Stirrer

A mixer and rack technology, applied in mixers, mixers with rotating containers, dissolving, etc., can solve the problems of unsatisfactory mixing effect, inability to mix materials evenly, and easy generation of air bubbles, so as to avoid cleaning the mixing slurry. The complicated process, the effect is ideal, the effect of eliminating bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

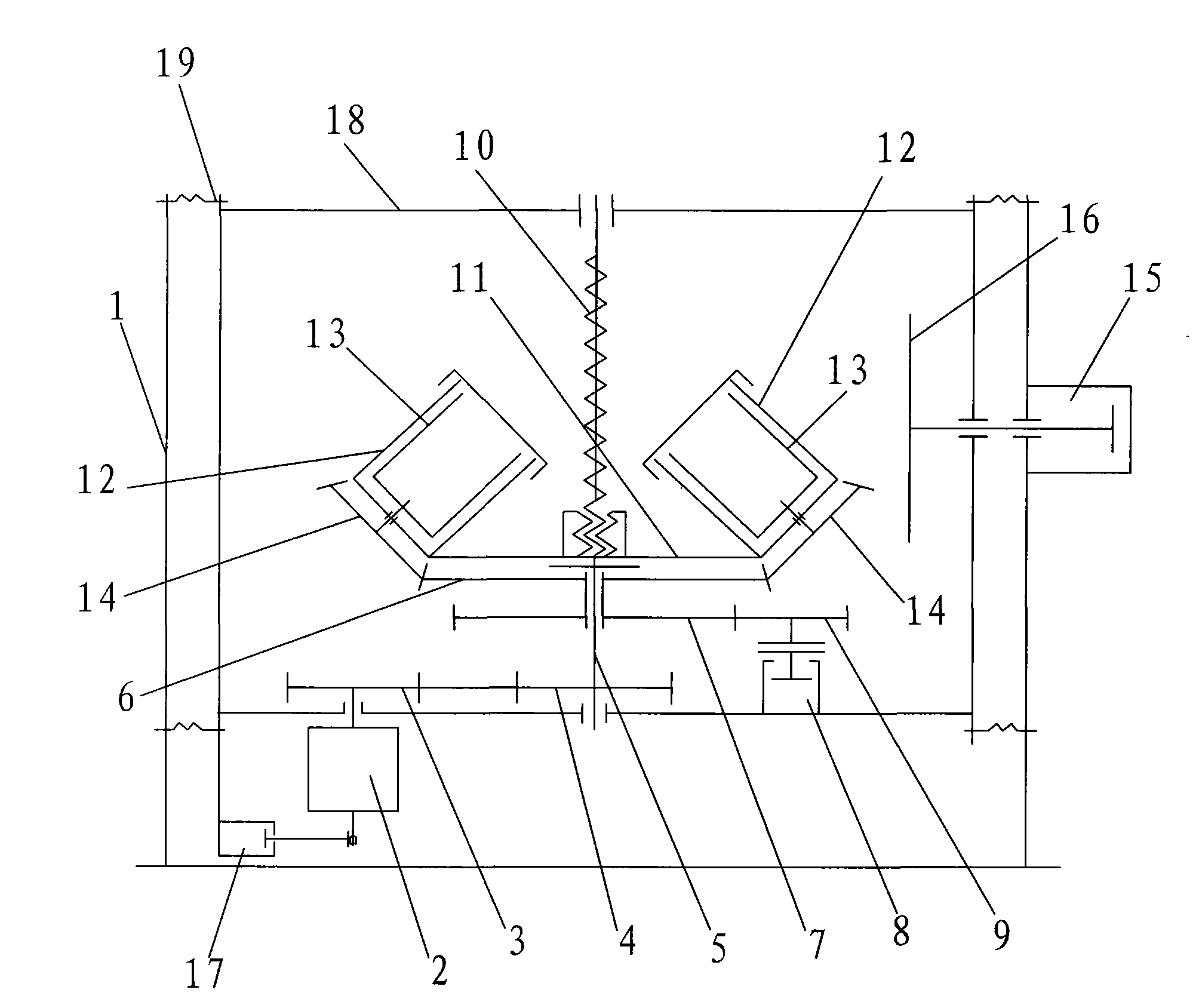

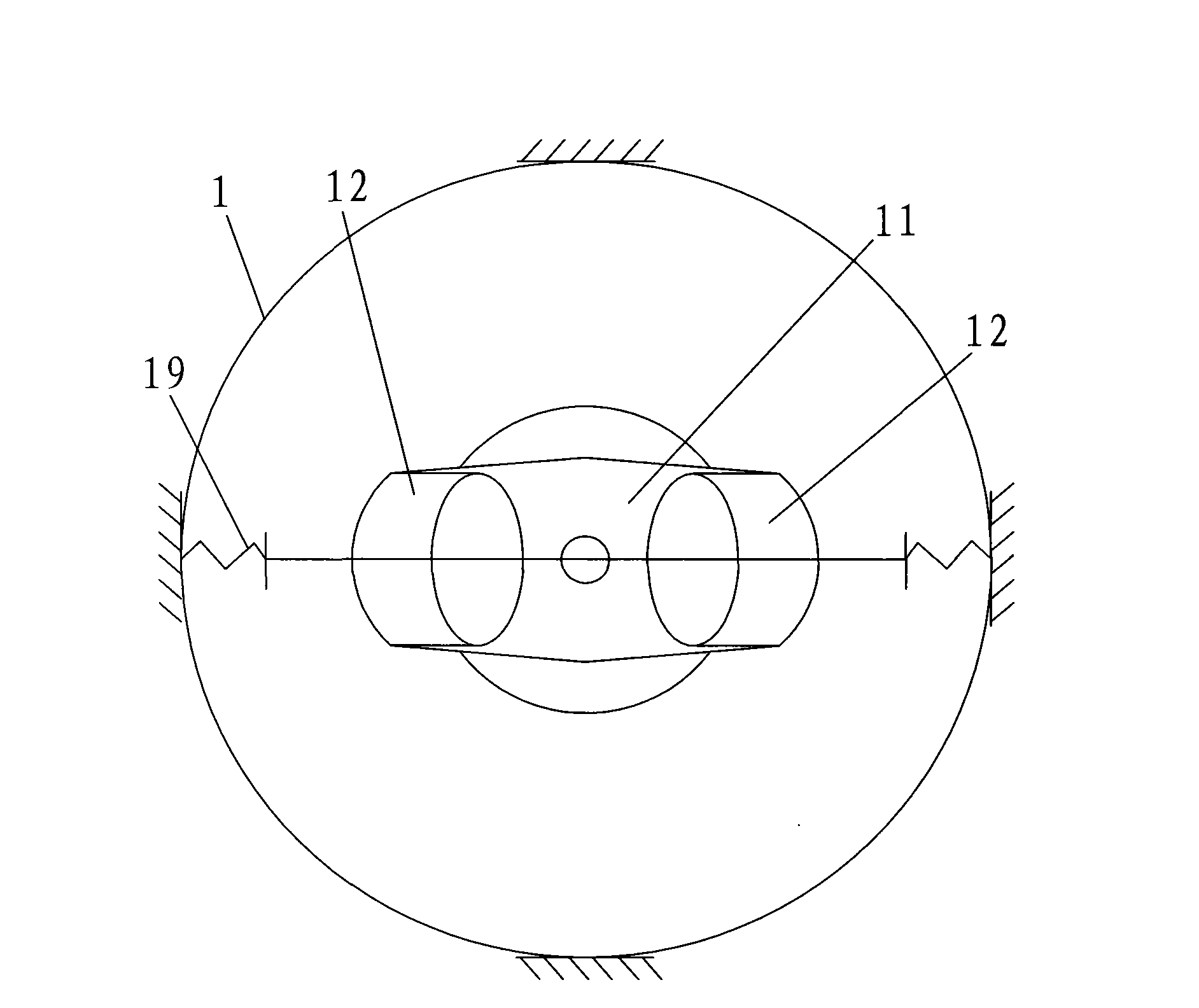

[0014] refer to figure 1 , figure 2 , a mixer, comprising a frame 1, the frame 1 is provided with a motor 2, on the rotating shaft of the motor 2 is connected with a main synchronous pulley 3, and the main synchronous pulley 3 passes through a synchronous belt and a slave synchronous belt The pulley 4 is connected, and the main shaft 5 passes through the shaft center of the synchronous pulley 4 and is socketed with it. The upper and lower gears 6 and 7 which are integrally connected are also set on the main shaft 5. The frame 1 is provided with a pneumatic clutch 8 , there is a speed change gear 9 set on the connecting shaft of the pneumatic clutch 8, the speed change gear 9 is meshed with the lower gear 7, the surface of the main shaft 5 is located above the upper gear 6 and is provided with a thread 10, and a receiving platform 11 passes through it The casing with internal thread is connected to the thread 10 on the main shaft 5, and the left and right sides of the receivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com