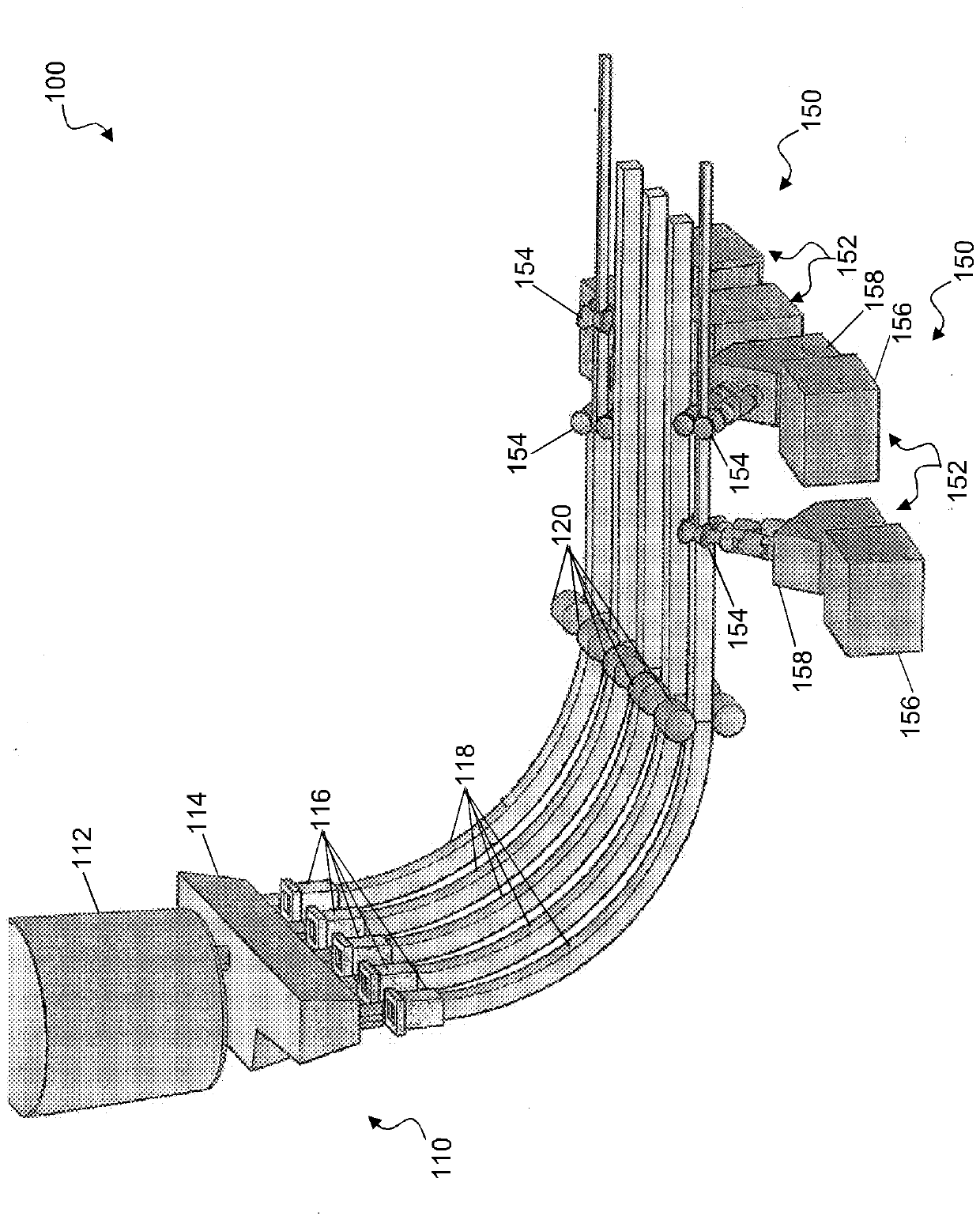

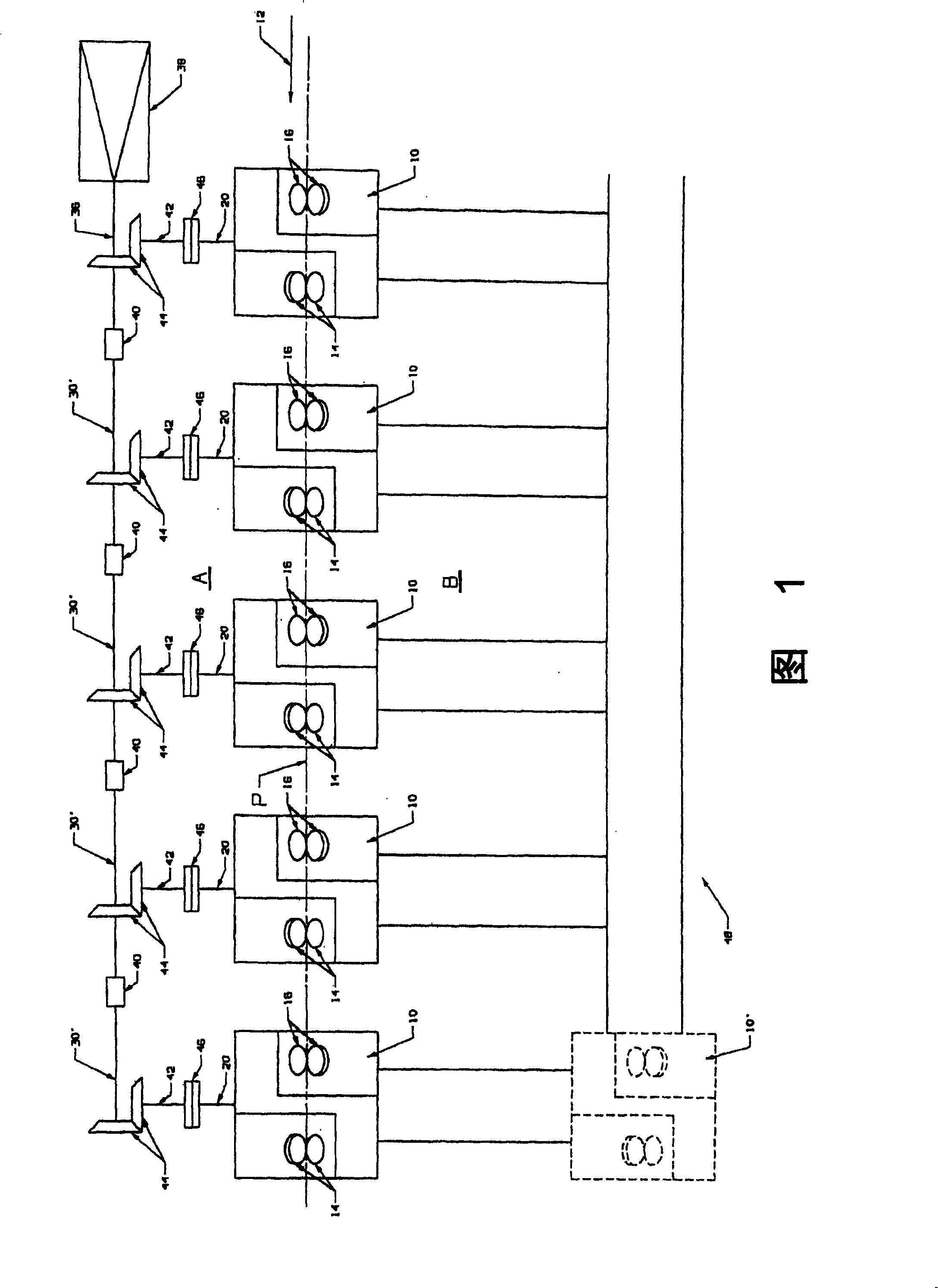

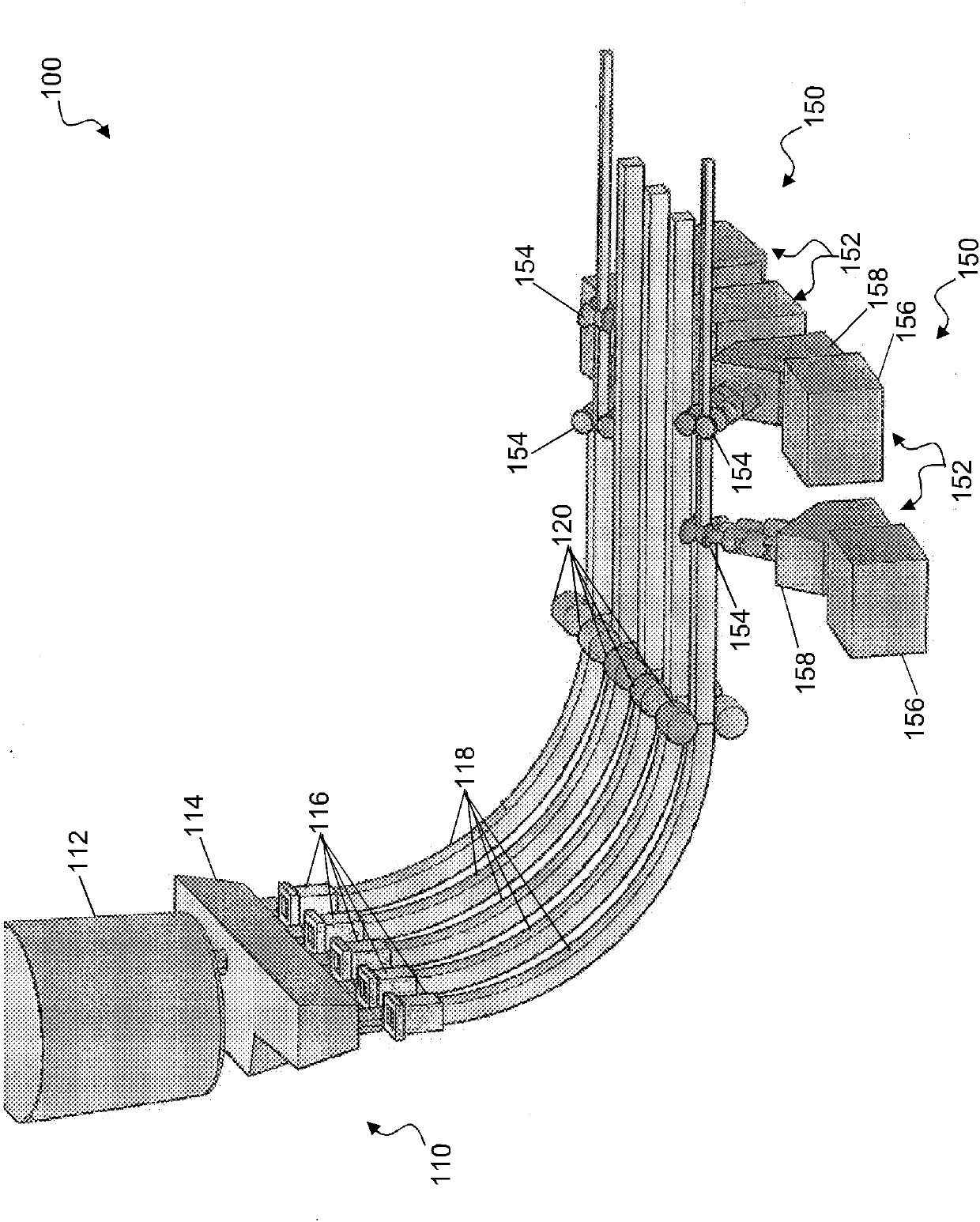

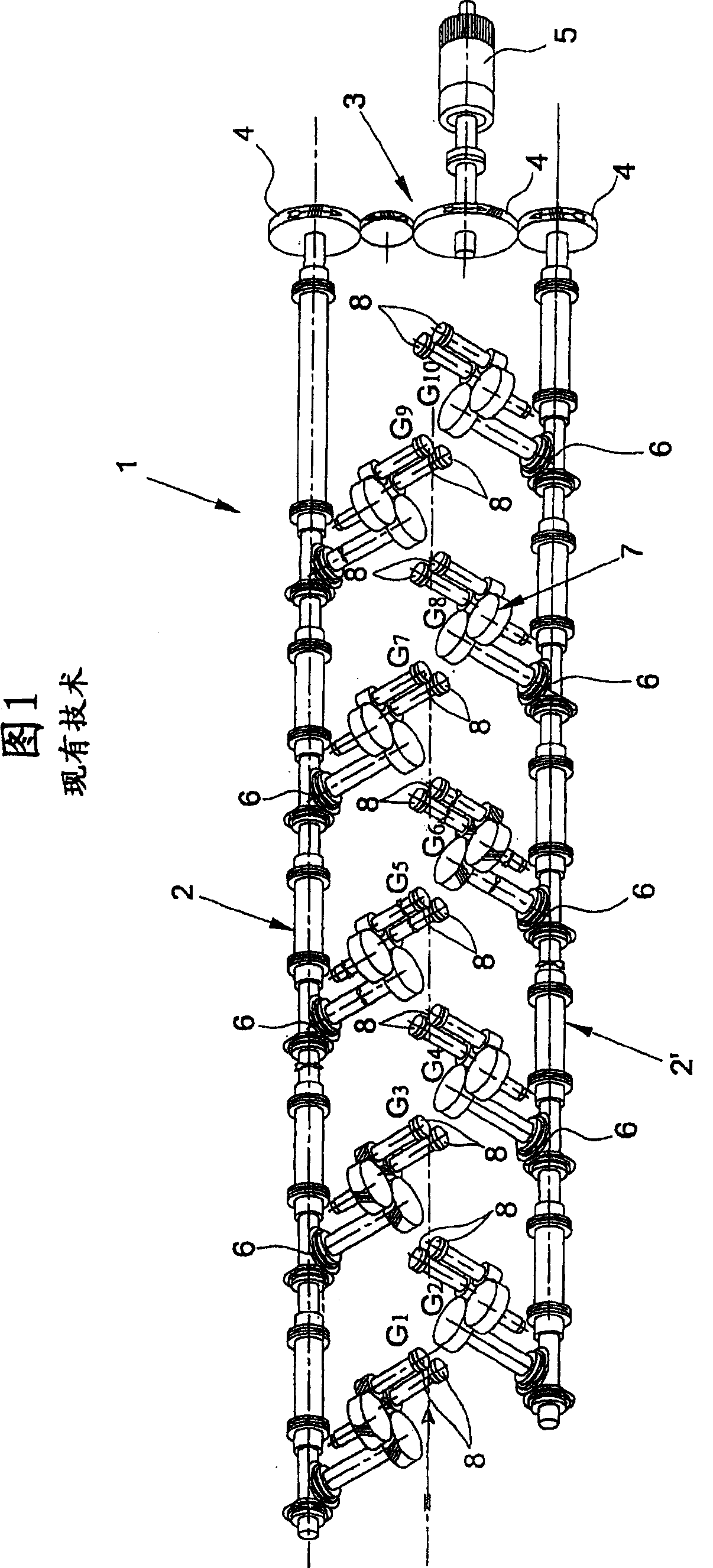

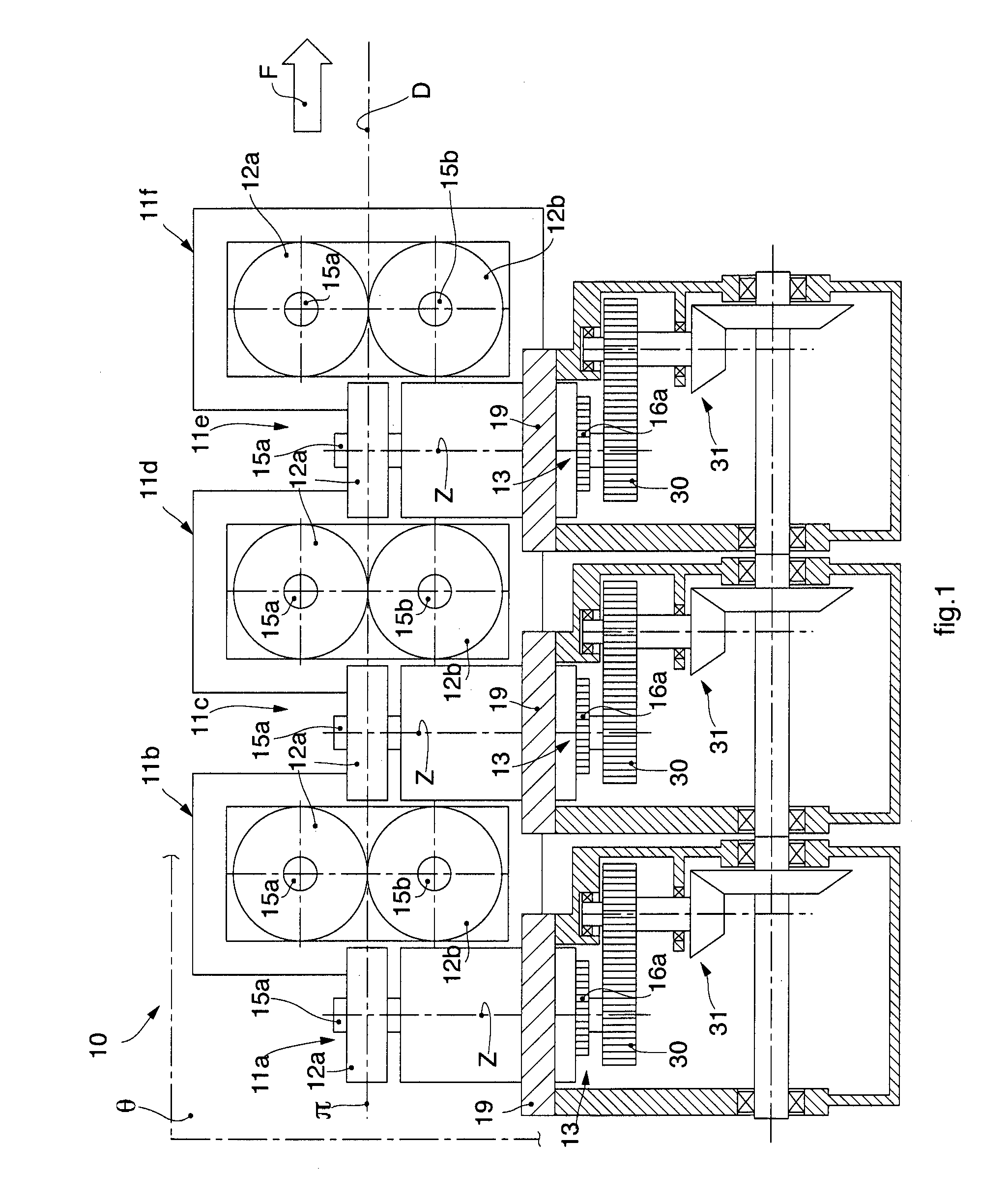

Modular rolling mill

InactiveUS7191629B1Metal rolling stand detailsGuiding/positioning/aligning arrangementsLine shaftWork roll

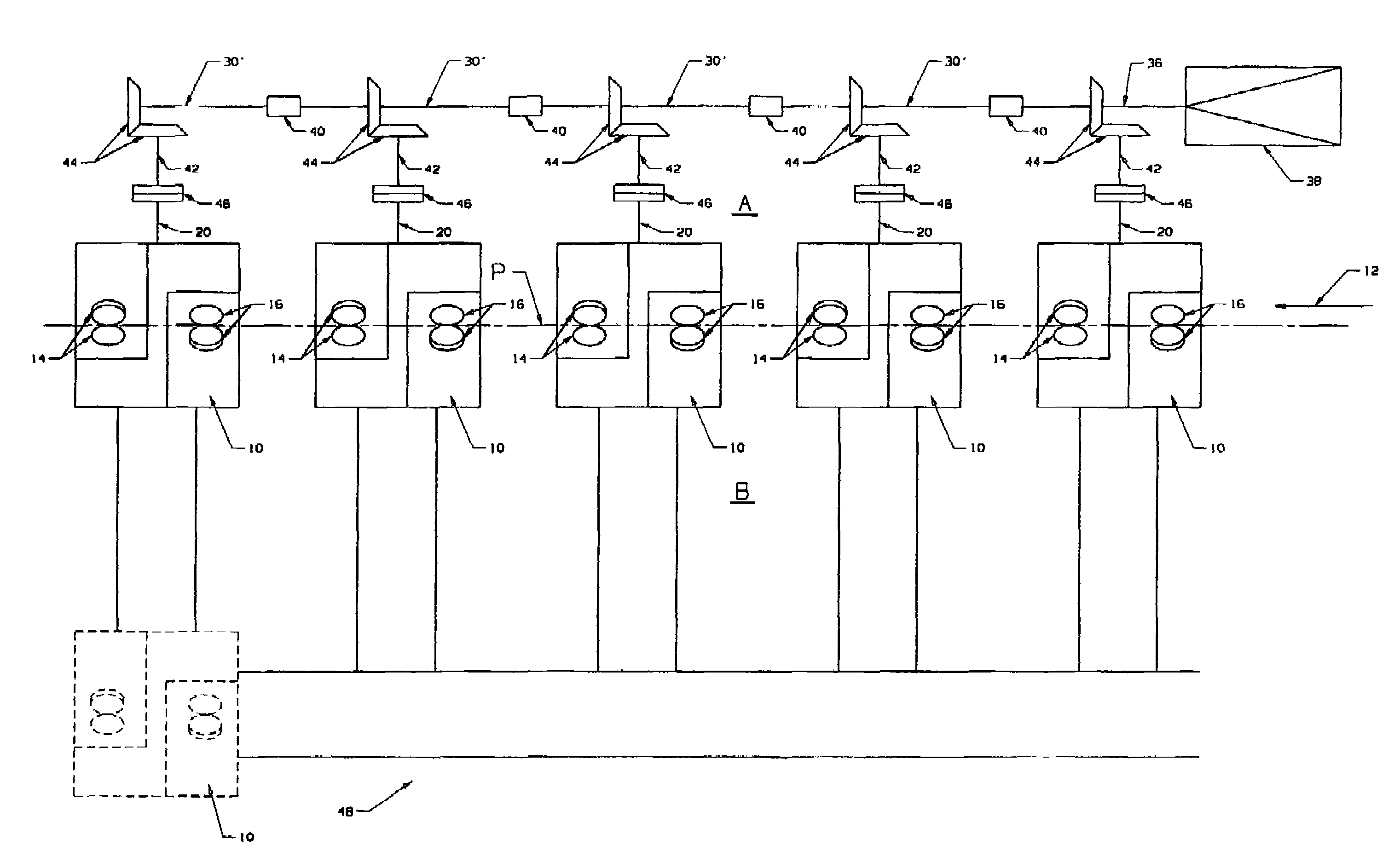

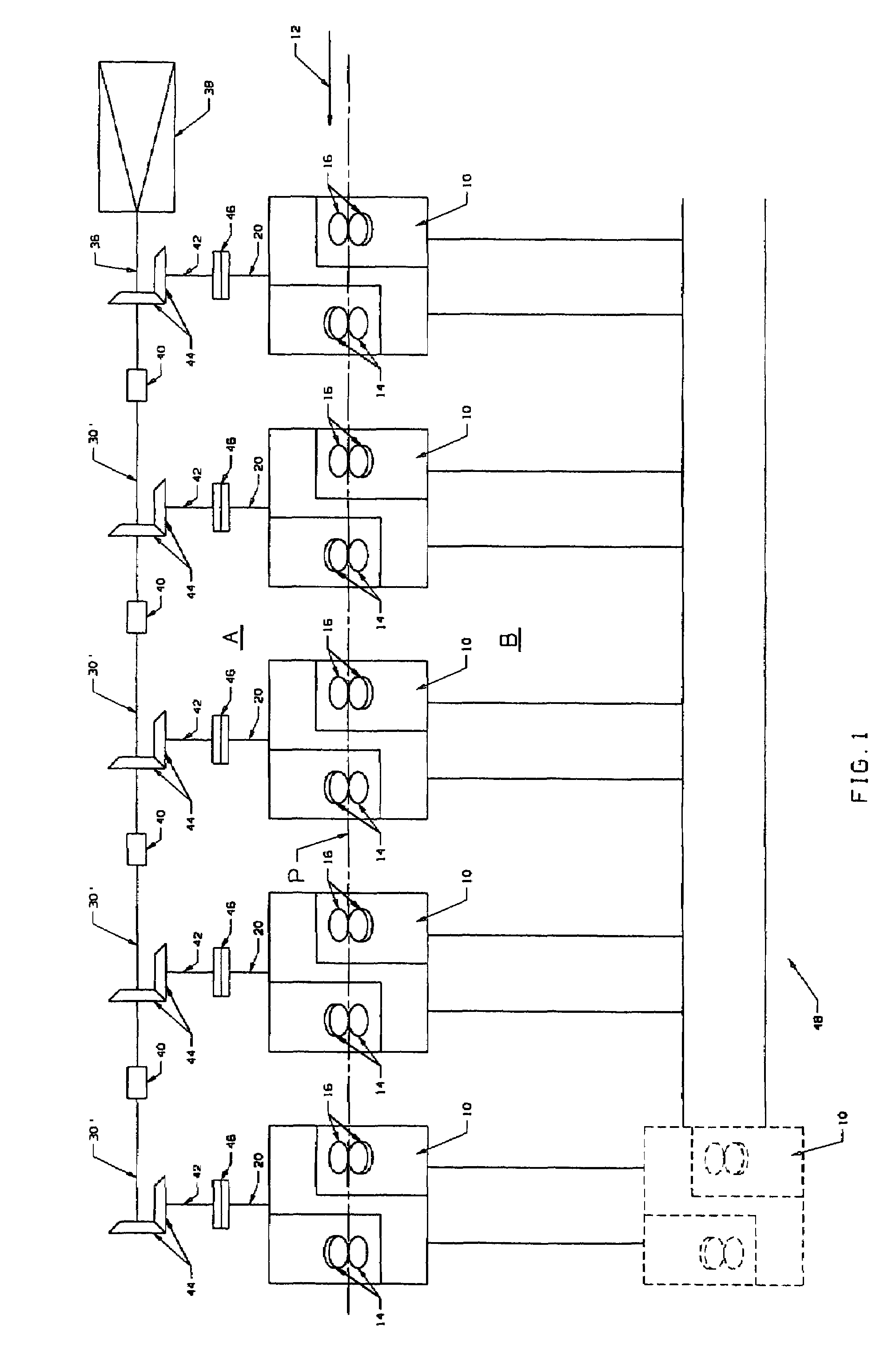

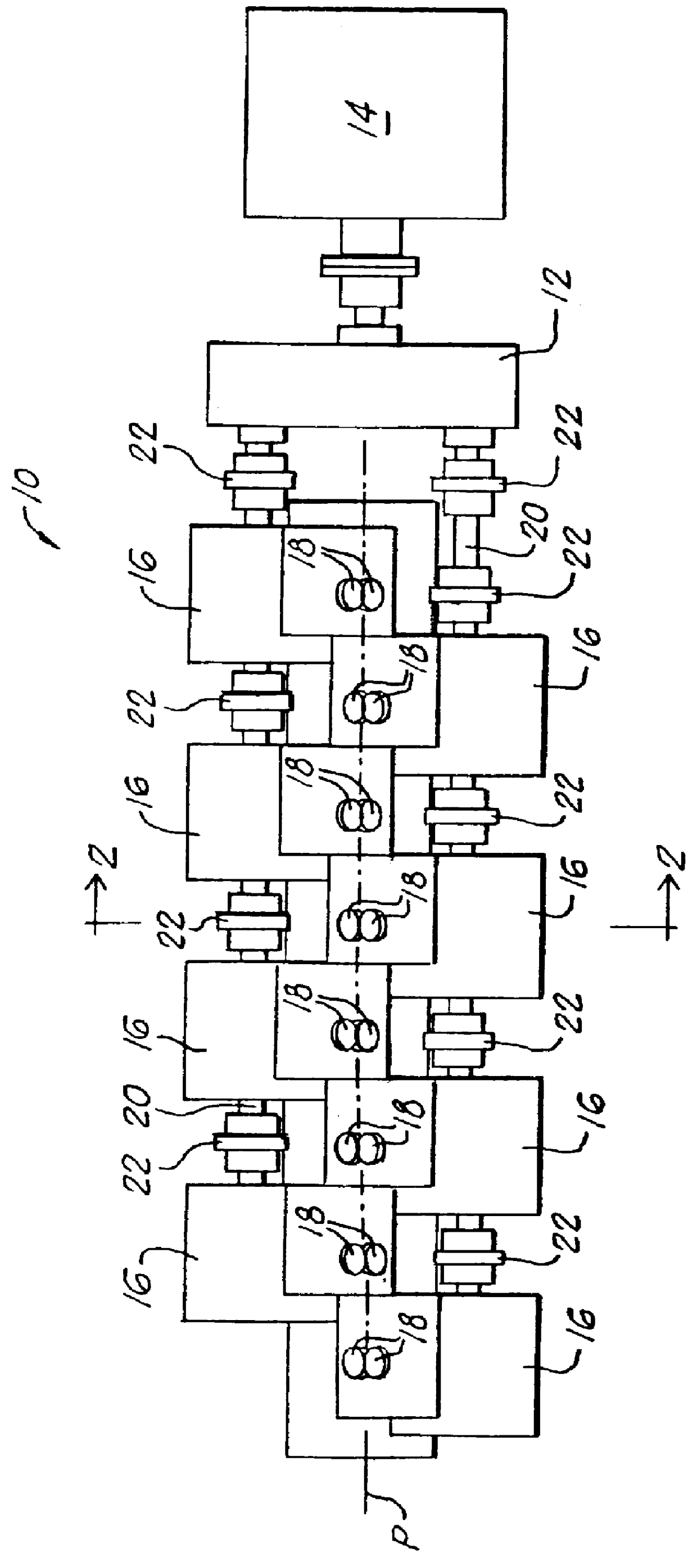

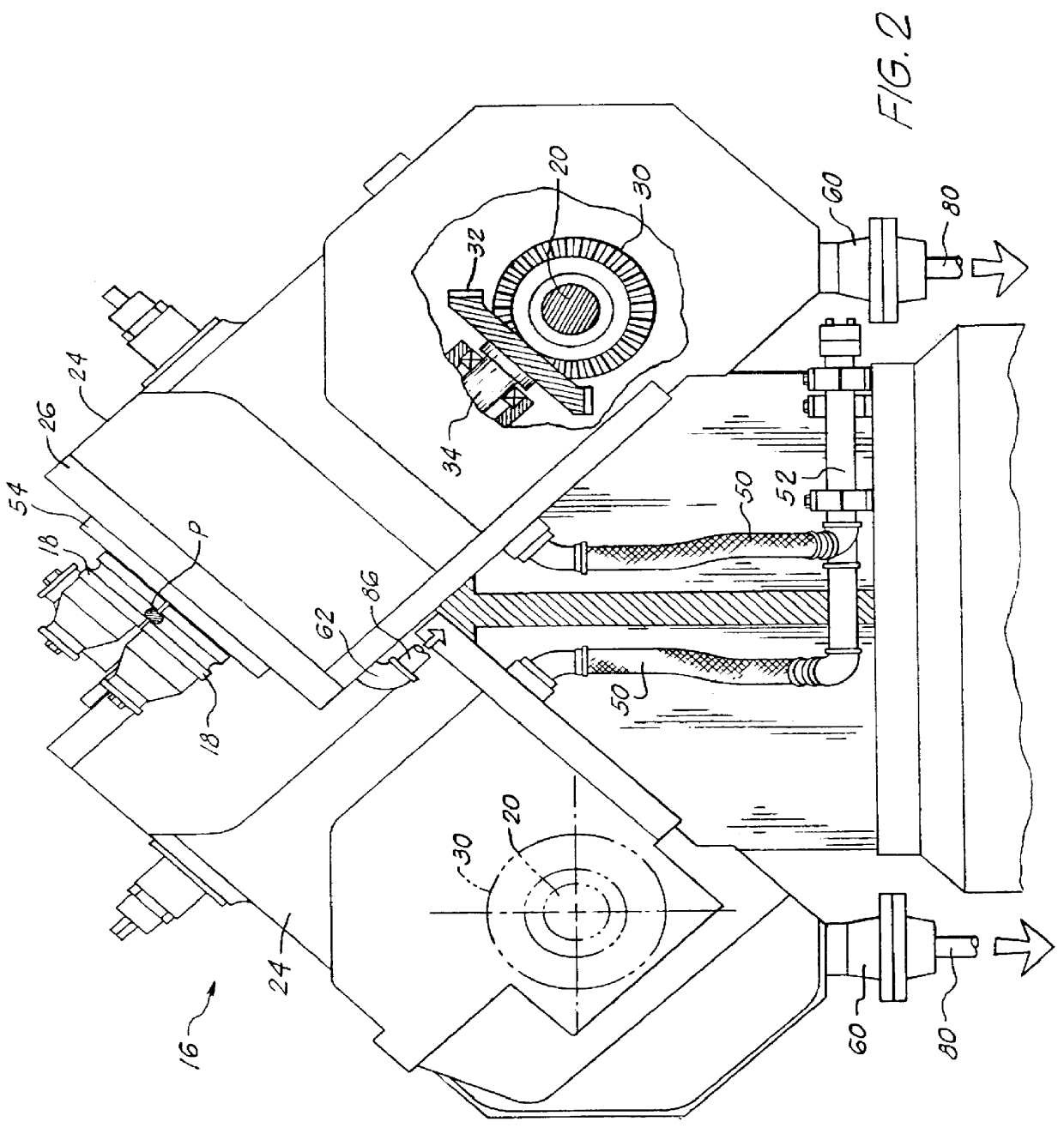

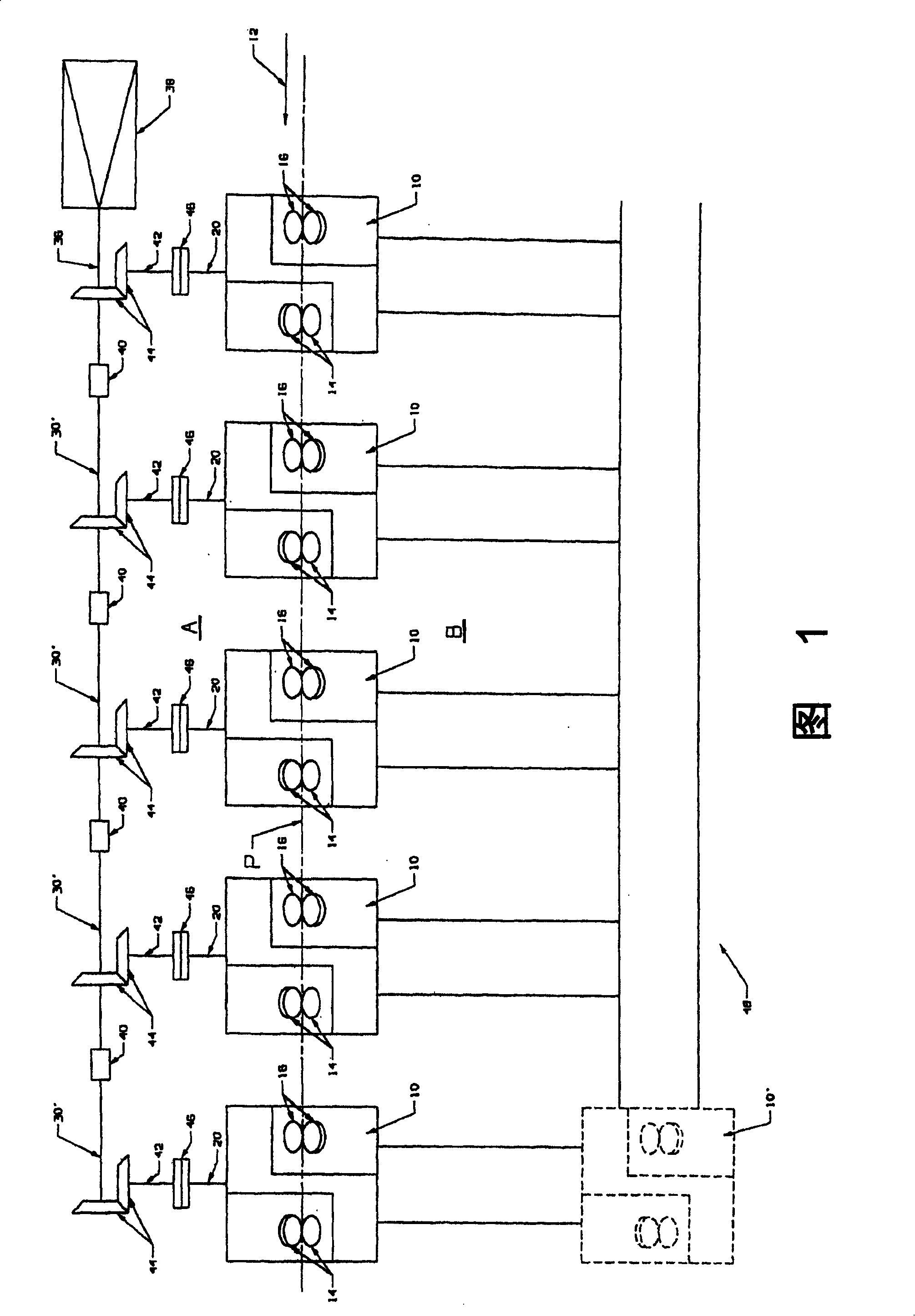

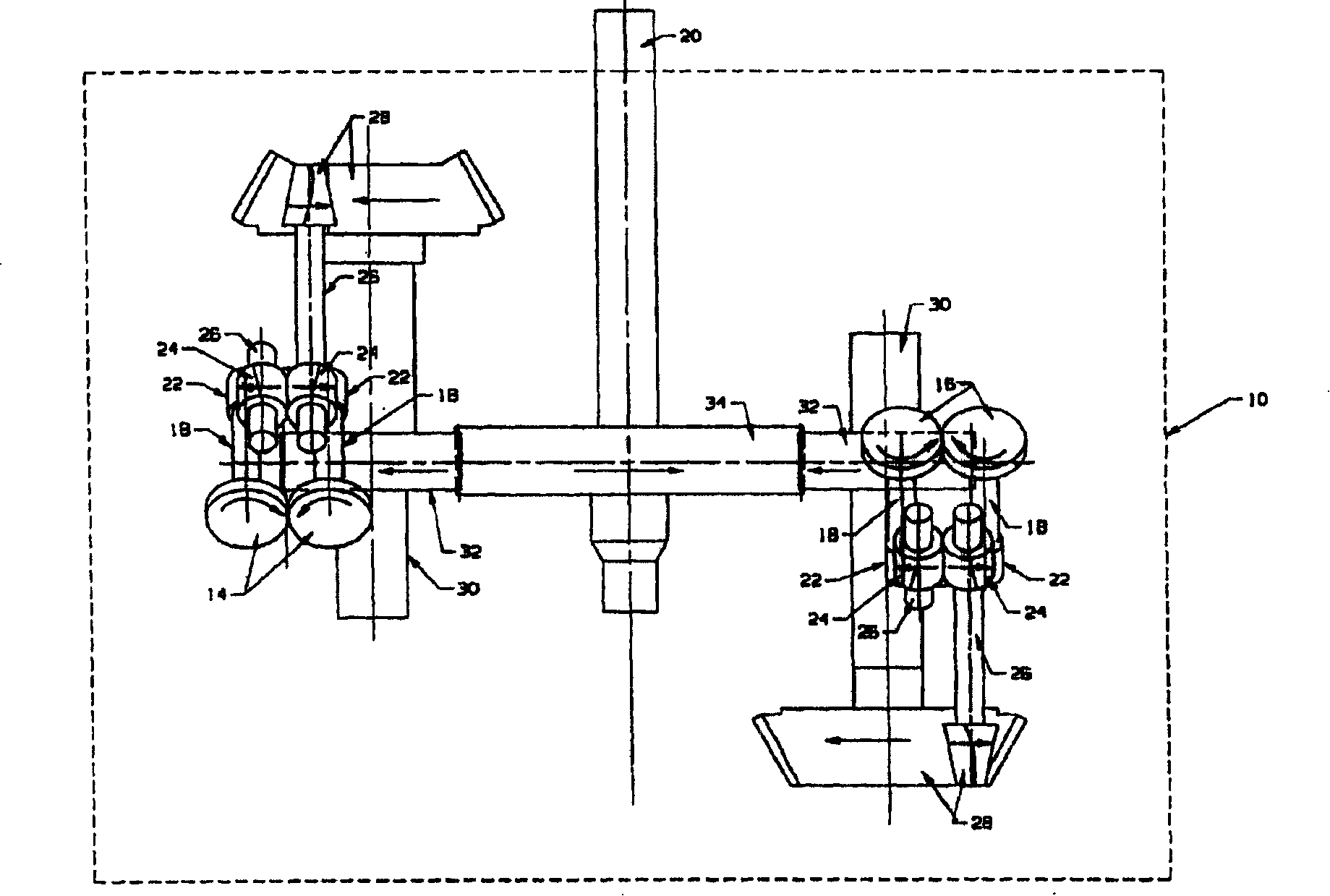

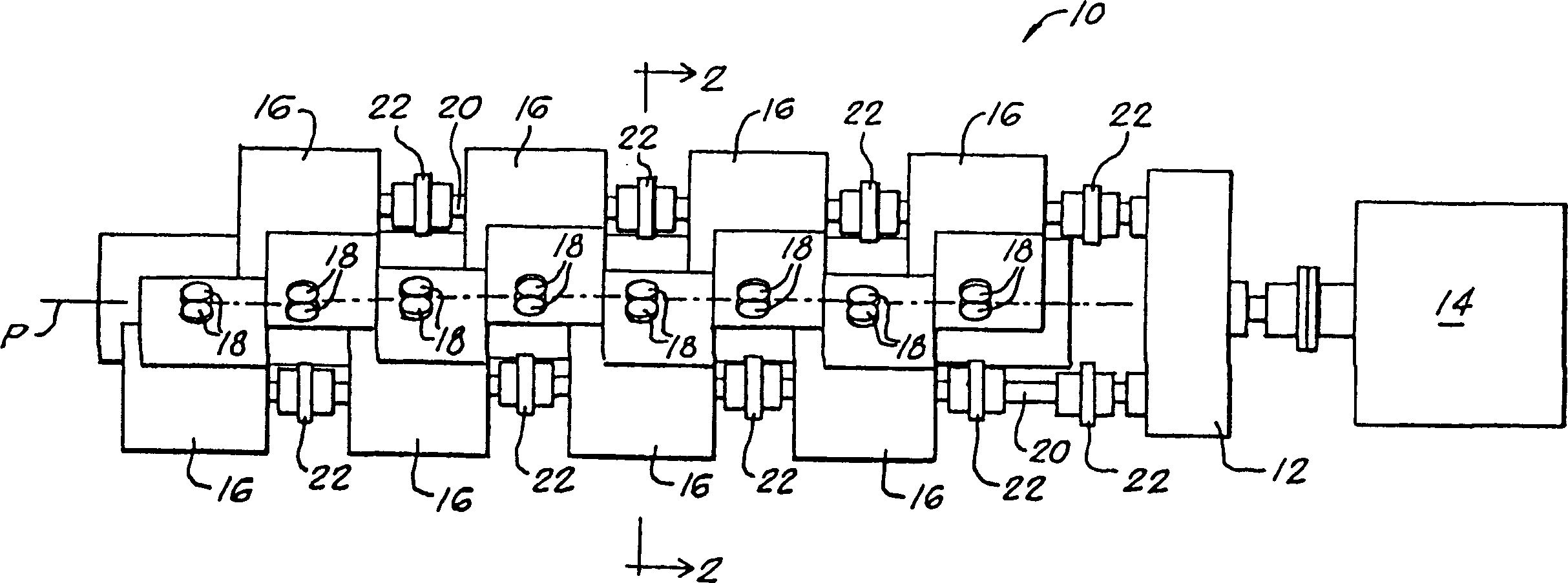

A modular rolling mill comprises a plurality of separate rolling units arranged along a mill pass line. Each rolling unit includes at least two pairs of work rolls defining oval and round roll passes and carried on roll shafts that are staggered 90° with respect to each other. The rolling units contain intermediate drive trains configured to connect the roll shafts to parallel input shafts projecting to a first side of the pass line from the respective rolling units. A single driven line shaft is parallel to and on the first side of the pass line. Output shafts are mechanically coupled to the line shaft by bevel gear sets. The output shafts project laterally from the line shaft towards the pass line and are connected by separable couplings to the input shafts of the rolling units.

Owner:PRIMETALS TECH USA

Lubrication system

A system is disclosed for applying a liquid lubricant to first and second components enclosed in a housing, with the lubricant applied to the second components being exposed to contamination by a liquid coolant applied to the exterior of the housing, and with the lubricant applied to the first components being substantially isolated from the liquid coolant. The system includes a partition internally subdividing the housing into a first chamber containing the first components and a second chamber containing the second components. Lubricant is delivered from a storage tank to the housing for application to the first and second components. A first conduit network communicates with the first chamber for returning the lubricant applied to the first components to the storage tank, and a second conduit network communicates with the second chamber for returning lubricant applied to the second components to the storage tank. A liquid coolant removal unit in the second conduit network removes liquid coolant from the lubricant being returned to the storage tank.

Owner:SIEMENS IND INC

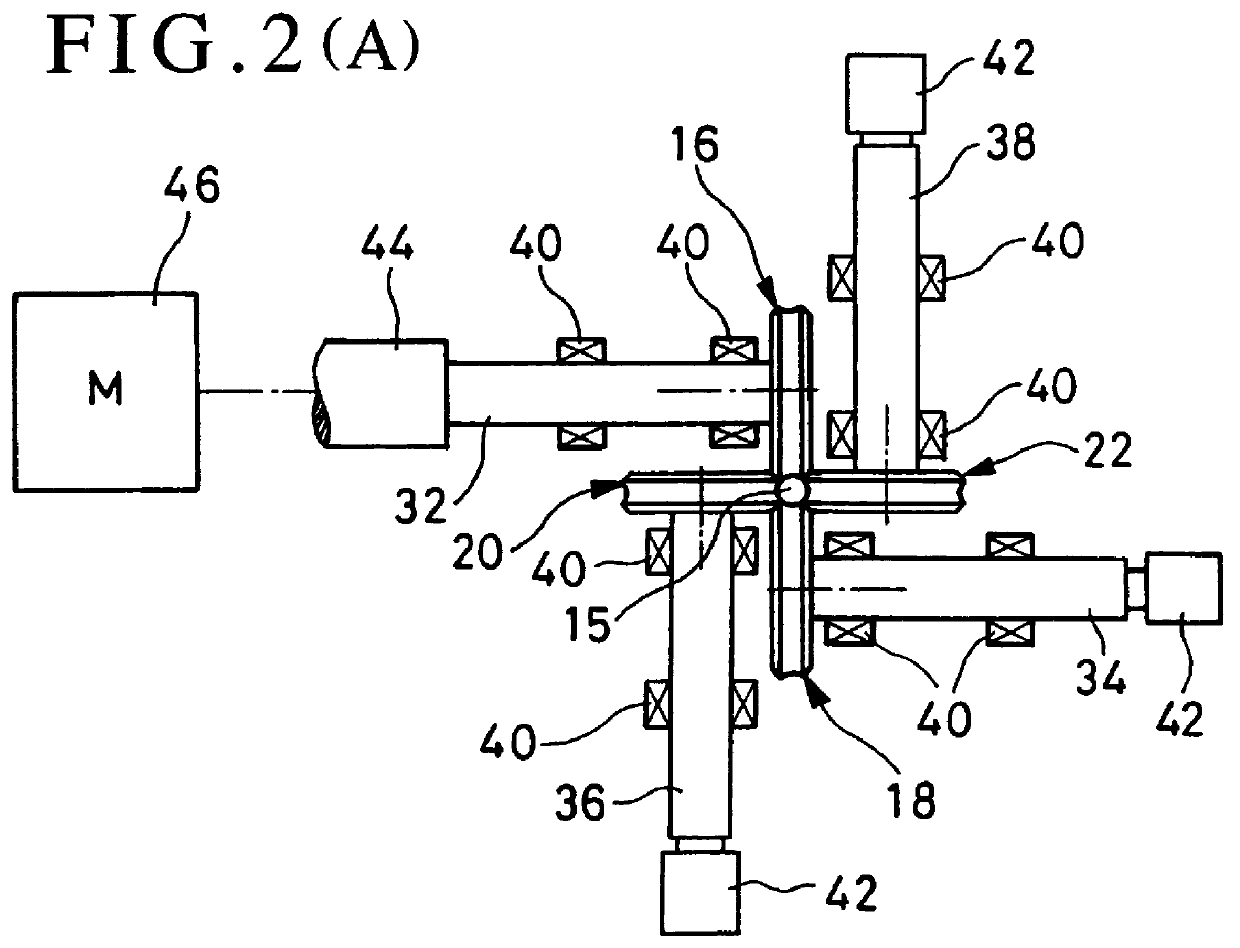

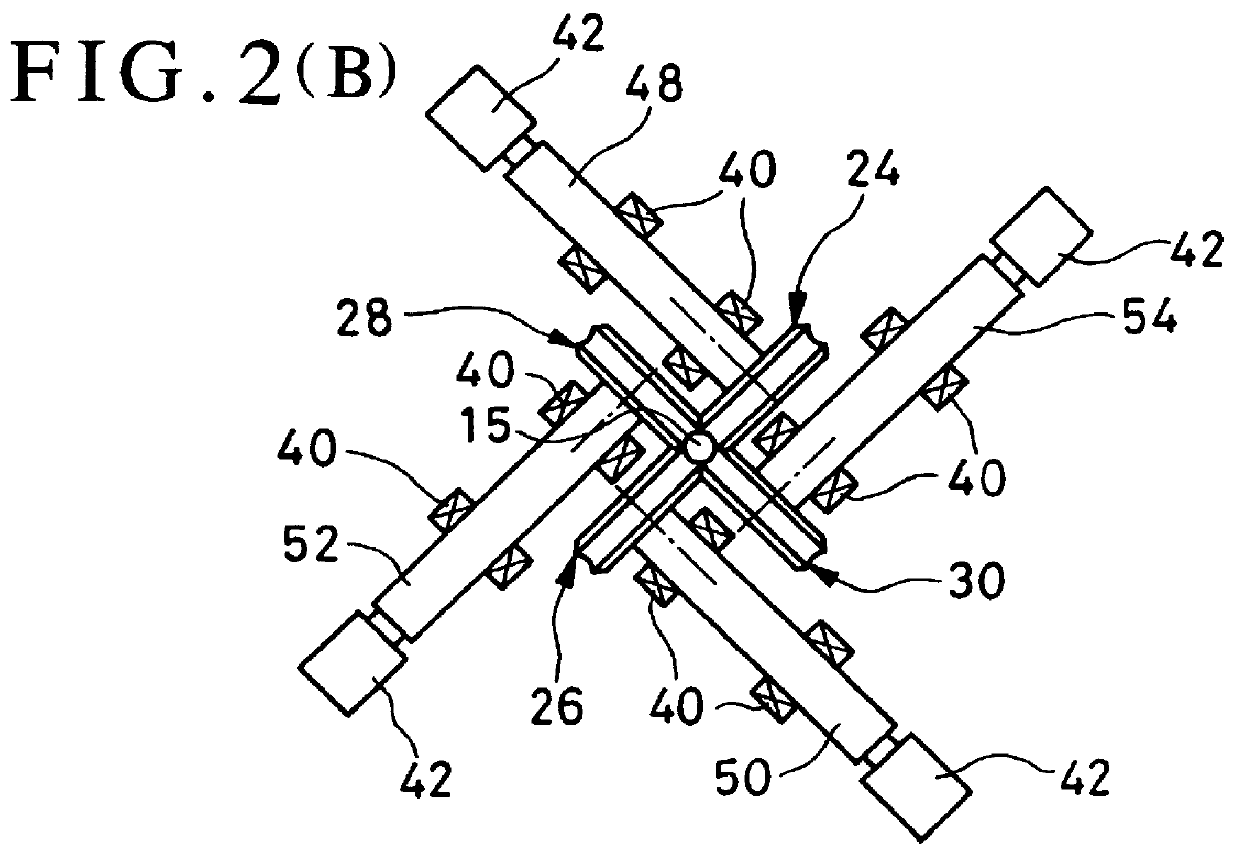

Eight-roller type rolling mill and method of rolling using the mill

A final finish-rolling stand of a rolling machine for producing round bar material is constructed as an eight-roller type rolling machine comprising: front four rollers of "+" distribution and back four rollers of "X" distribution which are contained in one housing block. Only one driving source is used for the rolling machine, and the driving force from the driving source is transmitted to one roller of the front four rollers to forcibly drive this roller. The remaining rollers are freely rotatable and rotate synchronously with transfer of the material being rolled so as to carry out rolling down of the material. Structure of the rolling machine is simple and adjustable range of sizes of the product is wide.

Owner:DAIDO STEEL CO LTD

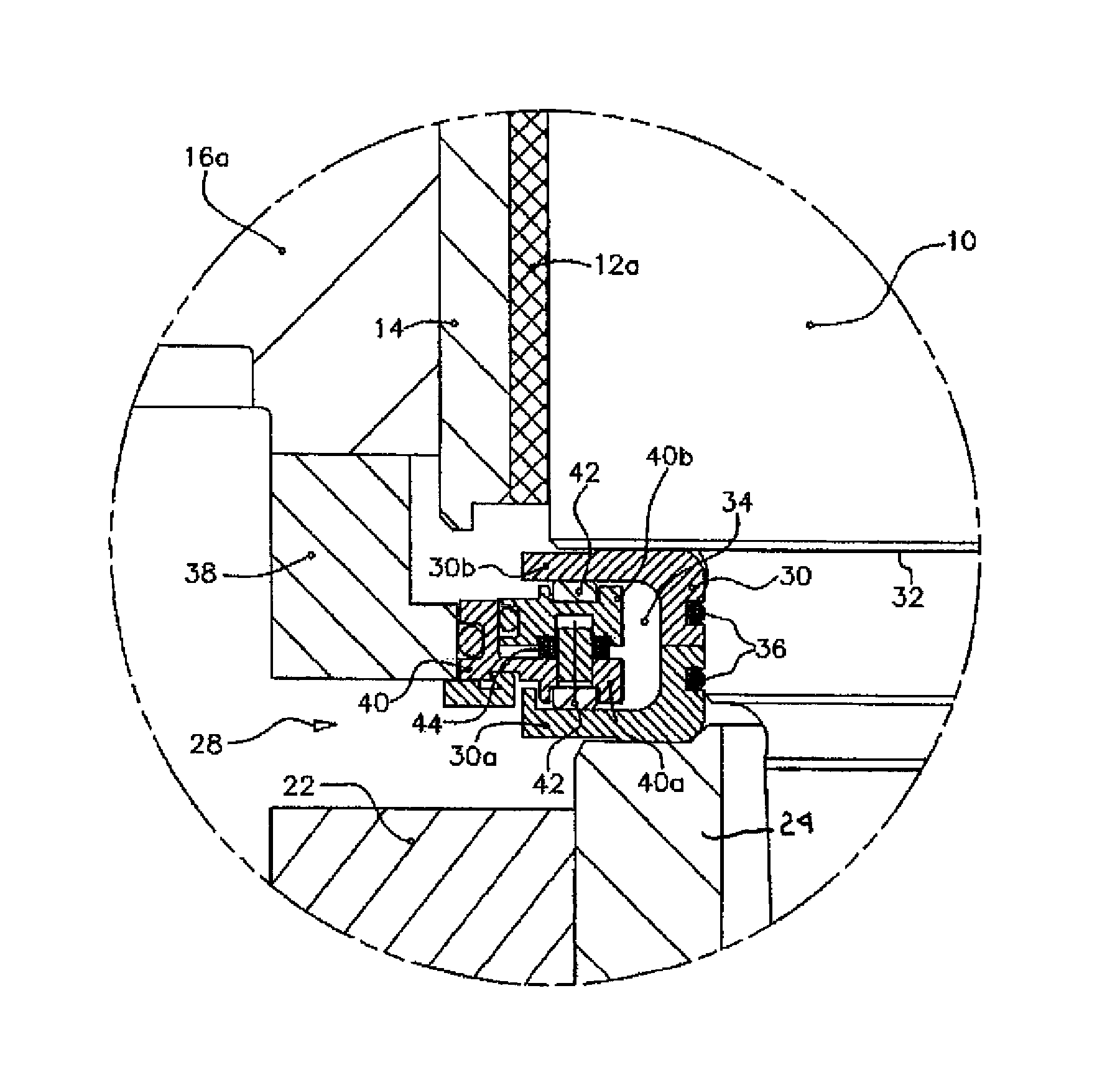

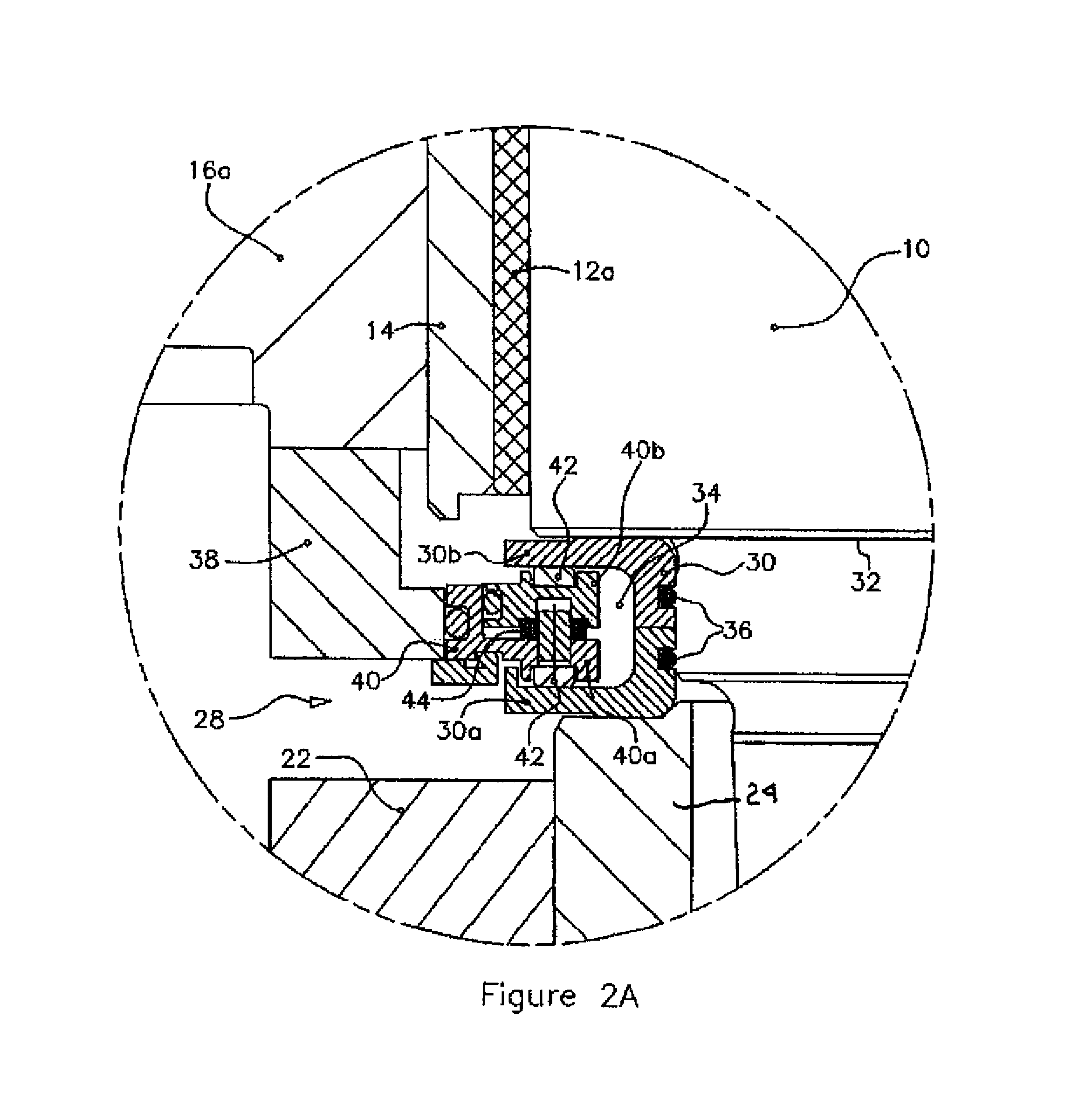

Seal assembly

ActiveUS20120018956A1Compensate for misalignmentIncrease contactEngine sealsMetal rolling stand detailsEngineeringFlange

A seal assembly is disclosed for use between a housing and a rotatable shaft protruding exteriorly from the housing, with the shat being journalled for rotation in an eccentric cartridge which in turn is rotatably adjustable. The seal assembly comprises a circular flinger mounted on the shaft for rotation therewith. The flinger has radially outwardly projecting flanges defining an axial space therebetween. A seal carrier surrounds the flinger and has axially spaced first and second inner rims projecting radially inwardly into the space between the flanges of the flinger. Ring seals are carried by the seal carriers. The inner rims are resiliently urged to maintain the ring seals in contact with the flinger flanges.

Owner:PRIMETALS TECH USA

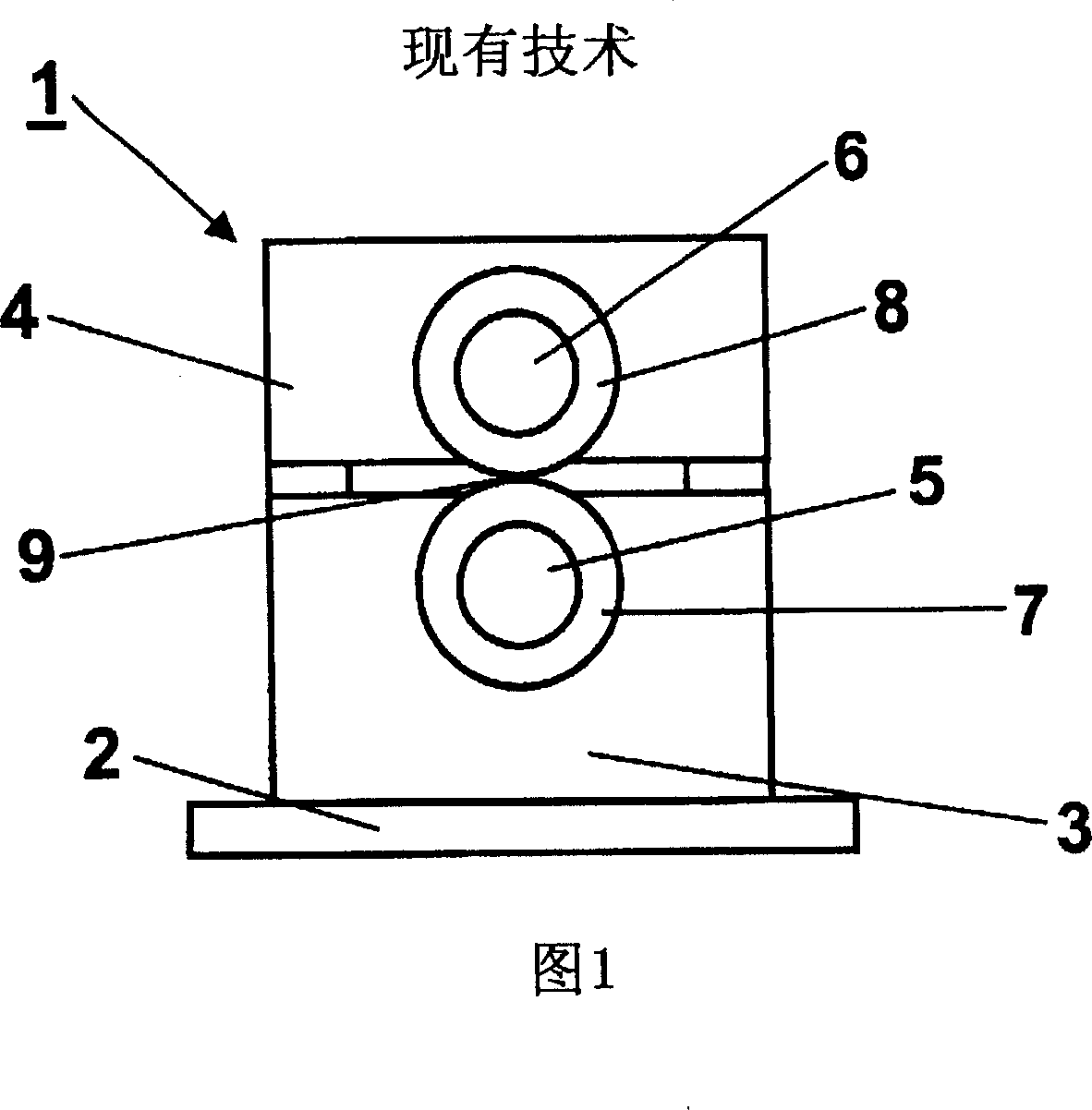

Modular rolling mill

InactiveCN101229551AMetal rolling stand detailsGuiding/positioning/aligning arrangementsLine shaftWork roll

A combination rolling mill includes a plurality of separate rolling units arranged along a mill pass line. Each rolling unit comprises at least two pairs of work rolls defining elliptical and circular rolling channels and supported on roll axes staggered at 90° relative to each other. The rolling units comprise an intermediate drive system configured to connect the roller shafts to parallel input shafts protruding from the respective rolling unit towards the first side of the pass line. A single transmission power axis is parallel to the roll line and on a first side of the roll line. The output shaft is mechanically coupled to the power shaft by a bevel gear set. An output shaft protrudes laterally from the power shaft roll line and is connected to the input shaft of the rolling unit by a separable coupling.

Owner:PRIMETALS TECH USA

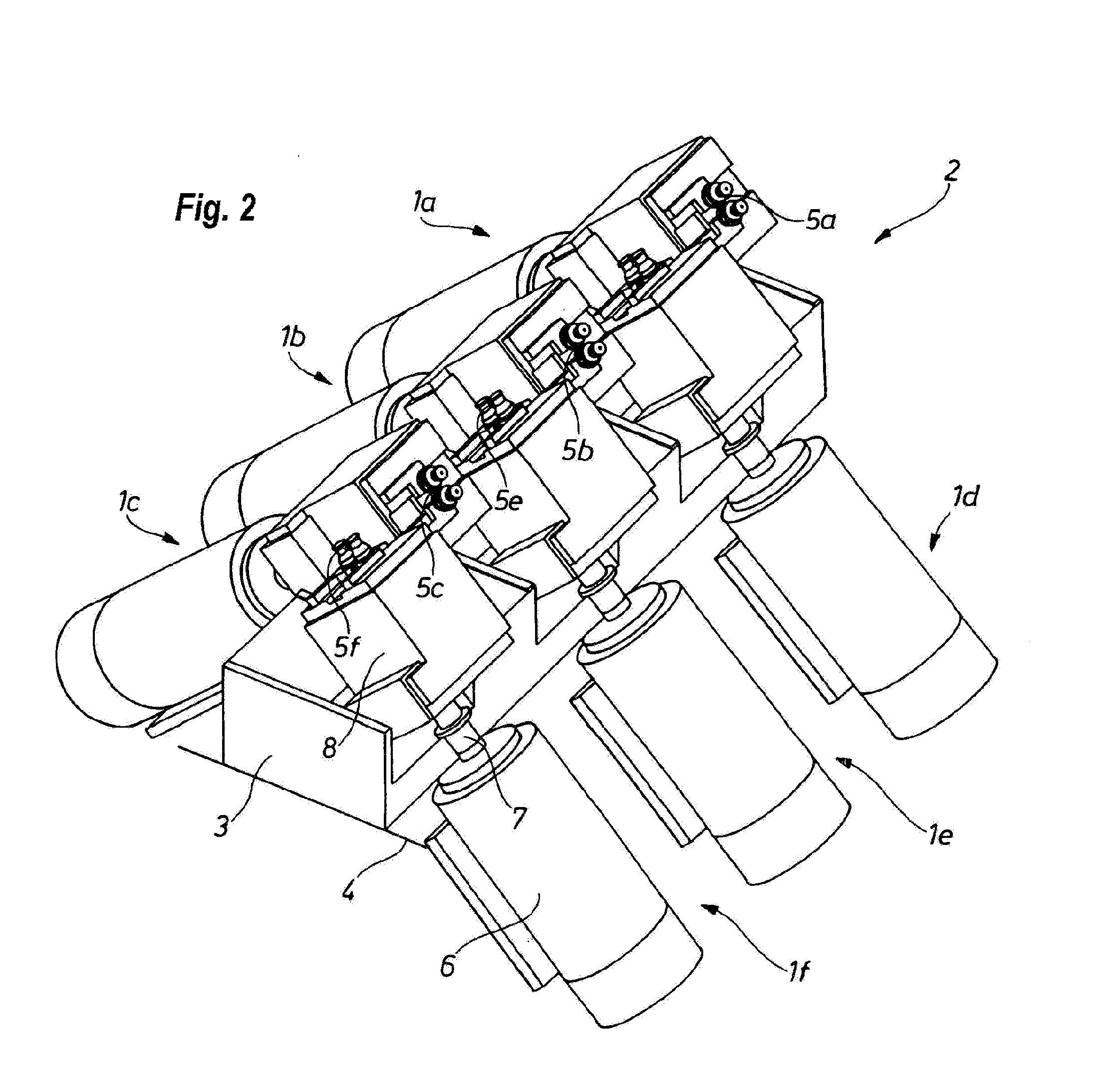

Wire roll stand with individual drive

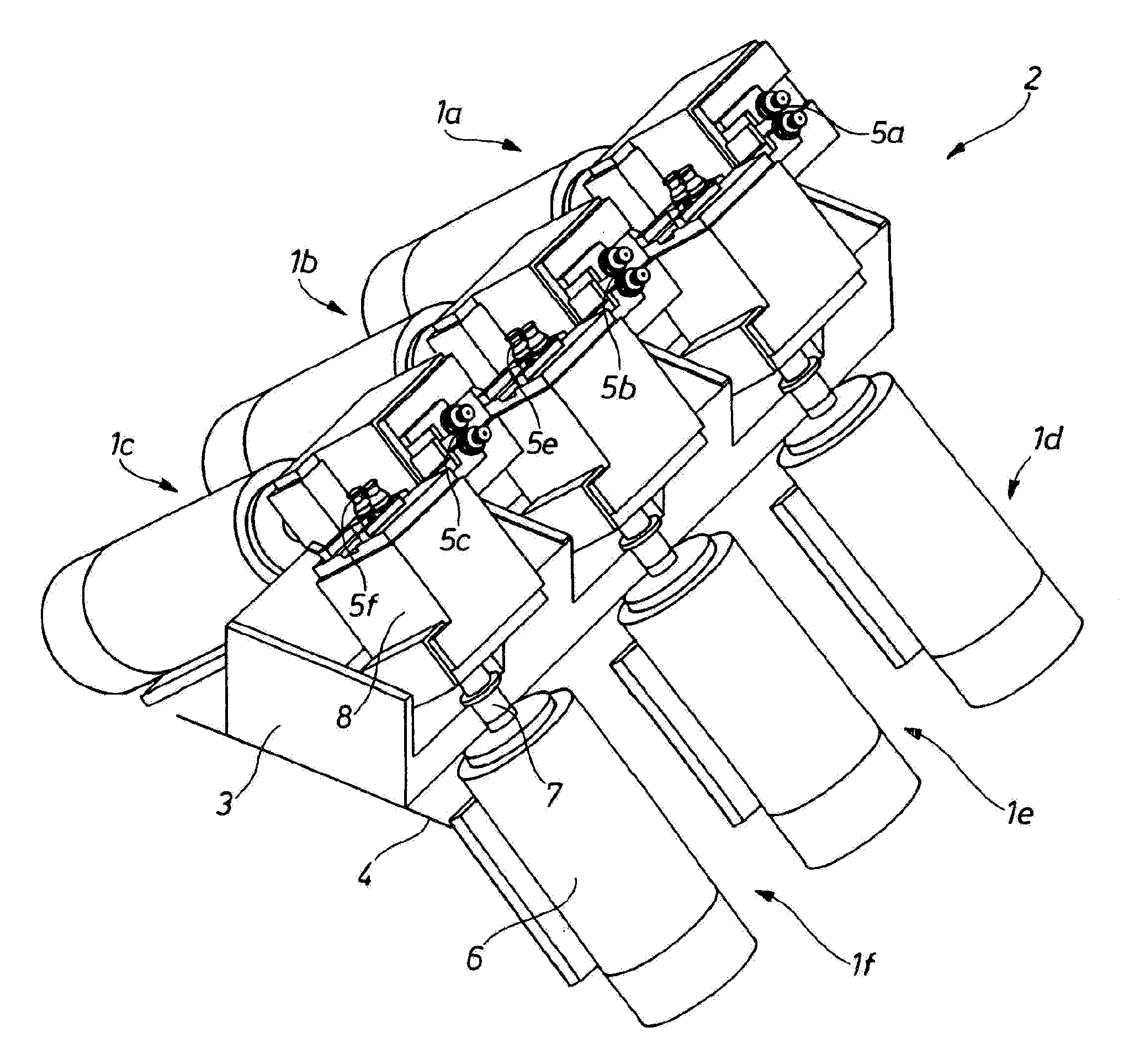

ActiveUS20120216588A1Increase flexibilityFlexible mannerMetal rolling stand detailsRolling mill drivesWire rodDrive shaft

The invention relates to a roll stand (1) as a constituent part of a roll stand group (2) in a high-speed wire mill, having at least one roll pair or roll ring pair (5) and a drive shaft (7) which is connected to a motor (6), characterized in that each roll stand (1) of this roll stand group (2) is assigned a motor (6) and a drive shaft (7), and the motor (6), the drive shaft (7) and the at least one roll pair or roll ring pair (5) are arranged linearly with respect to one another.

Owner:SMS MEER

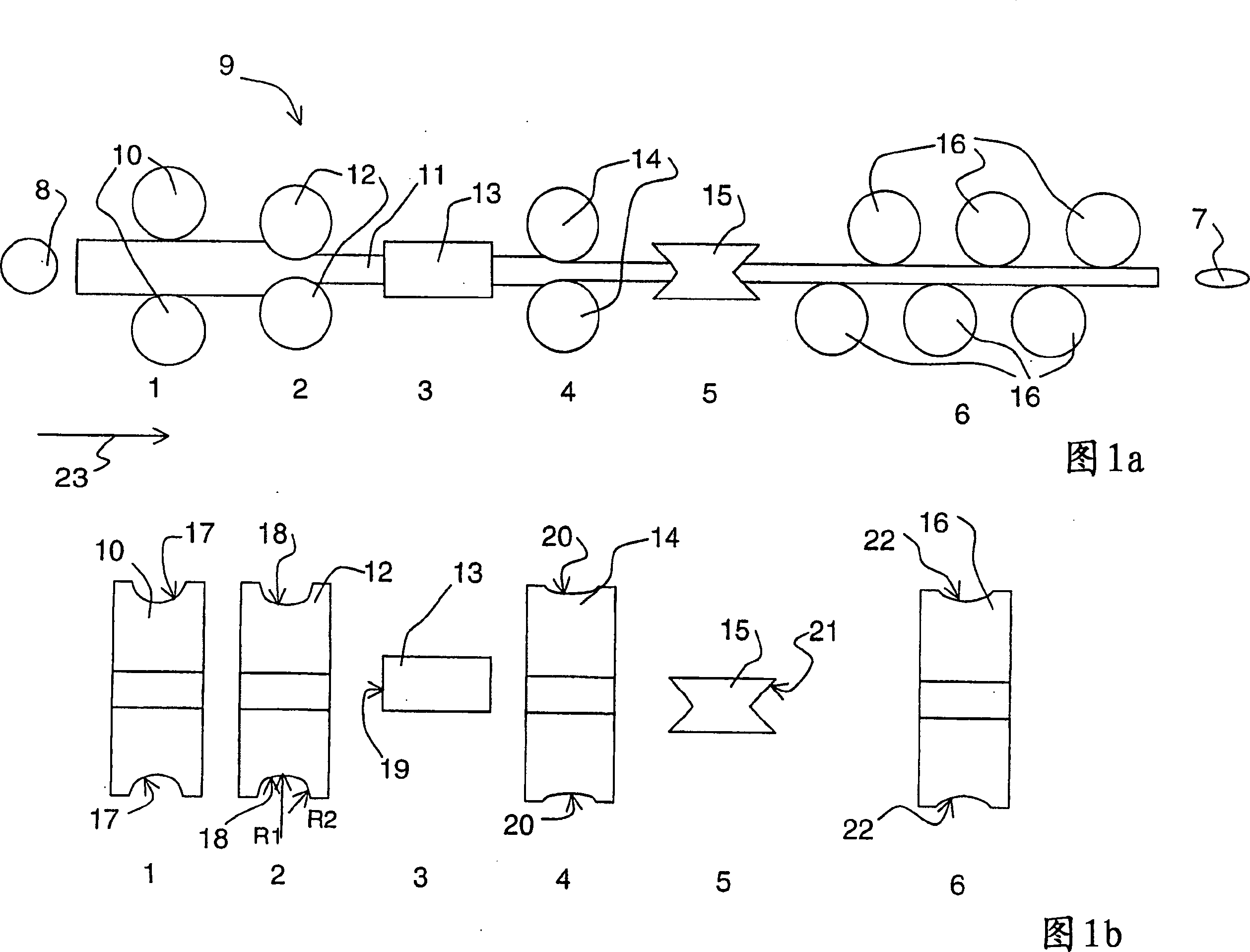

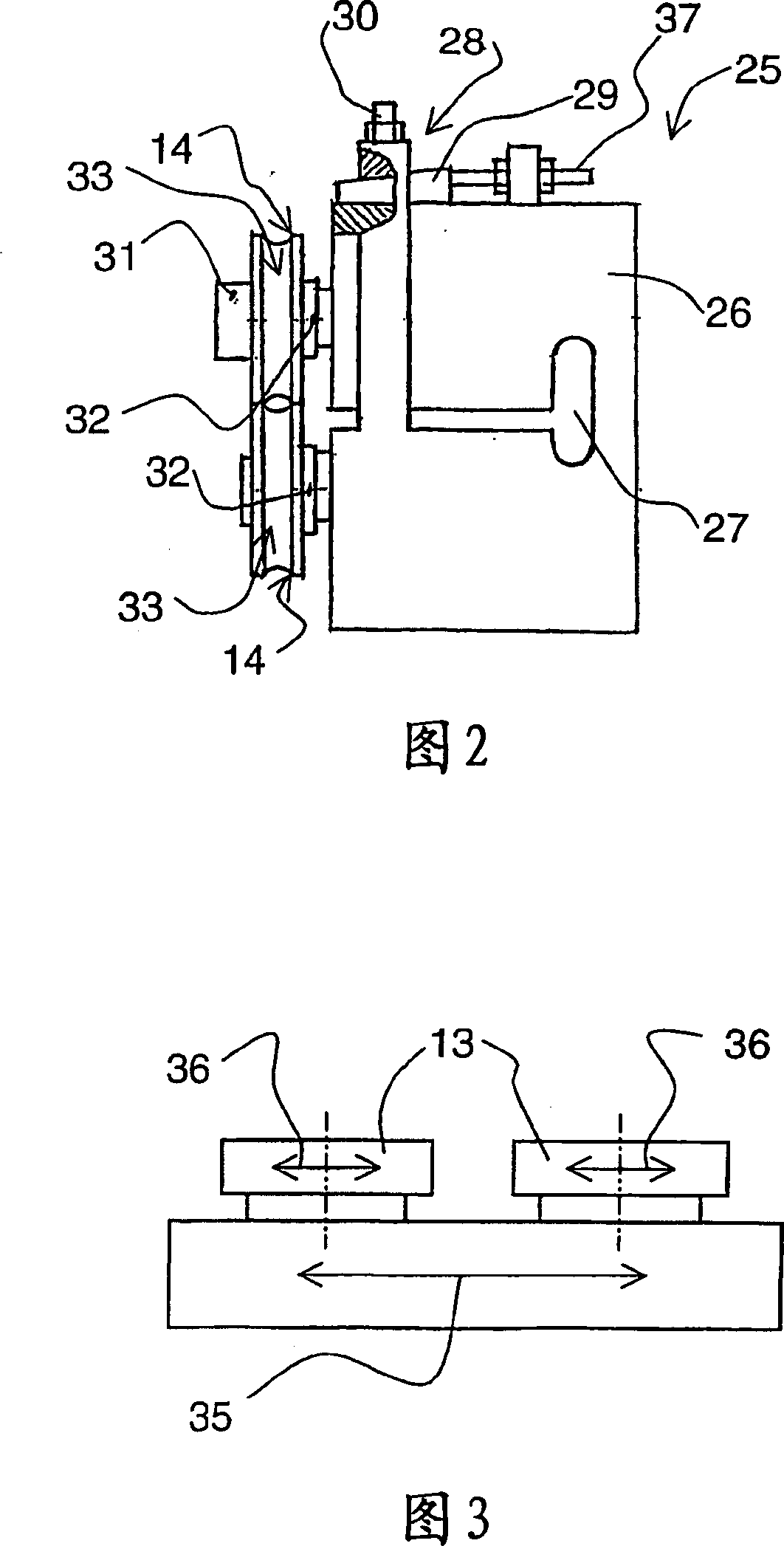

Method and apparatus for rolling a tube

InactiveCN1705527AReduce widthAvoid stayingMetal rolling stand detailsAuxillary arrangementsMetalMaterials science

The invention relates to a method for manufacturing ovalshaped metal tubes, where an essentially round-shaped metal tube is rolled both in the sideways direction and in the vertical direction of the tube, so that the metal tube (11) is rolled at least in two steps (2,4), and that between said rolling steps (2,4), the metal tube is rolled at least once in a direction that is perpendicular to the rolling direction of the rollng steps (2,4). In addition, the invention relates to an apparatus for manufacturing ovalshaped metal tubes.

Owner:库伯利集团有限公司

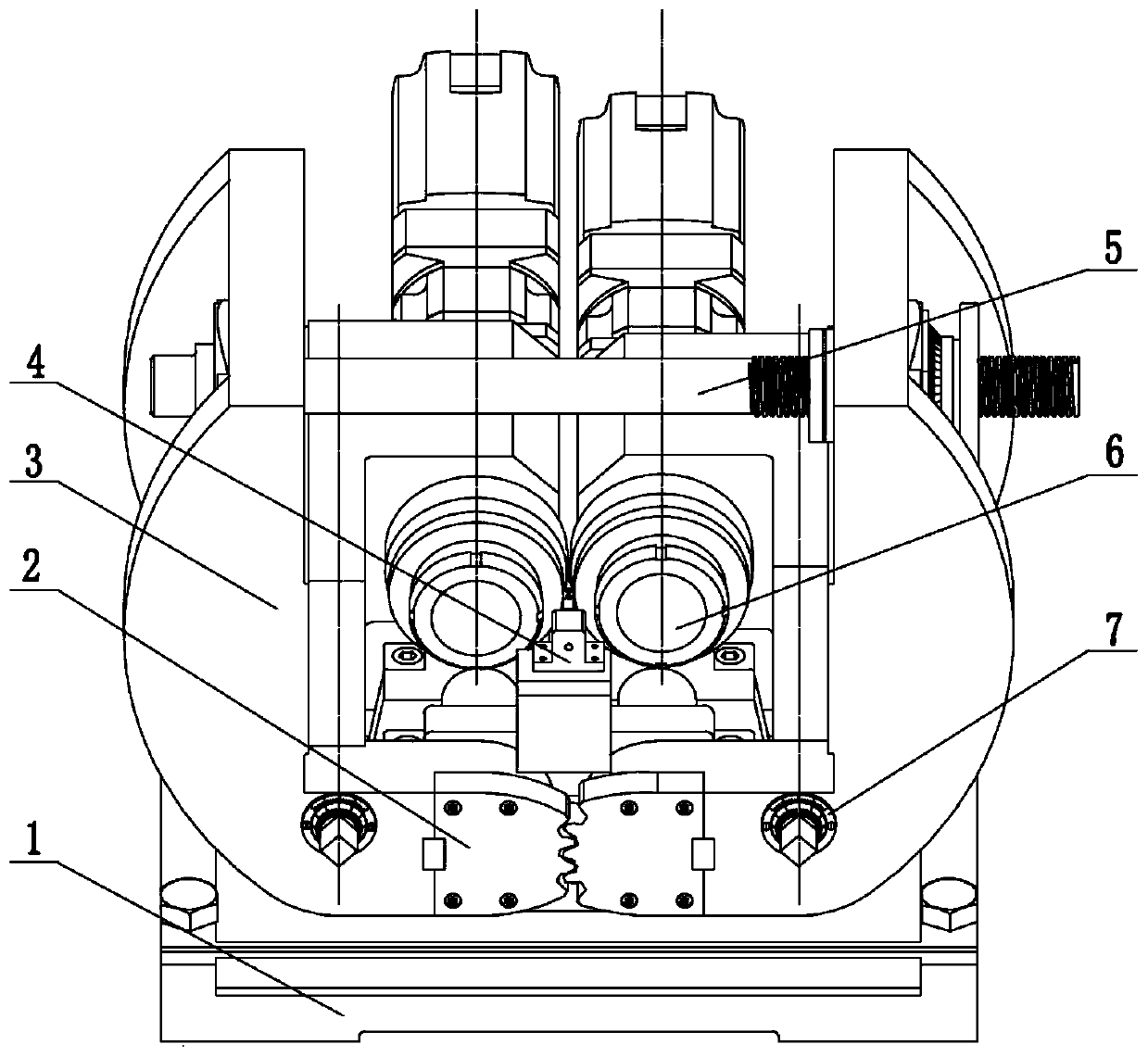

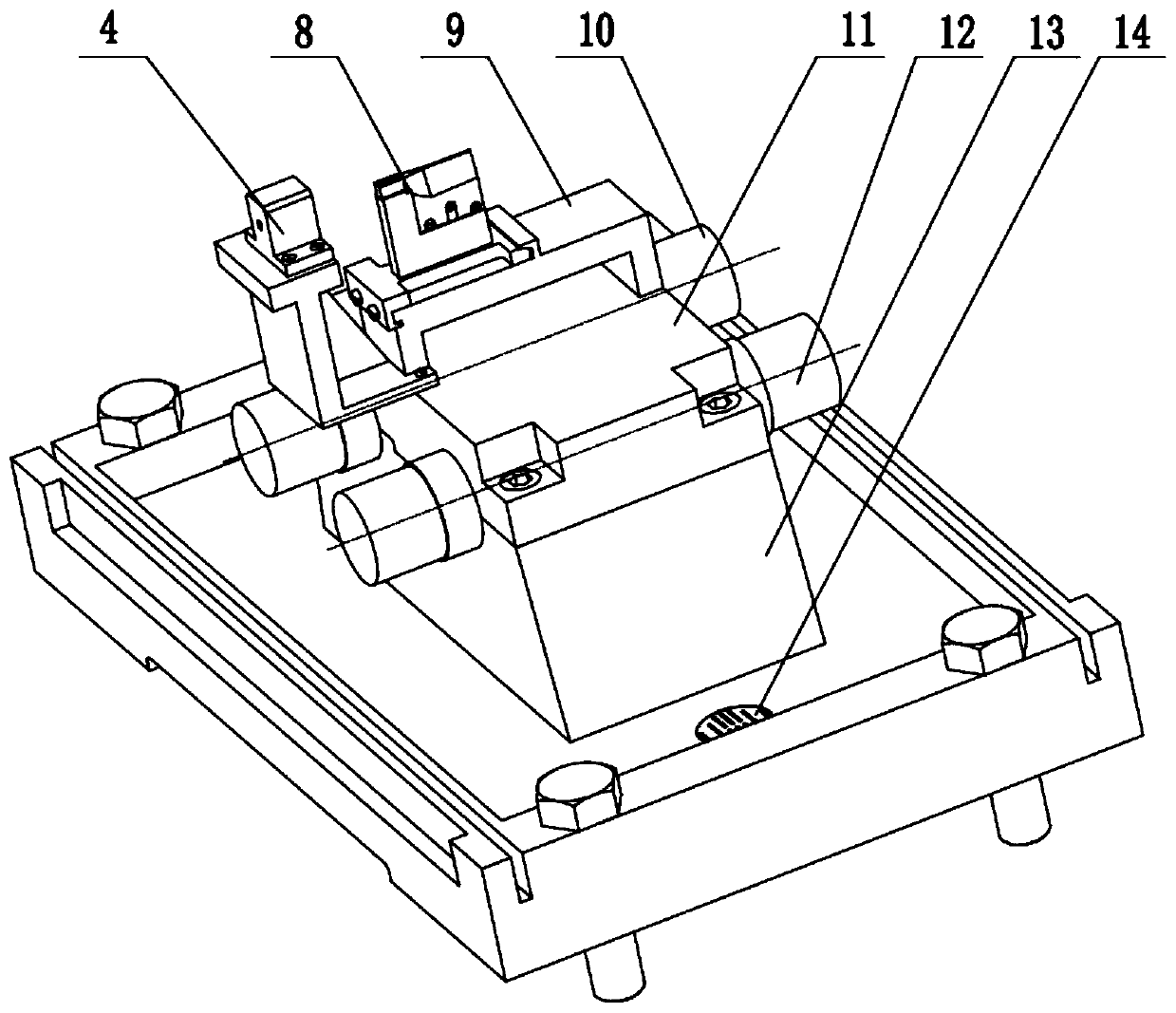

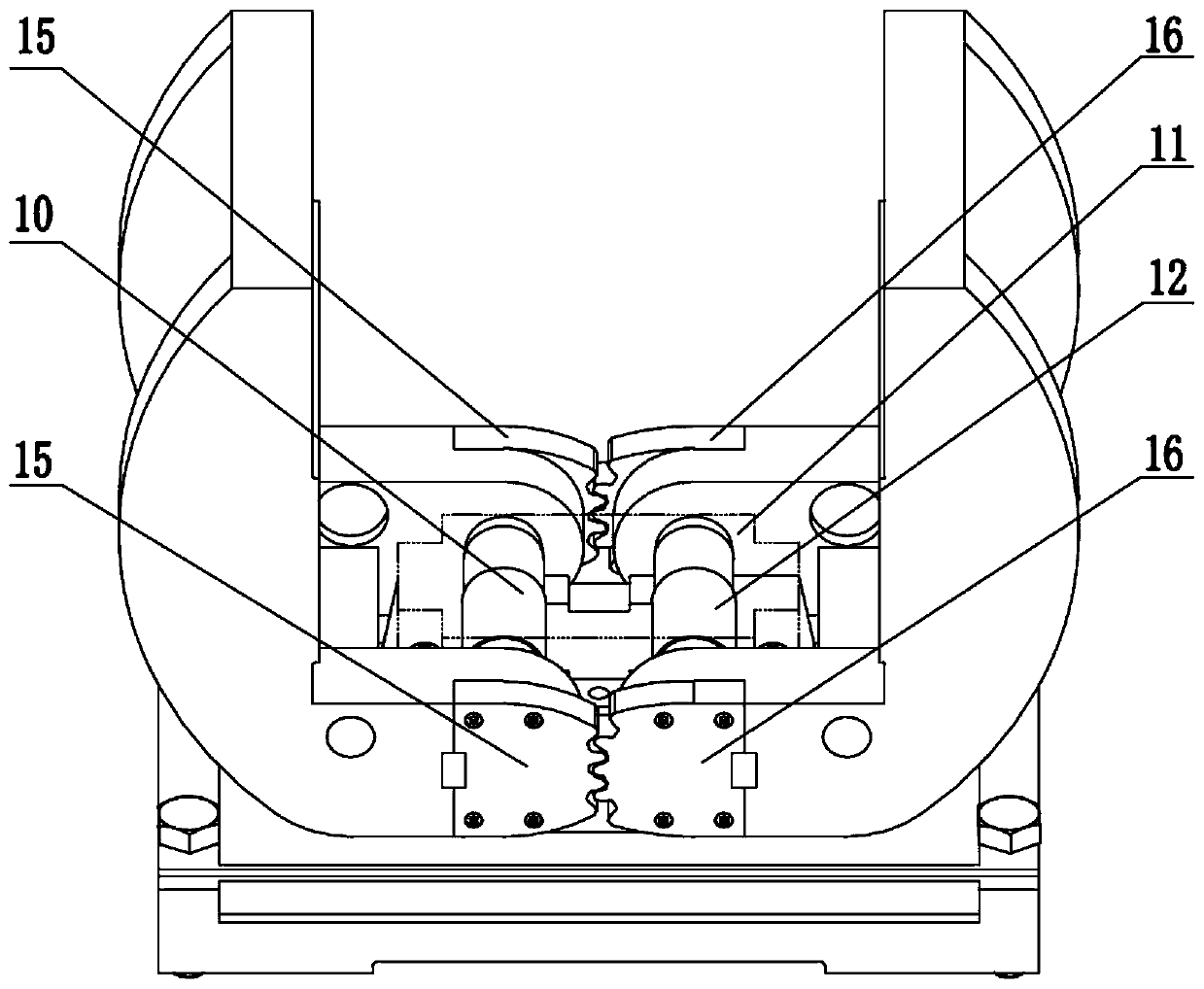

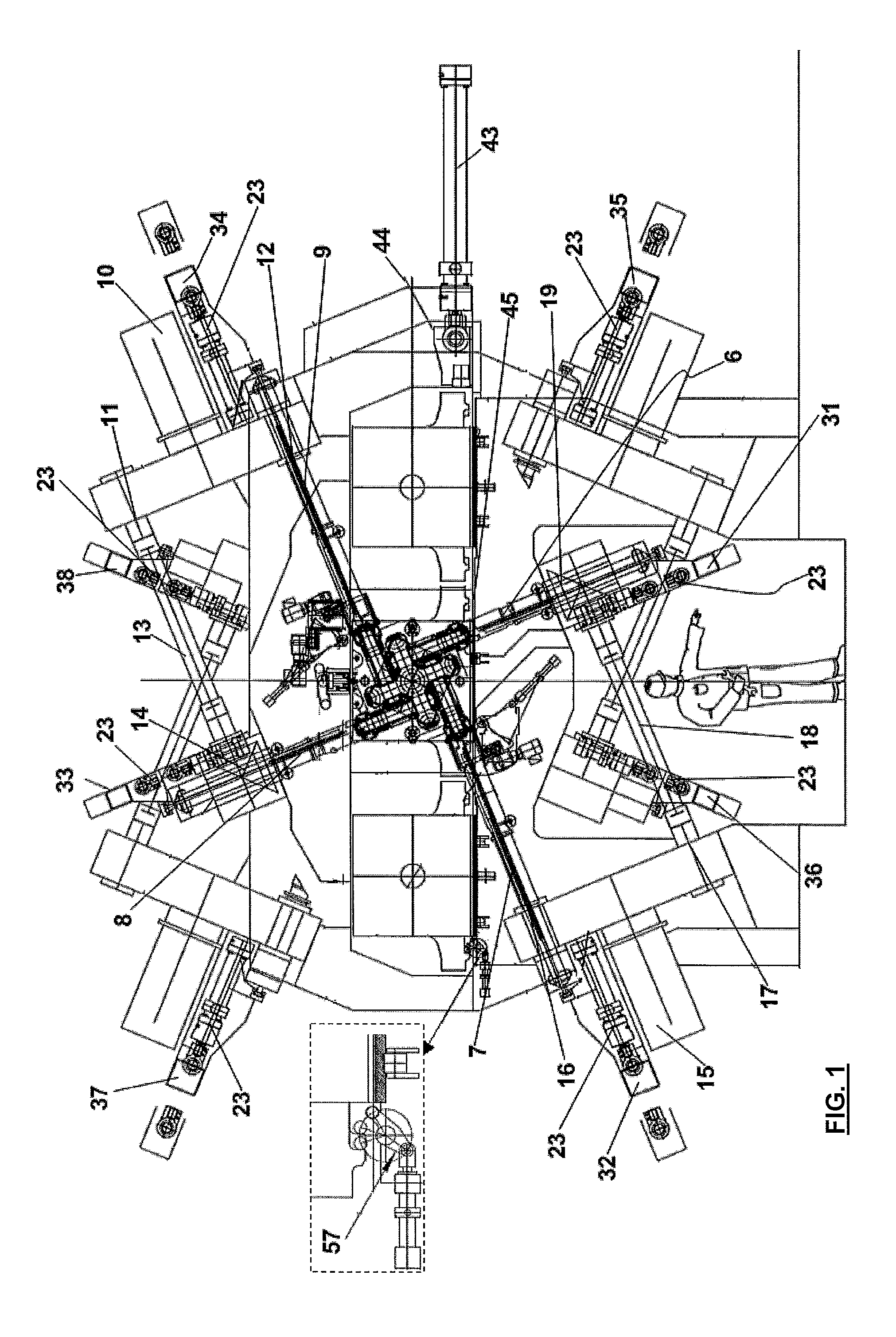

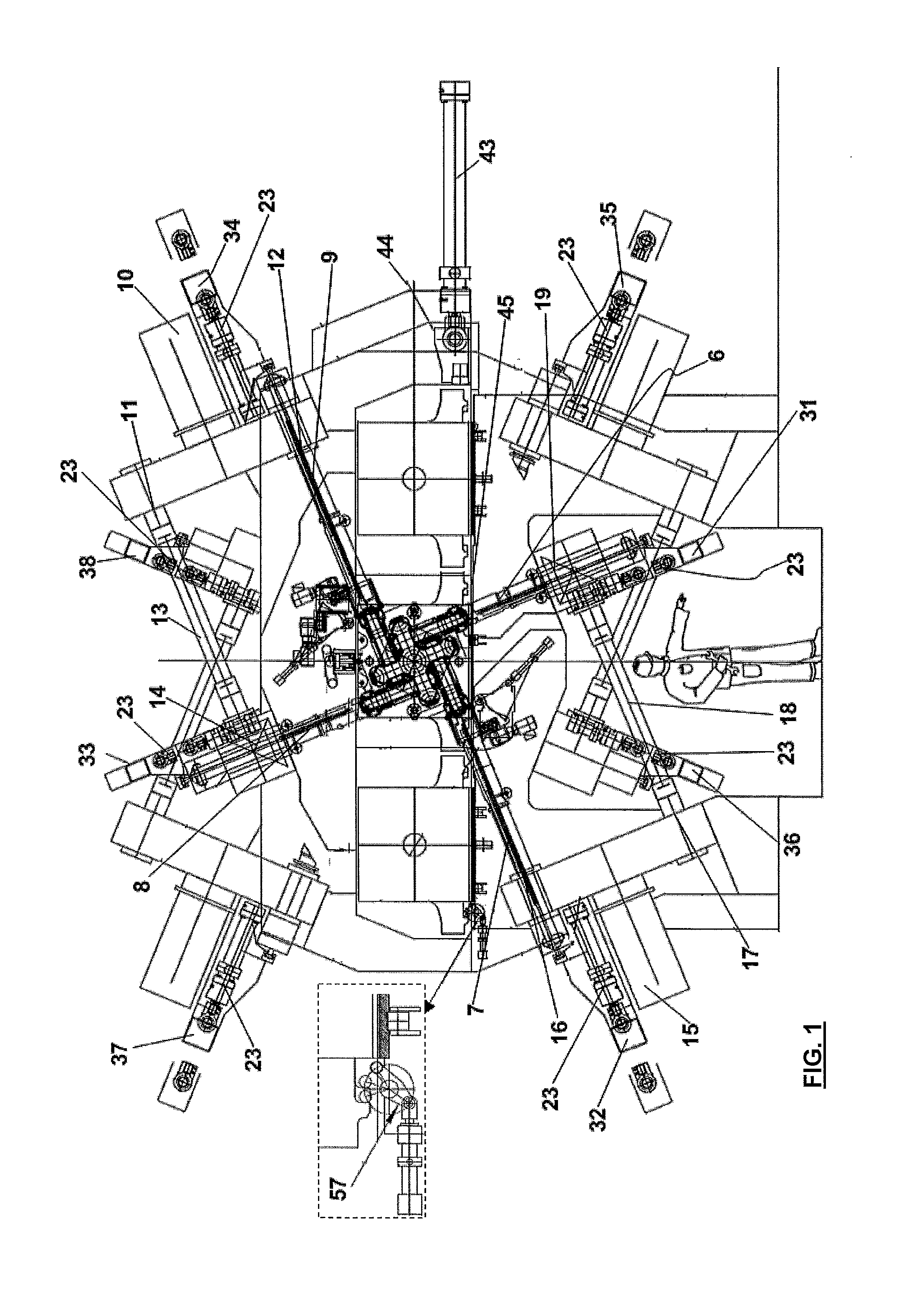

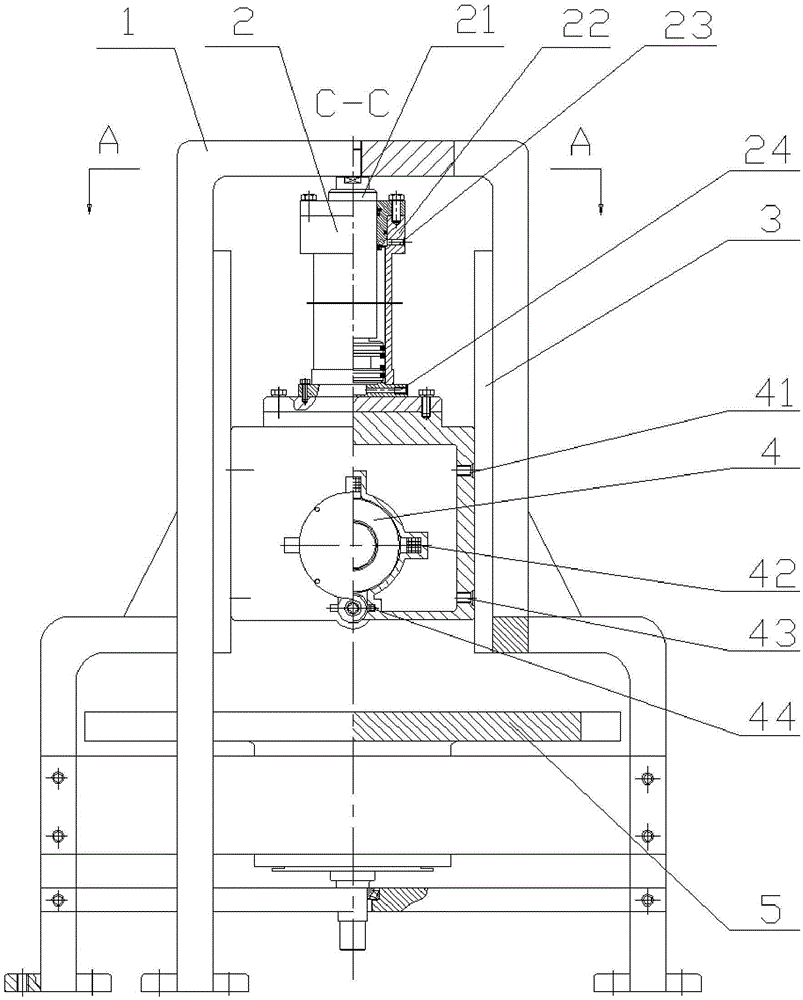

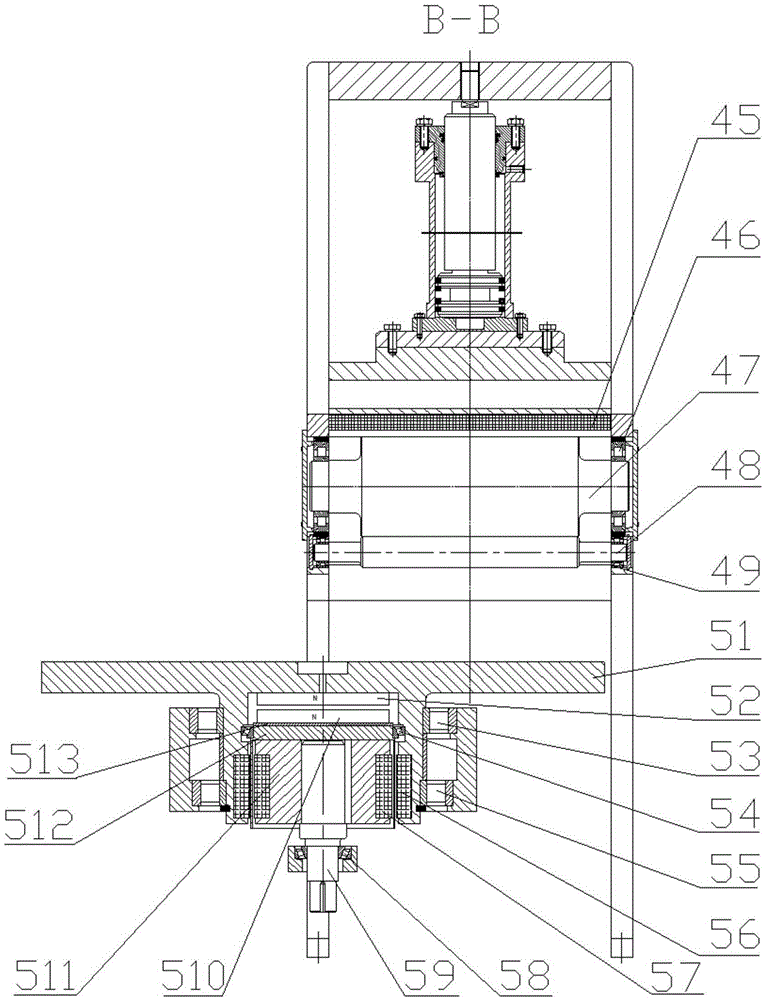

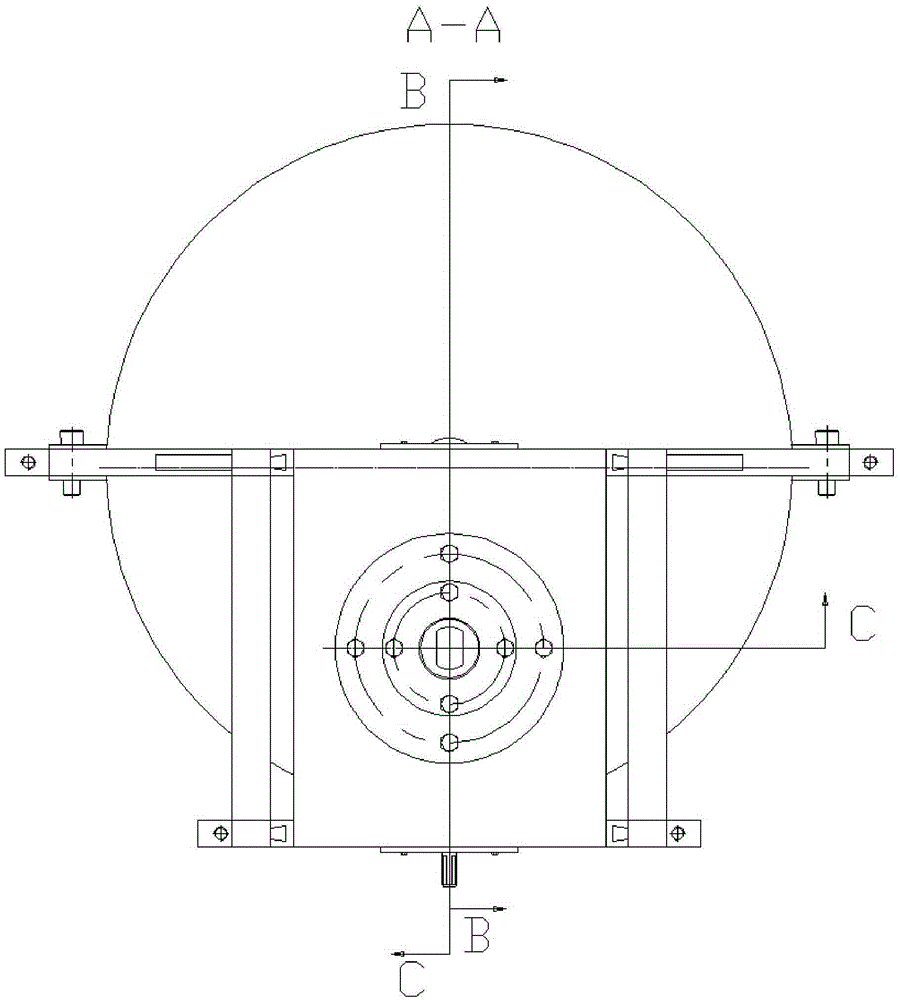

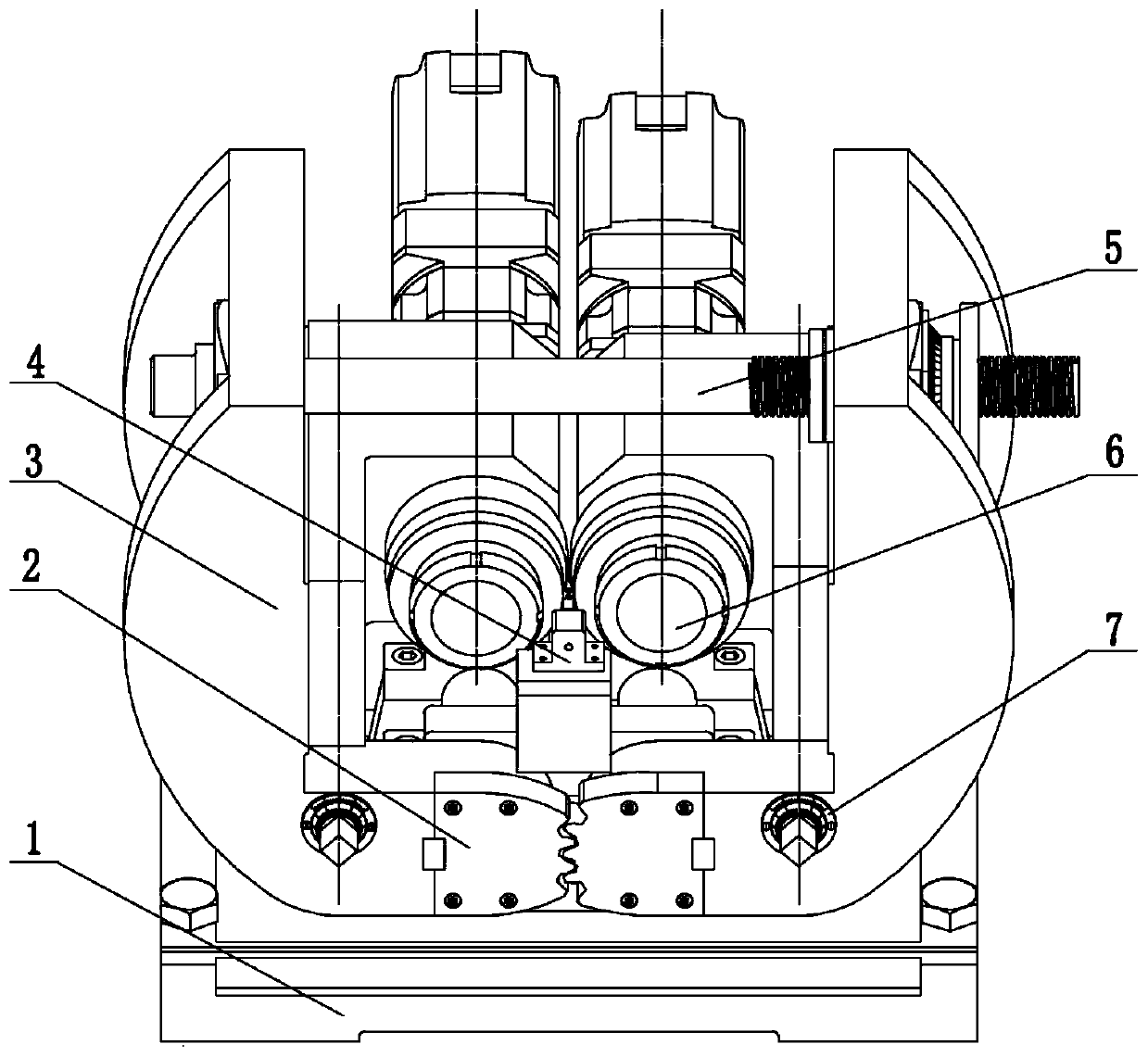

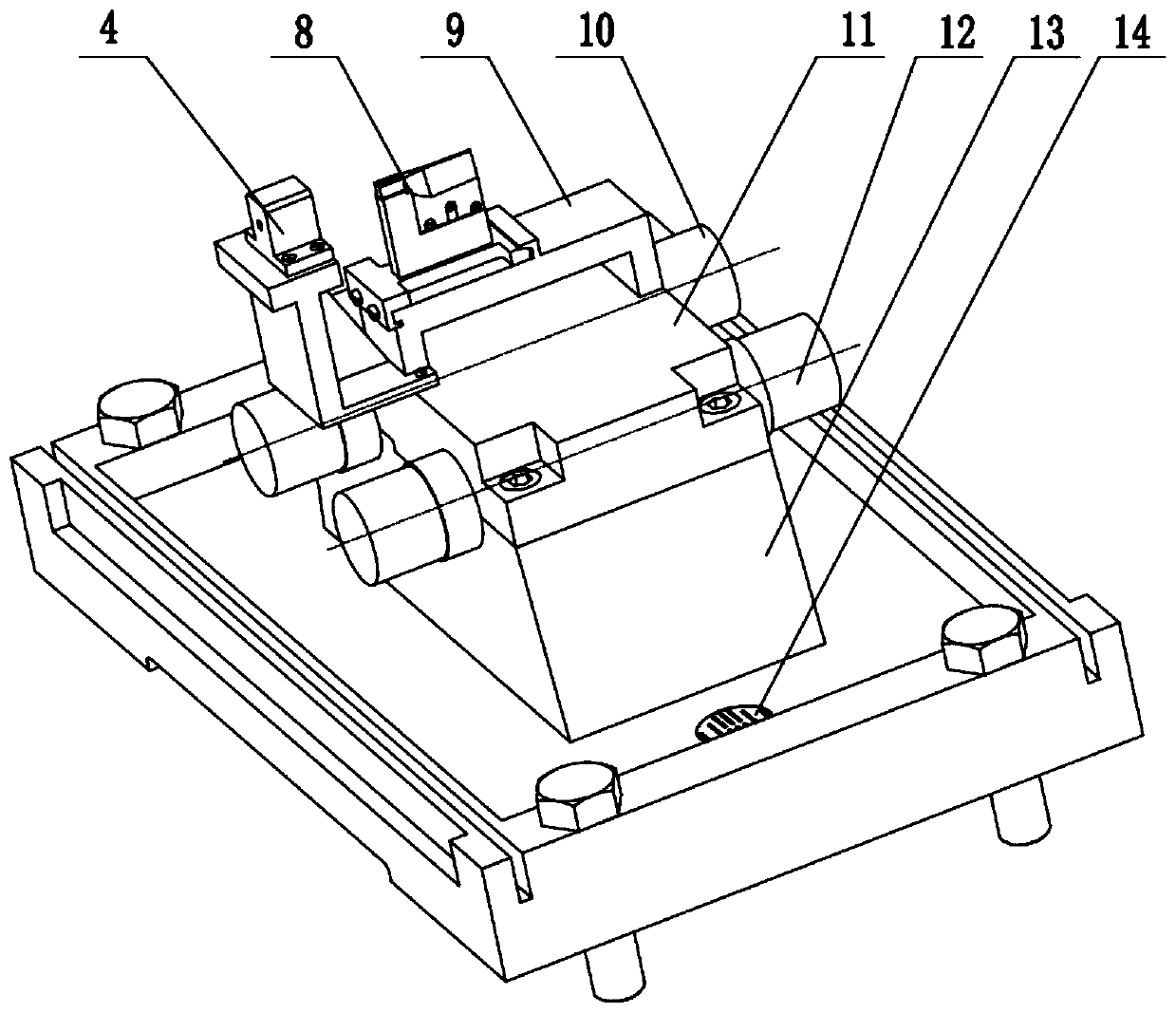

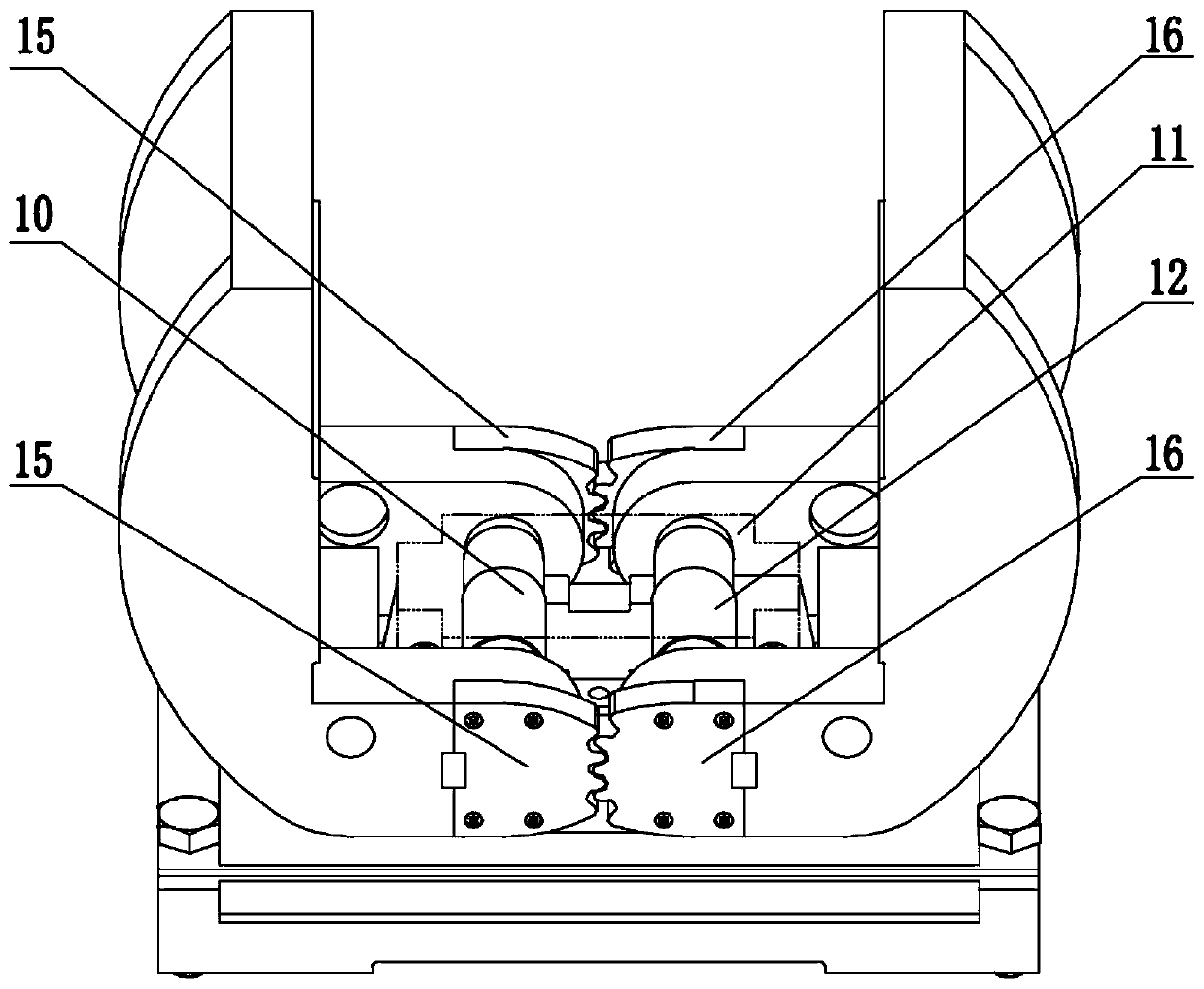

Double-rotating-shaft cantilever type skew rolling mill

ActiveCN110153339ASmall fluctuationShort to the axis of the roller systemSkewed roll standMetal rolling stand detailsGear wheelEngineering

The invention relates to the technical field of metal plastic forming processes and equipment, and provides a double-rotating-shaft cantilever type skew rolling mill. The skew rolling mill is mainly composed of a base, a cantilever type roller system, a gear synchronizing mechanism, a radial reduction mechanism, machine frames, a material guiding unit and inclination angle adjusting mechanisms, wherein the cantilever type roller system is tensioned by bolts on the backs of the machine frames of the rolling mill, and the roller system inclination angle adjustment is realized through the inclination angle adjusting mechanism below bearing seats; the two machine frames which are supported by double rotating shafts of the rolling mill base; synchronous alignment and reduction are realized on the two machine frames through the gear synchronizing mechanism, and the center line of the vertical direction of the rolling mill is ensured to be fixed; the radial reduction mechanism is arranged above the machine frames, and the roller distance adjustment of two rollers is realized by rotating reduction nuts; and the inclination angle adjusting mechanisms are arranged at the corners of the machine frames so that the space can be saved, moreover, the action line is long, and the high-precision adjustment of the inclination angle of the roller system can be realized. The double-rotating-shaftcantilever type skew rolling mill is ingenious in design, has the advantages of convenience in roller replacement, fixation of the vertical center line of the rolling mill, convenience in installationand adjustment and the like, and is suitable for the production of large-scale small-diameter steel balls.

Owner:UNIV OF SCI & TECH BEIJING

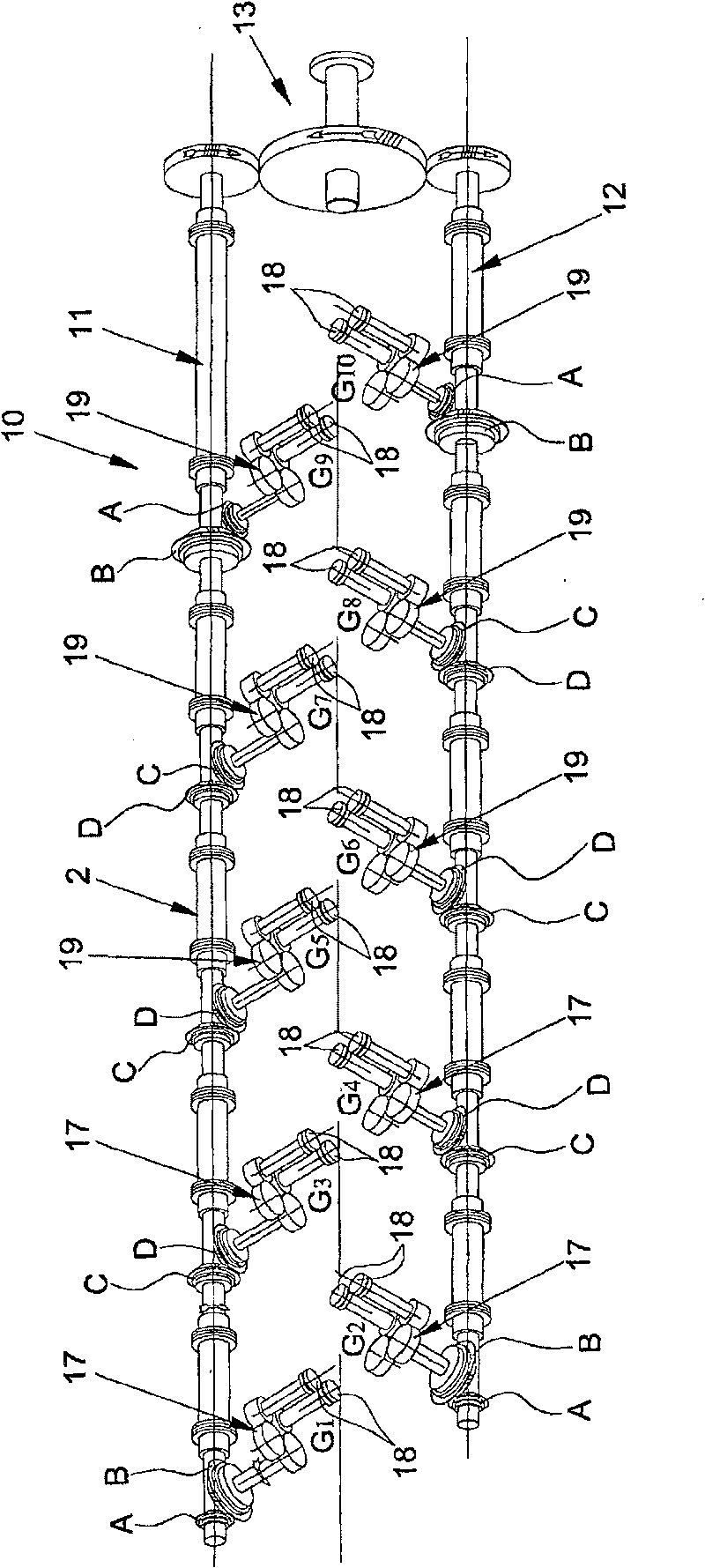

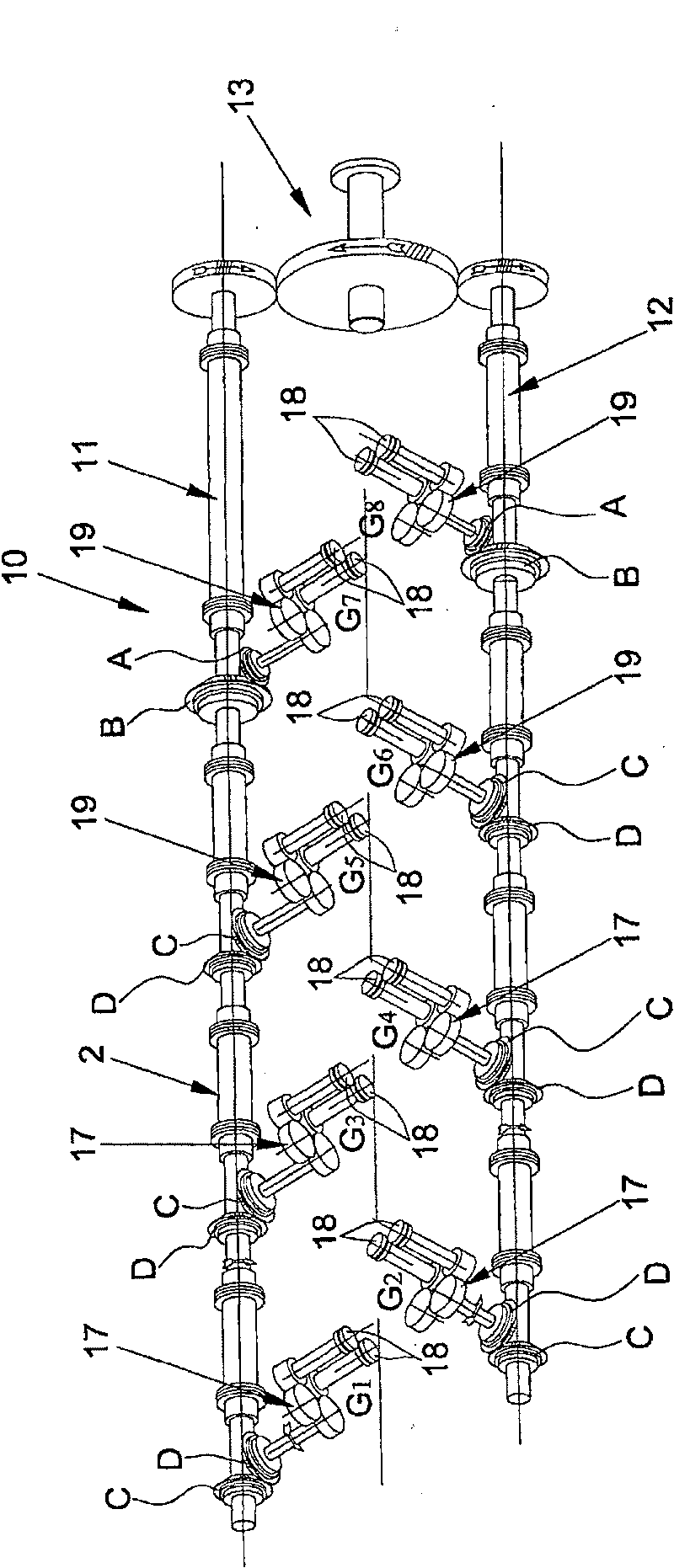

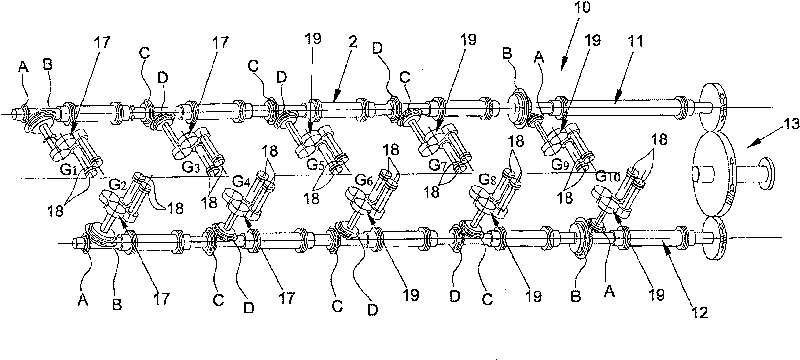

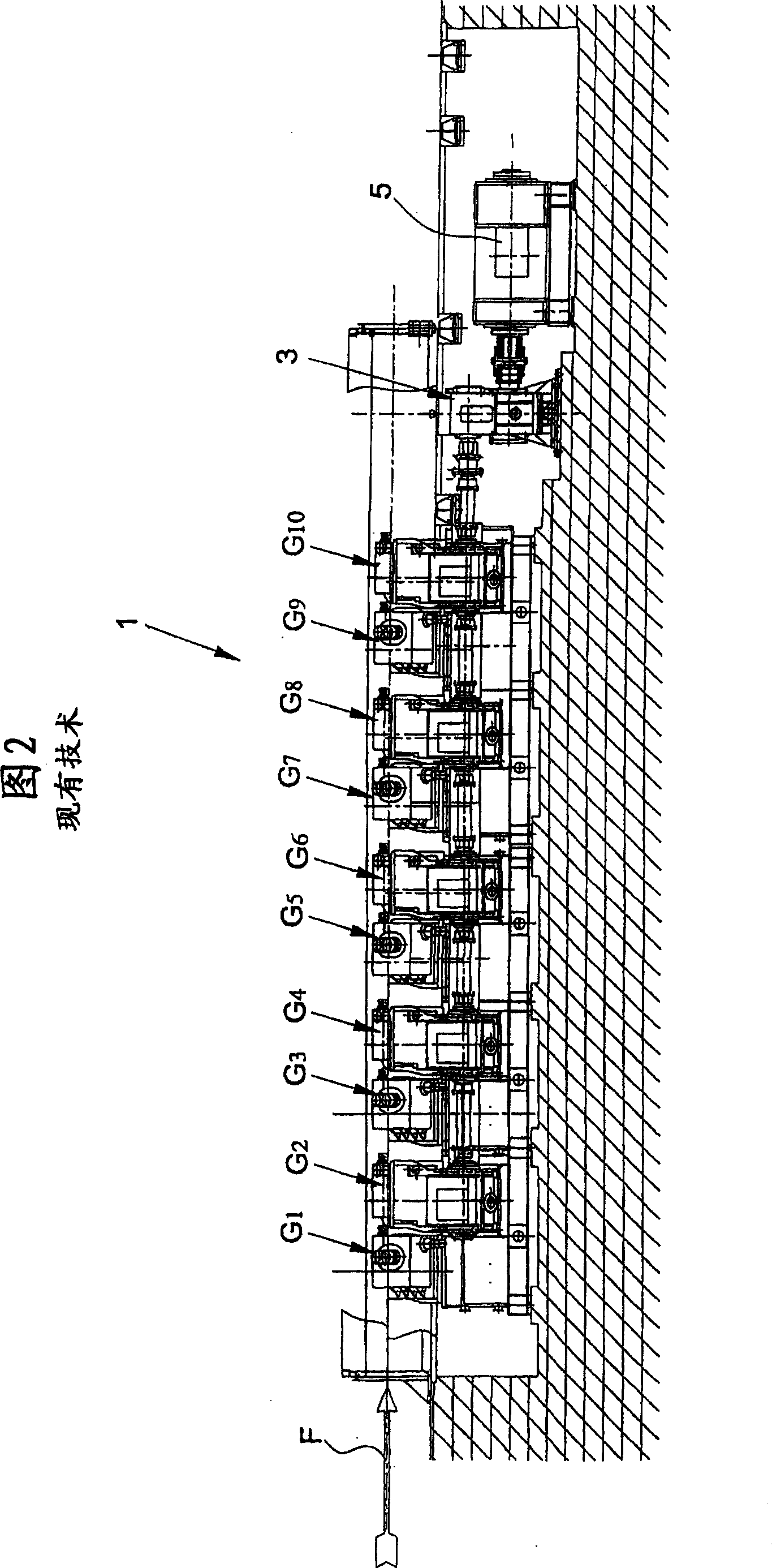

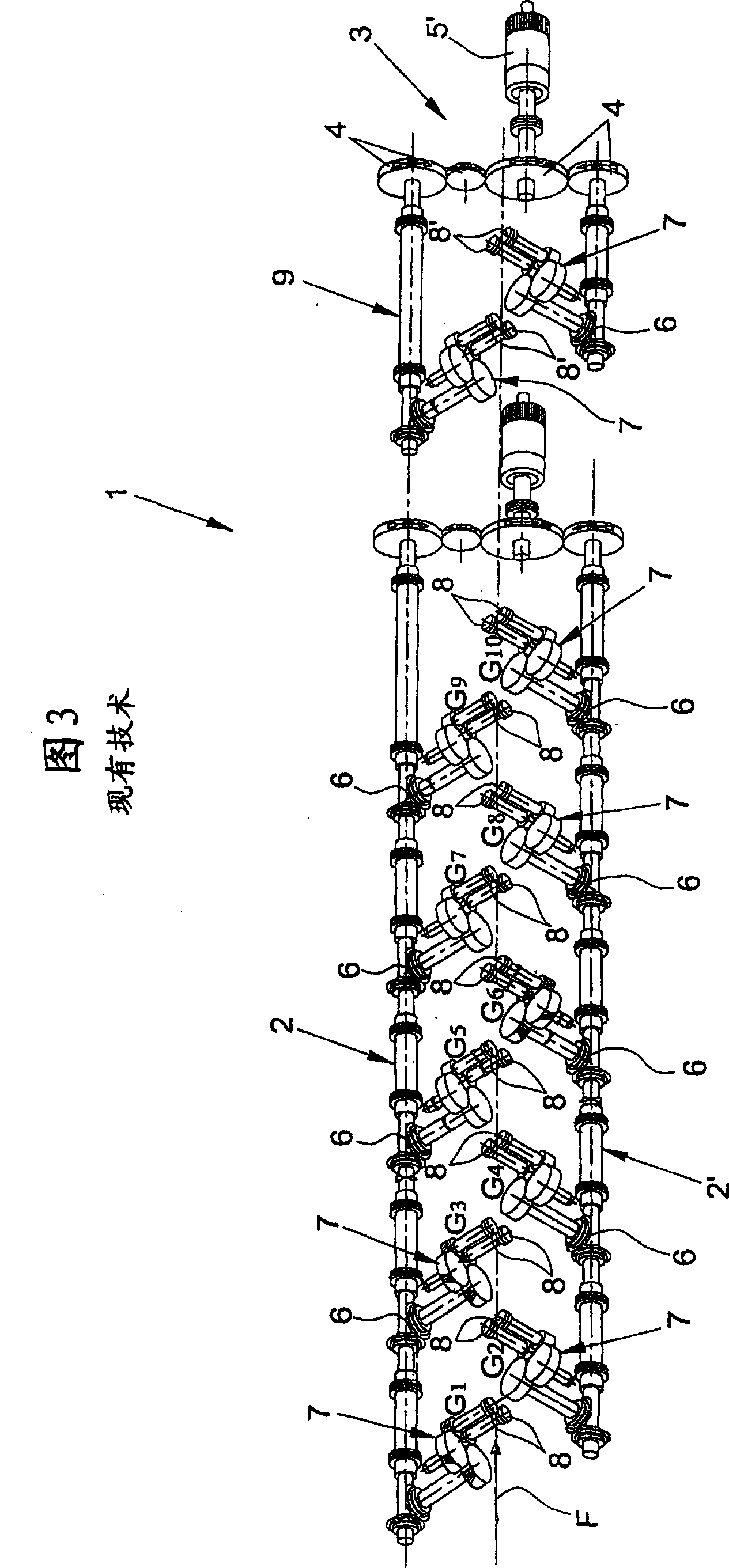

Finishing monoblock with optimised transmission ratio for a billet rolling plant

InactiveCN1993190ABest gear ratioDecrease stockRolling mill drivesMetal rolling arrangementsGear wheelEngineering

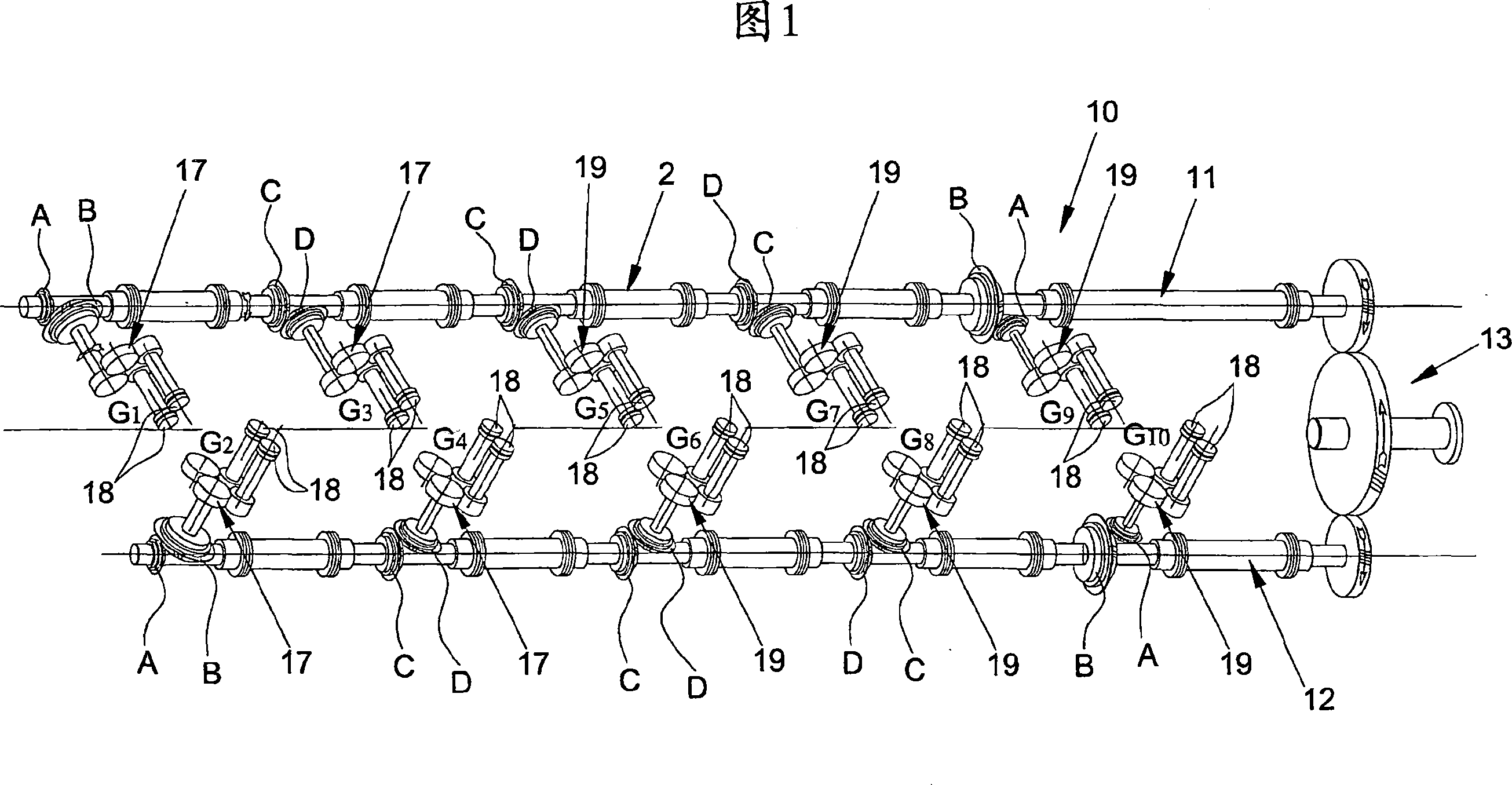

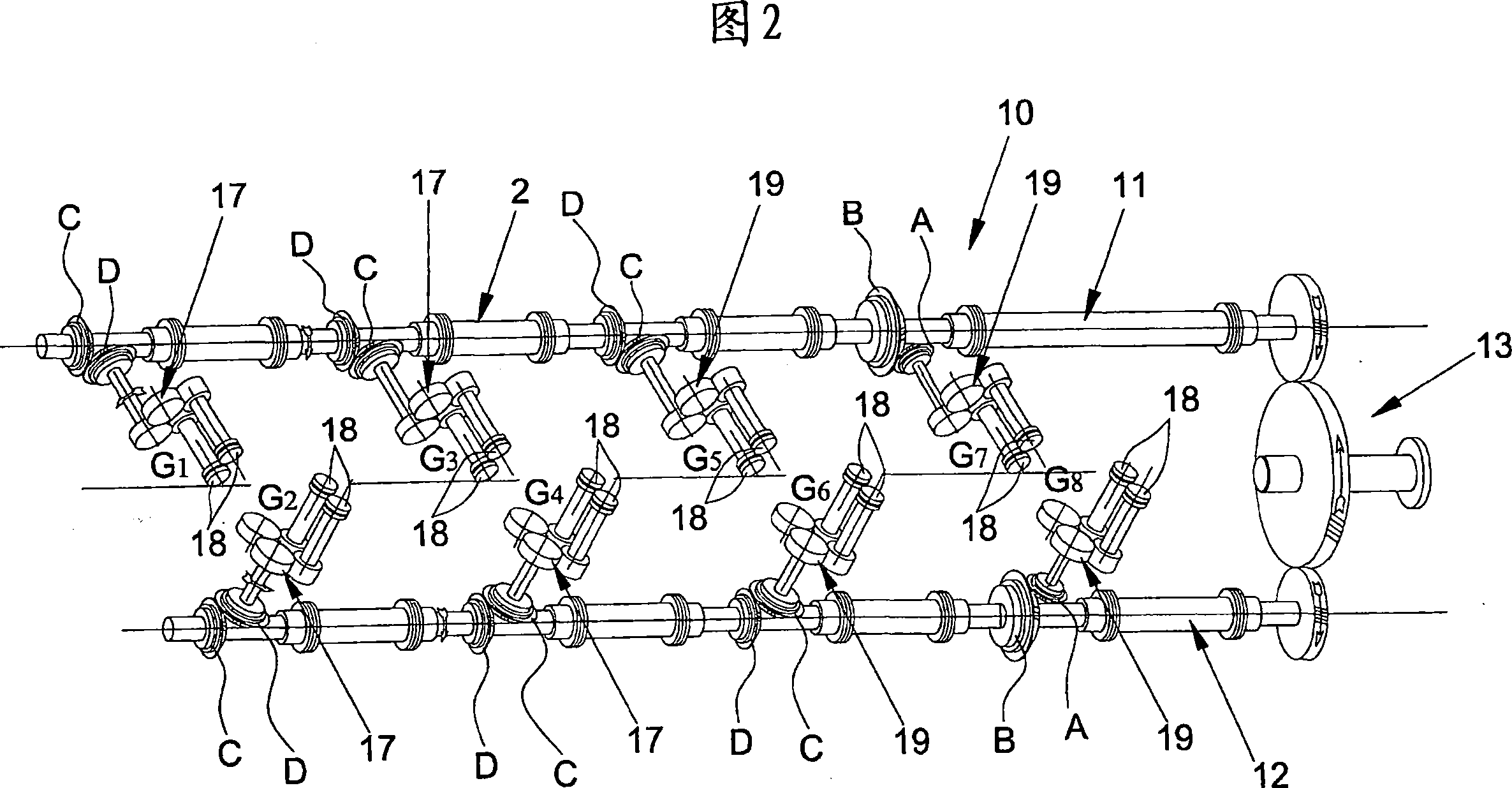

A finishing monoblock with optimised transmission ratio for a billet rolling plant comprises a plurality of rolling stands (Gl-Gn) arranged in sequence suitable for forming a rolling line and actuated by a pair of mechanical transmissions (11, 12) in which bevel gear pairs are foreseen for the variation of ratio in the stands of the rotation speed of rolling cylinders (18). According to the invention, such a variation of the ratio in the stands is carried out through the combination of a first type (A, B) of bevel gear pairs with a second type of bevel gear pairs (C, D) and there is a set of four of cylindrical gears suitable for making four stands (C, D) with the same transmission bevel gear pair.

Owner:VAI POMINI INC

Lubrication system

A system is disclosed for applying a liquid lubricant to first and second components enclosed in a housing, with the lubricant applied to the second components being exposed to contamination by a liquid coolant applied to the exterior of the housing, and with the lubricant applied to the first components being substantially isolated from the liquid coolant. The system includes a partition internally subdividing the housing into a first chamber containing the first components and a second chamber containing the second components. Lubricant is delivered from a storage tank to the housing for application to the first and second components. A first conduit network communicates with the first chamber for returning the lubricant applied to the first components to the storage tank, and a second conduit network communicates with the second chamber for returning lubricant applied to the second components to the storage tank. A liquid coolant removal unit in the second conduit network removes liquid coolant from the lubricant being returned to the storage tank.

Owner:SIEMENS IND INC

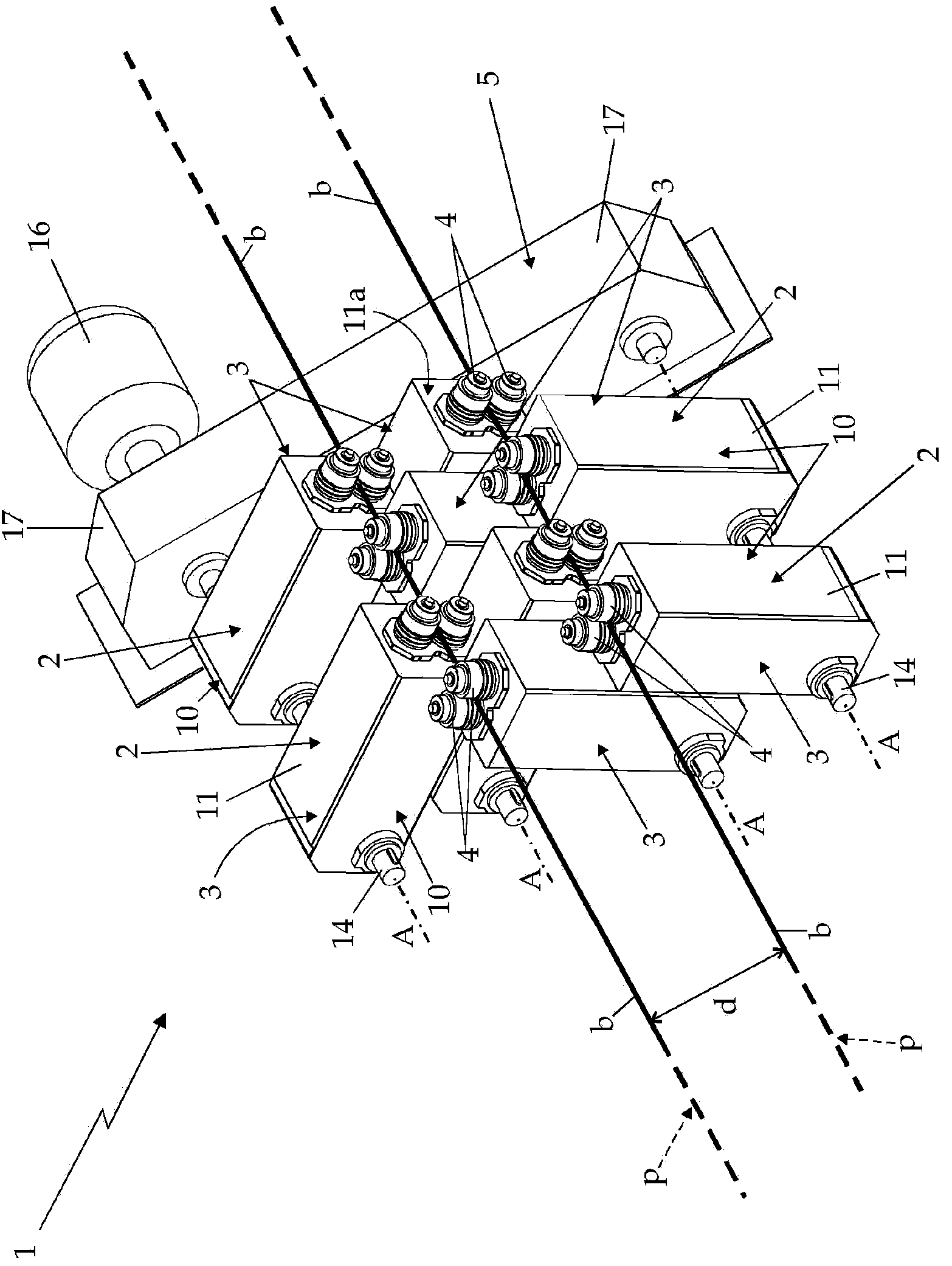

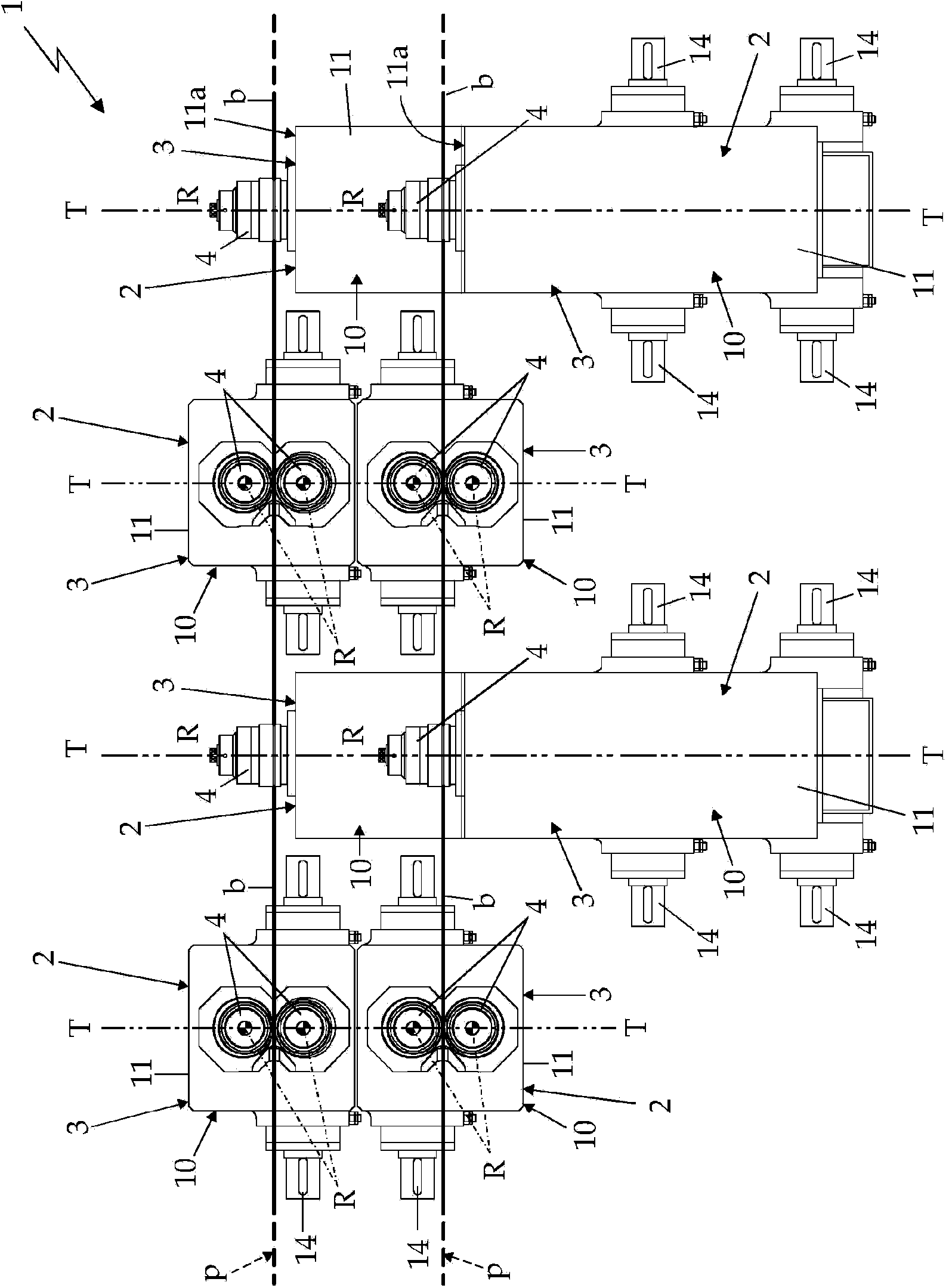

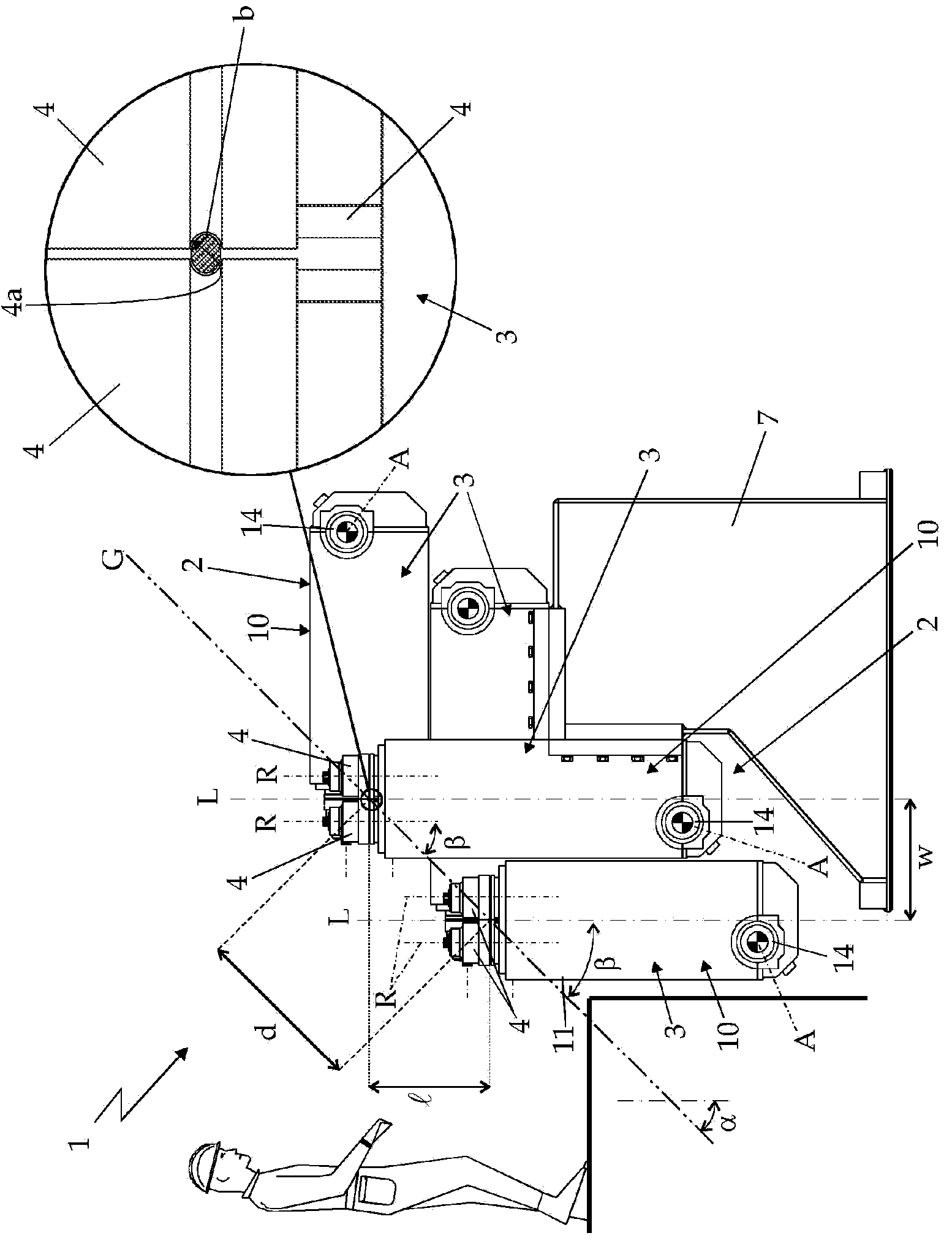

Wire-rod and the like hot-rolling machine

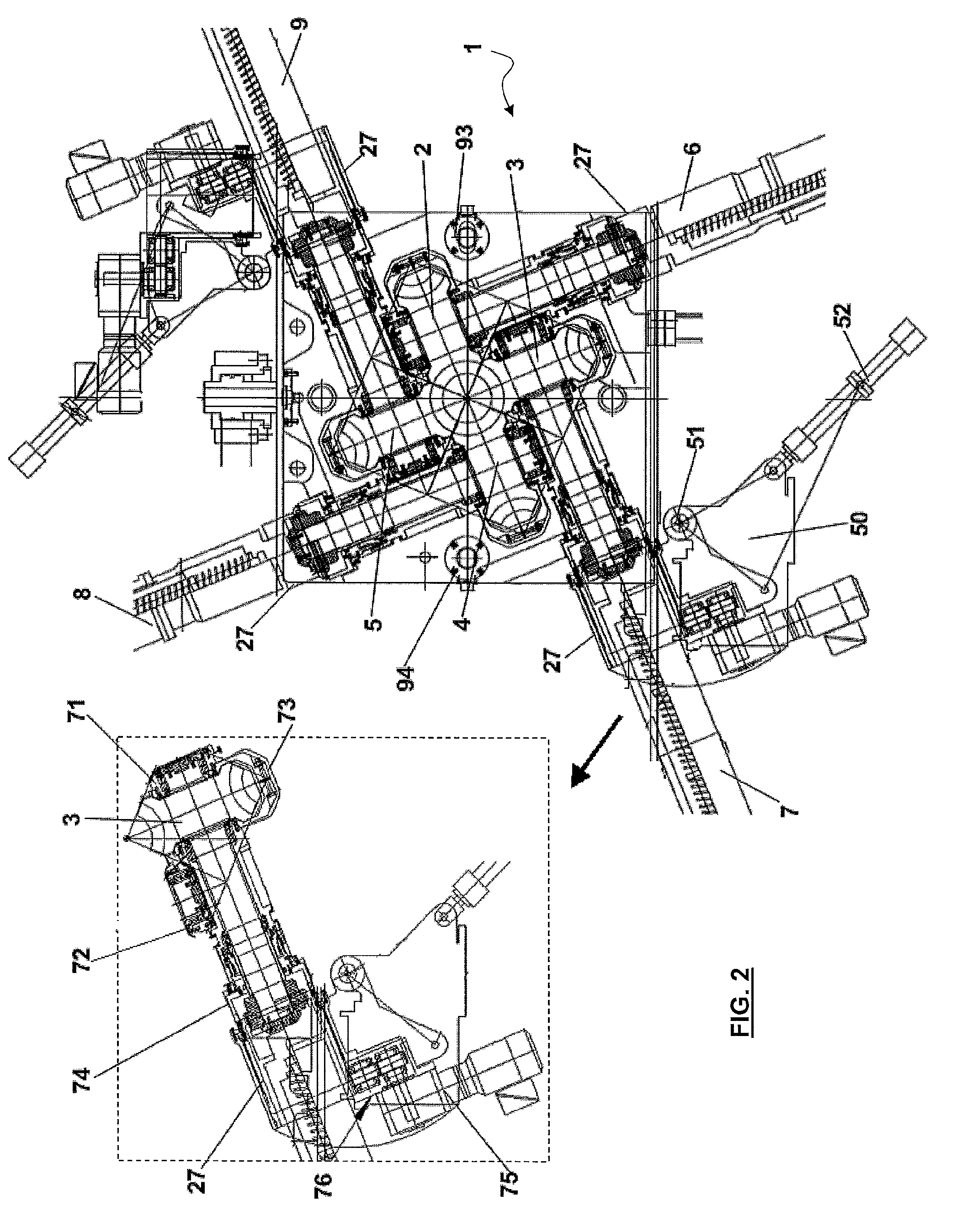

InactiveCN103974786AMinimized space gainMetal rolling stand detailsRolling mill drivesWire rodStrip mill

Wire-rod hot-rolling machine (1) which comprises a plurality of roller- provided rolling units (2) which are arranged one after the other along the wire-rod feeding paths (p); the roller-provided rolling unit (2) being formed by a plurality of rolling-mills assemblies (3) each of which is provided with a pair of opposite, counter-rotating rolling mill rollers (4), which are arranged parallel and adjacent each other; said rolling- mills assemblies (3) being arranged one beside the other, coplanar to a corresponding reference plane locally perpendicular to the feeding paths (p), each at the feeding path (p) of a respective wire rod (b), and are oriented so that the rotation axes (R) of the rolling mill rollers (4) of the various rolling- mills assemblies (3) are locally parallel to one another while intersecting the lying plane of the feeding paths (p) of the wire rods with an inclination angle (3) greater than 5 DEG and smaller than 85 DEG.

Owner:PERT

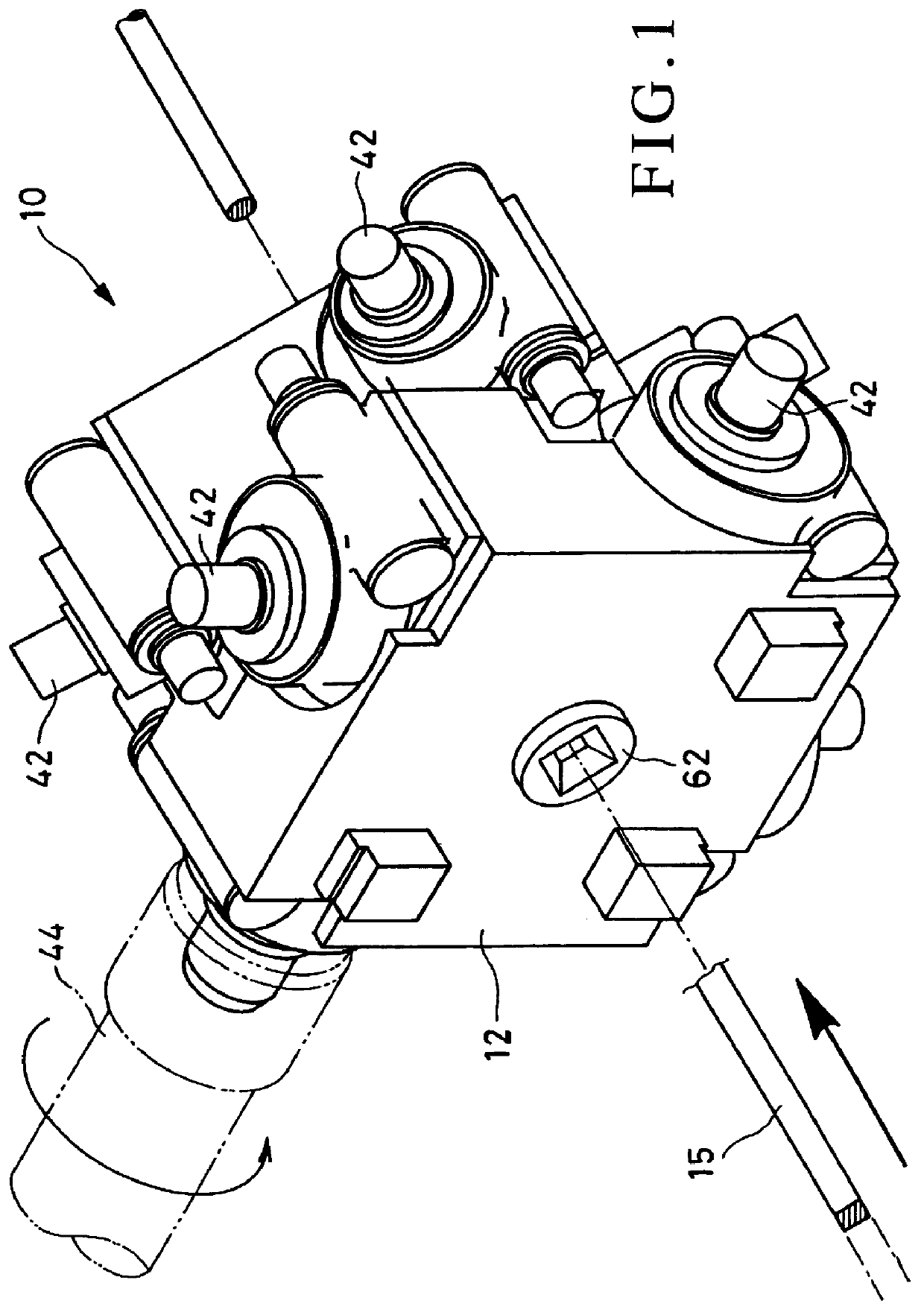

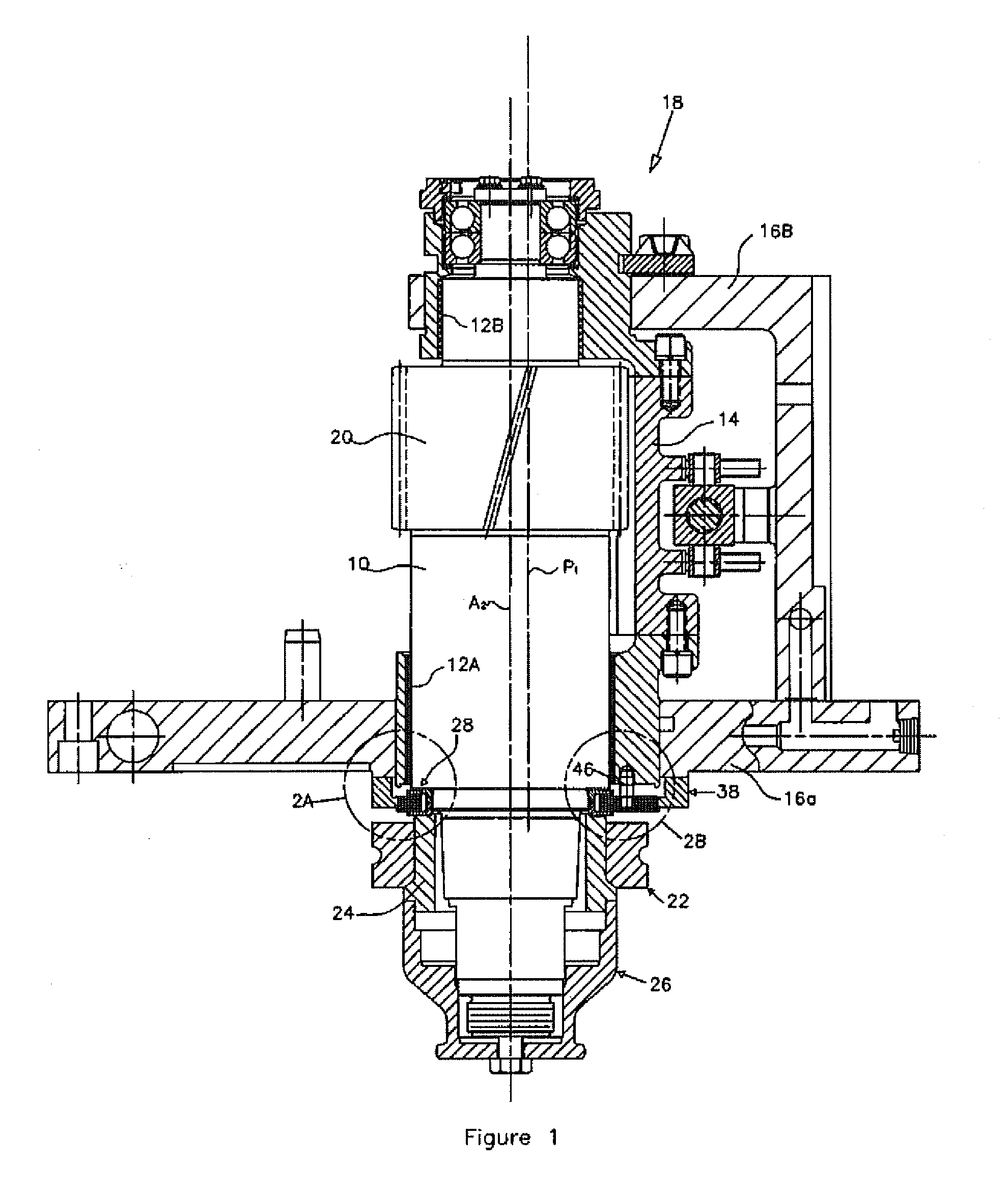

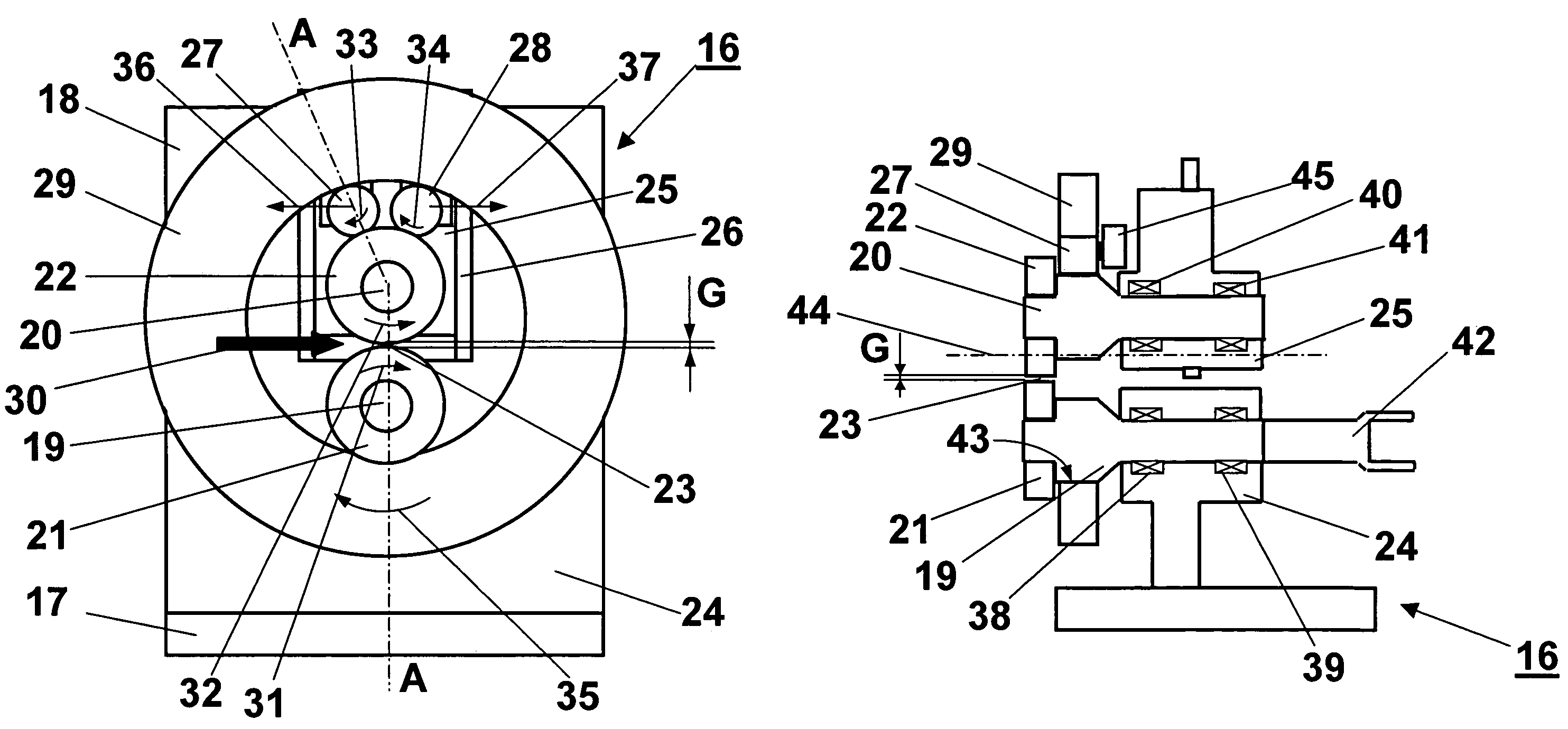

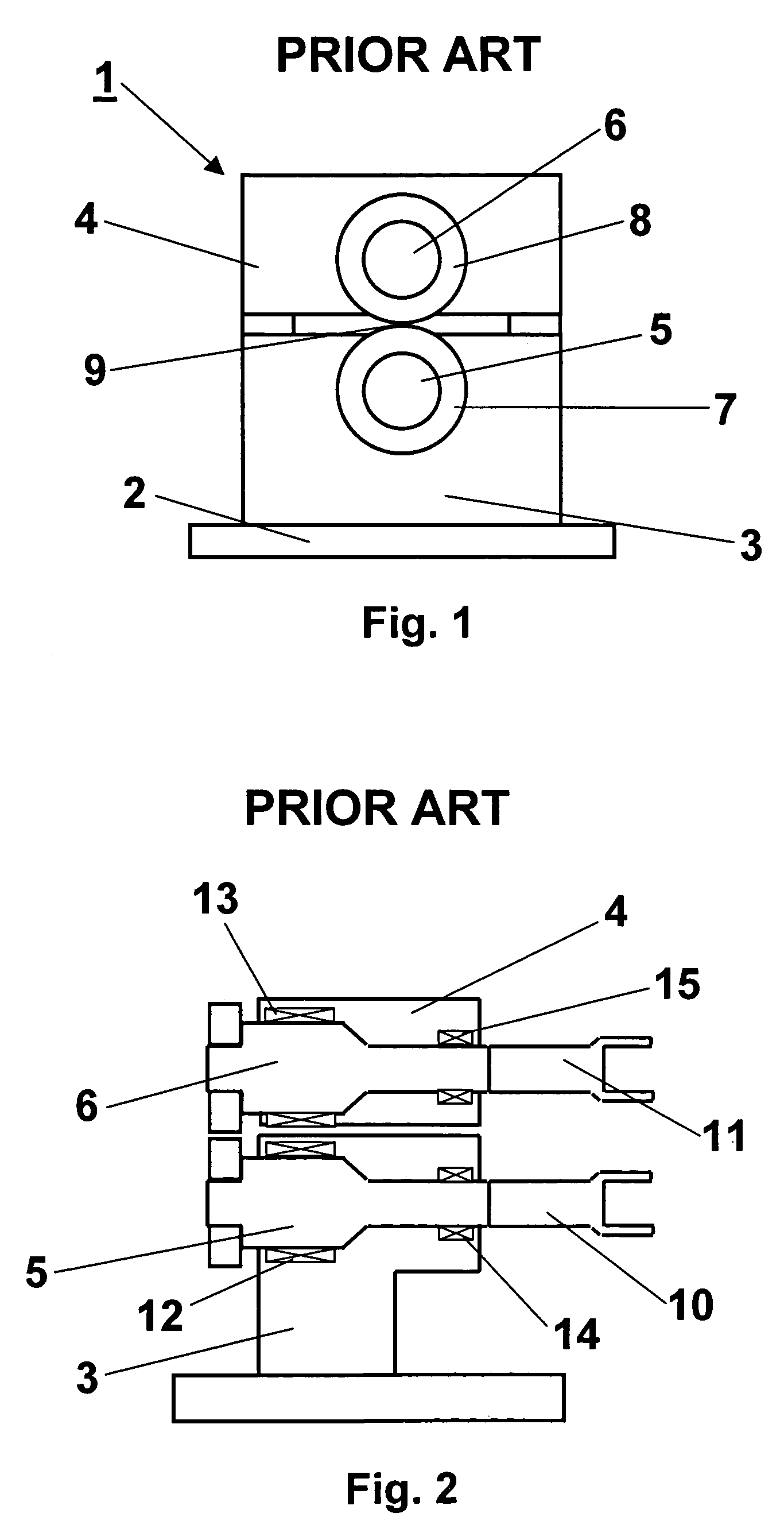

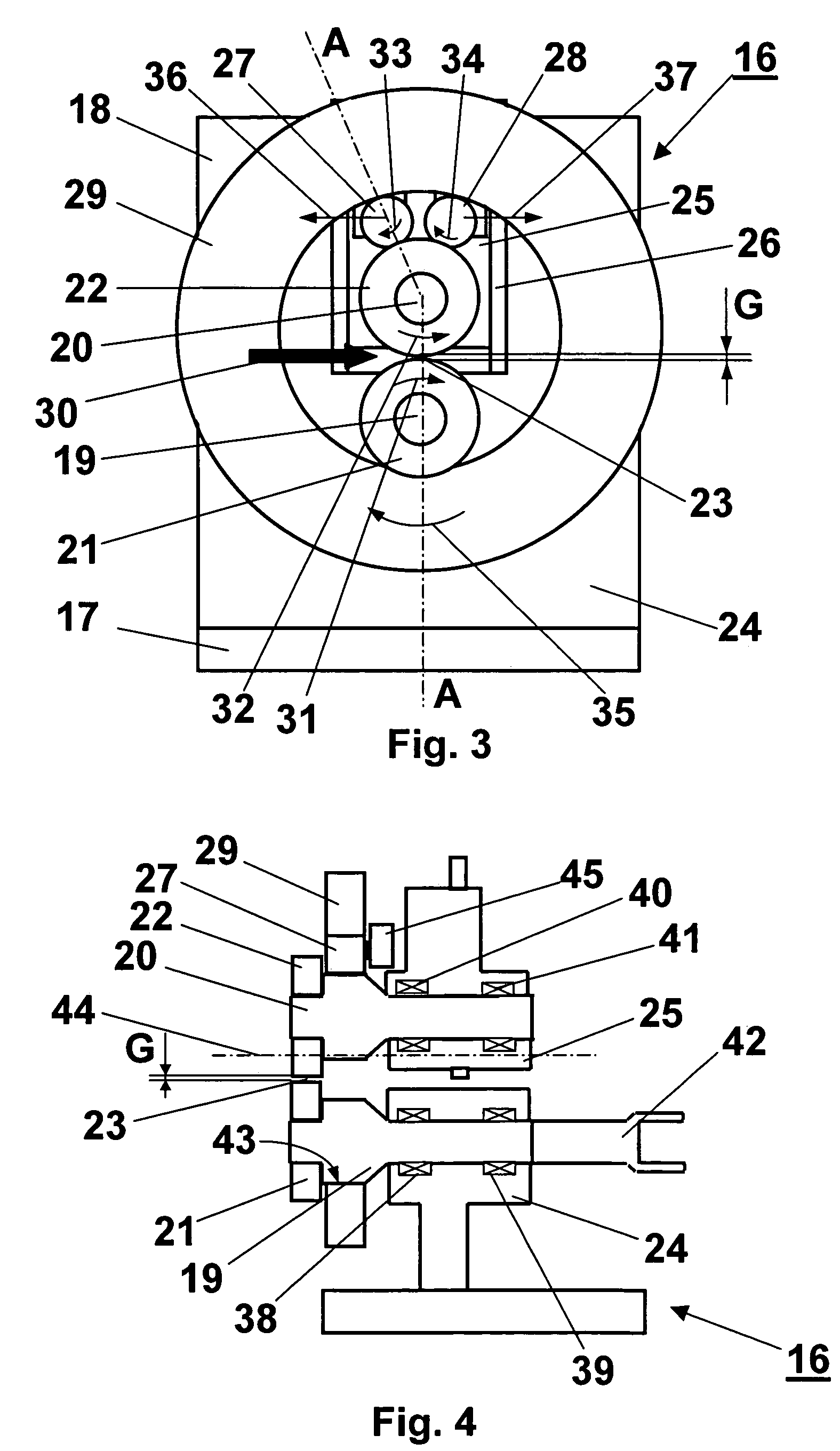

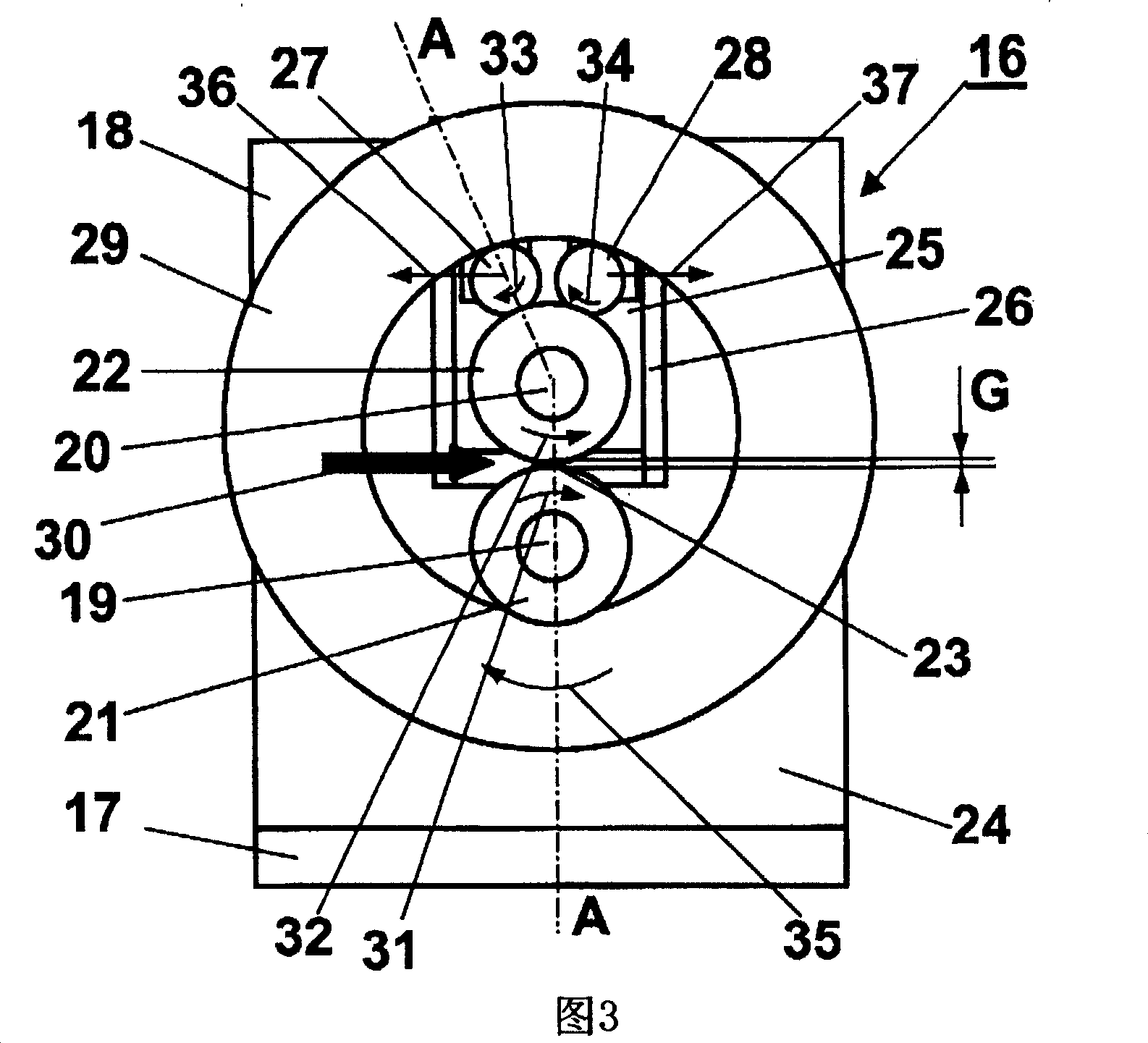

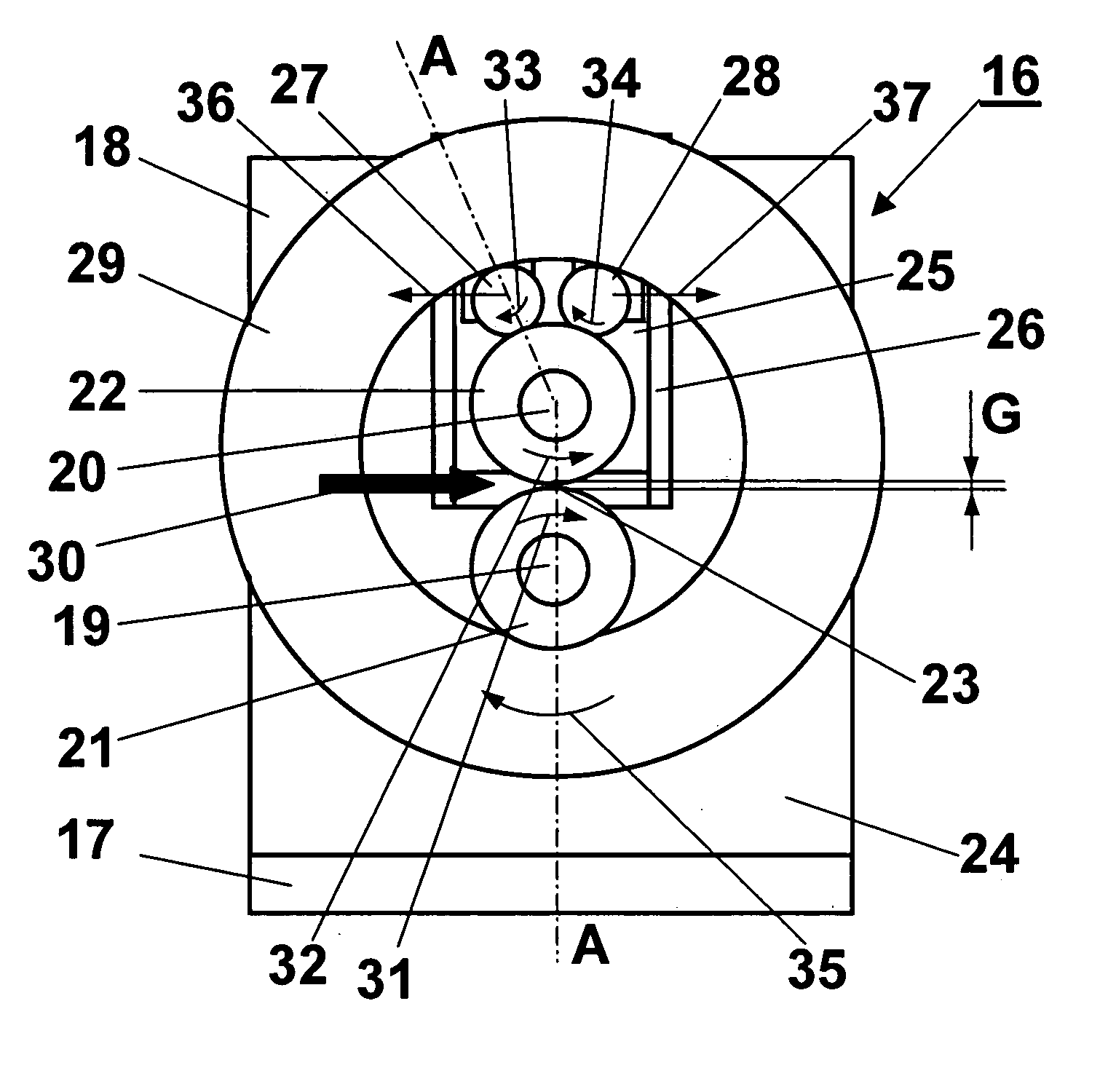

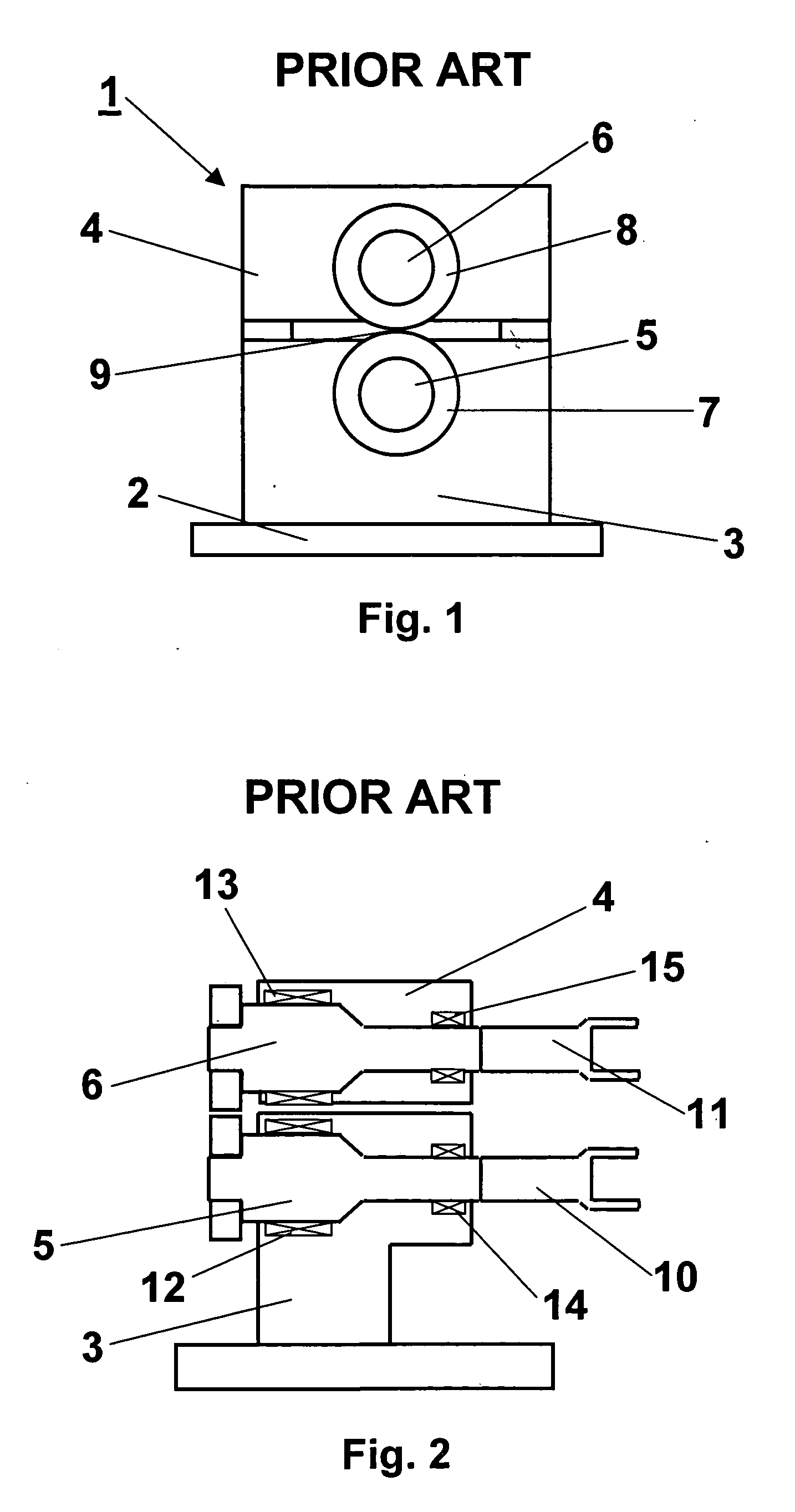

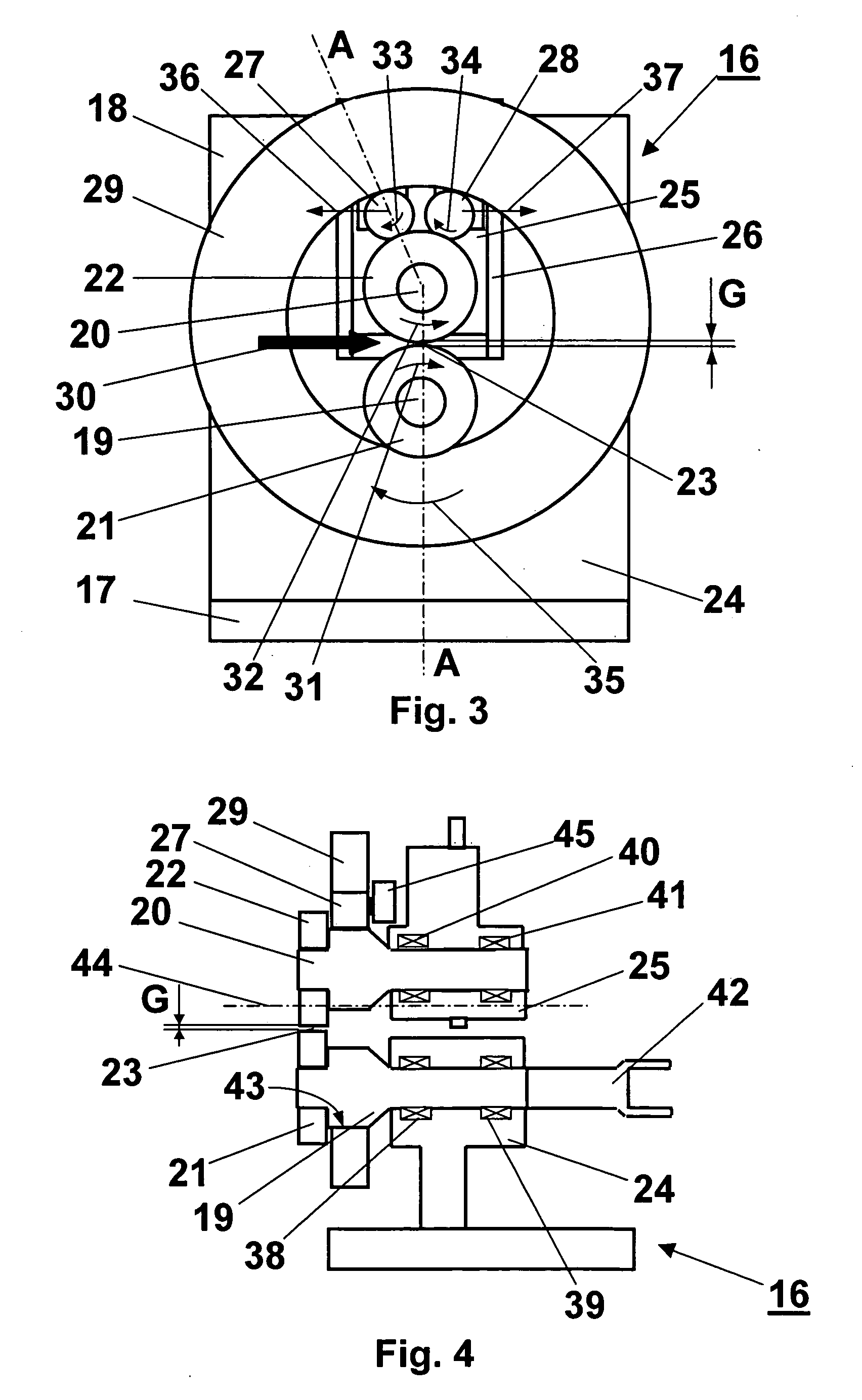

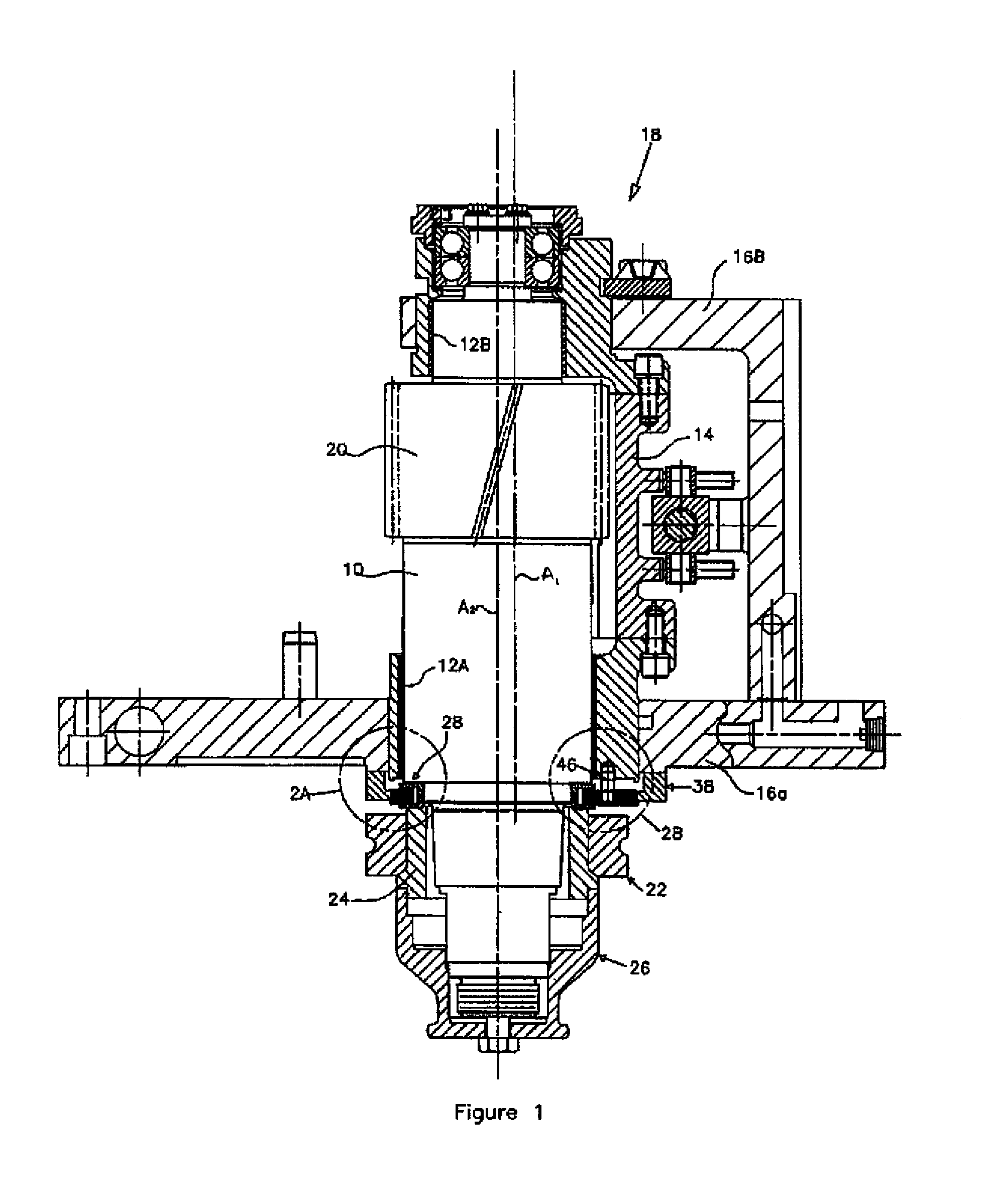

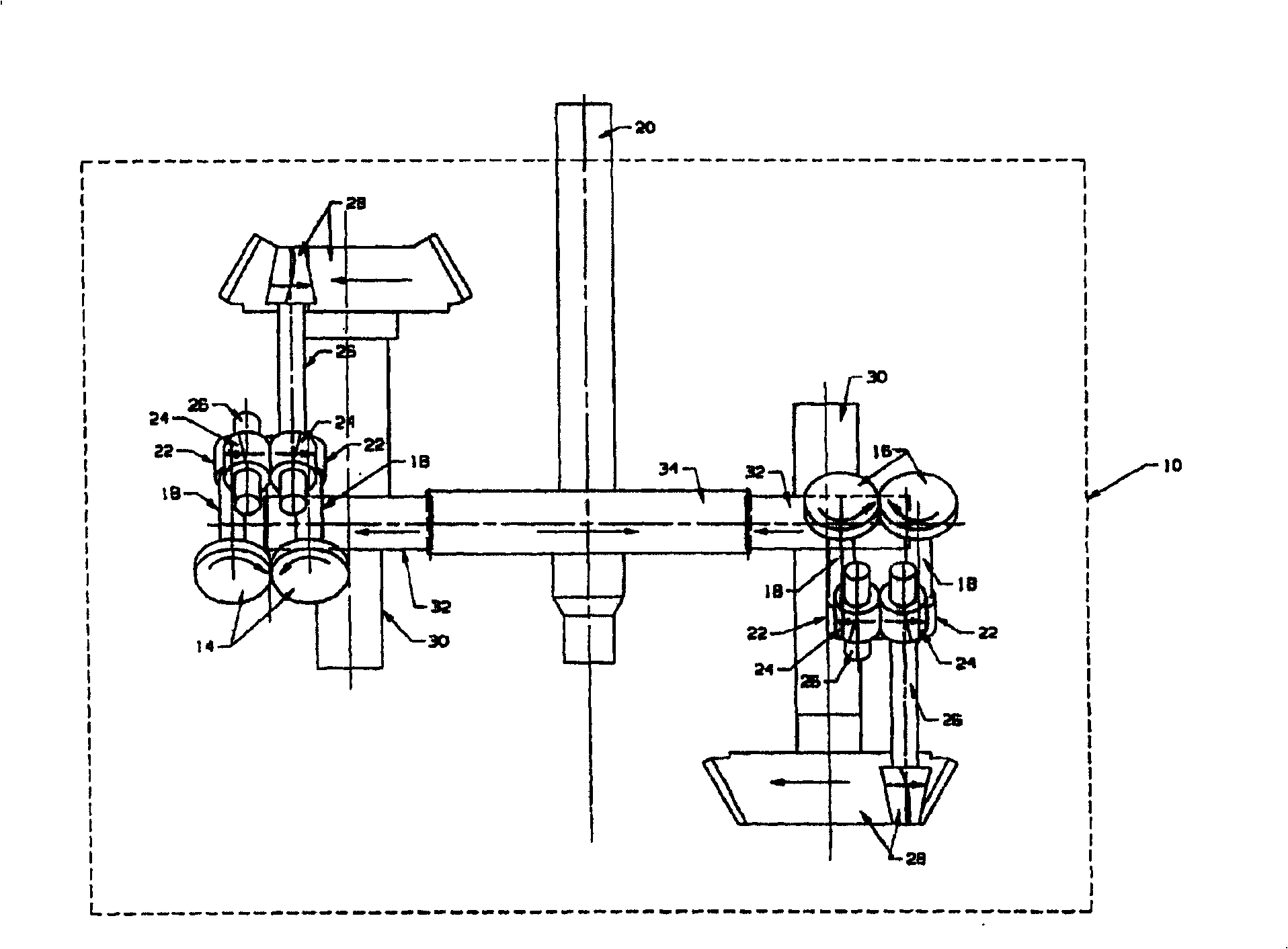

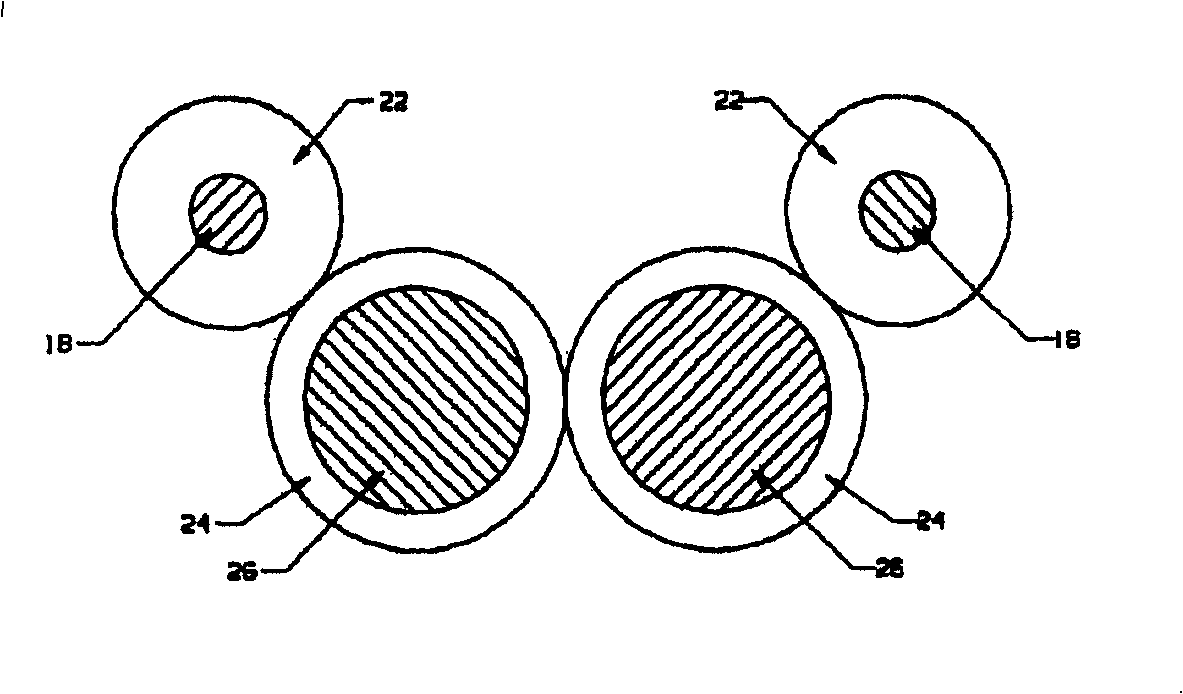

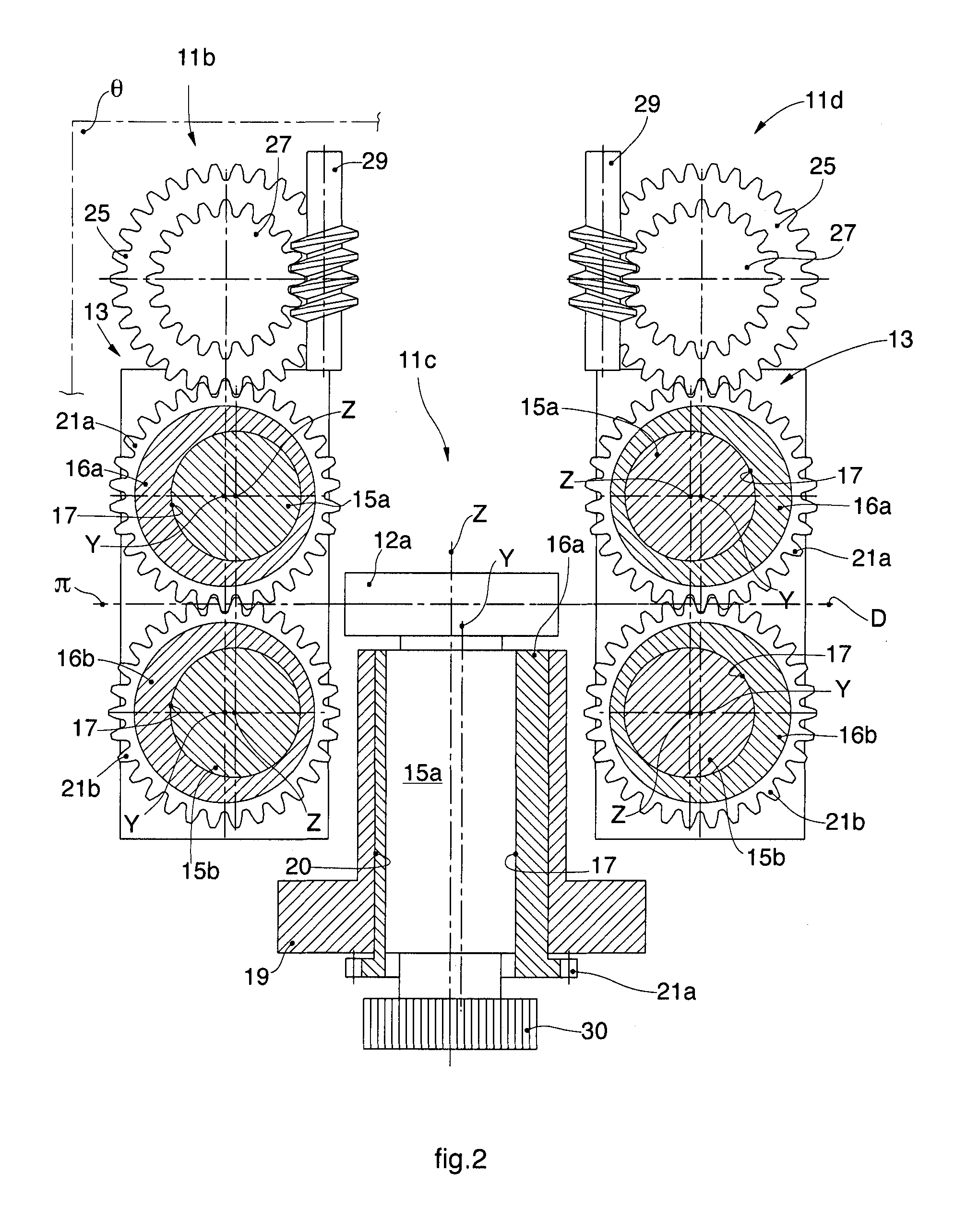

Compact cantilever rolling mill and a method of producing a metallic product

InactiveUS7257978B2High rolling forceKeep for a long timeMetal rolling stand detailsWork manipulationEngineeringCantilever

The invention relates to an apparatus for rolling a metallic product comprising a mill frame (18), a first cantilever roll shaft (19), a second cantilever roll shaft (20), both said roll shafts (19, 20) being mounted on the mill frame (18) with two sets of bearing assemblies (38, 39, 40, 41), a first rolling ring (21) mounted on the first roll shaft (19), a second rolling ring (22) mounted on the second roll shaft (20) said rolling rings (21, 22) forming a nip (23) in between, at least one ring (29) arranged with its inside surface (43) in rolling contact with the first roll shaft (19) and with at least one intermediate roll (27), which intermediate roll (27) is arranged also in rolling contact with the second roll shaft (20) and at least one drive end (42) arranged at the end of either roll shafts (19, 20) for driving the mill (16). The invention also relates to a method of producing a metallic product.

Owner:LUVATA OY

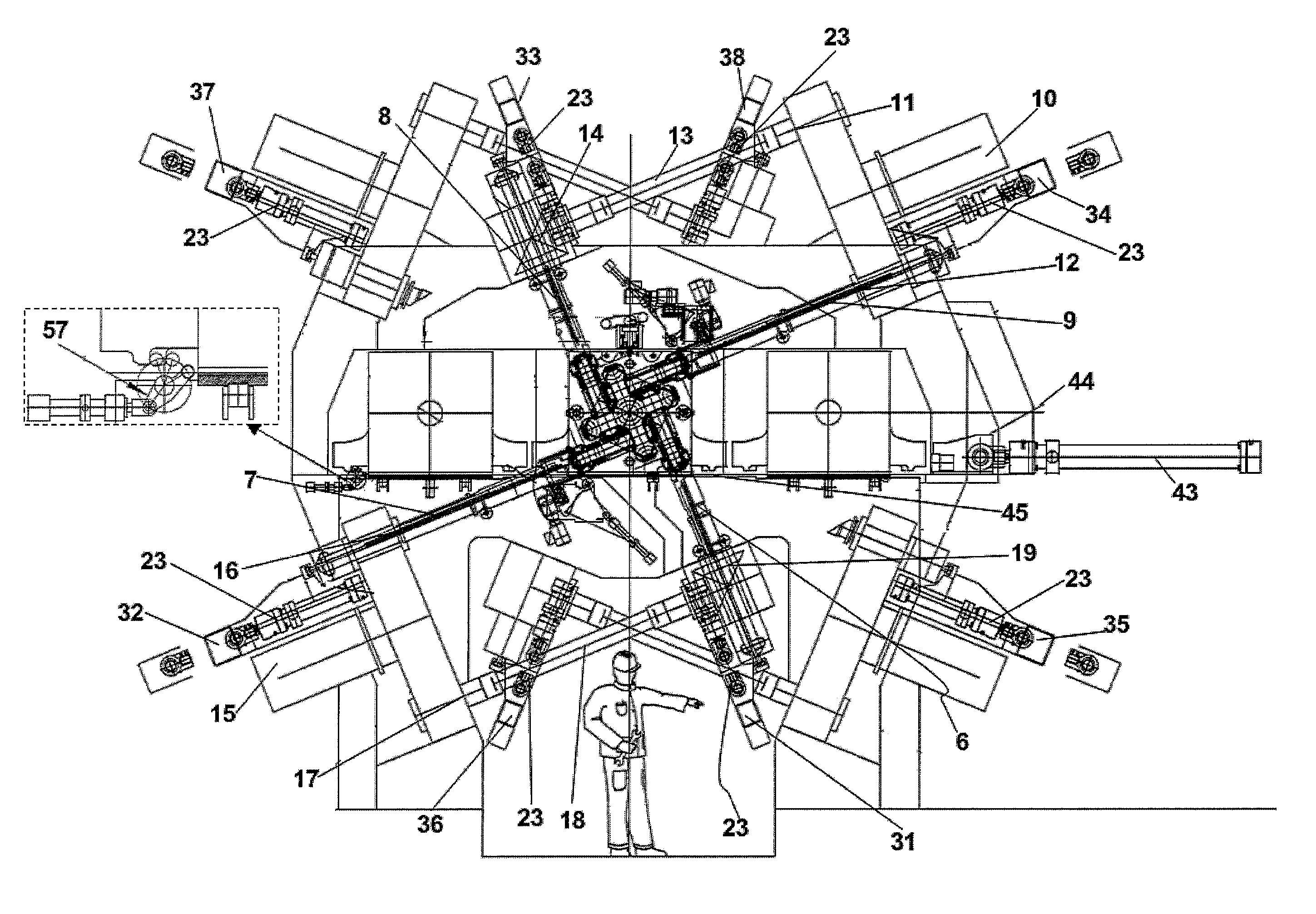

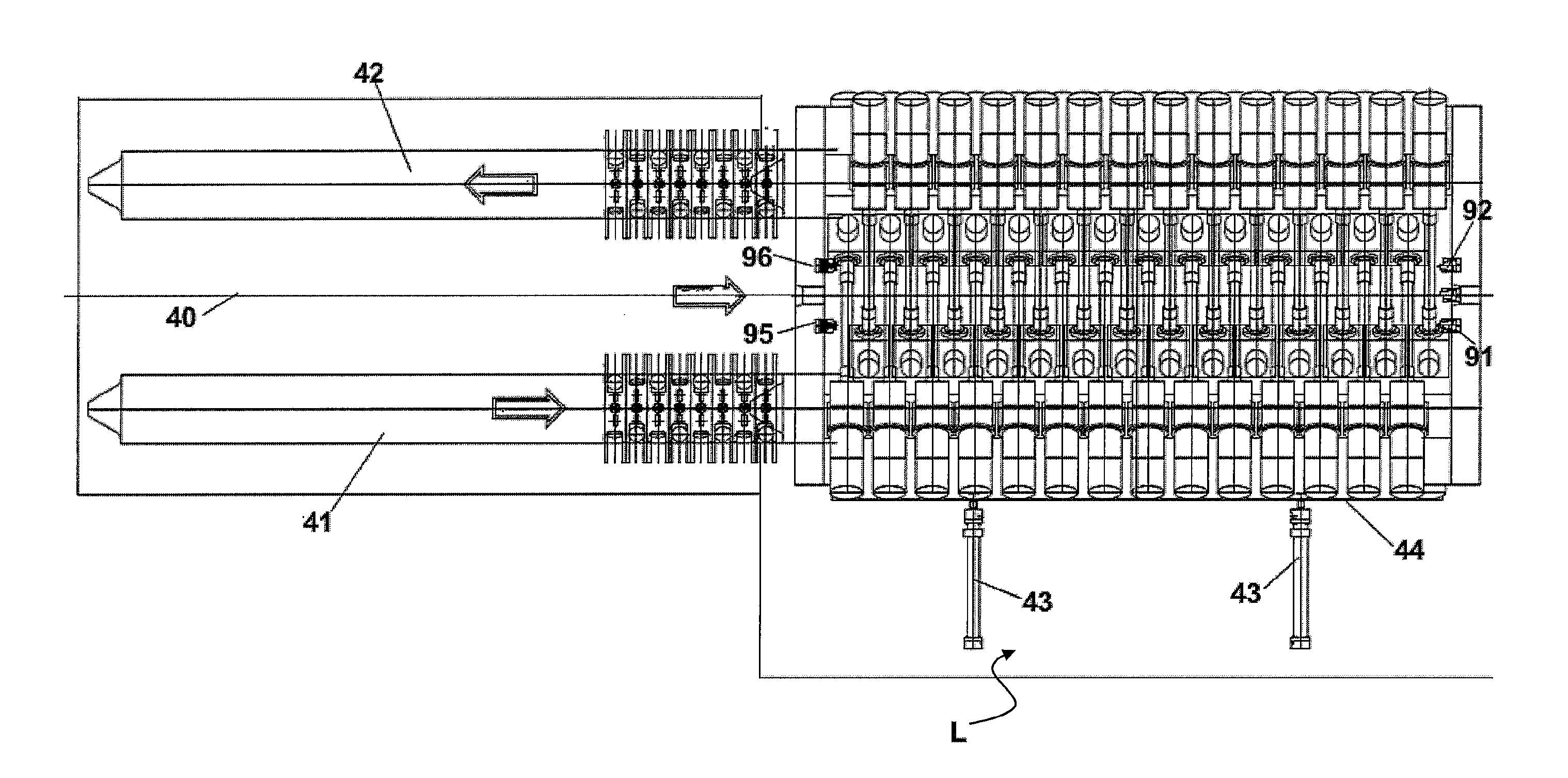

Multi-stand rolling mill of the longitudinal elongator kind for rod-shaped bodies, comprising four-rolls stands, and method for substituting the stands

There is described multi-stand rolling mill with stands having four motorized rolls and provided with controls outside the stand and retractile spindles, which comprises a central body with said stands; a first platform (41) on a side charge position carrying the substitution stands; a second platform (42) on a side discharge position, opposite to said side charge position; a transversal translation device (43, 44) adapted to push the substitution stands against the corresponding stands to be substituted on the central body. The stands to be substituted translate on the second platform, and the substitution stands substitute the stands to be substituted in the central body.

Owner:DANIELI & C OFF MEC SPA

Multi-stand rolling mill of the longitudinal elongator kind for rod-shaped bodies, comprising four-rolls stands, and method for substituting the stands

There is described multi-stand rolling mill with stands having four motorized rolls and provided with controls outside the stand and retractile spindles, which comprises a central body with said stands; a first platform (41) on a side charge position carrying the substitution stands; a second platform (42) on a side discharge position, opposite to said side charge position; a transversal translation device (43, 44) adapted to push the substitution stands against the corresponding stands to be substituted on the central body. The stands to be substituted translate on the second platform, and the substitution stands substitute the stands to be substituted in the central body.

Owner:DANIELI & C OFF MEC SPA

Compact cantilever rolling mill and a method of producing a metallic product

The invention relates to an apparatus for rolling a metallic product comprising a mill frame ( 18 ), a first cantilever roll shaft ( 19 ), a second cantilever roll shaft ( 20 ), both said roll shafts ( 19, 20 ) being mounted on the mill frame ( 18 ) with two sets of bearing assemblies ( 38, 39, 40, 41 ), a first rolling ring ( 21 ) mounted on the first roll shaft ( 19 ), a second rolling ring ( 22 ) mounted on the second roll shaft ( 20 ) said rolling rings ( 21, 22 ) forming a nip ( 23 ) in between, at least one ring ( 29 ) arranged with its inside surface ( 43 ) in rolling contact with the first roll shaft ( 19 ) and with at least one intermediate roll ( 27 ), which intermediate roll ( 27 ) is arranged also in rolling contact with the second roll shaft ( 20 ) and at least one drive end ( 42 ) arranged at the end of either roll shafts ( 19, 20 ) for driving the mill ( 16 ). The invention also relates to a method of producing a metallic product.

Owner:LUVATA OY

Compact cantilever rolling mill and a method of producing a metallic product

InactiveUS20050279149A1High rolling forceKeep for a long timeMetal rolling stand detailsWork manipulationCantileverRolling mill

The invention relates to an apparatus for rolling a metallic product comprising a mill frame (18), a first cantilever roll shaft (19), a second cantilever roll shaft (20), both said roll shafts (19, 20) being mounted on the mill frame (18) with two sets of bearing assemblies (38, 39, 40, 41), a first rolling ring (21) mounted on the first roll shaft (19), a second rolling ring (22) mounted on the second roll shaft (20) said rolling rings (21, 22) forming a nip (23) in between, at least one ring (29) arranged with its inside surface (43) in rolling contact with the first roll shaft (19) and with at least one intermediate roll (27), which intermediate roll (27) is arranged also in rolling contact with the second roll shaft (20) and at least one drive end (42) arranged at the end of either roll shafts (19, 20) for driving the mill (16). The invention also relates to a method of producing a metallic product.

Owner:LUVATA OY

Device in a wire rolling mill

InactiveUS6138886ASimple designSpace minimizationProjector film strip handlingMetal rolling stand detailsMotor driveEngineering

A device in a wire rolling mill includes a pair of grooved rolls. Each grooved roll is fixedly attached to the free end of a rotatably supported spindle. Each grooved roll is positionable relative to the other so that they between themselves define a rolling gap of adjustable size. At least one of the spindles is arranged integrally with the output shaft of an electro motor. The electro motor drives the spindle directly thereby avoiding heavy and space-requiring transmissions.

Owner:AB SKF

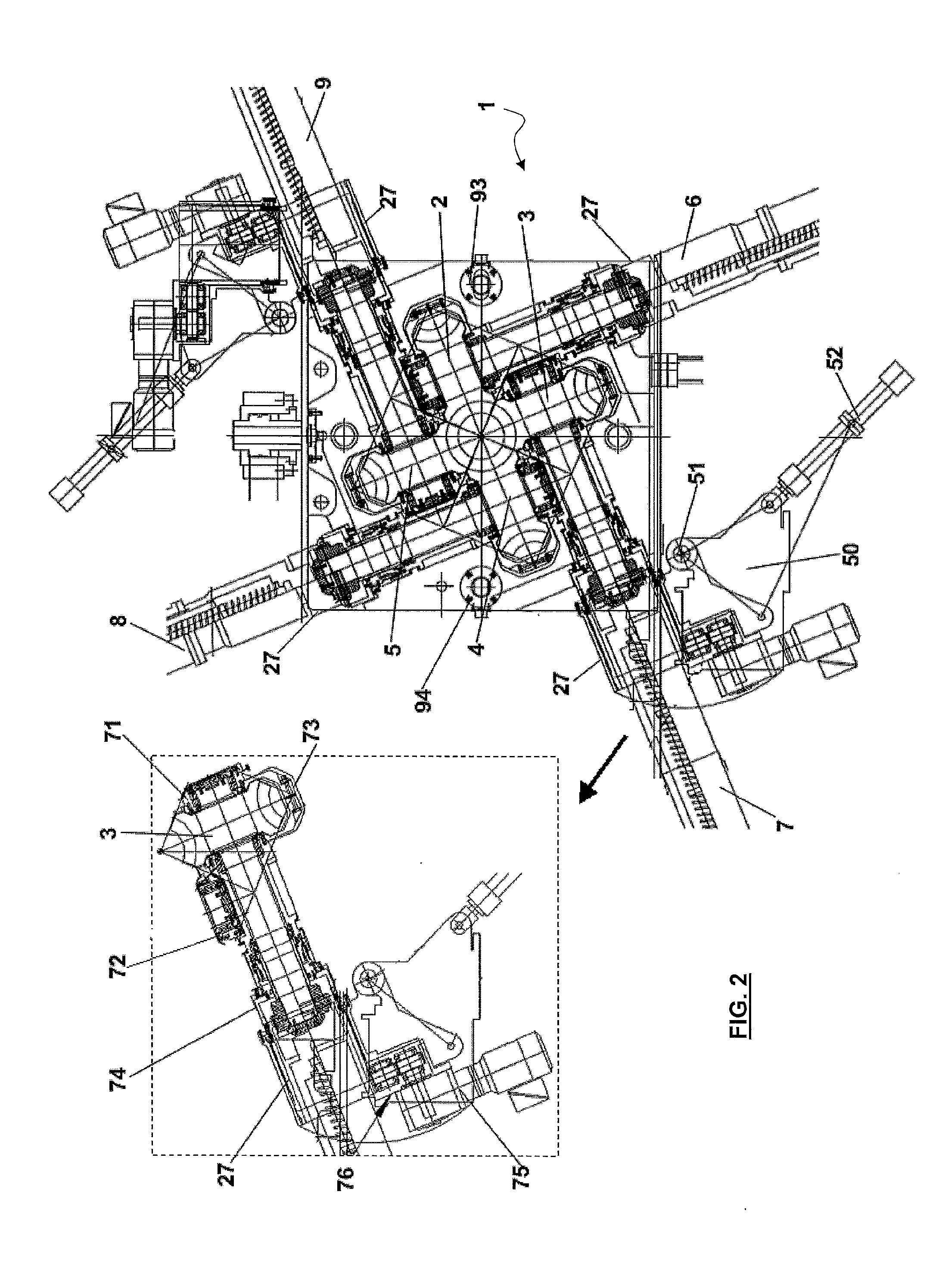

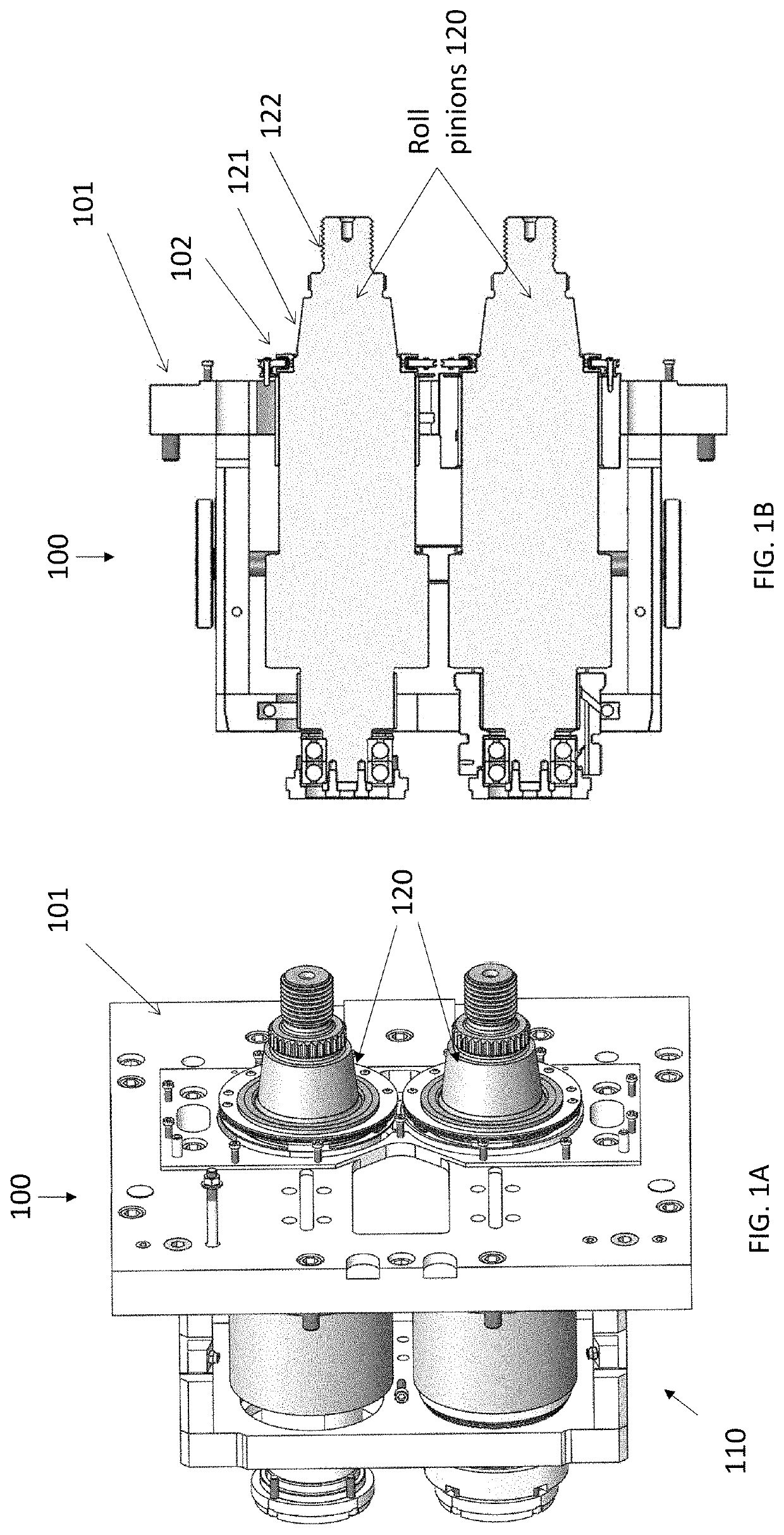

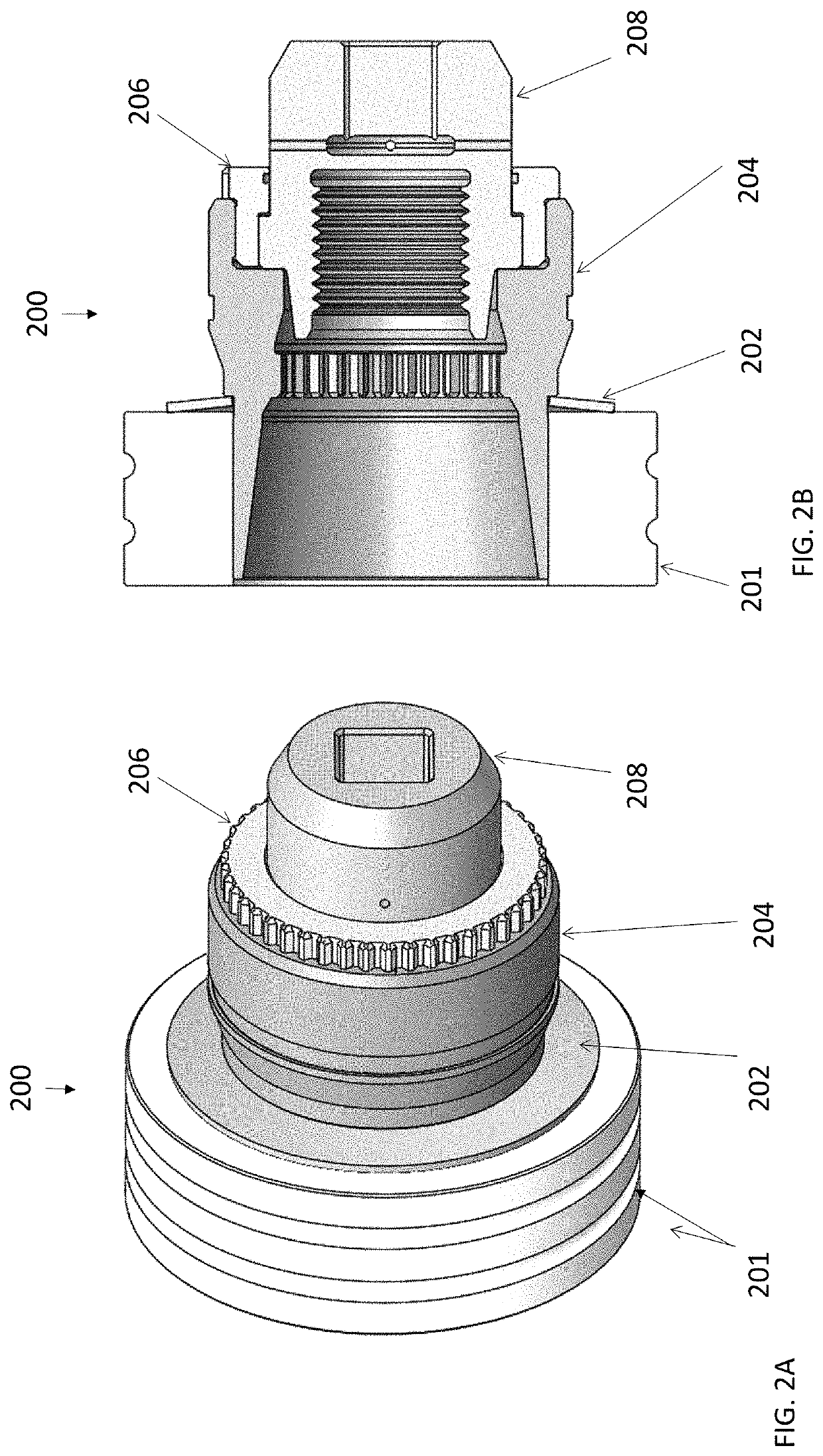

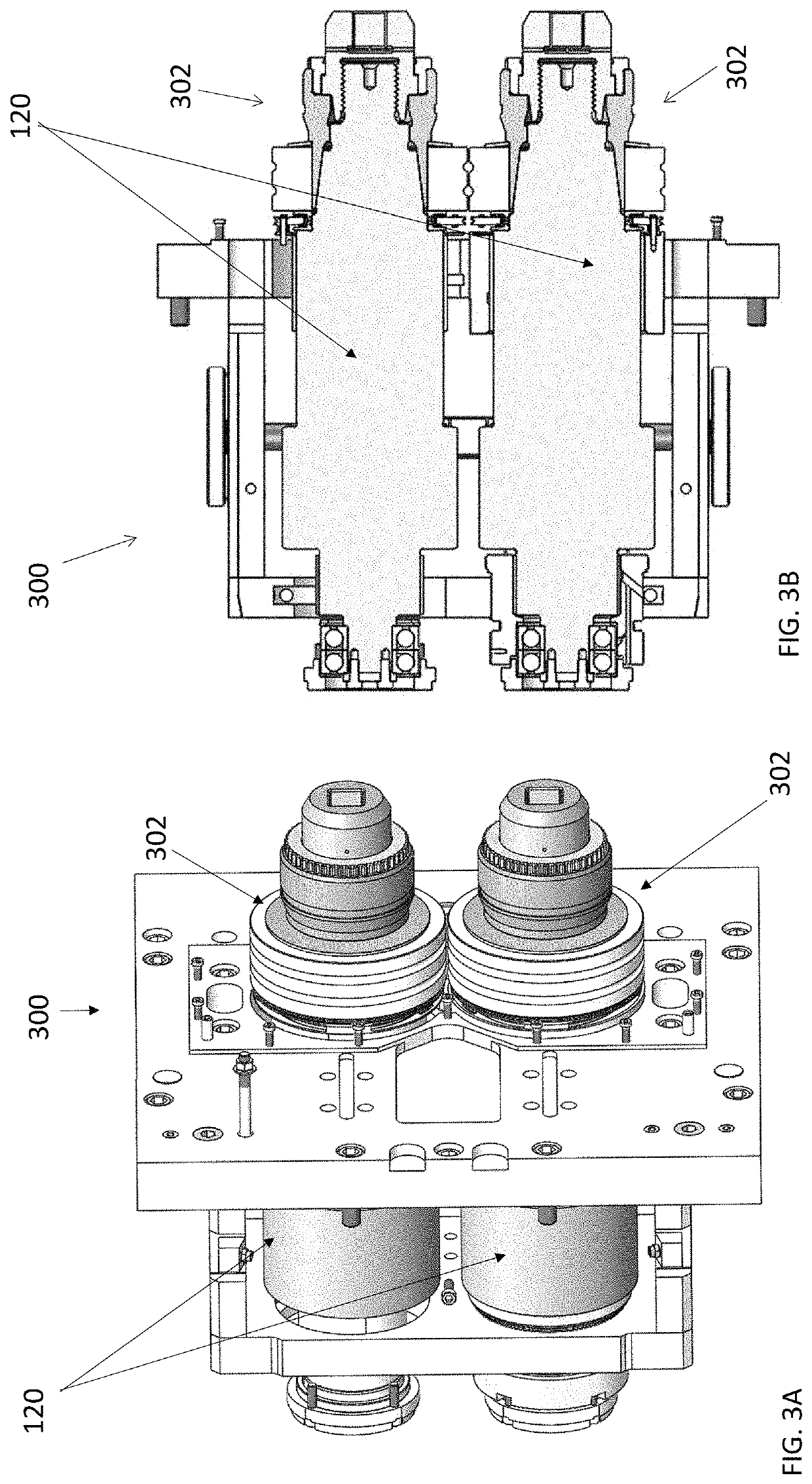

Mechanical high speed roll change system for use with robotic roll change system

A roll mounting system is provided that includes a roll assembly coupled to one or more rolls. The roll assembly is configured to position the one or more rolls using a tapered assembly for mounting or dismounting of the one or more rolls. Also, the roll mounting system includes a torque assembly coupled to the roll assembly. The torque assembly is configured to provide torque to the roll assembly for mounting or dismounting of the one more rolls.

Owner:PRIMETALS TECH USA

Method and apparatus for producing steel semi-finished products

InactiveCN105499271BExtend your lifeImprove reliabilityMultiple strand roll mill standMetal rolling stand detailsLiquid steelMaterials science

A method and equipment for producing steel semi-finished products. The invention discloses a method and equipment for continuously producing steel semi-finished products. A plurality of bloom strands are continuously produced by casting liquid steel into a plurality of molds using a continuous casting device. Subsequently, the one or more bloom strands are fed in-line to a corresponding rolling mill configured to hot-roll the input continuous casting bloom strands to produce rolled billets.

Owner:庞廷

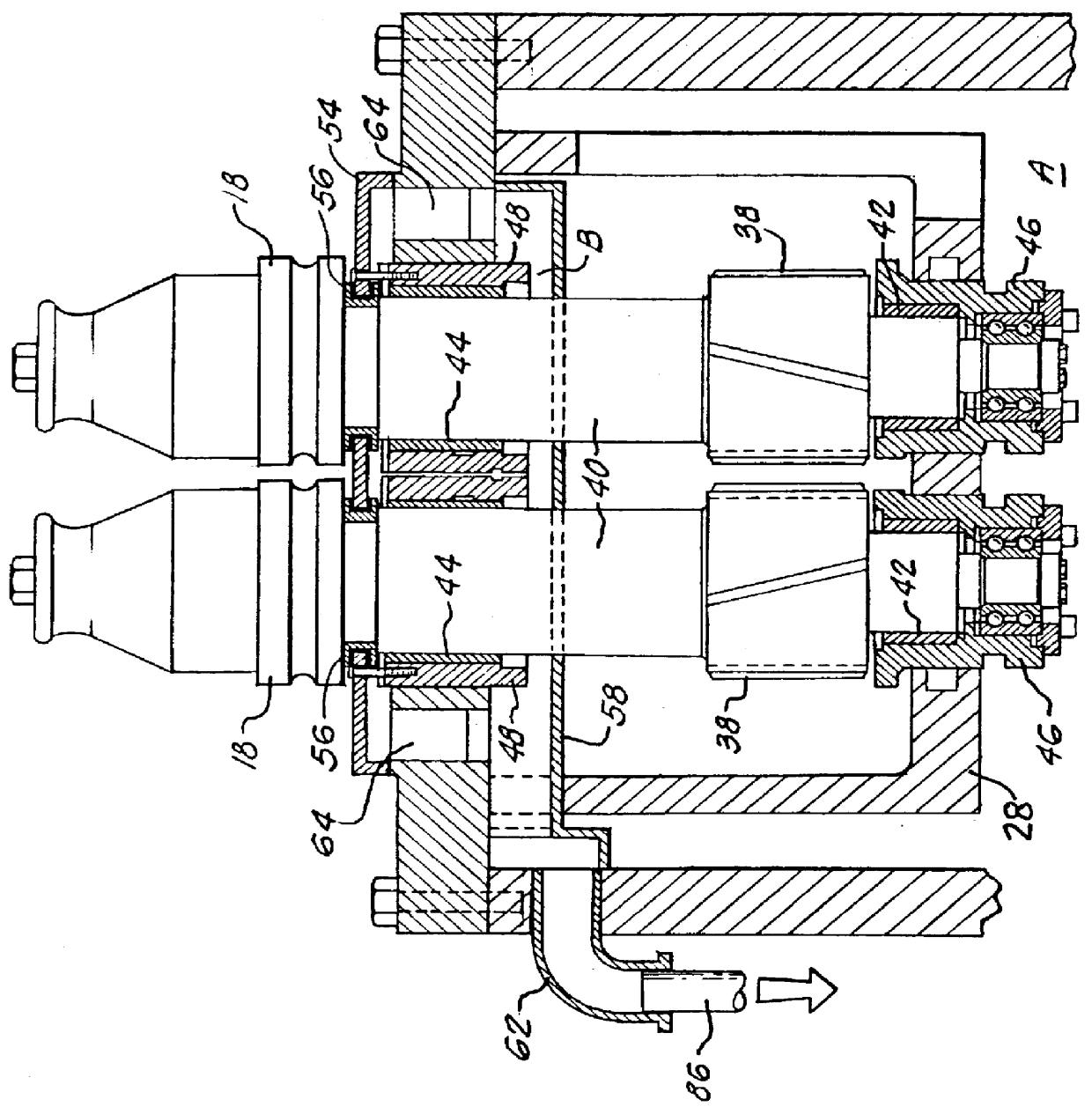

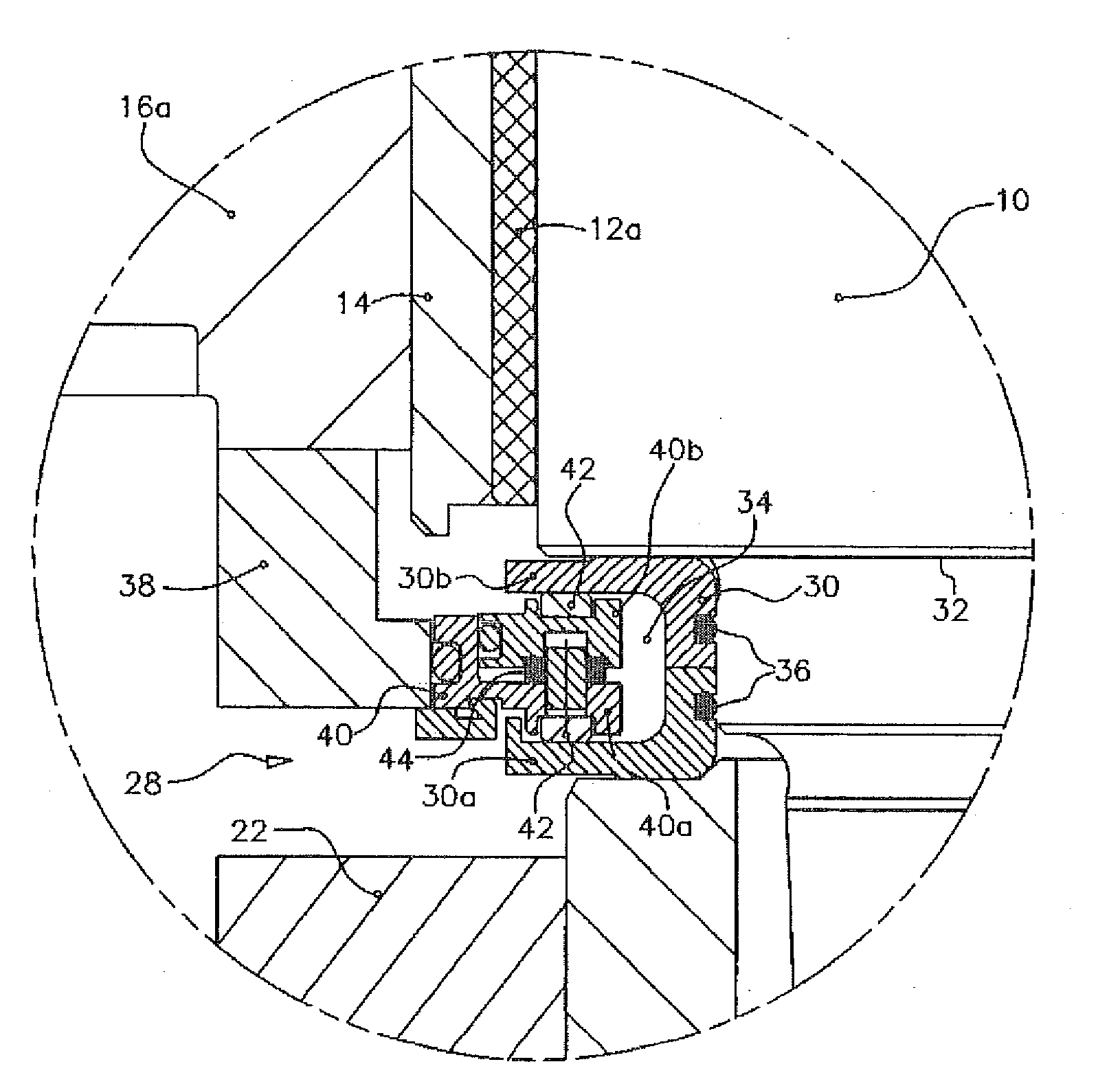

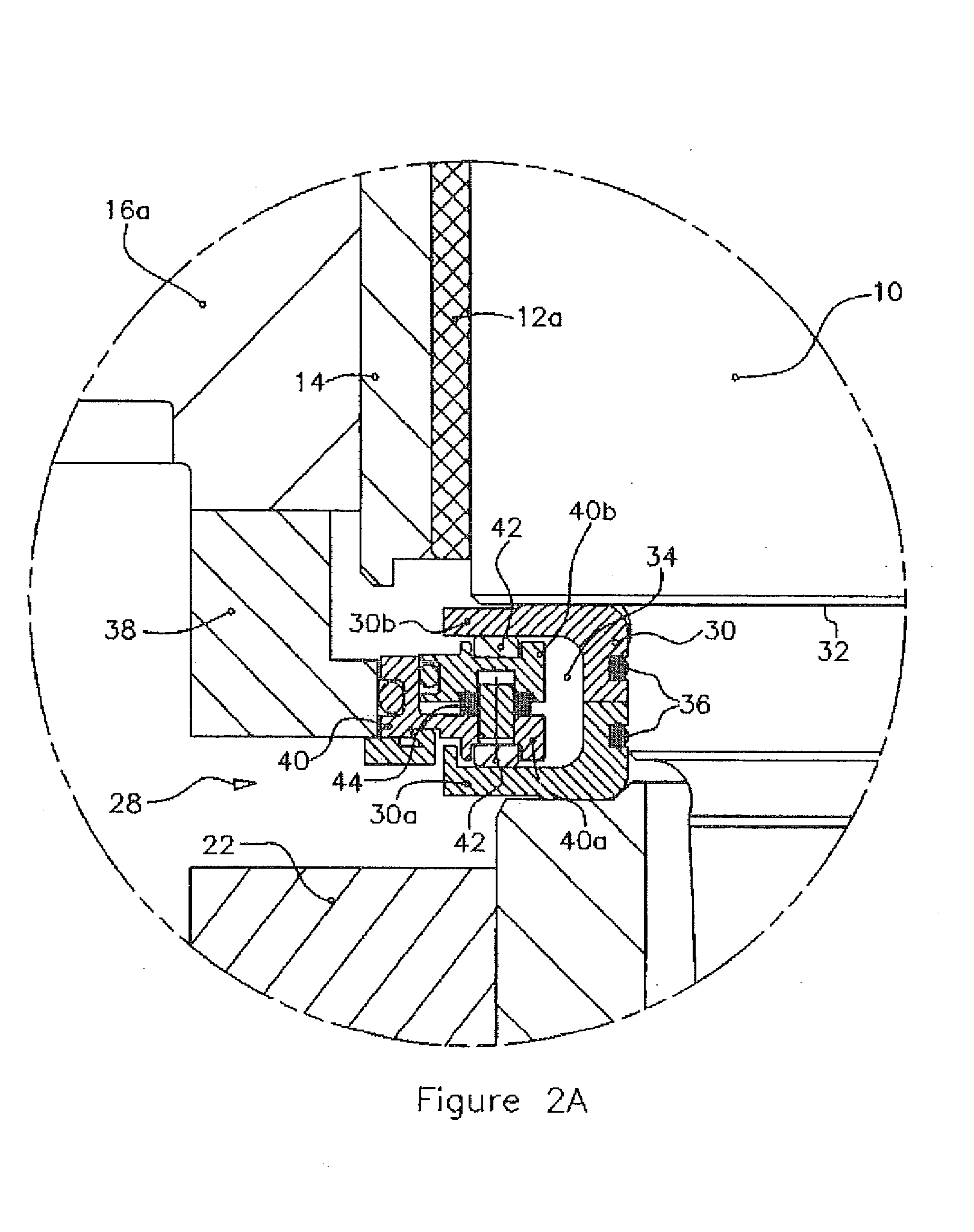

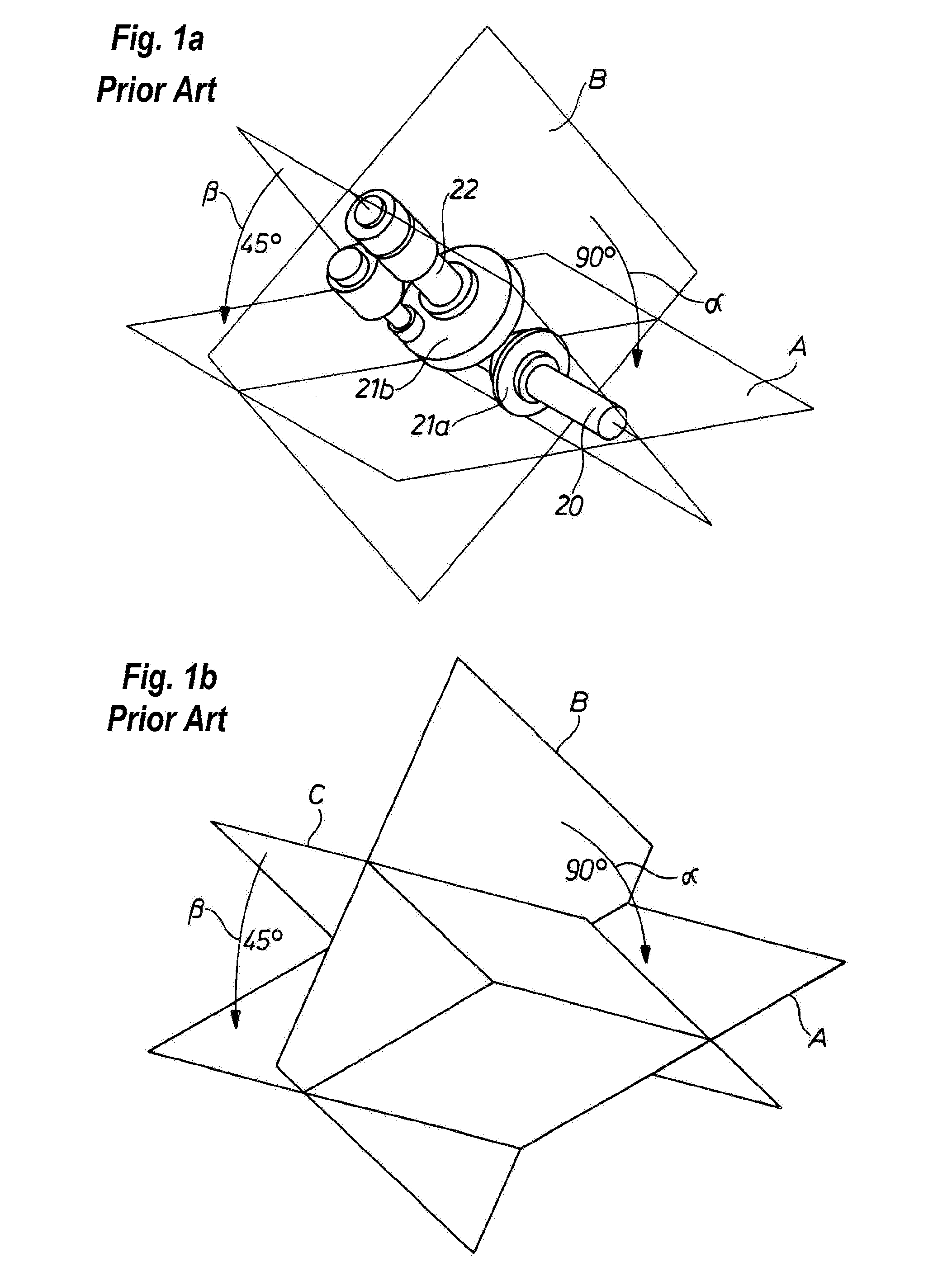

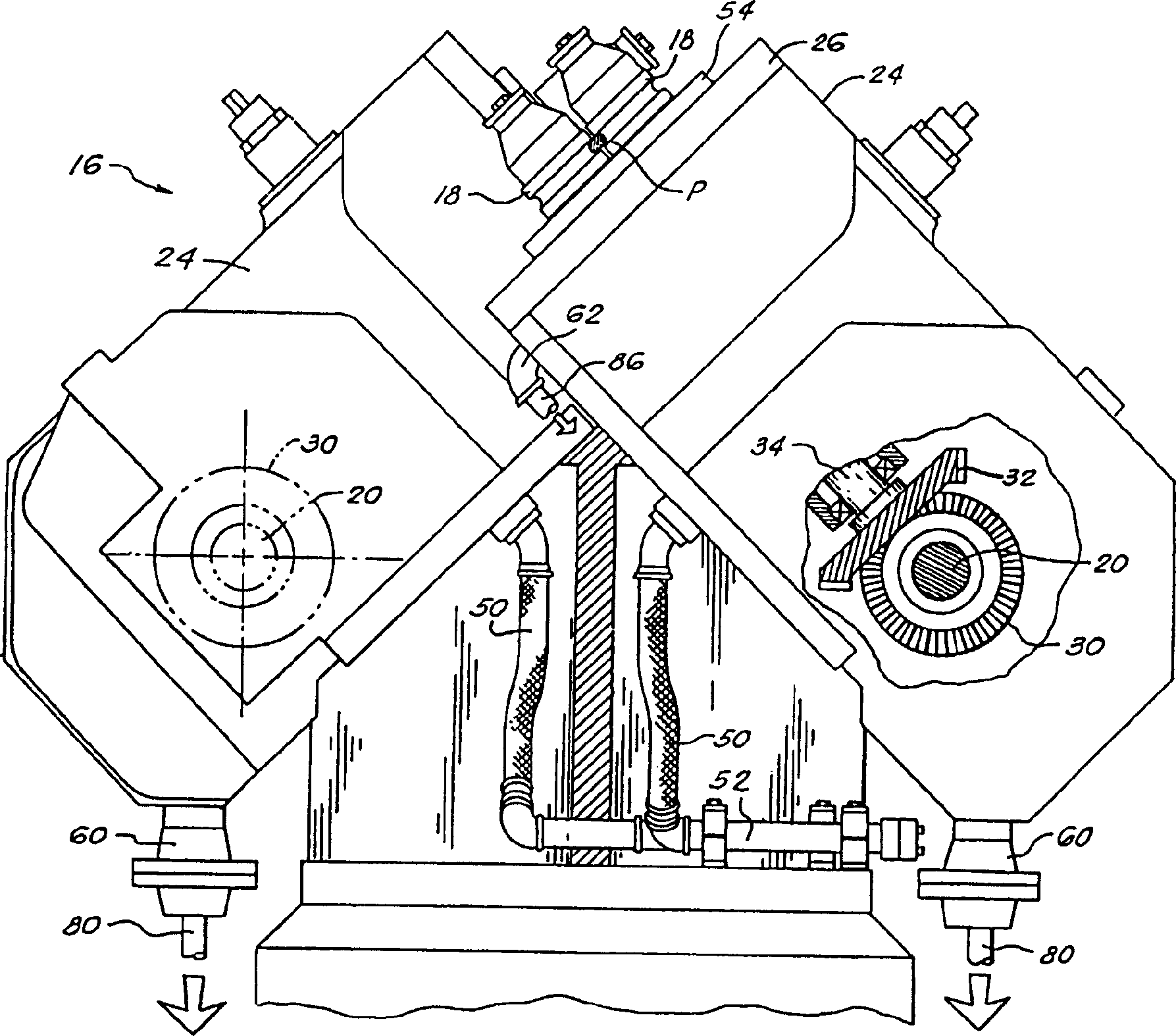

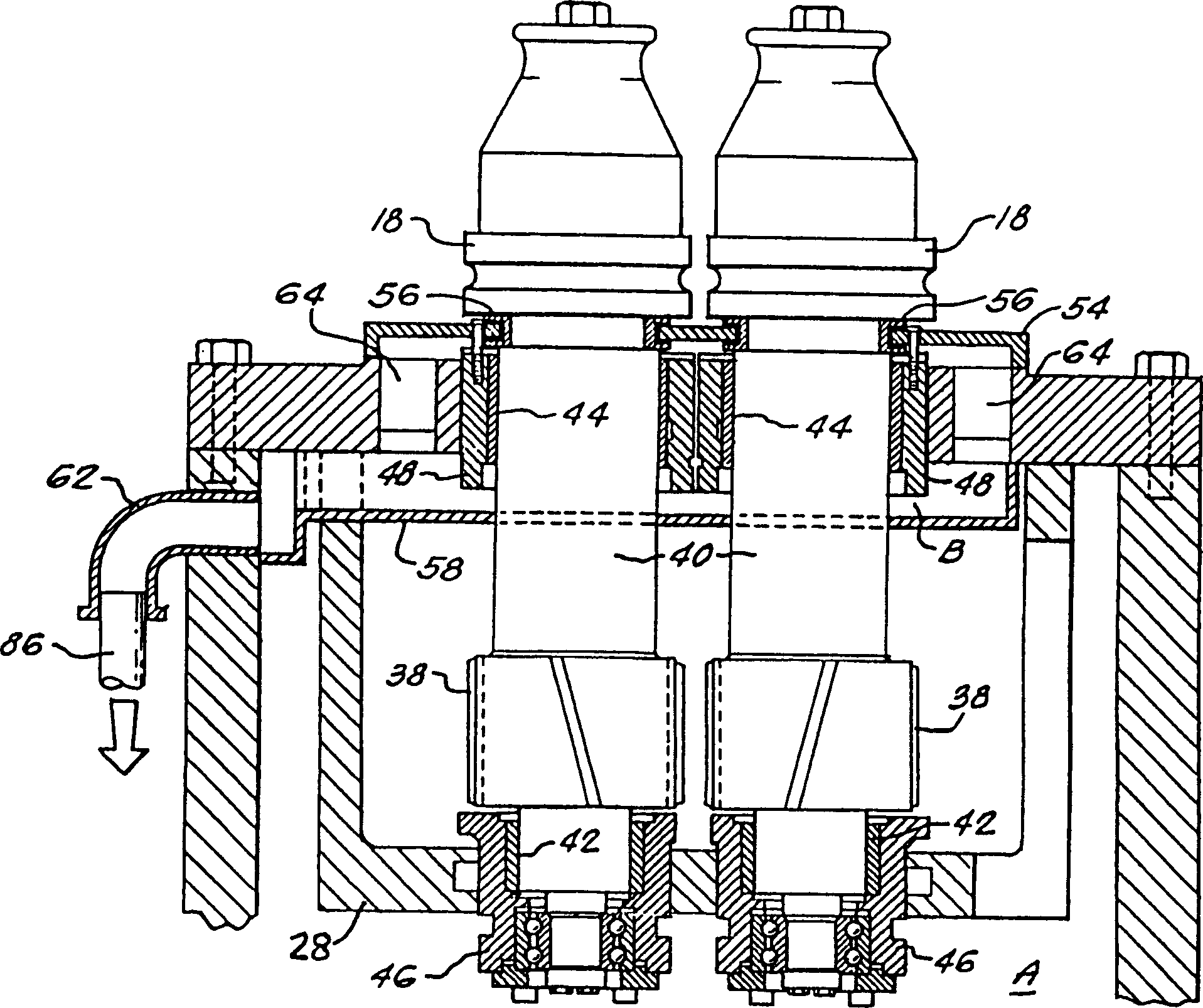

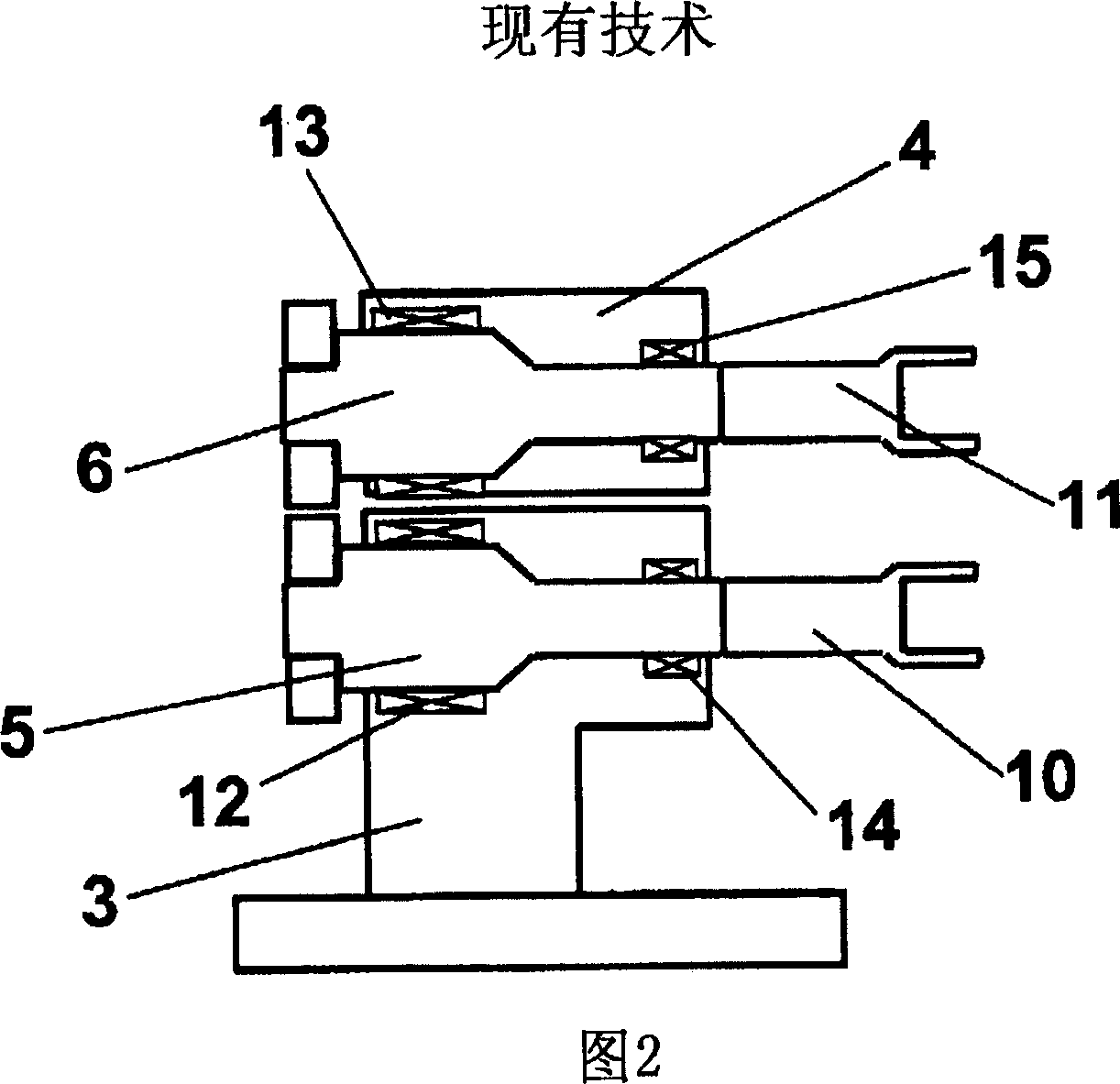

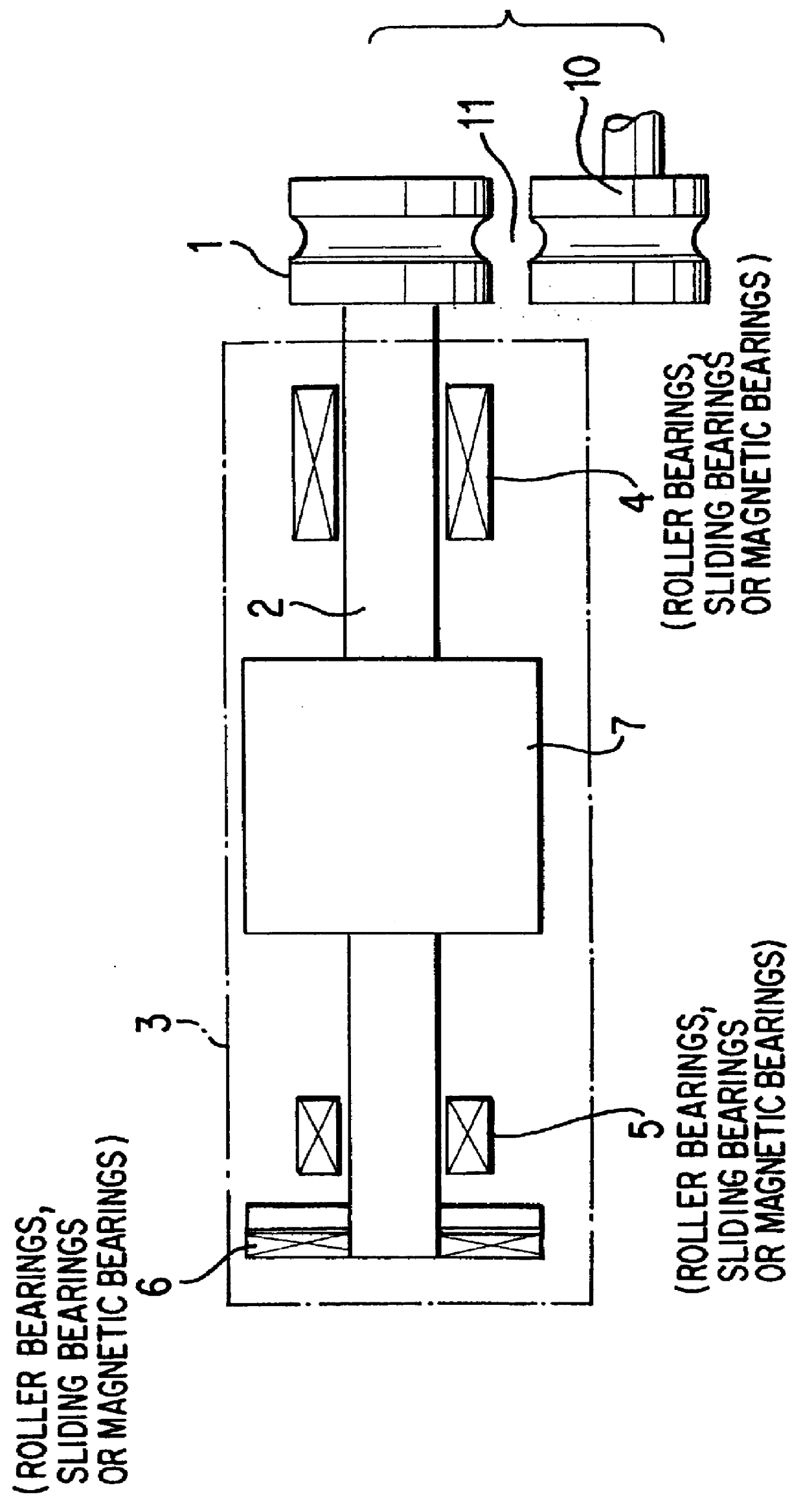

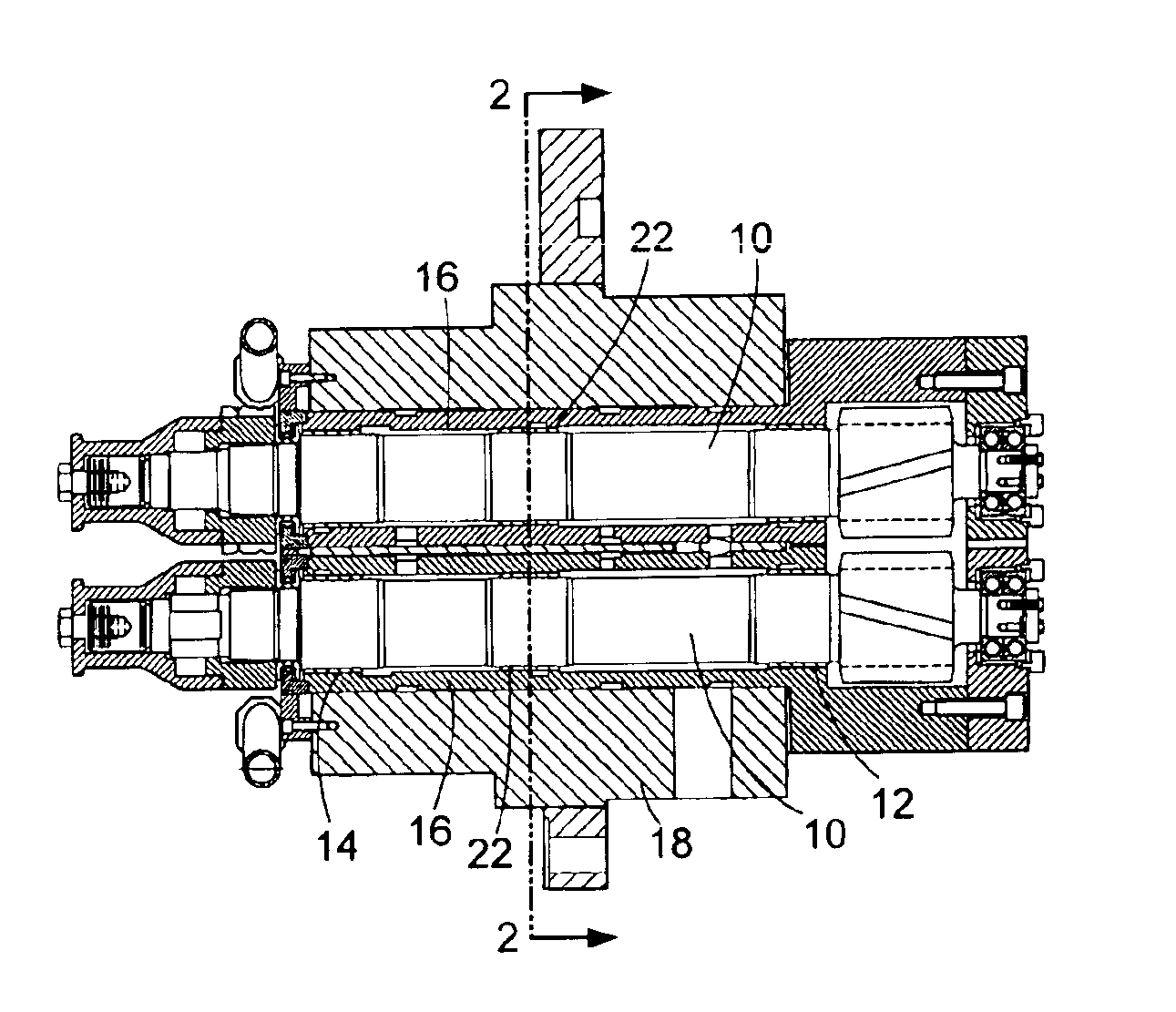

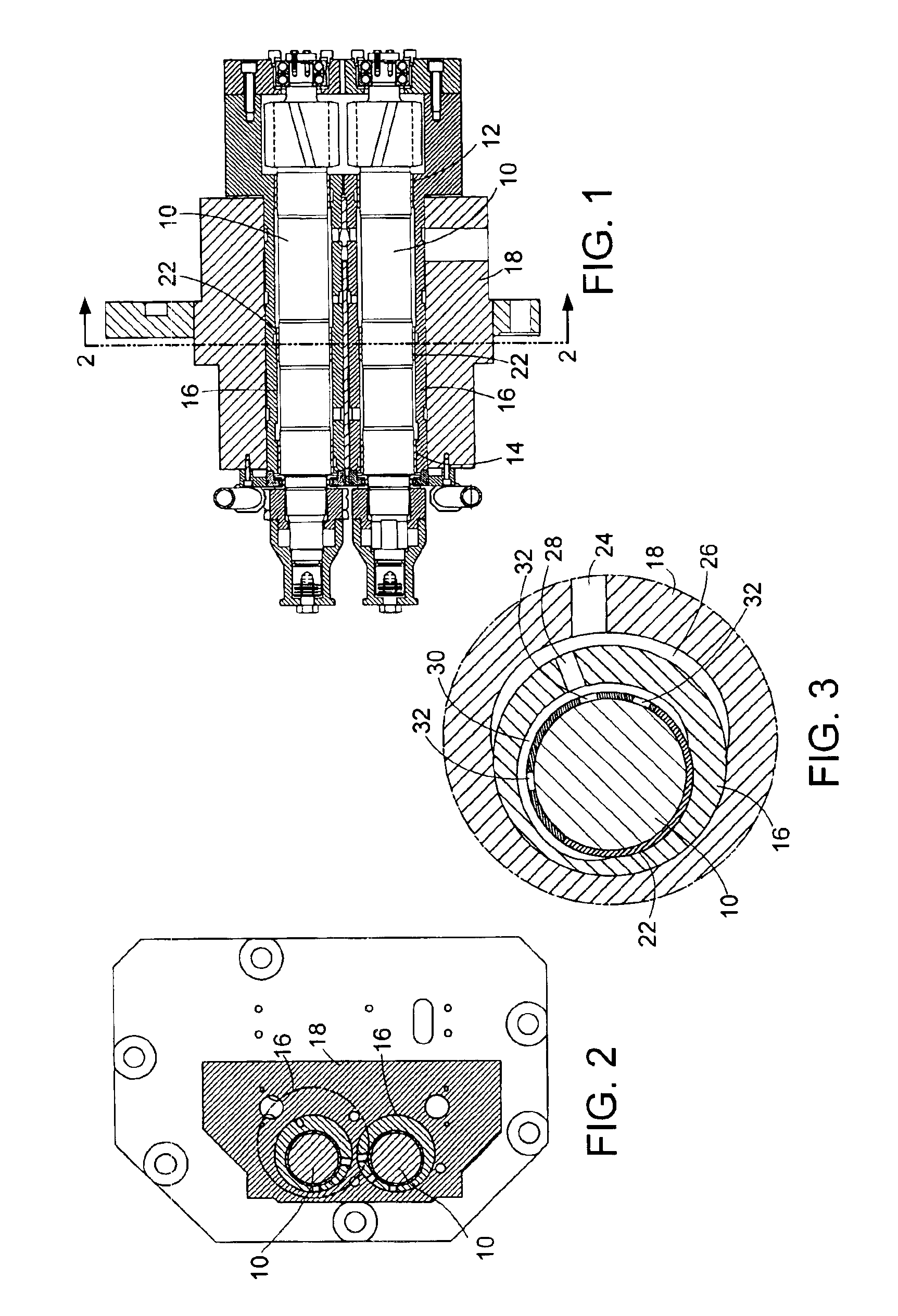

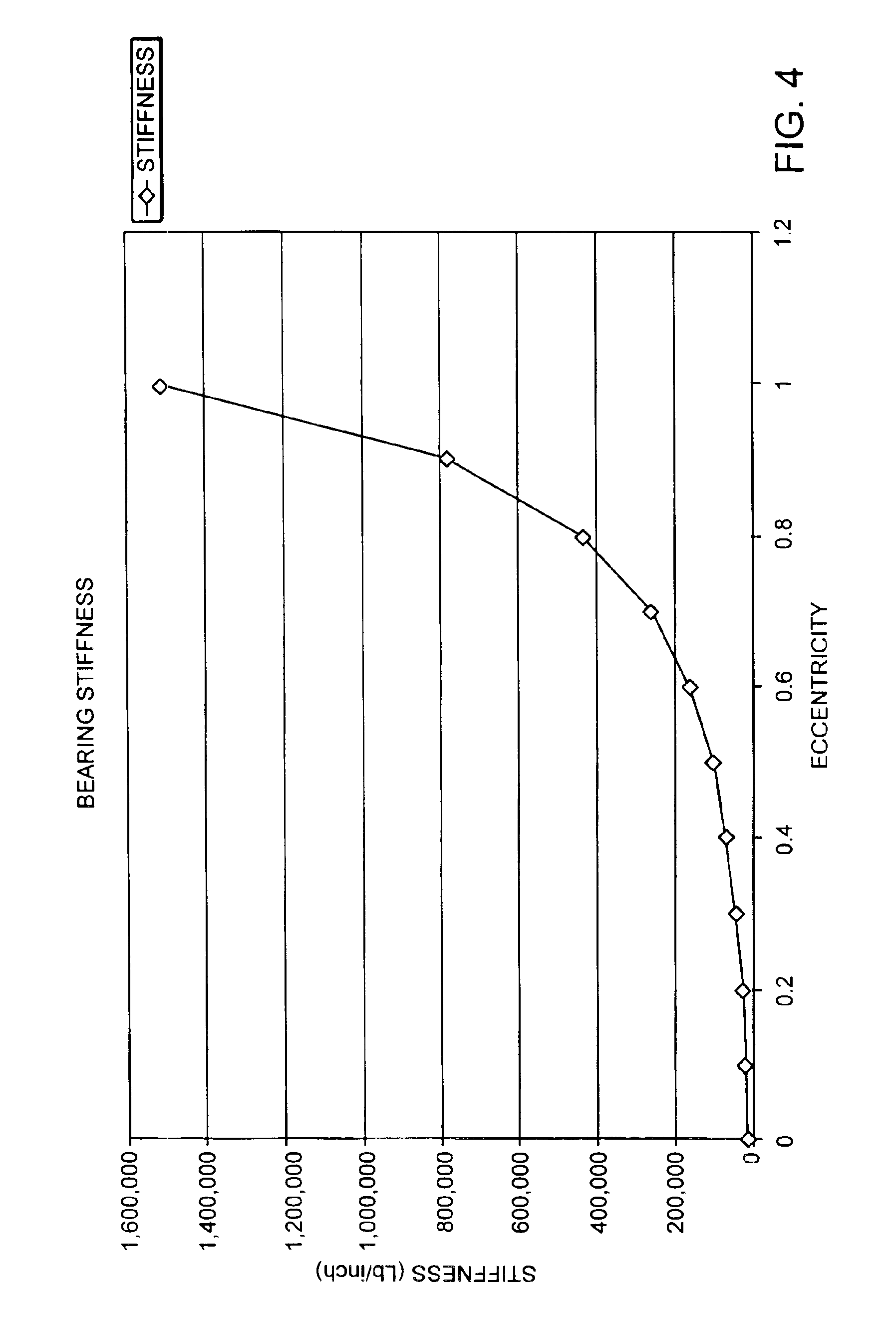

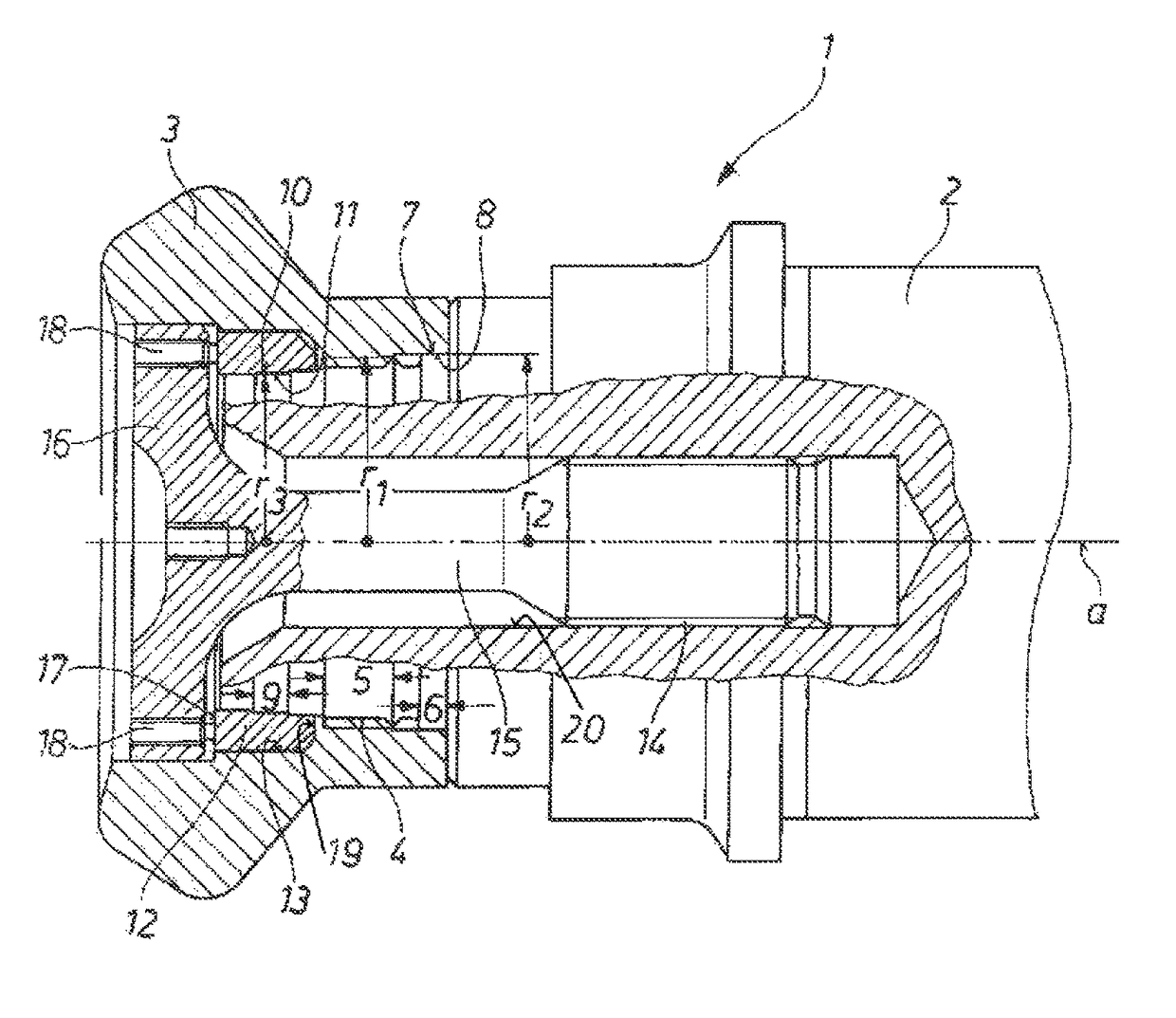

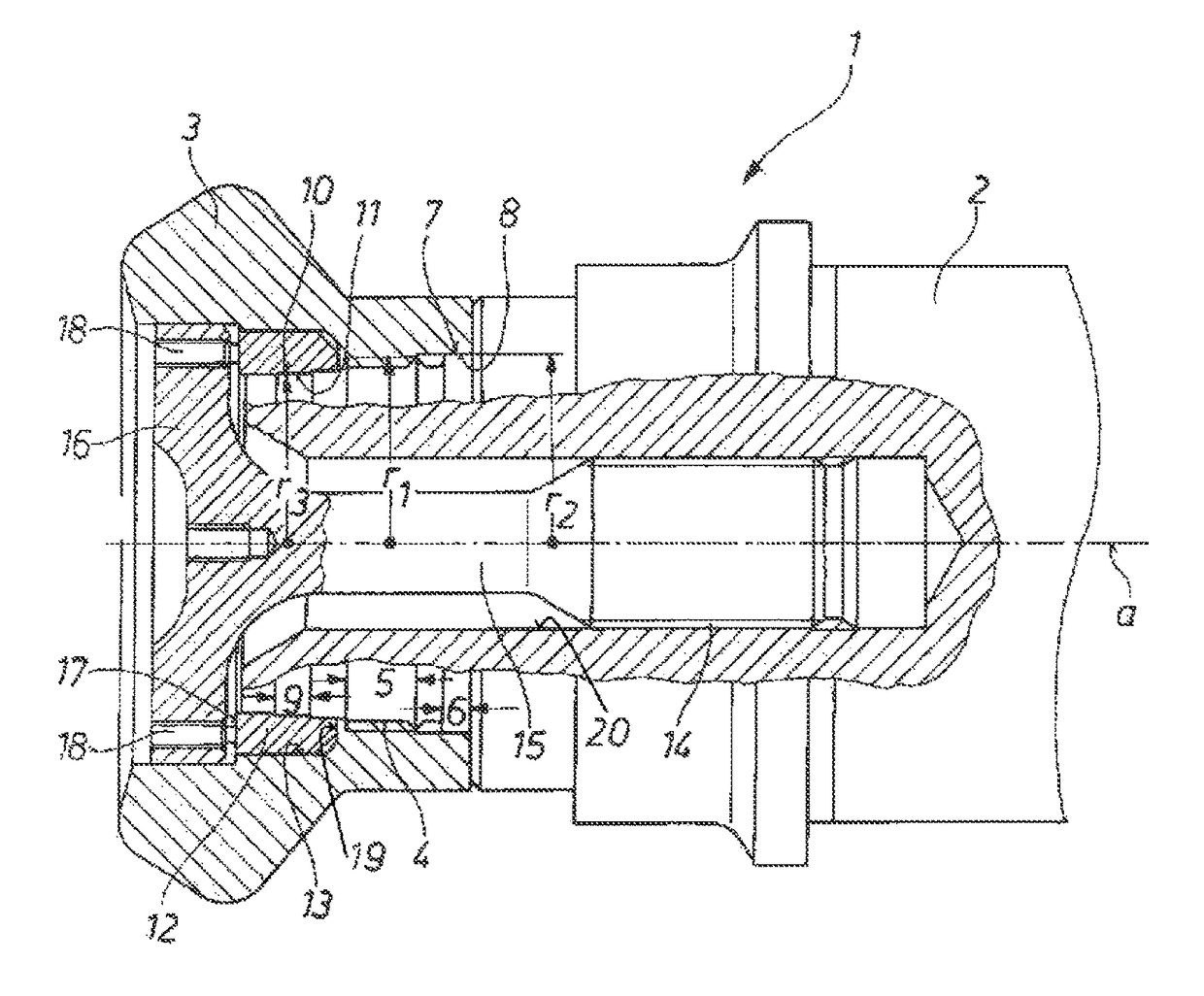

Triple bearing arrangement for cantilevered roll shafts

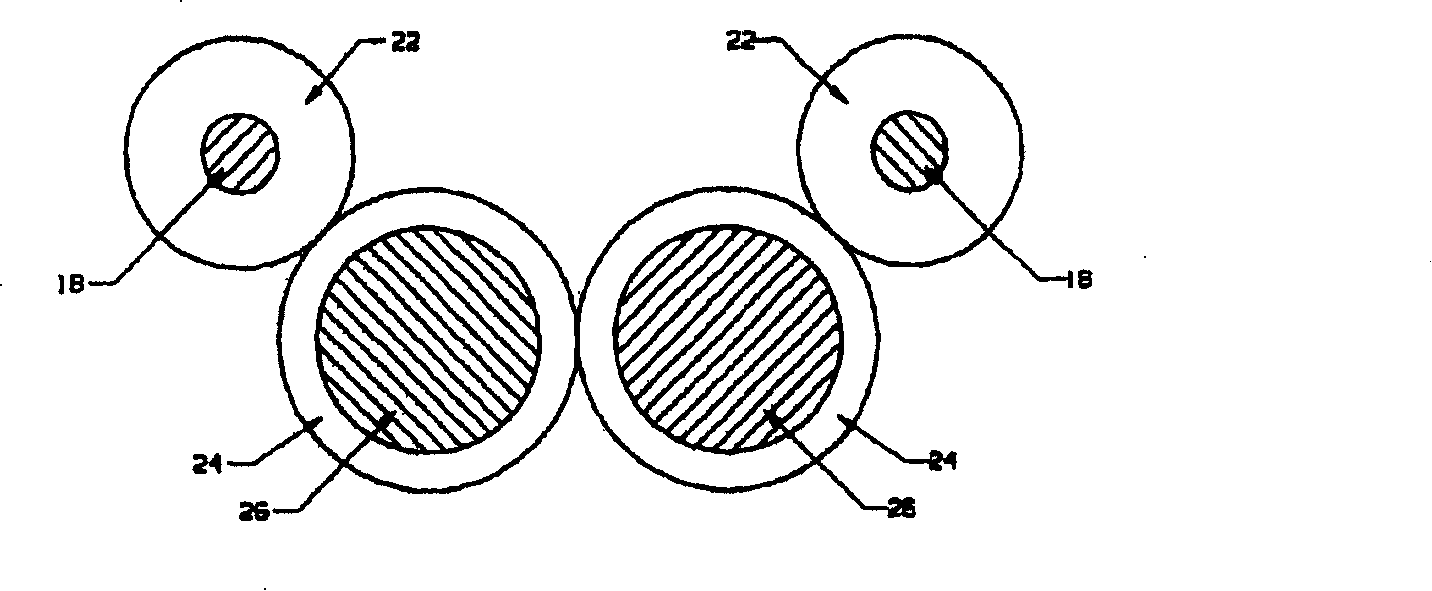

InactiveUS6959579B2Improve rigidityMetal rolling stand detailsSynthetic resin layered productsWork rollCantilever

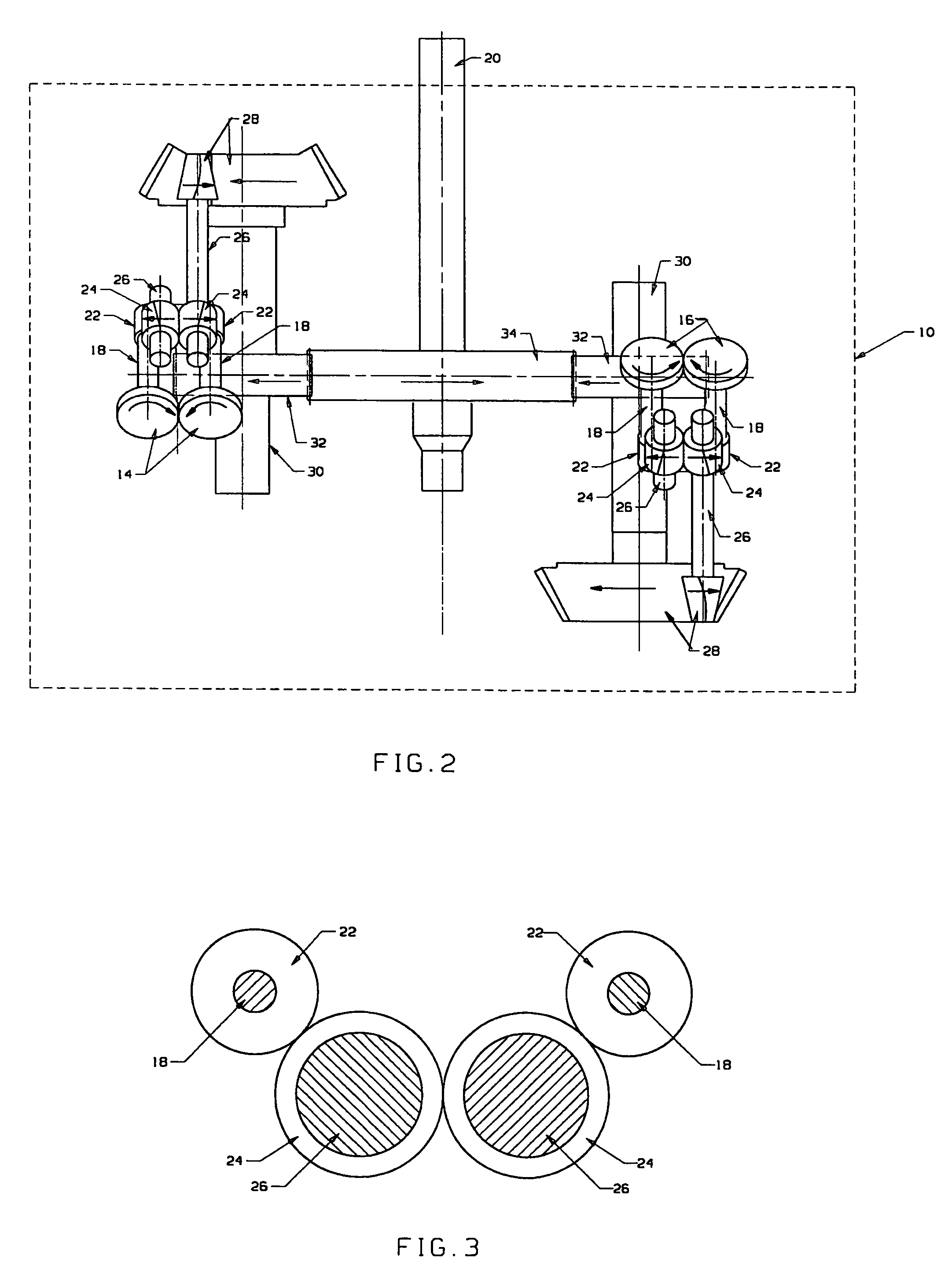

A rolling mill roll stand comprises parallel roll shafts rotatably supported by axially spaced first and second bearings contained in parallel eccentric sleeves. The eccentric sleeves are rotatably supported in a housing and the roll shafts have cantilevered ends that project externally from one side of the housing and that are adapted to carry work rolls. Third oil film bearings are contained by the eccentric sleeves and are arranged to rotatably support the roll shafts at intermediate locations between and spaced axially from both the first and second bearings.

Owner:PRIMETALS TECH USA

Seal assembly

ActiveUS8740462B2Compensate for misalignmentIncrease contactEngine sealsMetal rolling stand detailsEngineeringFlange

A seal assembly is disclosed for use between a housing and a rotatable shaft protruding exteriorly from the housing, with the shat being journalled for rotation in an eccentric cartridge which in turn is rotatably adjustable. The seal assembly comprises a circular flinger mounted on the shaft for rotation therewith. The flinger has radially outwardly projecting flanges defining an axial space therebetween. A seal carrier surrounds the flinger and has axially spaced first and second inner rims projecting radially inwardly into the space between the flanges of the flinger. Ring seals are carried by the seal carriers. The inner rims are resiliently urged to maintain the ring seals in contact with the flinger flanges.

Owner:PRIMETALS TECH USA

Magnetic suspension superconductive steel rolling machine

InactiveCN105414180AEven by forceAvoid uneven thicknessMetal rolling stand detailsMetal rolling arrangementsDrive shaftEngineering

The invention discloses a magnetic suspension superconductive steel rolling machine. A piston is connected with a frame through a thread. A cylinder body is connected with an upper rolling and pressing mechanism. The oil pressure pushes the upper rolling and pressing mechanism to move forwards and backwards along guide rails fixed to the two sides of the frame. Cooling is conducted through liquid nitrogen. The central line of a supporting roller and the central line of a working roller are kept parallel by adjusting the magnetic force of a permanent magnet. A steel plate to be rolled and pressed is flatly placed on a magnetic suspension rolling and pressing platform in the width direction of the working roller. The rotary central line of the rolling and pressing platform intersects with the central line of the working roller. The rolling and pressing platform supports the steel plate to be rolled and pressed and squeezes the working roller. The permanent magnet is installed under the rolling and pressing platform. Permanent magnetic repulsive force is generated between the rolling and pressing platform and a powered electromagnet, so that the rolling and pressing platform bears rolling and pressing force to be suspended. An external power driving shaft drives an inner permanent magnet to rotate, and an outer permanent magnet is coupled to rotate, so that the rolling and pressing platform is driven to rotate. Friction is generated between the rolling and pressing platform and the steel plate to be rolled and pressed through the rolling and pressing force of the working roller, and the rolled steel plate is pushed to move forwards. The magnetic suspension superconductive steel rolling machine has the advantages that the roller peak, the working roller which is used for plane rolling and adjusted through magnetic force and the supporting roller are parallel, and a permanent magnetic coupler drives the rolling and pressing platform to rotate so that the rolled steel plate can be pushed.

Owner:DALIAN JIAOTONG UNIVERSITY

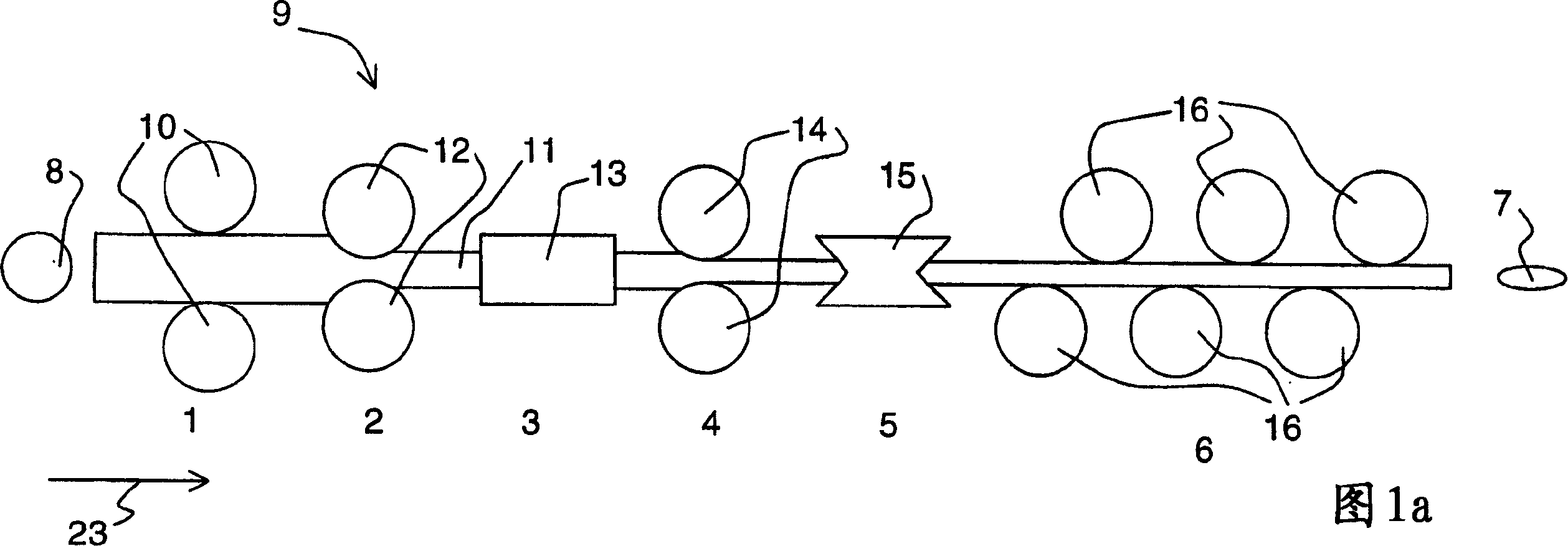

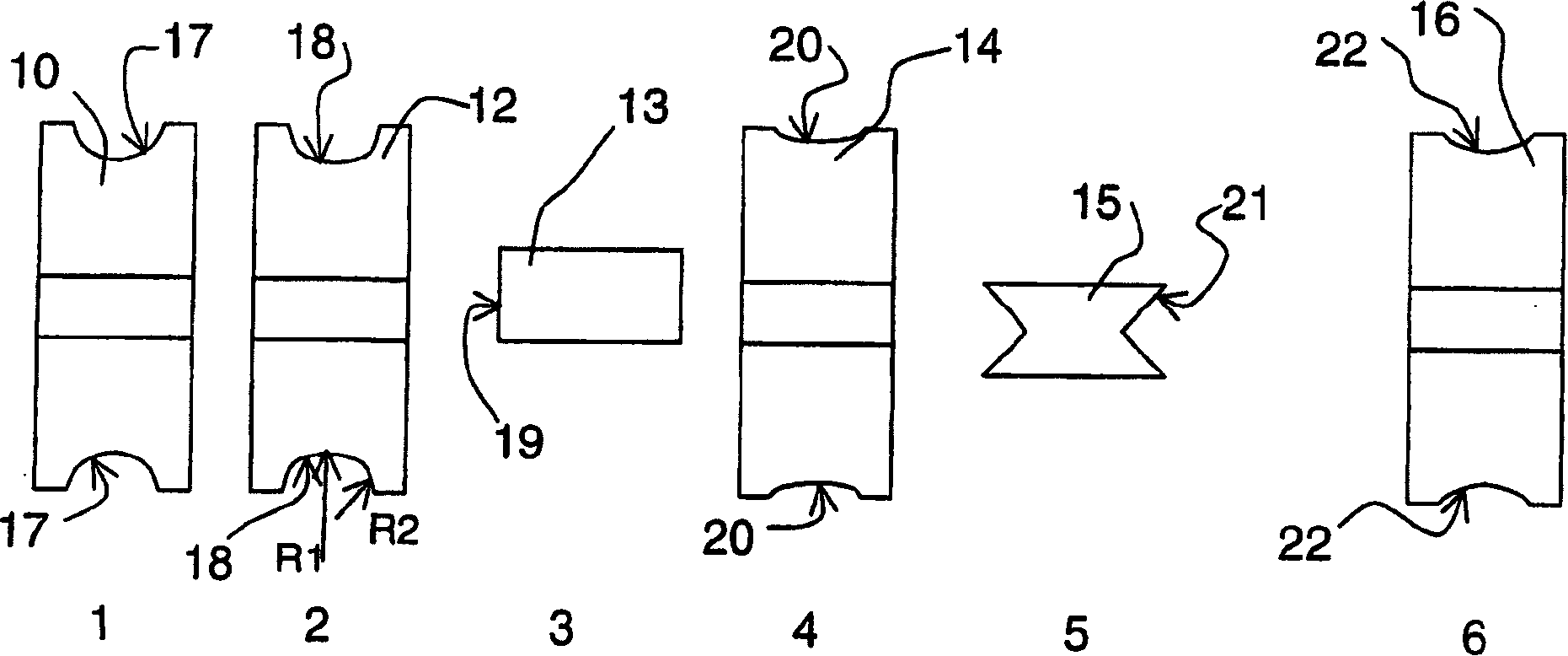

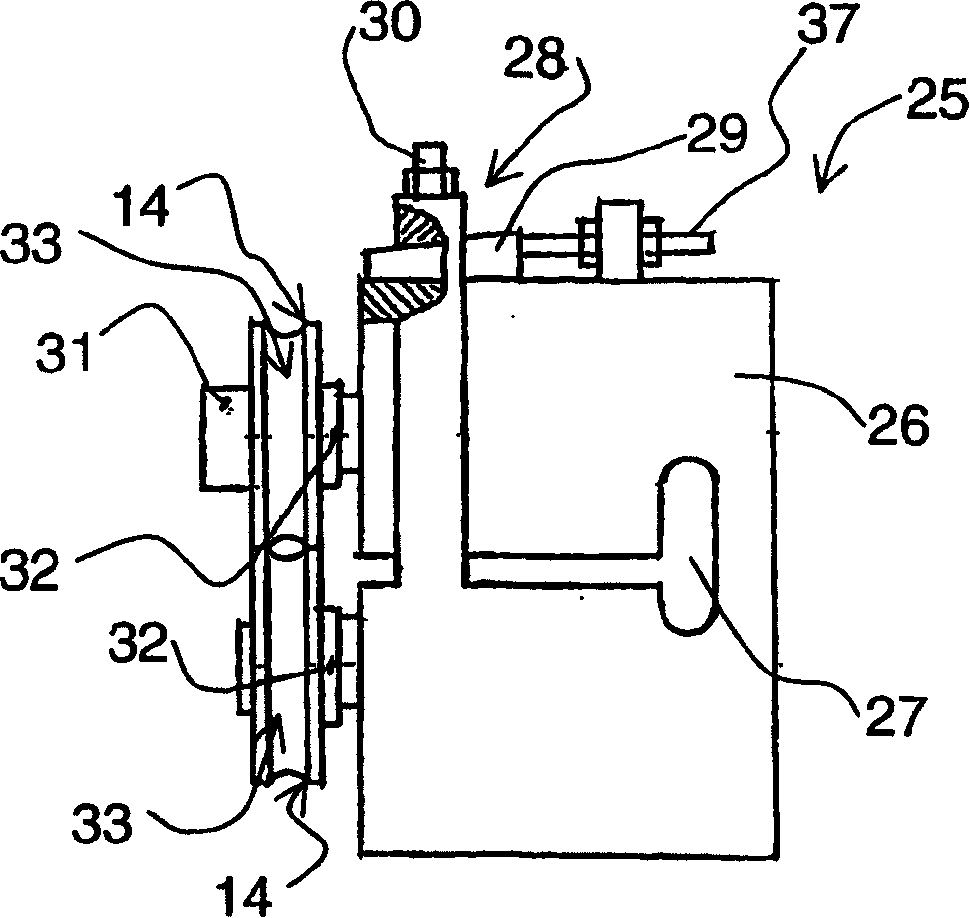

Method and apparatus for rolling a tube

InactiveCN1329137CReduce widthAvoid stayingMetal rolling stand detailsAuxillary arrangementsMetalMaterials science

The invention relates to a method for manufacturing ovalshaped metal tubes, where an essentially round-shaped metal tube is rolled both in the sideways direction and in the vertical direction of the tube, so that the metal tube (11) is rolled at least in two steps (2,4), and that between said rolling steps (2,4), the metal tube is rolled at least once in a direction that is perpendicular to the rolling direction of the rollng steps (2,4). In addition, the invention relates to an apparatus for manufacturing ovalshaped metal tubes.

Owner:库伯利集团有限公司

Workpiece-shaping tool assembly

ActiveUS9868141B2Reduce wearExtended service lifeShaping toolsMetal-working feeding devicesDrive shaftEngineering

A workpiece-shaping tool assembly has a drive shaft having an outer end centered on and rotatable about an axis and a tool fittable with the end of the drive shaft. A torque coupling is formed by shaft splines formed on the drive shaft and tool splines formed on the tool, complementary to the shaft splines, and interfitting with the shaft splines. A radial-force coupling is formed by an inner cylindrical shaft surface formed on the shaft axially offset from the shaft splines and centered on the axis and a respective inner cylindrical tool surface formed on the tool offset from the tool splines, centered on the axis, and radially juxtaposed and engageable with the inner shaft surface.

Owner:SMS MEER

Combined type rolling mill

InactiveCN101229551BMetal rolling stand detailsGuiding/positioning/aligning arrangementsLine shaftWork roll

A modular rolling mill comprises a plurality of separate rolling units arranged along a mill pass line. Each rolling unit includes at least two pairs of work rolls defining oval and round roll passes and carried on roll shafts that are staggered 90 DEG with respect to each other. The rolling units contain intermediate drive trains configured to connect the roll shafts to parallel input shafts projecting to a first side of the pass line from the respective rolling units. A single driven line shaft is parallel to and on the first side of the pass line. Output shafts are mechanically coupled tothe line shaft by bevel gear sets. The output shafts project laterally from the line shaft towards the pass line and are connected by separable couplings to the input shafts of the rolling units.

Owner:PRIMETALS TECH USA

Method and apparatus for producing steel intermediate products

InactiveCN105499271AExtend your lifeImprove reliabilityMultiple strand roll mill standMetal rolling stand detailsWork in processLiquid steel

A method and an apparatus for continuously producing steel intermediate products are disclosed. Liquid steel is cast into plural moulds to continuously produce plural bloom strands using continuous casting apparatus. Subsequently, one or more of the bloom strands is fed in-line to respective rolling mills configured to hot roll the input continuously cast bloom strands to produce rolled billets.

Owner:庞廷

A double-shaft cantilever skew rolling mill

ActiveCN110153339BSmall fluctuationShort to the axis of the roller systemSkewed roll standMetal rolling stand detailsGear wheelMachine

The invention relates to the technical field of metal plastic forming processes and equipment, and provides a double-rotating-shaft cantilever type skew rolling mill. The skew rolling mill is mainly composed of a base, a cantilever type roller system, a gear synchronizing mechanism, a radial reduction mechanism, machine frames, a material guiding unit and inclination angle adjusting mechanisms, wherein the cantilever type roller system is tensioned by bolts on the backs of the machine frames of the rolling mill, and the roller system inclination angle adjustment is realized through the inclination angle adjusting mechanism below bearing seats; the two machine frames which are supported by double rotating shafts of the rolling mill base; synchronous alignment and reduction are realized on the two machine frames through the gear synchronizing mechanism, and the center line of the vertical direction of the rolling mill is ensured to be fixed; the radial reduction mechanism is arranged above the machine frames, and the roller distance adjustment of two rollers is realized by rotating reduction nuts; and the inclination angle adjusting mechanisms are arranged at the corners of the machine frames so that the space can be saved, moreover, the action line is long, and the high-precision adjustment of the inclination angle of the roller system can be realized. The double-rotating-shaftcantilever type skew rolling mill is ingenious in design, has the advantages of convenience in roller replacement, fixation of the vertical center line of the rolling mill, convenience in installationand adjustment and the like, and is suitable for the production of large-scale small-diameter steel balls.

Owner:UNIV OF SCI & TECH BEIJING

Finishing monoblock with optimized transmission ratio for a billet rolling plant

InactiveCN1993190BBest gear ratioDecrease stockRolling mill drivesMetal rolling arrangementsGear wheelEngineering

A finishing monoblock with optimised transmission ratio for a billet rolling plant comprises a plurality of rolling stands (Gl-Gn) arranged in sequence suitable for forming a rolling line and actuatedby a pair of mechanical transmissions (11, 12) in which bevel gear pairs are foreseen for the variation of ratio in the stands of the rotation speed of rolling cylinders (18). According to the invention, such a variation of the ratio in the stands is carried out through the combination of a first type (A, B) of bevel gear pairs with a second type of bevel gear pairs (C, D) and there is a set of four of cylindrical gears suitable for making four stands (C, D) with the same transmission bevel gear pair.

Owner:VAI POMINI INC

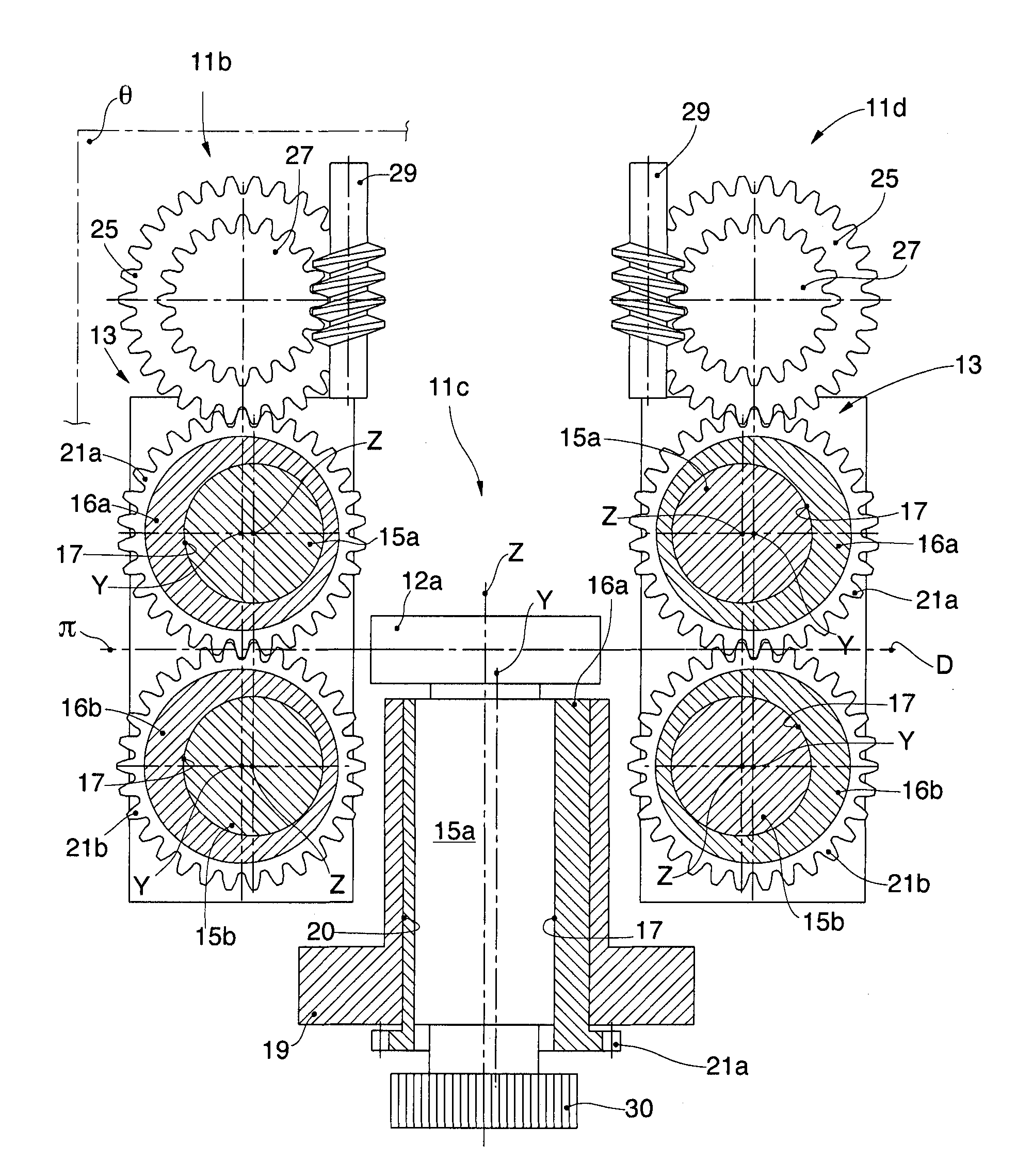

Finishing monoblock for a billet lamination plant for producing high-quality wire rods

A finishing monoblock for a billet lamination plant of the type comprises a plurality of lamination cages (G1Gn) arranged in sequence suitable for forming a lamination line and actuated by a pair of mechanical transmissions (22, 22′) actuated through at least one command reducer (23) for the lamination of the billet. According to the invention, said monoblock comprises at least one first module (M1) and a second module (M2′, M2″), of which at least one is disengageable from the lamination line through a pair of detachable joints (40).

Owner:VAI POMINI INC

Rolling unit

ActiveUS20140238098A1Shorten the lengthPrevent insertionMetal rolling stand detailsMetal rolling arrangementsGear wheelClassical mechanics

Owner:DANIELI & C OFF MEC SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com