Modular rolling mill

A rolling mill and combined technology, applied in the direction of cantilever rolling mill stand, metal rolling stand, metal rolling stand, etc., can solve complex and expensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

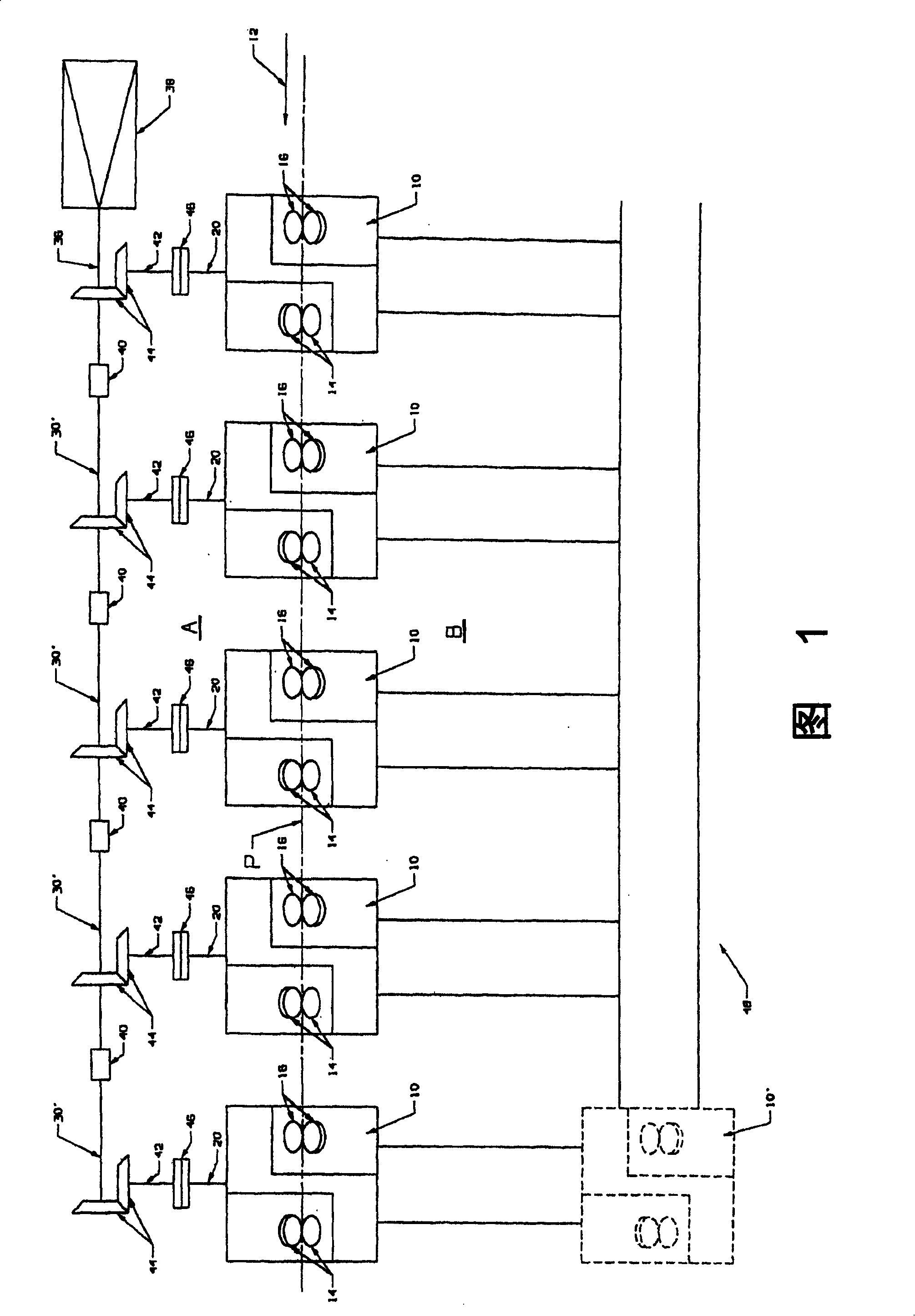

[0017] Referring to Fig. 1, a combination rolling mill according to the present invention comprises a plurality of separate rolling units 10 arranged along a mill pass line "P". The direction of rolling is indicated by arrow 12 . Each rolling unit has at least two pairs of work rolls 14, 14 and 16, 16 configured to define elliptical and circular rolling channels. Each pair of consecutive rolls is staggered at 90° to implement twist-free rolling of long products such as rods and rods.

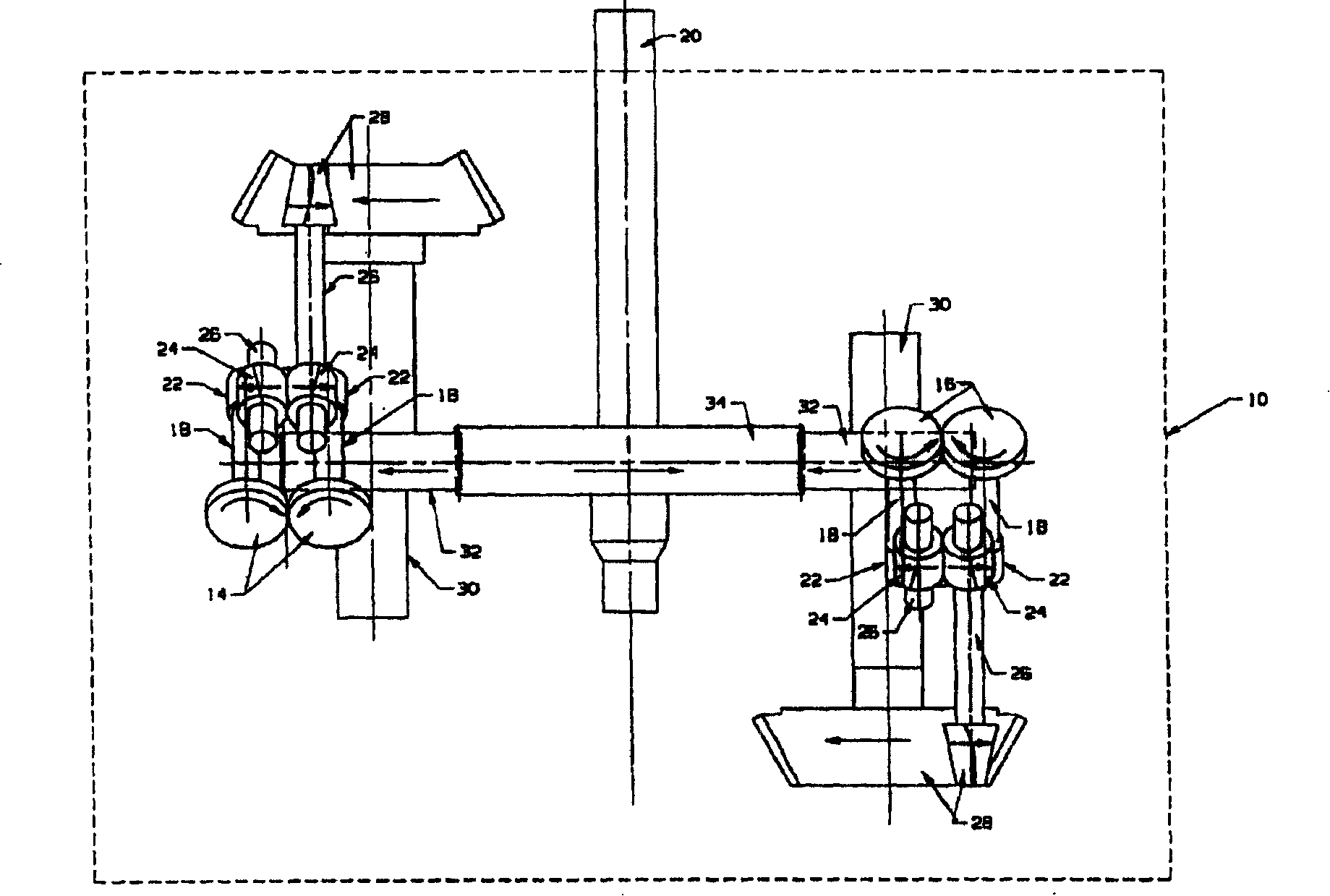

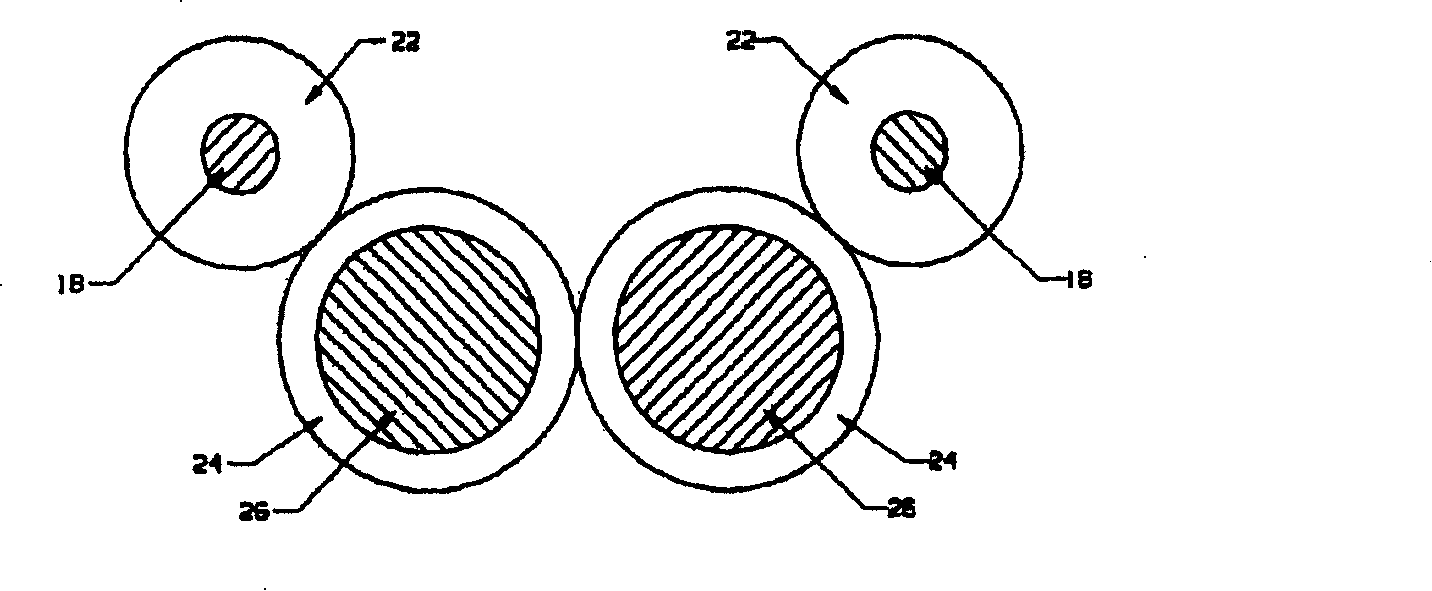

[0018] additionally refer to figure 2 with 3 , it can be seen that the work rolls are mounted on the roll shaft 18 and the intermediate drive system is included in the rolling unit to mechanically couple the roll shaft to the input shaft 20 . The input shafts are parallel and project towards the first side "A" of the roll line. The intermediate transmission system includes gears 22 on roller shafts meshing with intermeshing gears 24 on shafts 26 , one of the two shafts 26 being connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com