Bidirectional coaxial reducer motor

A technology of deceleration motor and deceleration mechanism, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of large size, loss of superiority, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

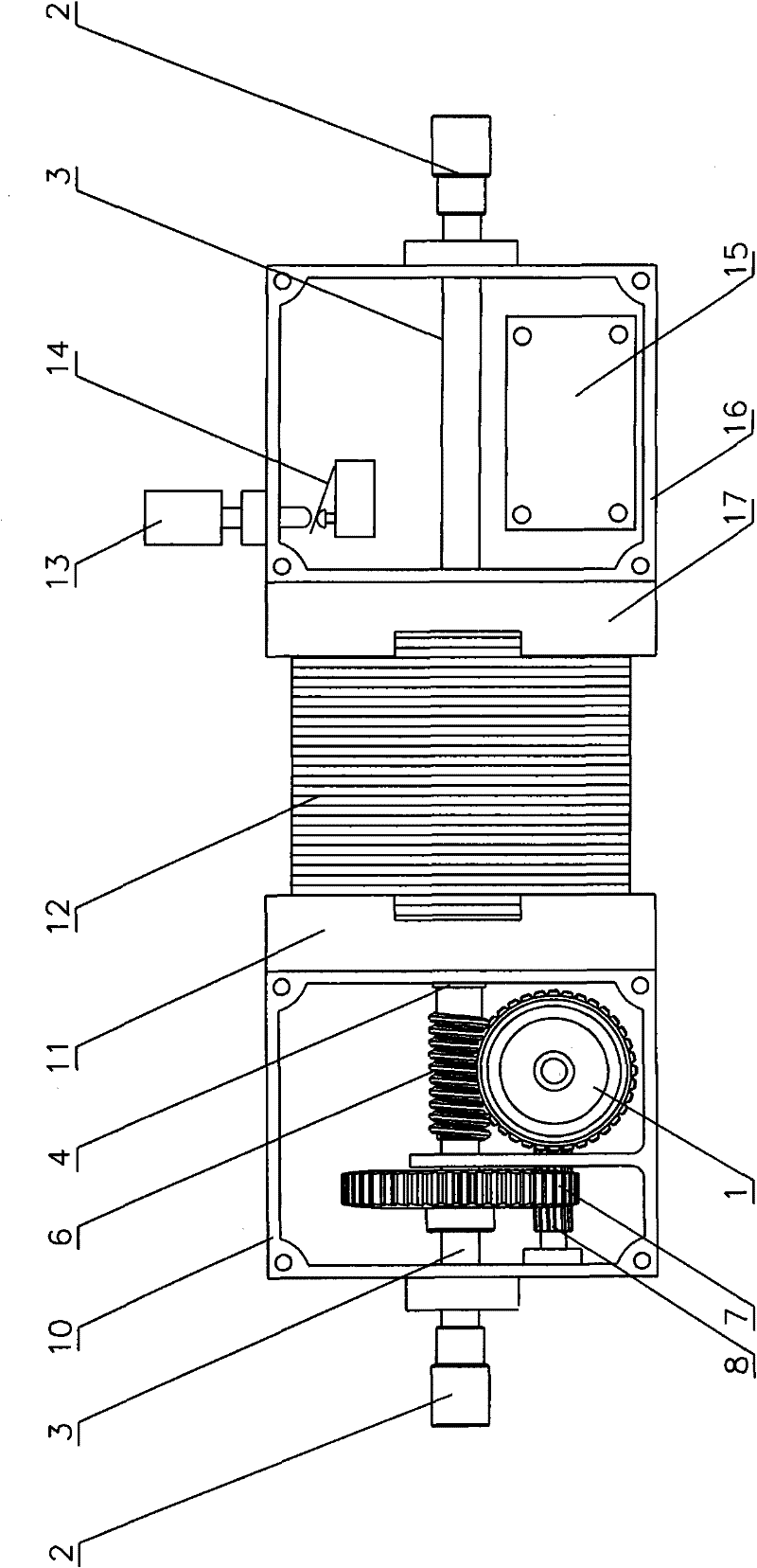

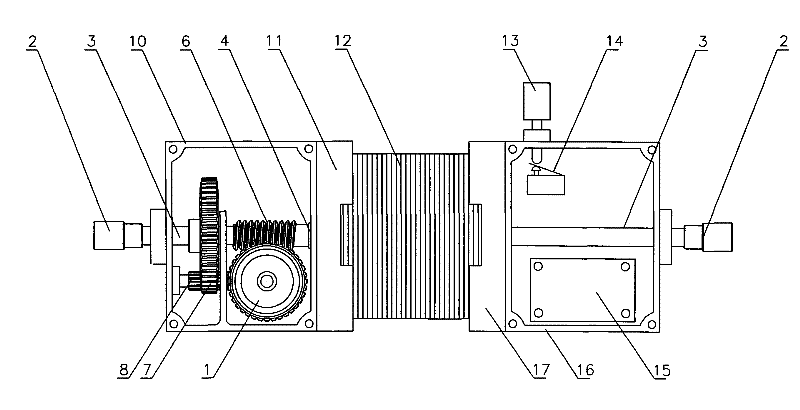

[0016] As shown in the figure, a left end cover (11) and a right end cover (17) are installed at both ends of the motor stator group (12), a reduction box (10) is installed on the left end cover (11), and a right end cover (17) ) is equipped with electrical control box (16), these two casings all have the installation hole that position is coaxial with rotating shaft and output shaft, and bearing is installed in the hole.

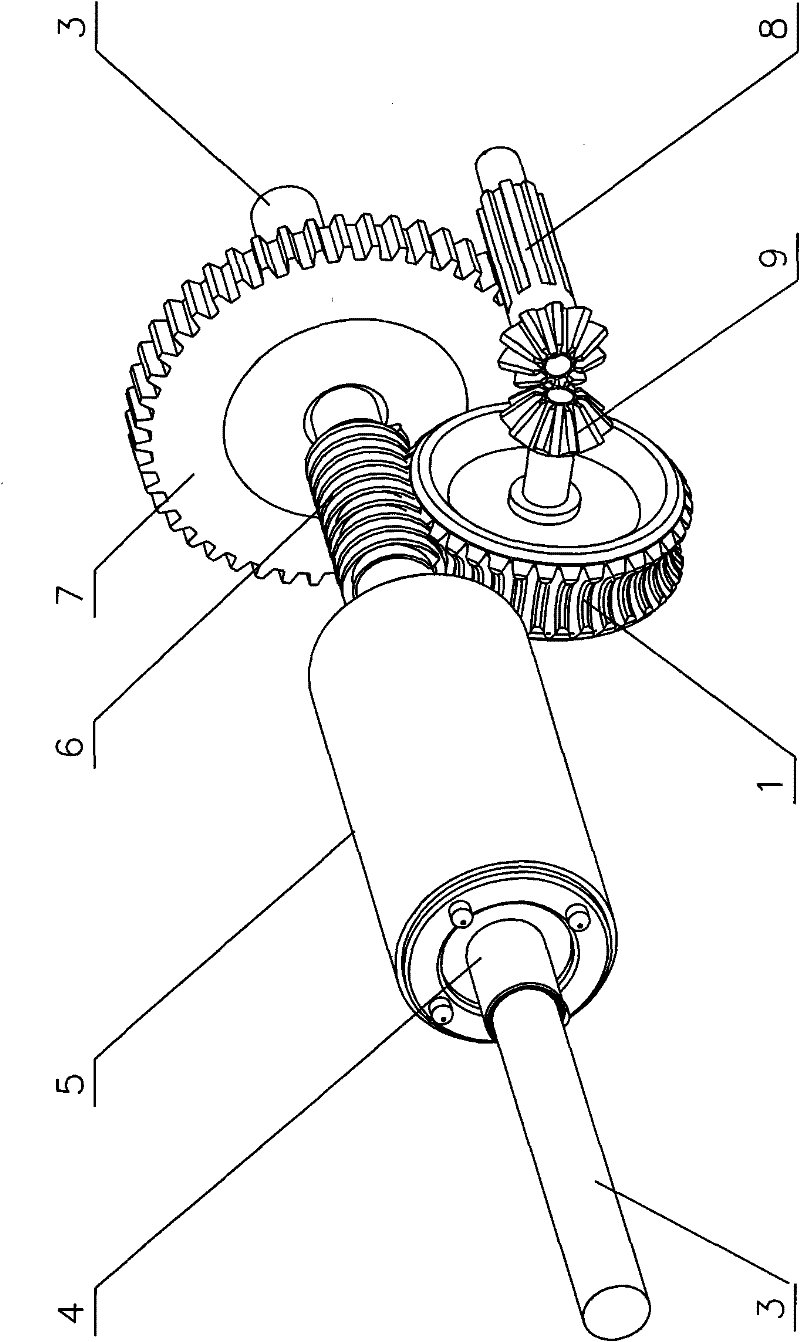

[0017] The motor rotor (5) is installed in the motor stator group (12), and in the motor rotor (5), there is a through-hole shaft (4) assembled as a whole, and the longer end of the through-hole shaft (4) is processed into a worm (6), and the through-hole shaft (4) become an integral shaft with a through hole; a worm wheel (1), a large spur gear (7), a spur bevel gear (8) and an umbrella are installed in the reduction box (10) The gear (9) and the through-hole shaft (4) with the worm (6) form a worm gear reduction mechanism. The installation position of the...

Embodiment 2

[0022] The difference from Example 1 is that if there is a higher requirement for the deceleration performance of the deceleration motor, other types and structural forms of deceleration mechanisms can be used to achieve the purpose of deceleration. The longer end of the motor rotor through-hole shaft is a worm or gear. And in the design of the reduction mechanism, the position of the output shaft coaxial with the through-hole shaft of the motor rotor is reserved, so that the output shaft can pass through the through-hole shaft of the motor rotor, thereby realizing the power output function of bidirectional coaxiality. If there are requirements for the type and performance of the motor used, the motor needs to be specially designed, but the motor rotor must be a through-hole shaft. Because other types and structural forms of the reduction mechanism have their own characteristics in their structures, they are relatively complicated to implement, the volume will become larger, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com