Patents

Literature

50results about How to "High mixing precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

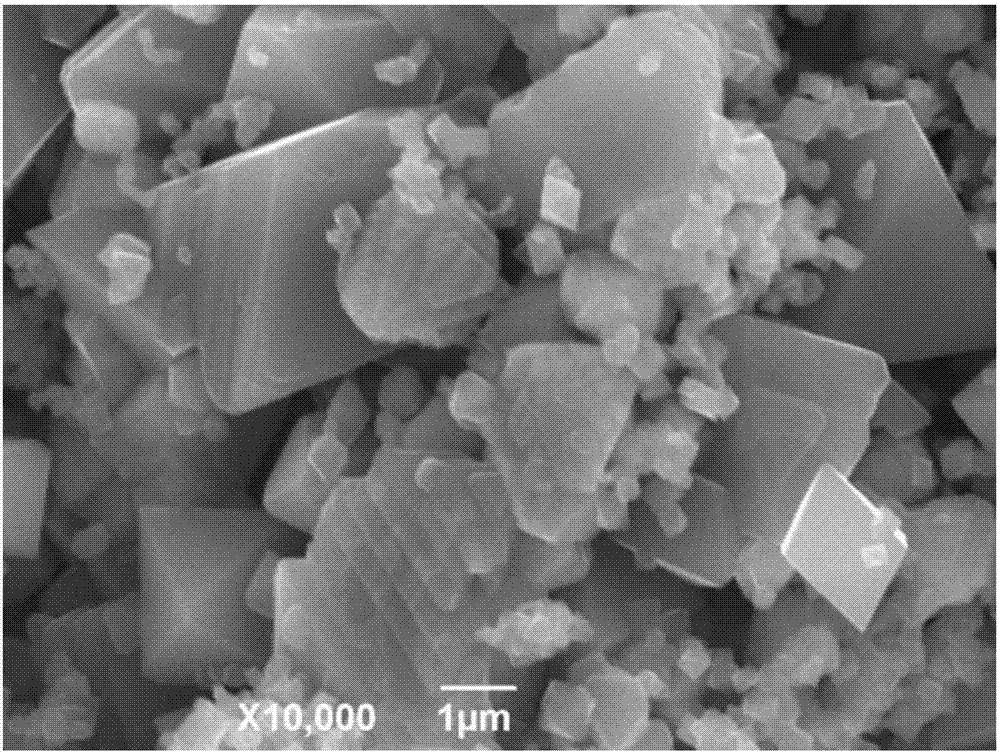

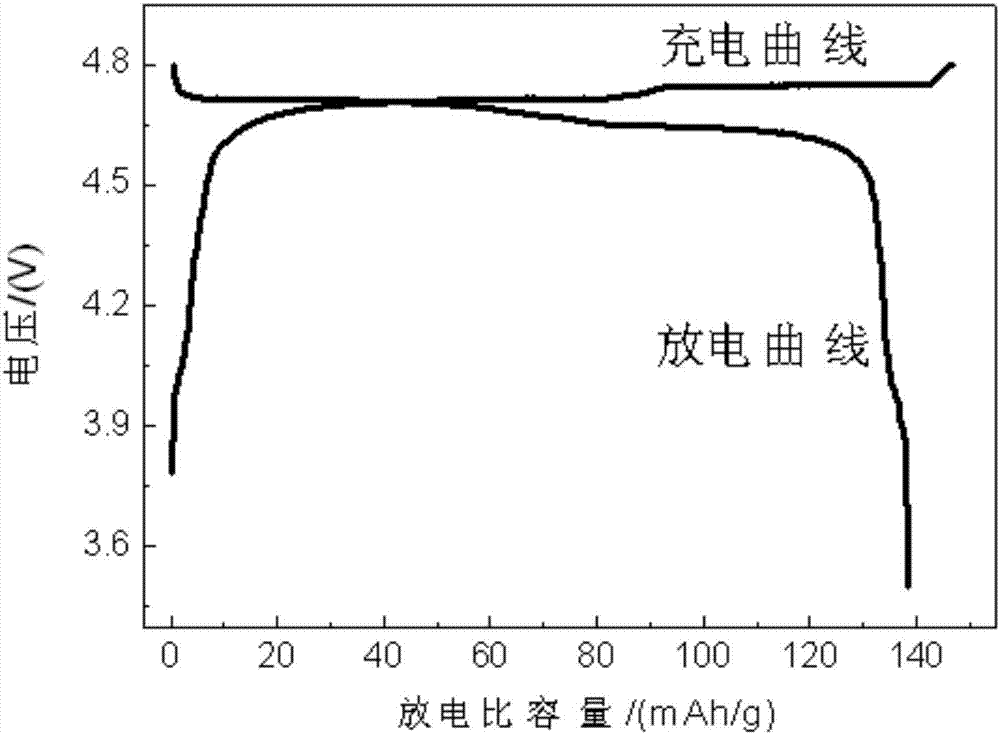

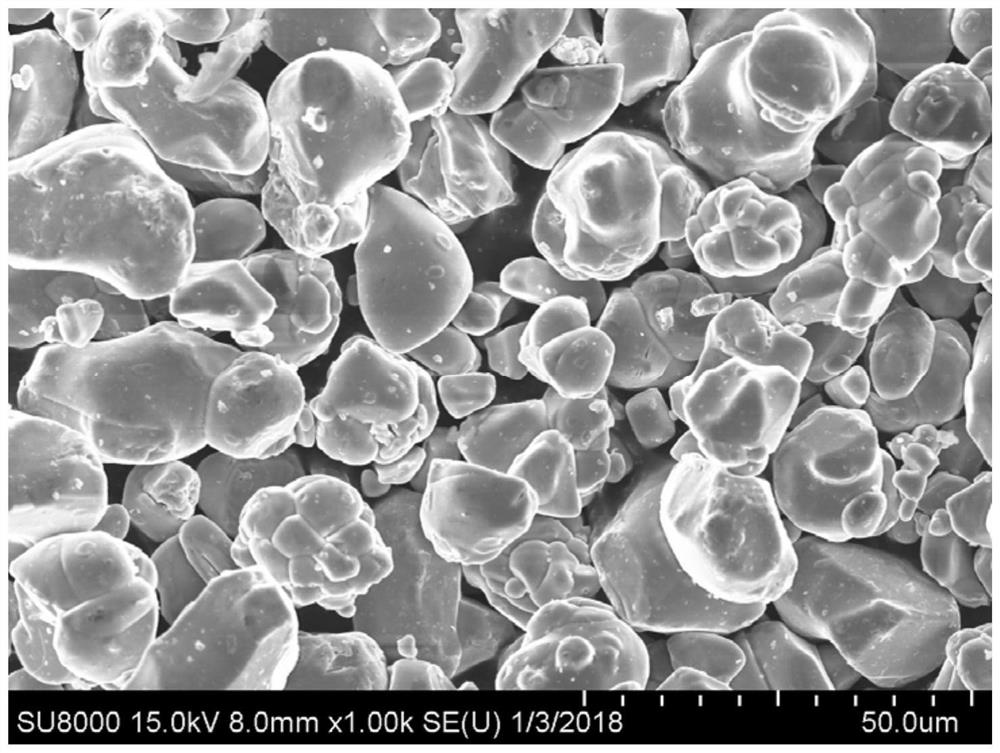

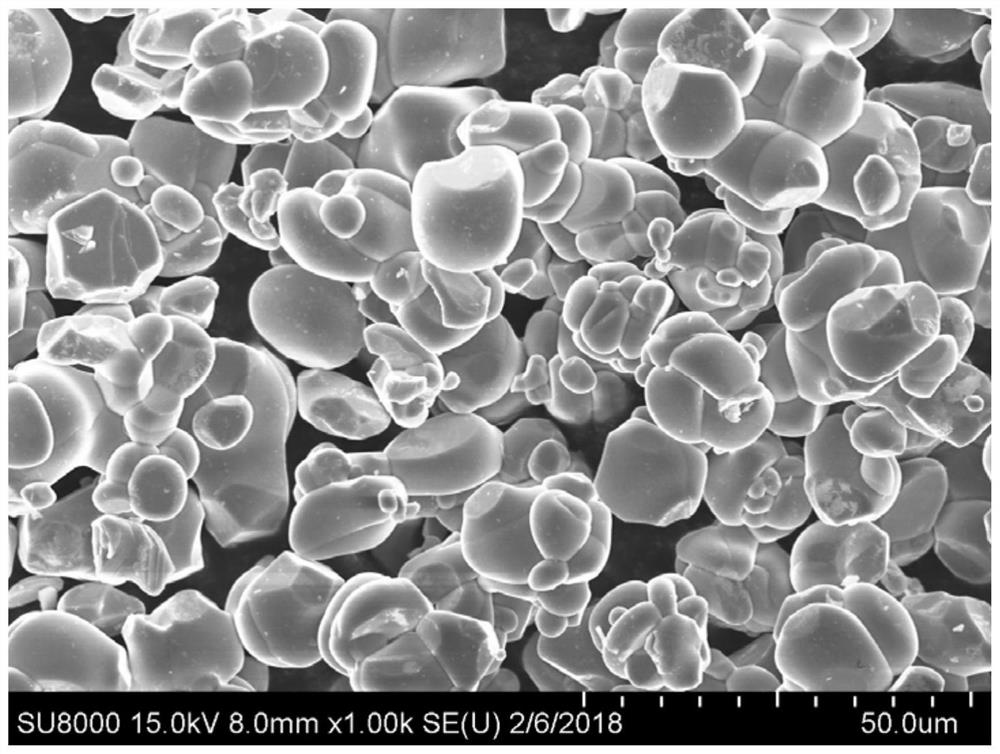

Preparation method of high-voltage lithium cobalt oxide cathode material

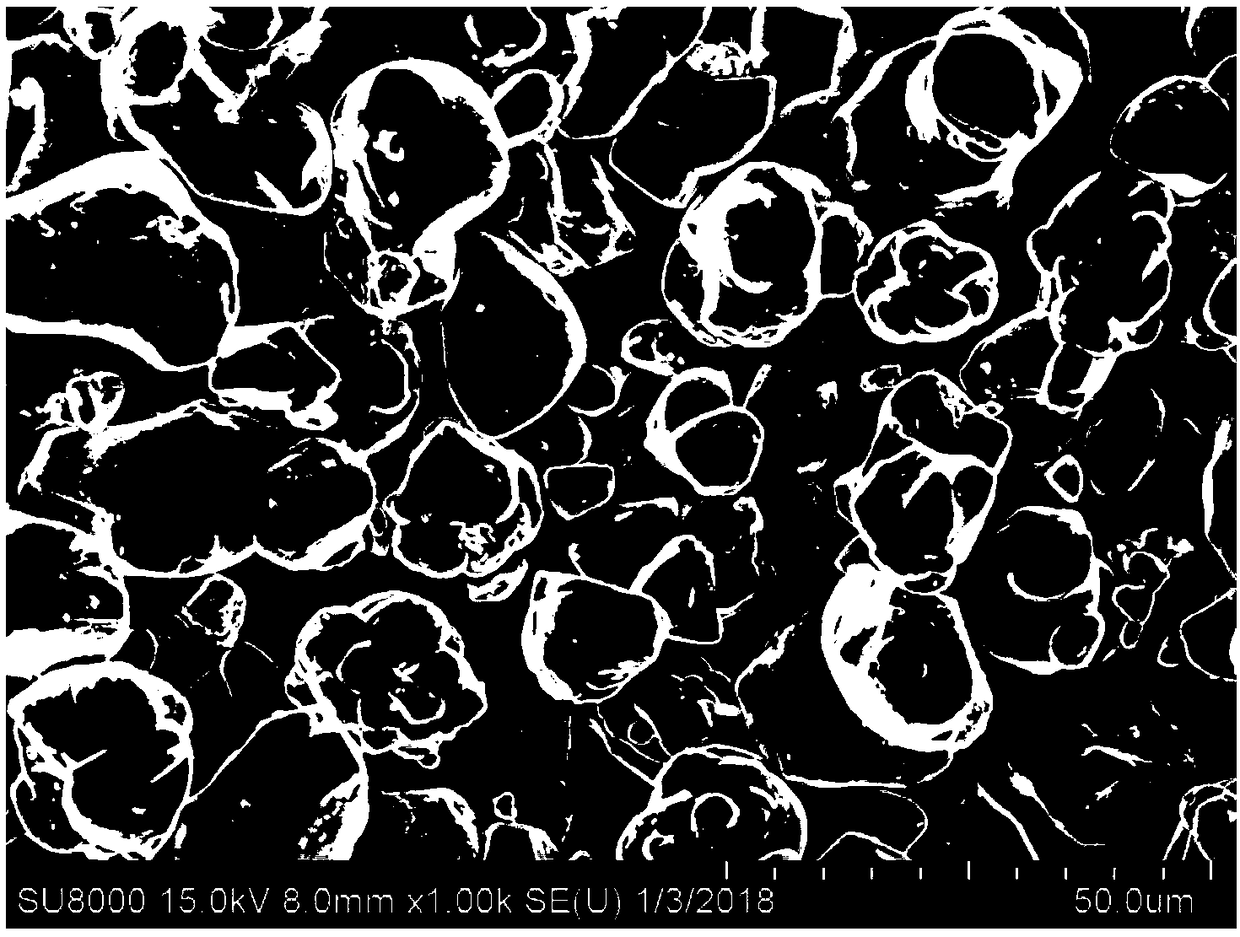

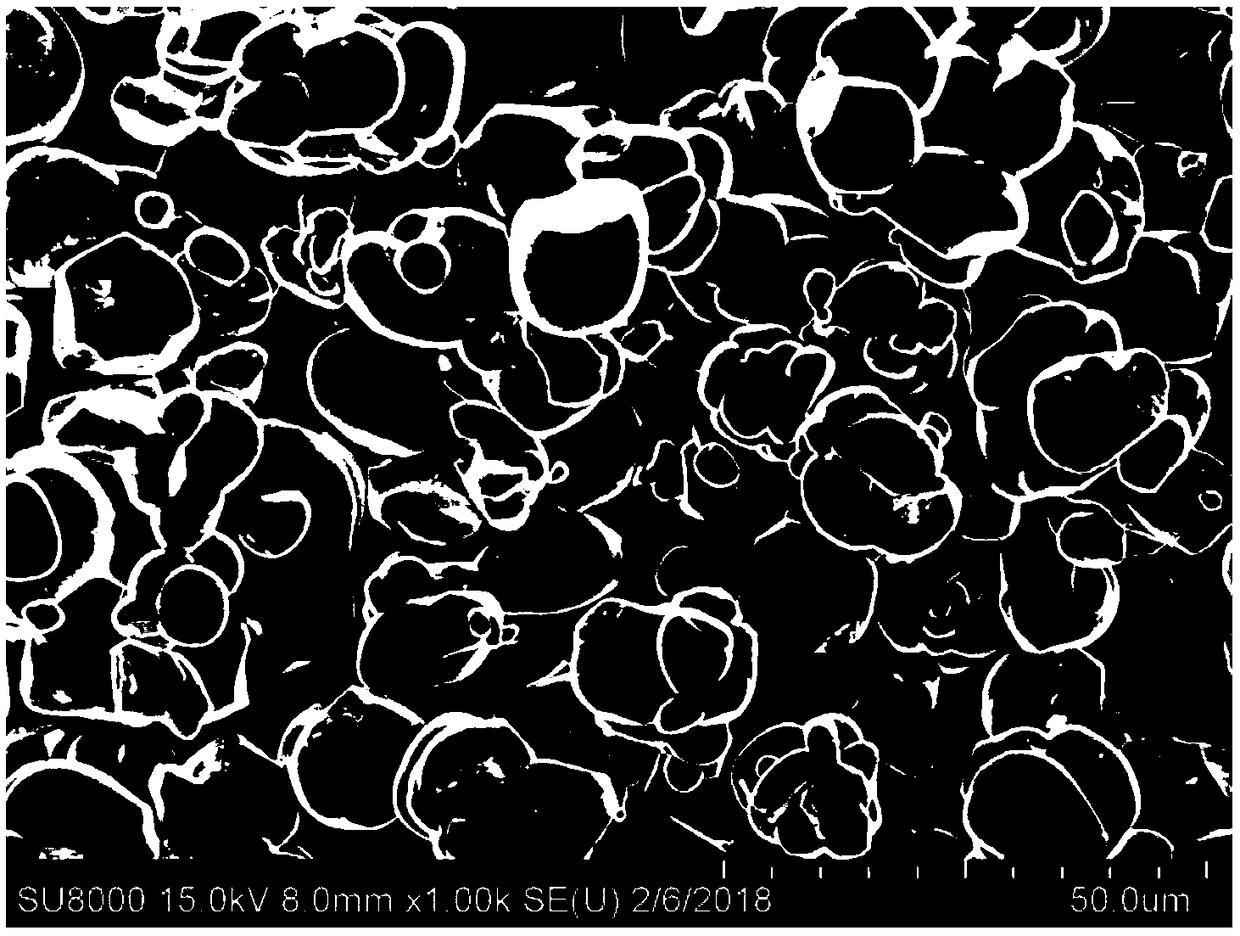

ActiveCN109326781AEvenly distributedWell mixedSecondary cellsPositive electrodesDual effectCobalt(II,III) oxide

The invention discloses a preparation method of a high-voltage lithium cobalt oxide cathode material which comprises the steps: (1) mixing cobaltosic oxide containing doped element M, a lithium source, oxide containing doped element M', a grain refiner and a fluxing agent to obtain a primary mixture; (2) sintering and smashing the primary mixture to obtain primary sintered powder; (3) mixing the primary sintered powder with a coating material to obtain a secondary mixture; (4) sintering and smashing the secondary mixture to obtain the lithium cobalt oxide cathode material. According to the preparation method disclosed by the invention, the problem of microscale segregation of distribution of doped elements in the product is solved by two modes of doped element premixing and dry-method mixing; a coulter type mixing technology is utilized to solve the problem of segregation of different matters in material mixing; the grain refiner and the fluxing agent are combined for use to synthesizea material in a mixed morphology; technologies such as dual effects of doped element surface crystallization catalysis and the coating material and the like are utilized; thus, performance of the high-voltage lithium cobalt oxide is obviously improved.

Owner:HUNAN CHANGYUAN LICO CO LTD

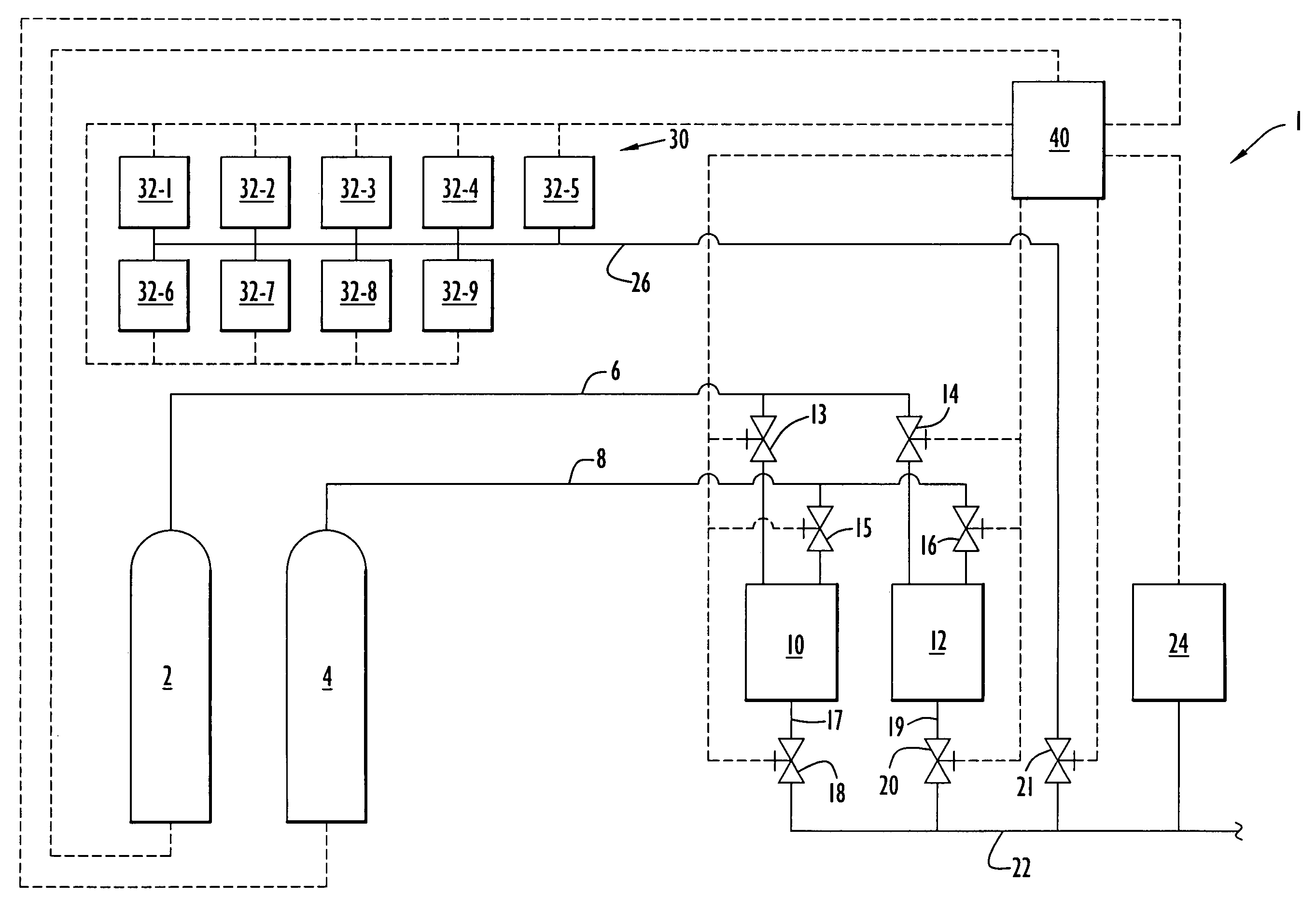

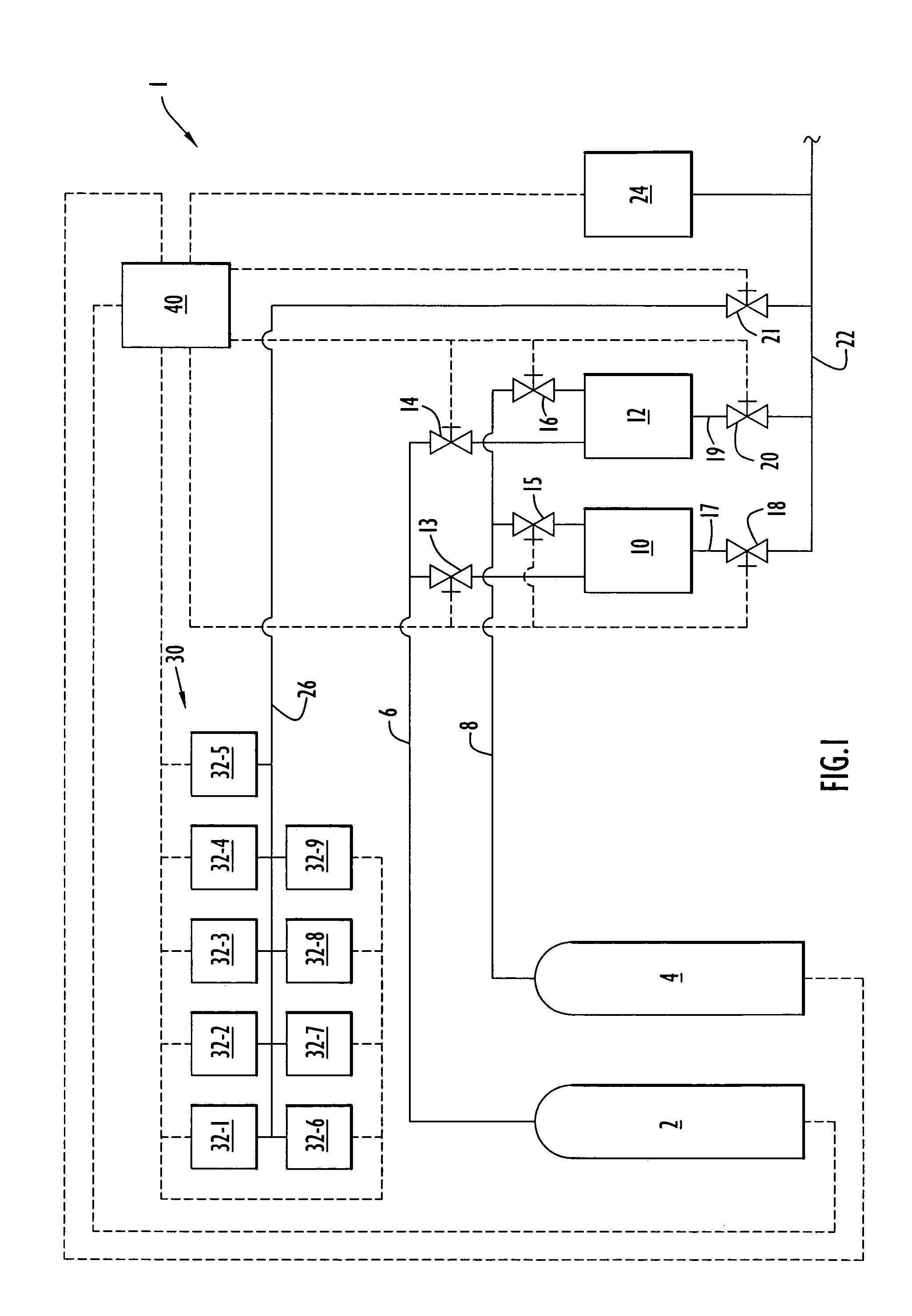

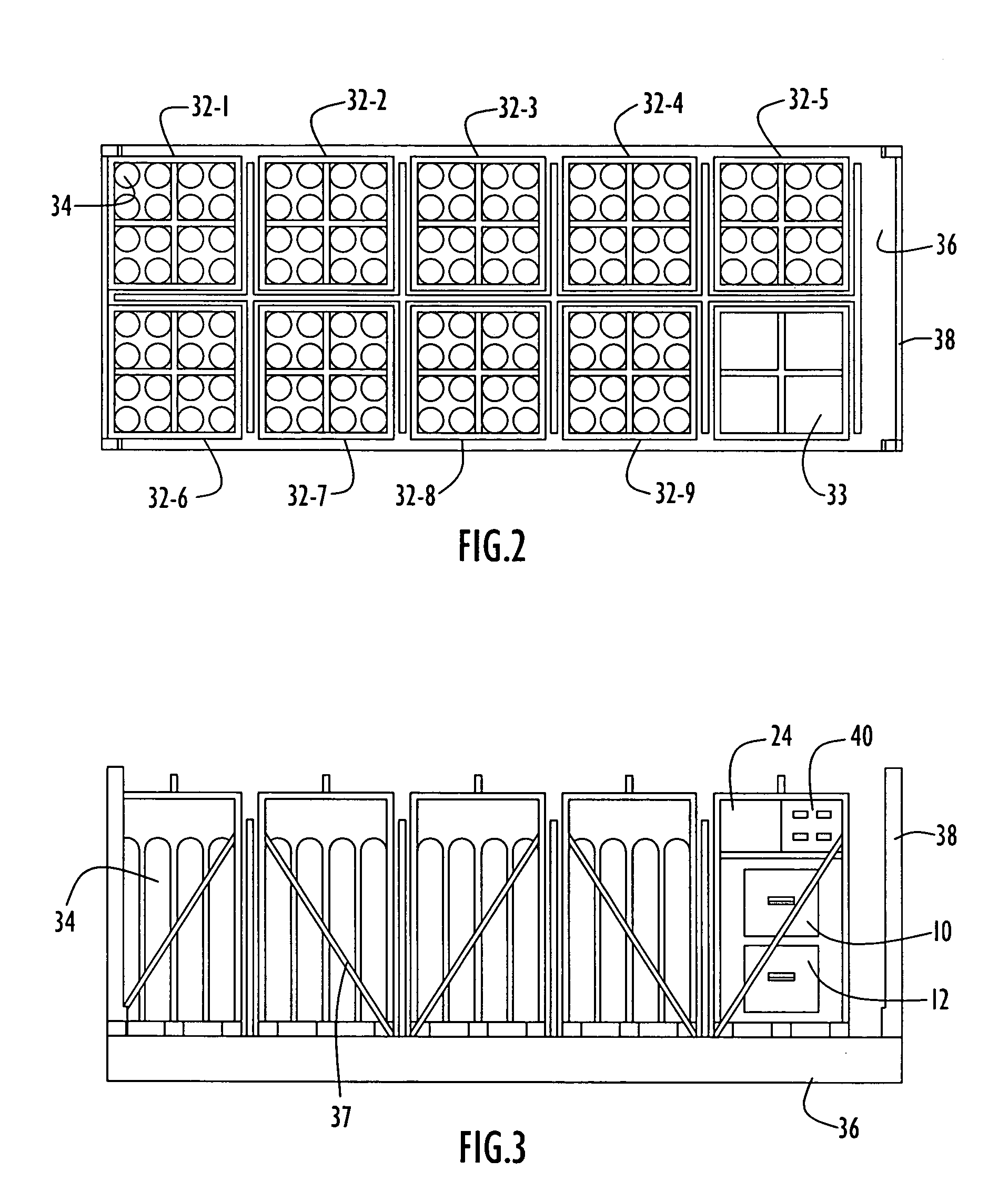

Modular fluid supply system

ActiveUS7201179B2High mixing precisionControlling ratio of multiple fluid flowsPipeline systemsLine tubingEngineering

A modular fluid supply system for use with a liquid supply source includes a plurality of container packs, a fluid delivery line in fluid communication with the containers of the packs, and a controller. Each container pack includes at least one container that contains a fluid mixture of at least two different fluid components. The fluid delivery line is configured to deliver fluid mixtures from the containers to a tool that utilizes the fluid mixtures, and the controller is configured to selectively and automatically control the flow of the fluid mixture from each container pack to the tool. The modular fluid system can be integrated with a main fluid supply system or independently implemented for continuous and reliable supply of mixed fluids to a particular application, such as off-shore pipeline welding operations.

Owner:AIR LIQUIDE IND US LP

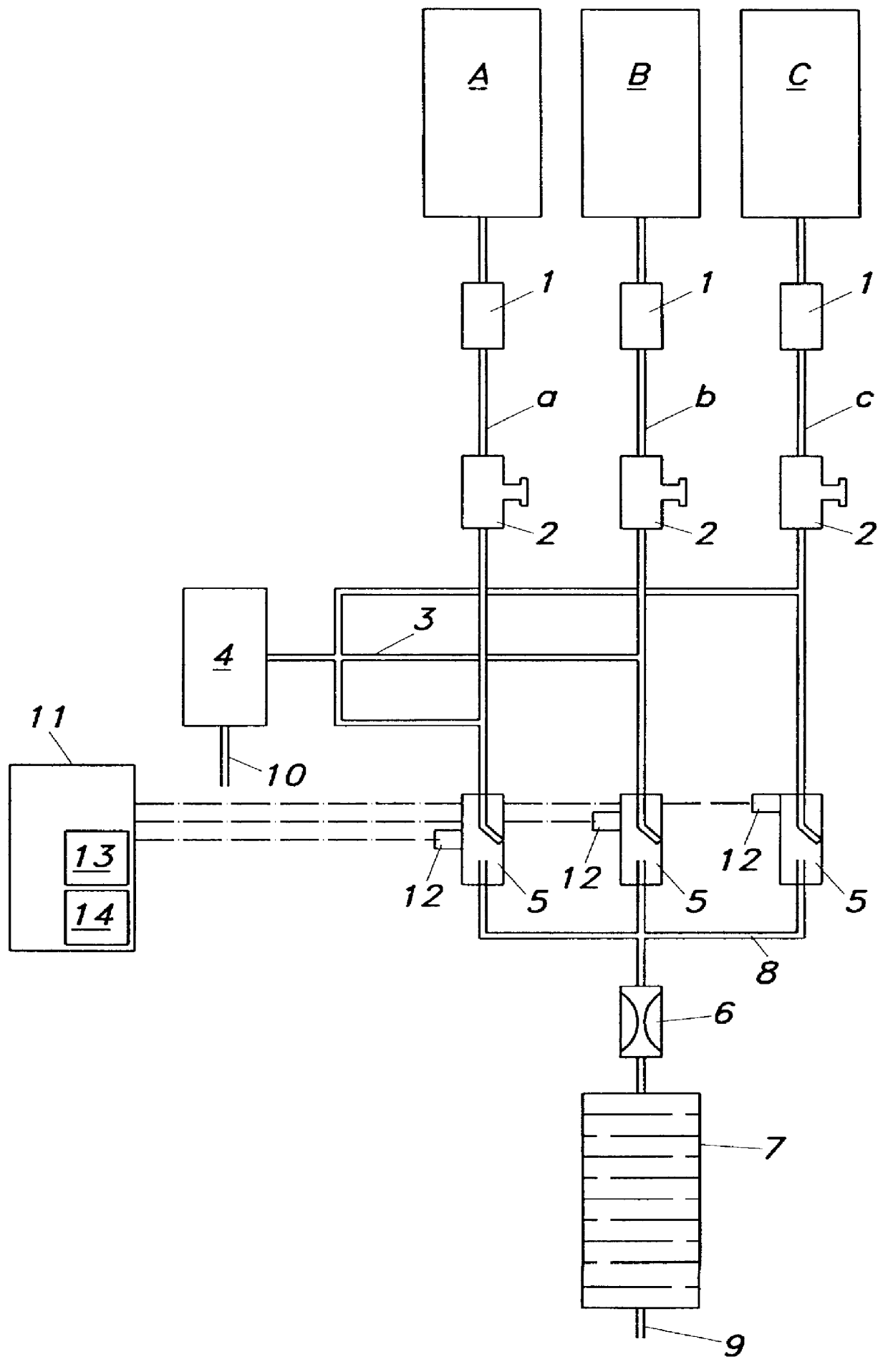

Method and device for production of high-precision, continuous streams of mixed gas

InactiveUS6047719AAmplified equalizationHigh mixing precisionControlling ratio of multiple fluid flowsWatering devicesLine tubingProduct gas

In a gas mixing system for producing high-precision, continuous streams of mixed gas consisting of a plurality of individually metered gas components, with an individual gas line including a pressure reducing element and, if desired, a precision pressure regulator for each gas component, precision is further improved by providing that each gas line lead to a separate valve which is timed by electronic control means, the valves being connected at the input side via a jointly vented system of lines for pressure equalization, and communicating at the output side via a mixed gas line with a mixing chamber downstream thereof.

Owner:AVL MEDICAL INSTR

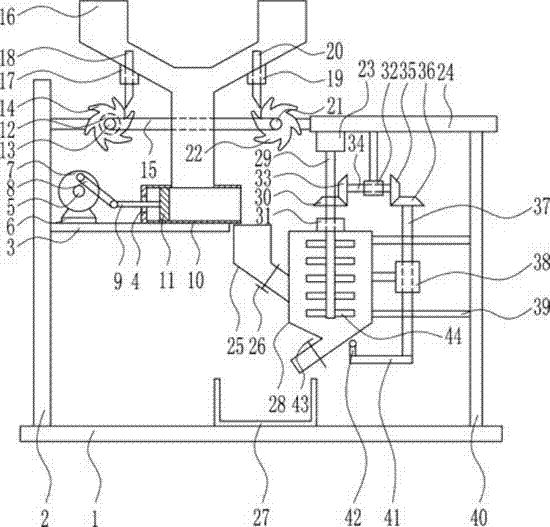

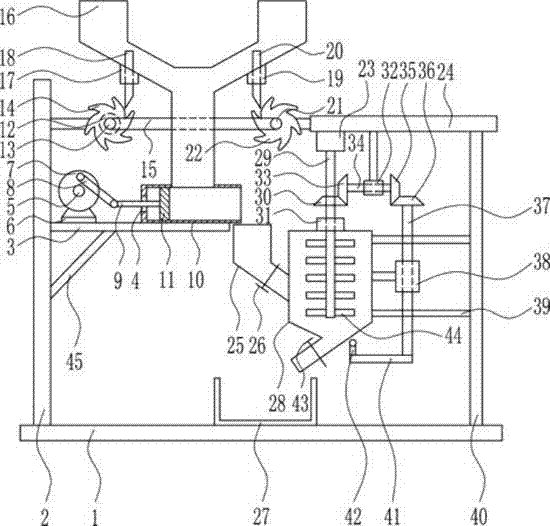

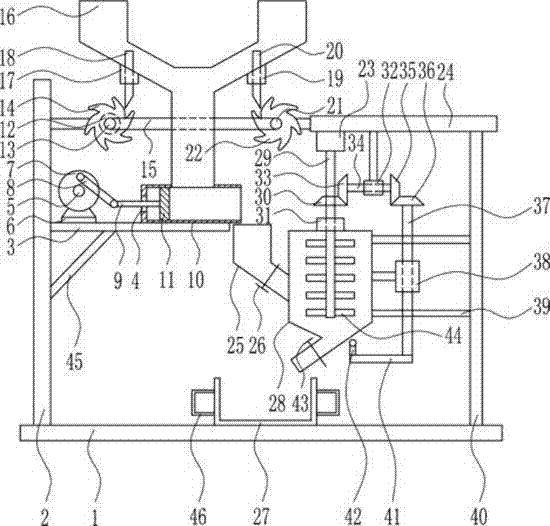

Preparation device of soft magnetic composite raw materials

InactiveCN107096420AHigh strengthImprove stabilityRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention relates to a preparation device. The preparation device comprises a bottom plate, a left frame, a first fixed plate, a first motor, a mounting platform, a rotating plate, a first connecting rod, a second connecting rod, a material pushing cylinder, a piston, a second motor, a first belt wheel and the like; the second motor and the first fixed plate are arranged on the right side of the left frame; the second motor is positioned above the first fixed plate; a first ratchet wheel and the first belt wheel are arranged in front of the second motor; the first ratchet wheel is positioned behind the first belt wheel. The preparation device achieves the effects of high uniform mixing precision, simple structure and high preparation speed, can start a third motor to rotate positively and negatively and can move left and right when driving a spring and a steel bead to rotate.

Owner:六安双收技术转移服务有限公司

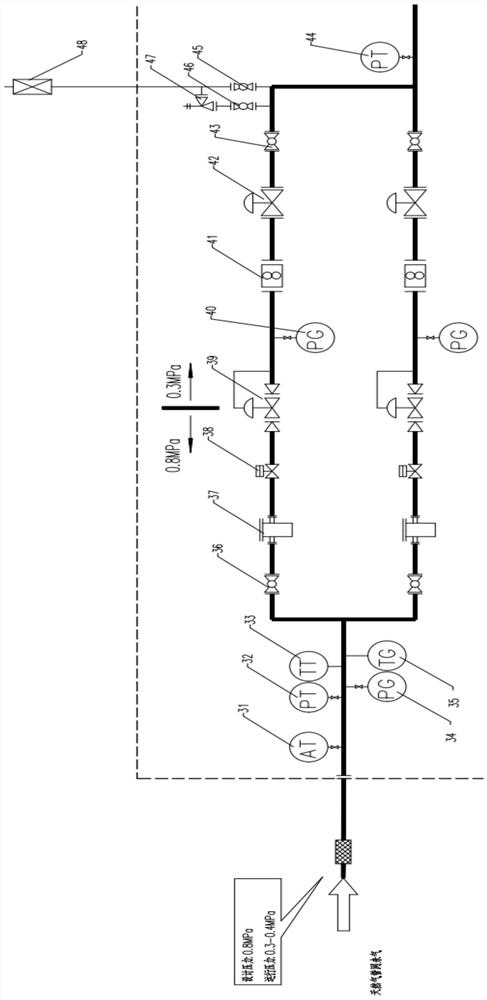

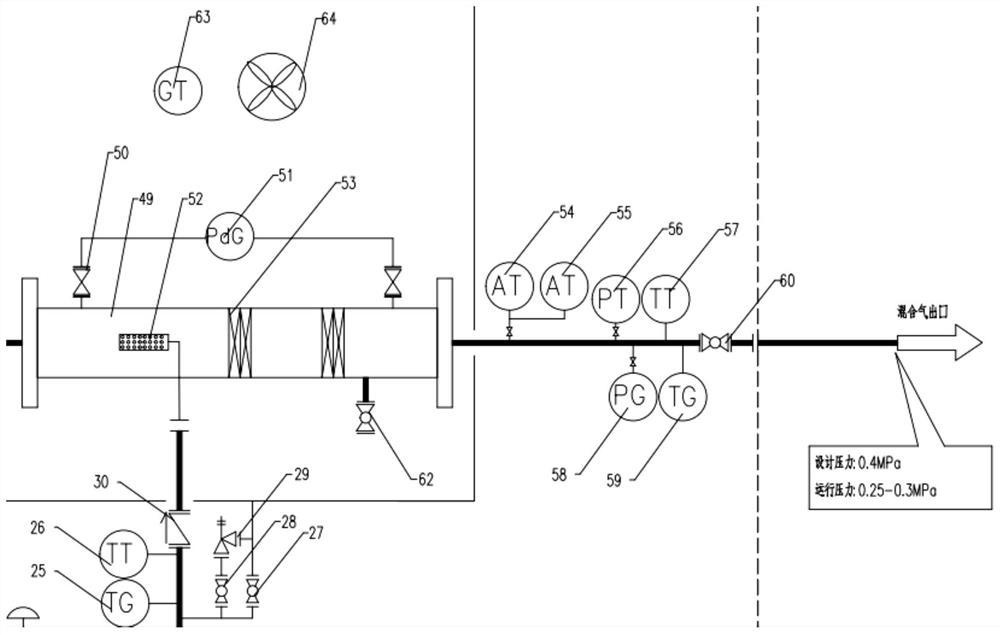

Hydrogen energy utilization gas mixing system and hydrogen and natural gas proportioning control method

PendingCN111992071AFast and stable dynamic followSafe and stable gas supplyFlow mixersTransportation and packagingThermodynamicsEngineering

The invention discloses a hydrogen energy utilization gas mixing system and a hydrogen and natural gas proportioning control method, and relates to the technical field of renewable energy utilization.Source hydrogen enters a gas mixing pipeline and passes through an inlet ball valve, a pneumatic cut-off valve and a filter, the hydrogen flow is metered through a flow meter, the hydrogen consumption is adjusted through an adjusting valve, and then the hydrogen enters a gas mixing device through an outlet ball valve; source natural gas enters the gas mixing pipeline, passes through the inlet ball valve and a filter stop valve, is pressure-regulated and metered, reaches the outlet ball valve via the adjusting valve and then enters a gas mixing device; and detection equipment at a mixed gas outlet is matched with the flow value after temperature and pressure compensation to jointly control the opening degree of an adjusting valve on a natural gas and hydrogen pipeline and control the volume flow of hydrogen, online adjustment and automatic following of the hydrogenation amount are conducted, and natural gas and hydrogen proportioning is achieved. According to the invention, a stable gas mixing ratio of two gases is realized, the mixing precision is high, the equipment is integrally skid-mounted, and a stainless steel box body with heat preservation and noise reduction functions isexternally arranged, so that the equipment is compact and attractive, and is convenient to install and migrate.

Owner:JINCHENG MINGSHI COAL LAYER USING +1

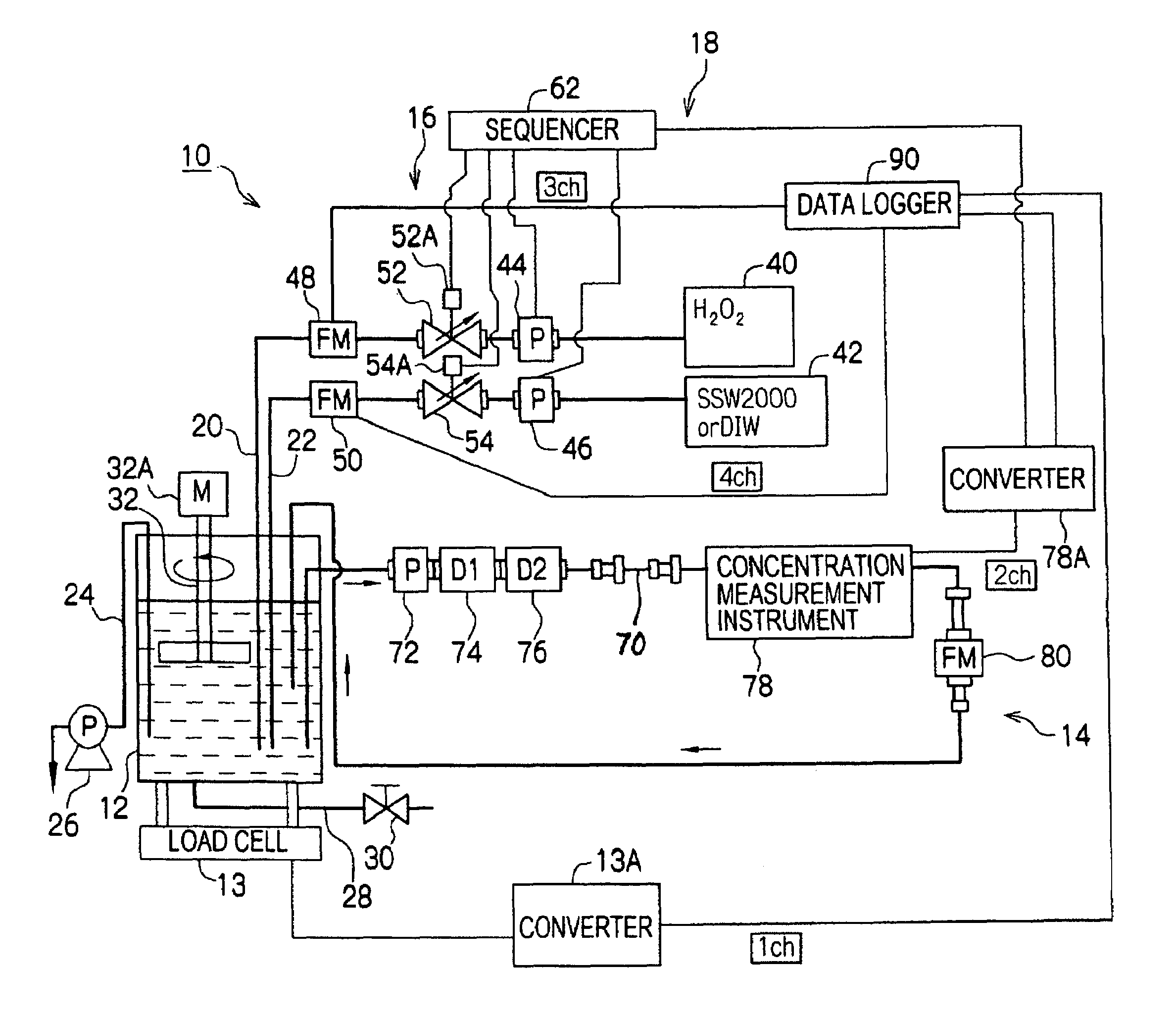

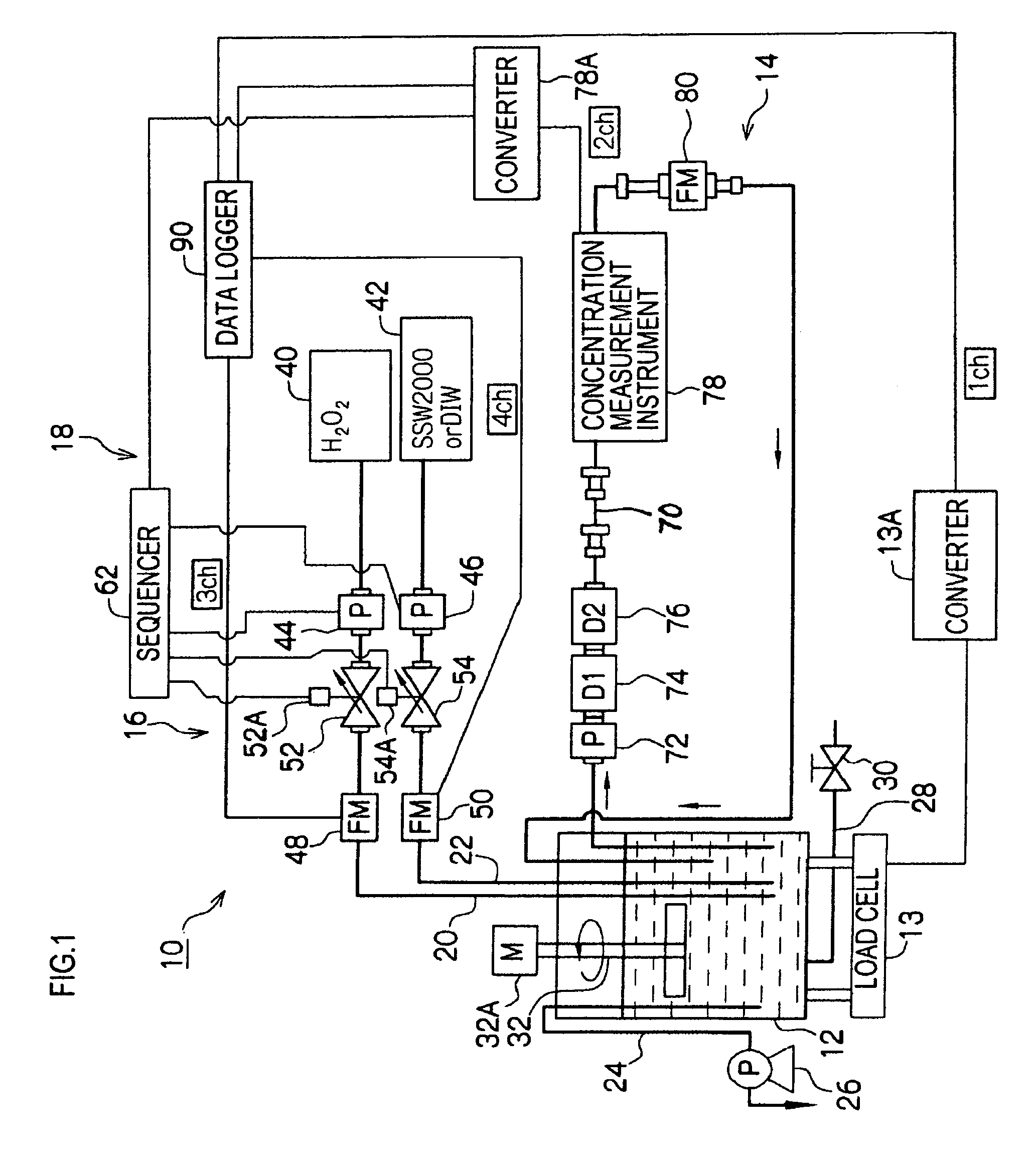

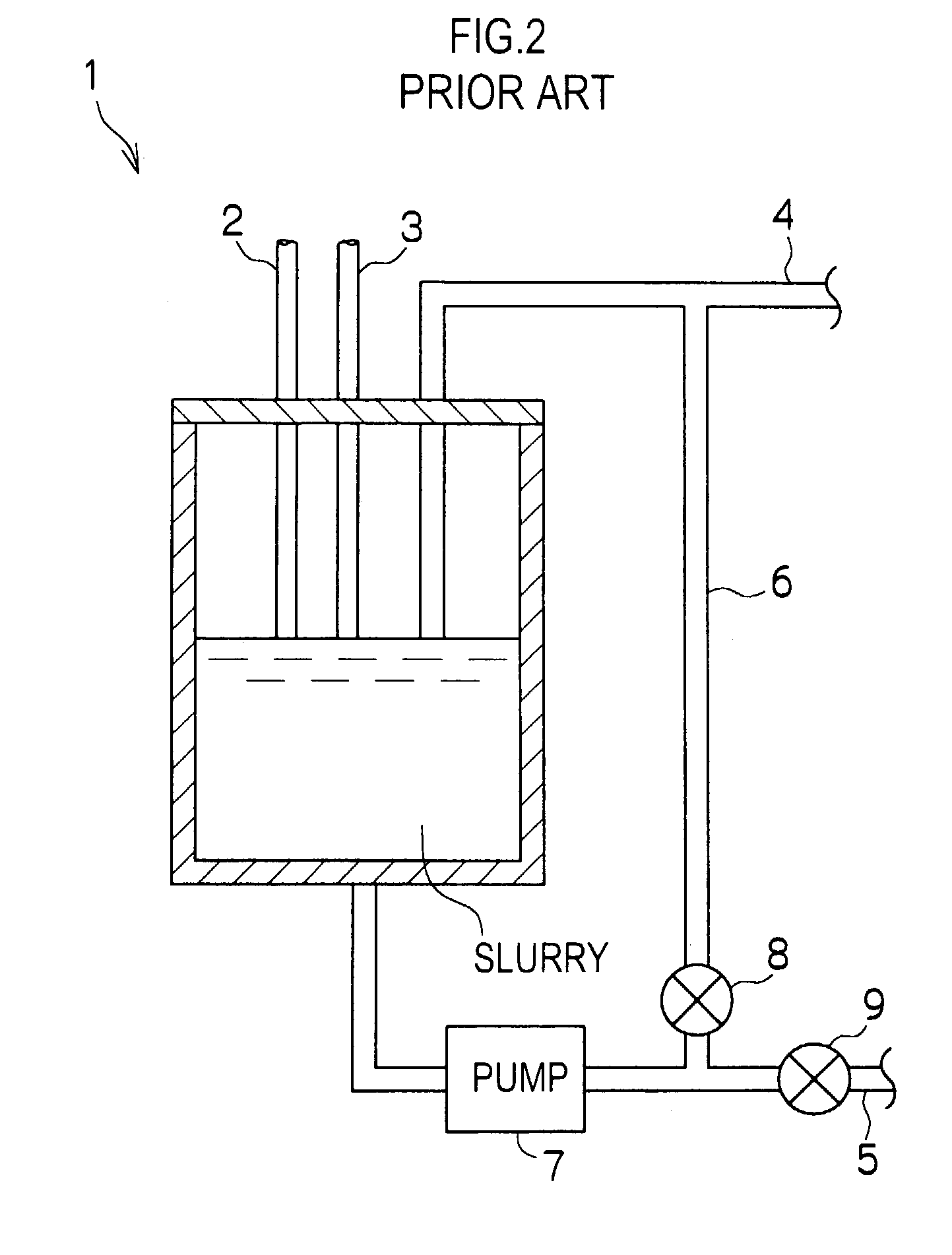

Method and apparatus for preparing slurry for CMP apparatus

InactiveUS6955764B2Accurately measureImprove accuracyLiquid degasificationIon-exchanger regenerationProcess engineeringEngineering

The method and apparatus are provided for preparing a slurry for a CMP apparatus with which mixing accuracy for a slurry is improved and accurate measurement is automatically accomplished for H2O2 as a small amount of additive. A slurry preparation apparatus for a CMP apparatus comprises a tank for preparing the slurry, a stock solution feeder for the slurry which feeds a stock solution for the slurry into the tank, and a concentration measurement instrument located outside the tank, which is capable of measuring an additive concentration in the slurry in the tank. The concentration measurement instrument measures the additive concentration in the slurry in the tank, and the amount of the stock solution for the slurry to be supplied is controlled according to the measurements.

Owner:TOKYO SEIMITSU

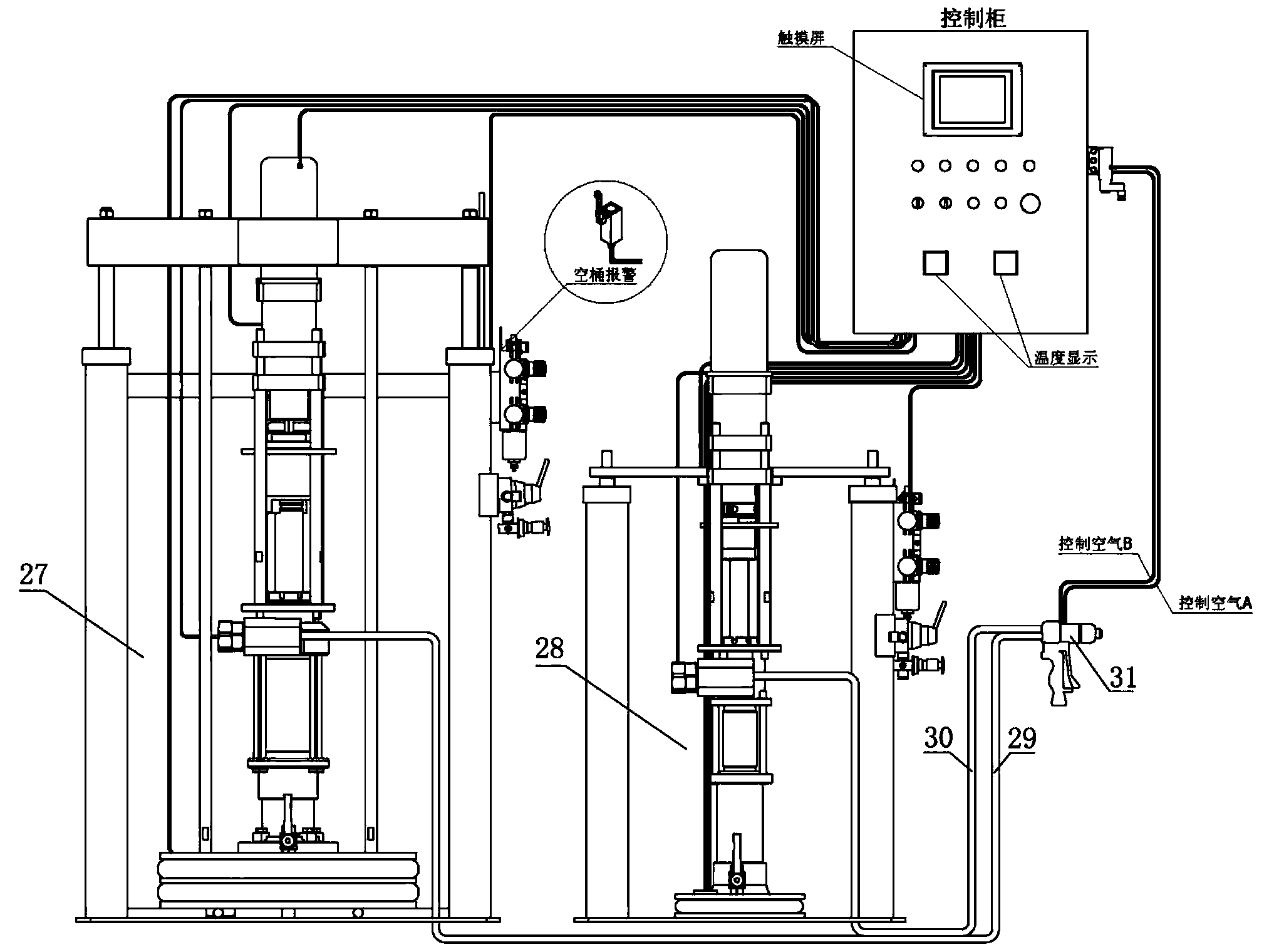

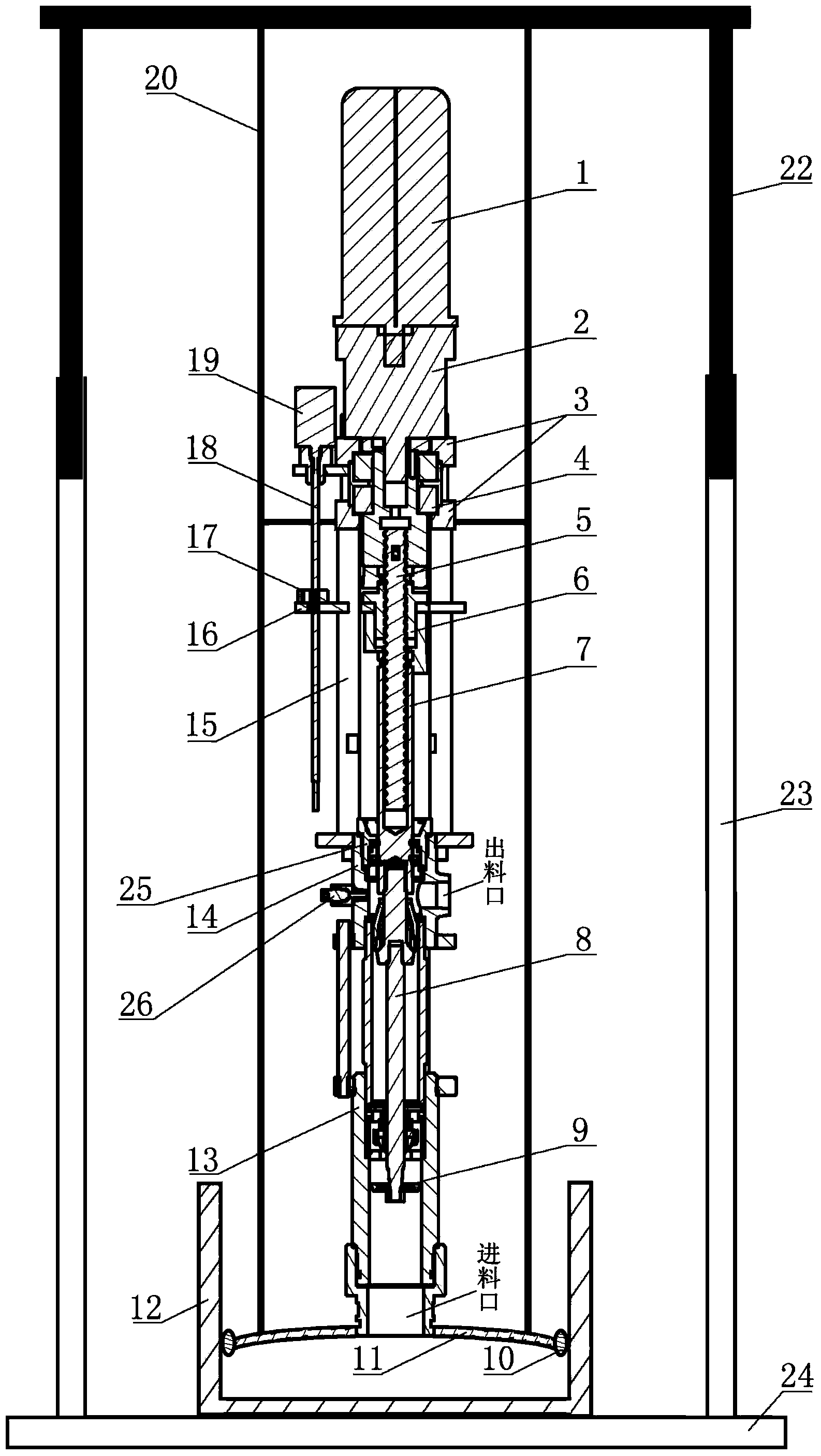

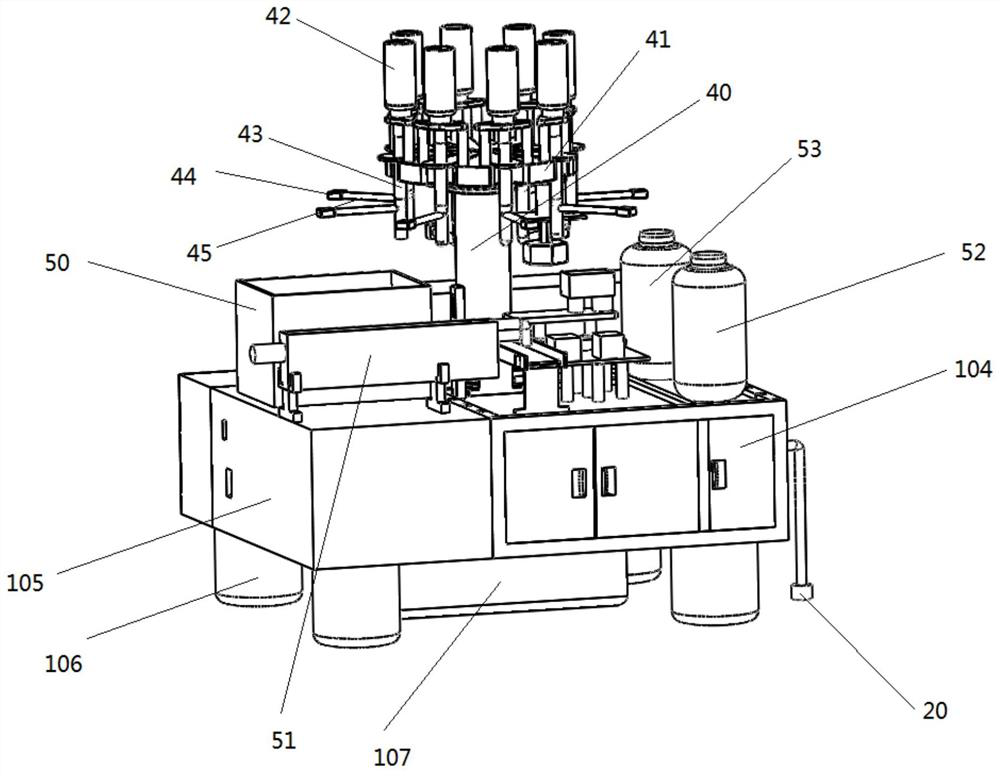

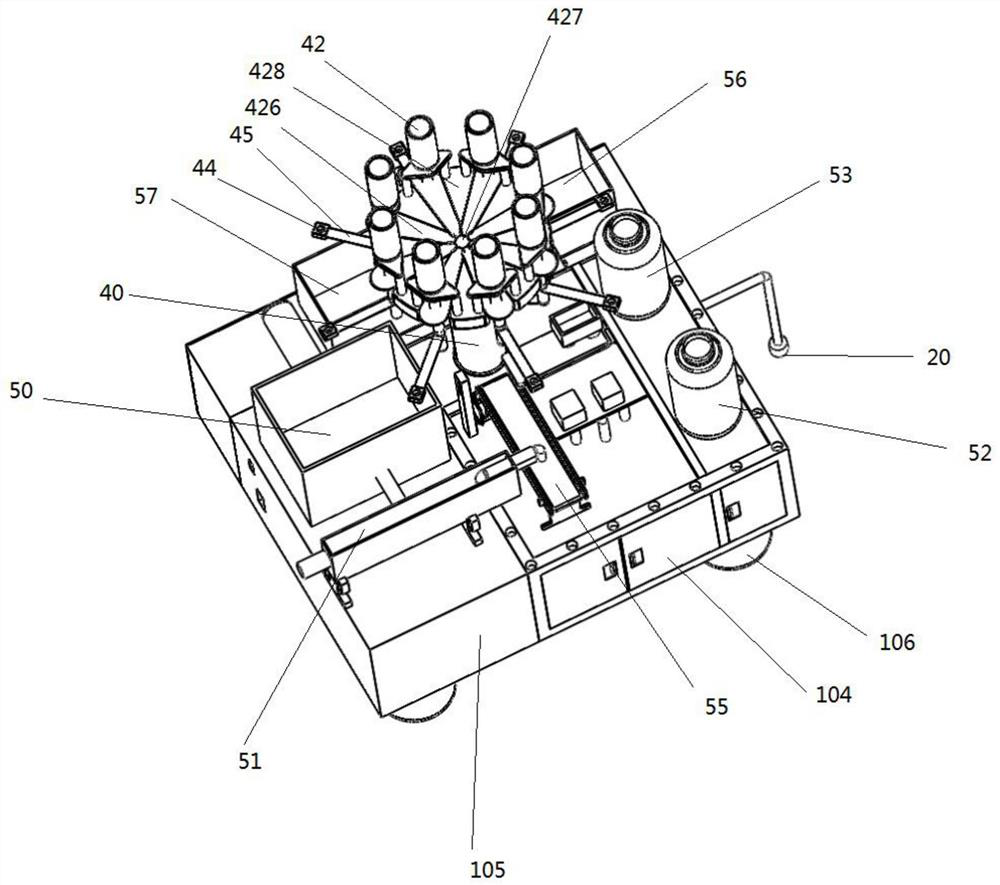

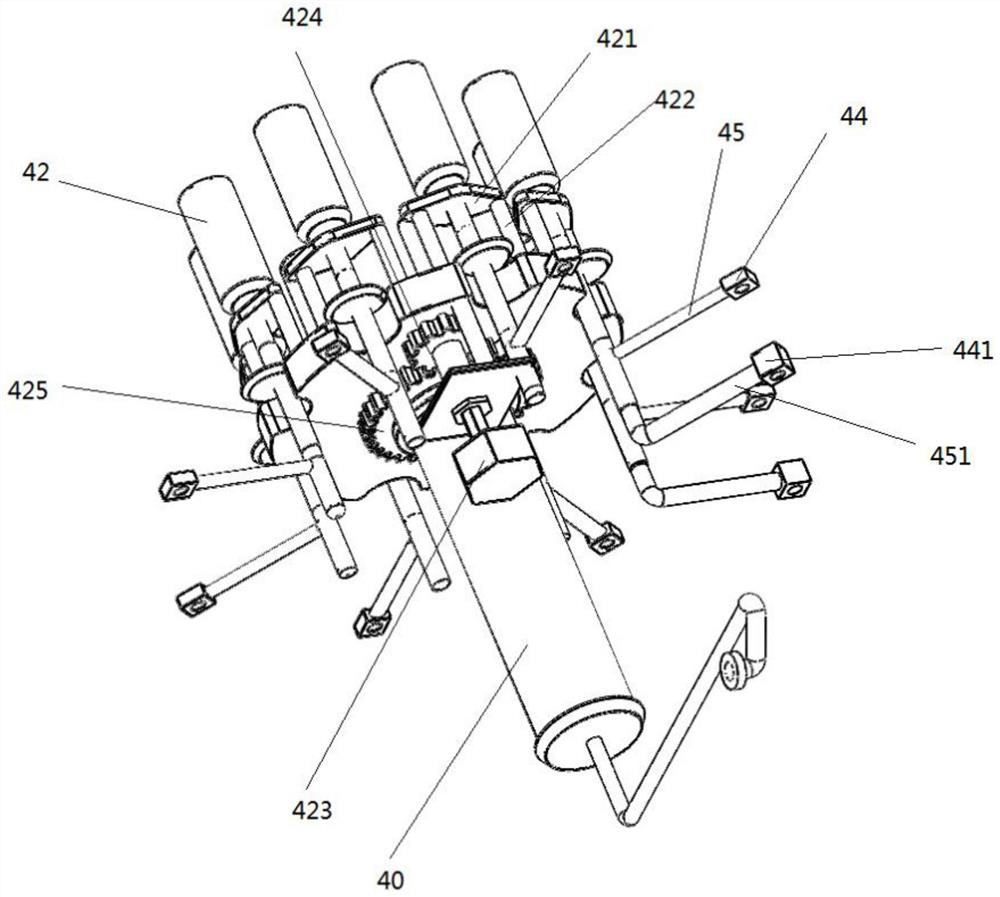

Double-component gluing equipment

ActiveCN104069969ASolve problems such as poor sealingHigh traffic identification abilityLiquid surface applicatorsLiquid spraying apparatusColloidEngineering

The invention relates to the field of a real-time online mixing technology of a double-component material, and provides double-component gluing equipment. The double-component gluing equipment adopts two electronic metering plunger pumps with new structures, wherein the two electronic metering plunger pumps respectively and independently execute the fluid transportation and metering of two components, so as to match with a glue mixer to finish the online matching mixture of double component colloids. The defects that the glue mixture is easy for failure, low in precision, difficult to regulate the mixture proportion or a prepared special mixed glue is complicate in equipment structure, tedious to operate, high in cost and the like in an existing technology can be overcome.

Owner:成都澳诺科技有限公司

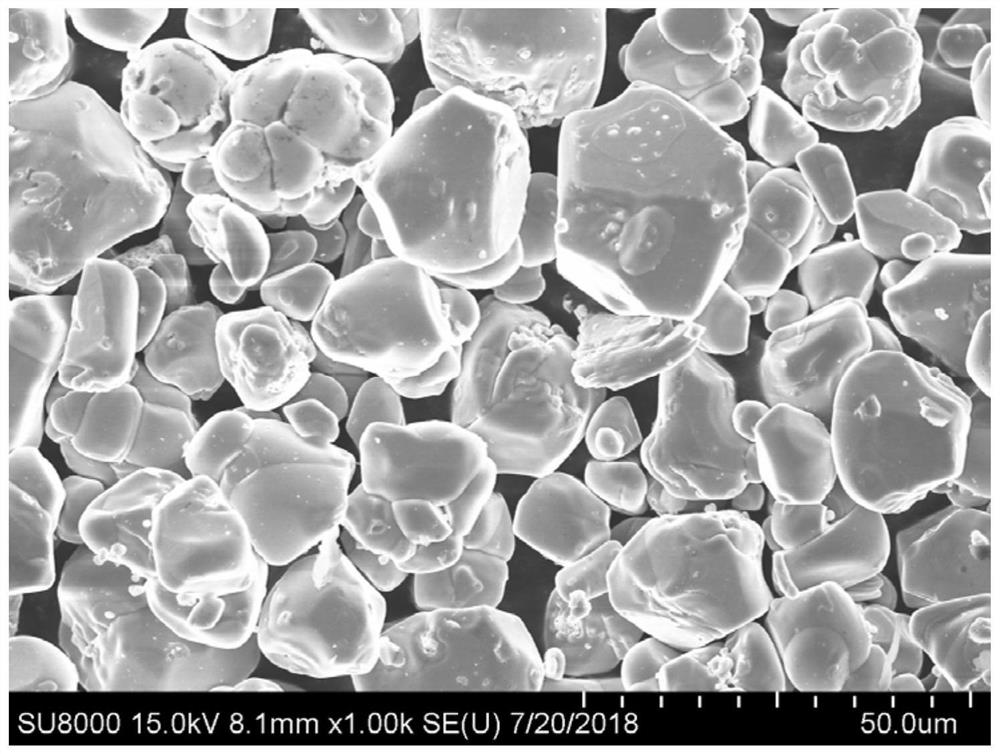

High-voltage spinel and lithium nickel manganese oxide anode material and method for preparing same

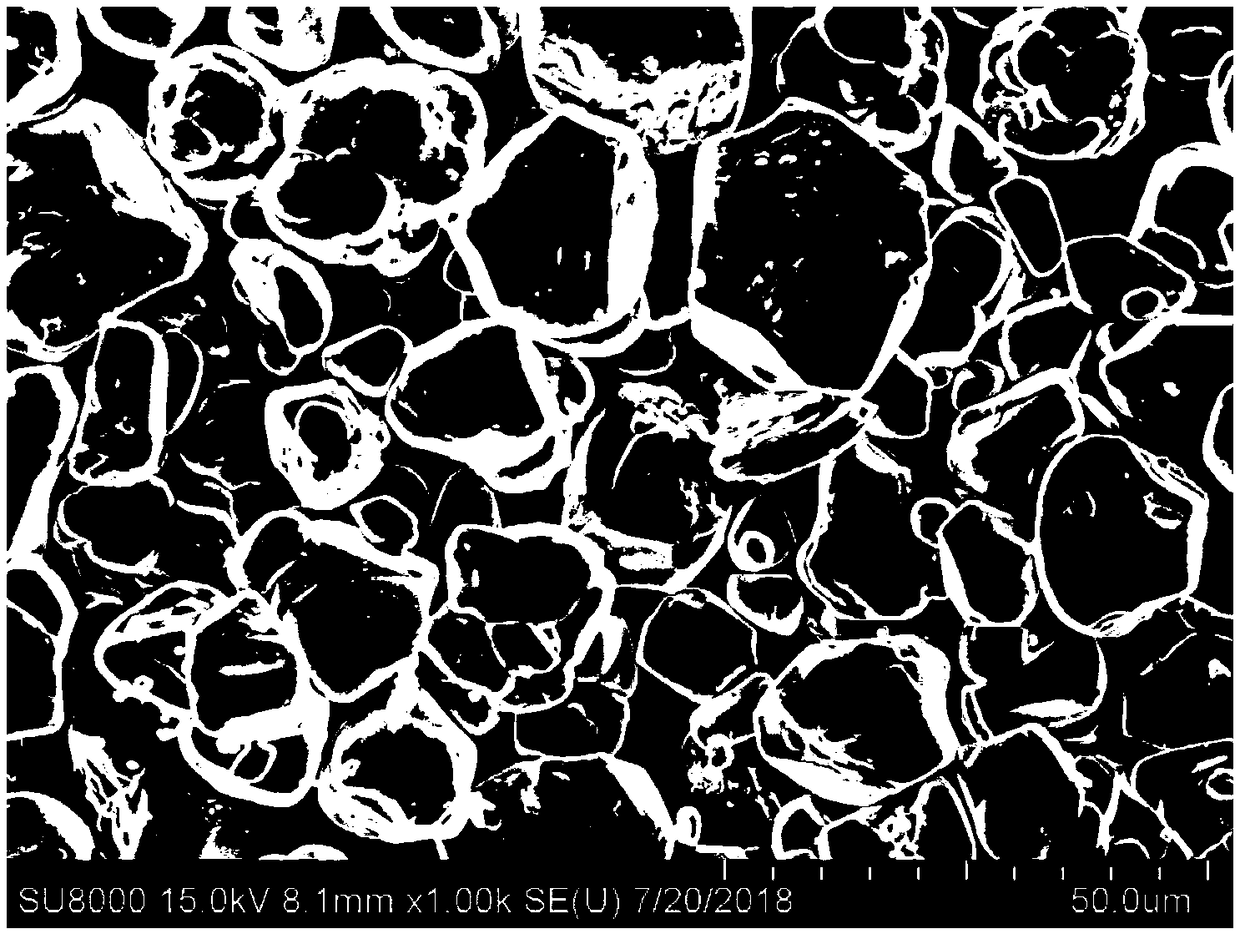

ActiveCN107364901AEvenly distributedIncrease product capacityCell electrodesSecondary cellsMicrometerSingle crystal

The invention provides a high-voltage spinel and lithium nickel manganese oxide anode material and a method for preparing the same. Spinel type nickel and aluminum co-doped trimanganese tetroxide prepared by the aid of wet processes is used as an important material for the high-voltage spinel and lithium nickel manganese oxide anode material prepared by the aid of the method. The method includes steps of (1), uniformly mixing lithium sources and the nickel and aluminum co-doped trimanganese tetroxide with one another to obtain mixed materials; (2), sintering the mixed materials to obtain the high-voltage spinel and lithium nickel manganese oxide anode material. The high-voltage spinel and lithium nickel manganese oxide anode material and the method have the advantages that the method includes simple procedures, and organic solvents can be omitted; the D50 of a product which is the high-voltage spinel and lithium nickel manganese oxide anode material prepared by the aid of the method is 8.932-9.466 micrometers, the specific surface area of the high-voltage spinel and lithium nickel manganese oxide anode material is 2.185-2.434 m<2> / g, component particles of the high-voltage spinel and lithium nickel manganese oxide anode material are single crystals, manganese elements, nickel elements and aluminum elements are uniformly distributed in the high-voltage spinel and lithium nickel manganese oxide anode material, the large and small component particles are the single crystals, and accordingly the high-voltage spinel and lithium nickel manganese oxide anode material is stable in structure, high in discharge capacity, good in rate capability and excellent in cycle performance.

Owner:HUNAN CHANGYUAN LICO CO LTD

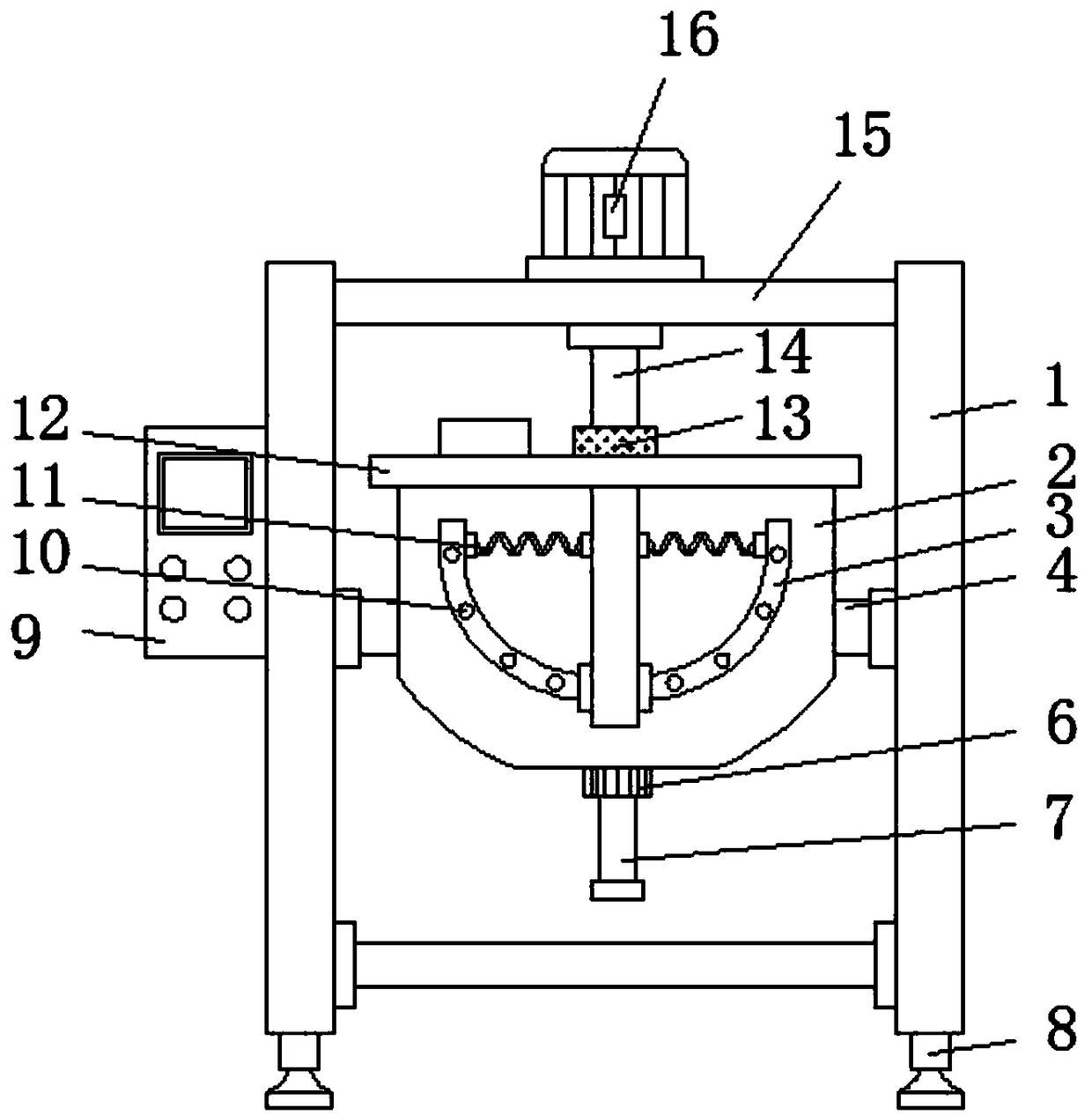

Chemical material stirring and mixing equipment with cleaning device

InactiveCN106693776AExpand the spraying areaSpraying speed is fastRotary stirring mixersTransportation and packagingEngineeringWater pipe

The invention provides chemical material stirring and mixing equipment with a cleaning device. The chemical material stirring and mixing equipment comprises a tank body; a mixing cavity is arranged in the tank body; an upper cover is arranged in an opening at the top part; the cleaning device is arranged on the upper cover; the cleaning device comprises a transmission case, a first motor, a water inlet pipe and a rotary spraying disc; a stirring device is arranged at the bottom part of the mixing cavity; the stirring device comprises a second motor, a stirring shaft, a horizontal stirring sheet, a vertical stirring sheet and a stirring plate; and the side wall of the rotary spraying disc is fixedly connected with a scraper plate. The spraying area and the spraying speed of clean water are increased and accelerated through the cleaning device, so that the used tank body can be conveniently efficiently cleaned; due to the arrangement of the stirring device, the material in the tank body is efficiently stirred and mixed through the horizontal stirring sheet, the vertical stirring sheet and the stirring plate; due to the arrangement of the scraper plate, the material adhered on the inner wall of the tank body is scraped, the material mixing accuracy is improved, the material can be completely discharged in the process of discharging the material, and the use ratio of the material is improved.

Owner:河南微服网络科技有限公司

Processing technology used for quantitatively mixed liquid media

InactiveCN105289343AShorten mixing timeHigh mixing precisionMixing methodsMixer accessoriesLiquid mediumControl engineering

The invention discloses a processing technology used for quantitatively mixed liquid media. By arranging a plurality of metering pumps and a controller used for controlling the rotation speeds of the metering pumps, various kinds of material liquid can be mixed strictly according to a set proportion, mixing time of material liquid is shortened, mixing precision is improved, and continuous production can be achieved.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

High-precision combustible gas mixer

ActiveCN110898693AGuaranteed mixing efficiencyGuaranteed mixed precisionTransportation and packagingMixer accessoriesElectric machineCombustible gas

Belonging to the technical field of combustible gas mixing, the invention particularly relates to a high-precision combustible gas mixer. The high-precision combustible gas mixer comprises a support seat, a mixing tank is fixedly mounted at the top of the support seat, a first threaded rod is rotatably mounted in the mixing tank, a speed reducing motor is fixedly mounted on one side of the mixingtank, one end of the first threaded rod extends out of the mixing tank and is fixedly connected to an output shaft of the speed reducing motor, a piston is slidably and airtightly installed in the mixing tank, the piston is in threaded connection with the first threaded rod, a sliding rod is fixedly installed in the mixing tank, and the sliding rod runs through the piston and is slidably and airtightly connected to the piston. The high-precision combustible gas mixer provided by the invention is easy to operate, high in practicability and adjustable in volume, can guarantee the mixing efficiency and precision in mixing gas of any volume, at the same time can change the pressure and flow of different raw material gases during entering, can balance the pressure difference when different rawmaterial gases enter, and improves the mixing precision.

Owner:苏州浦煦流体控制系统有限公司

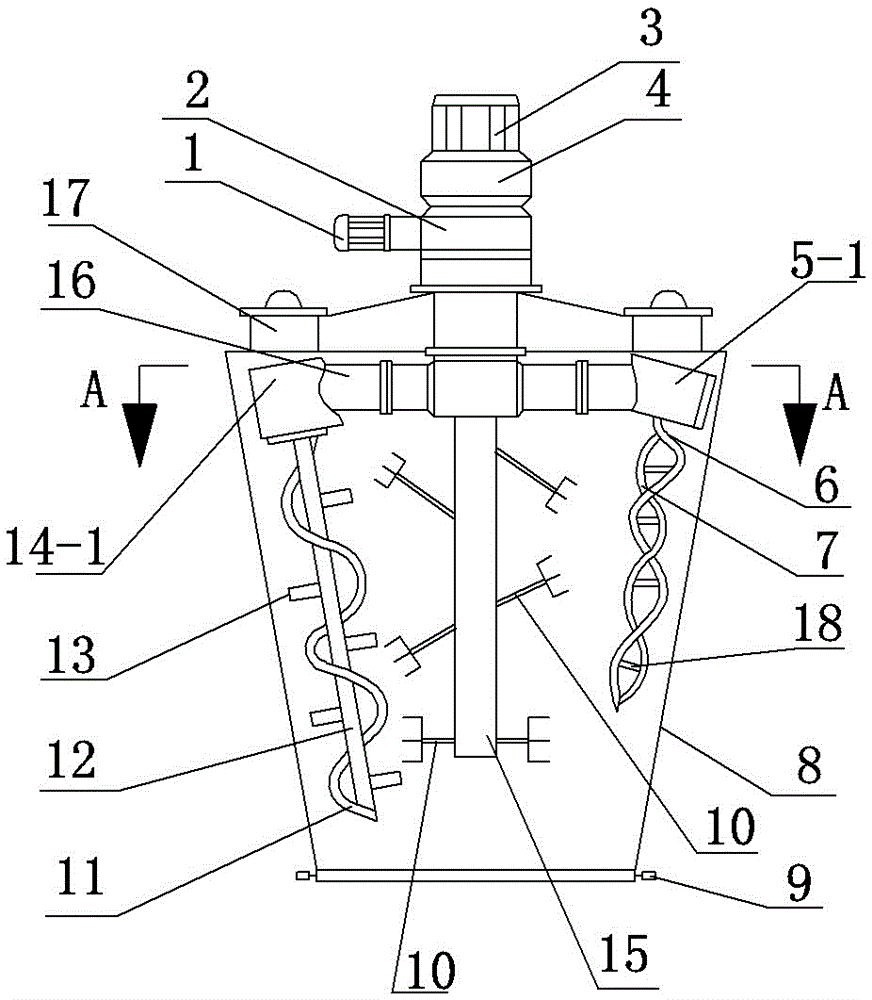

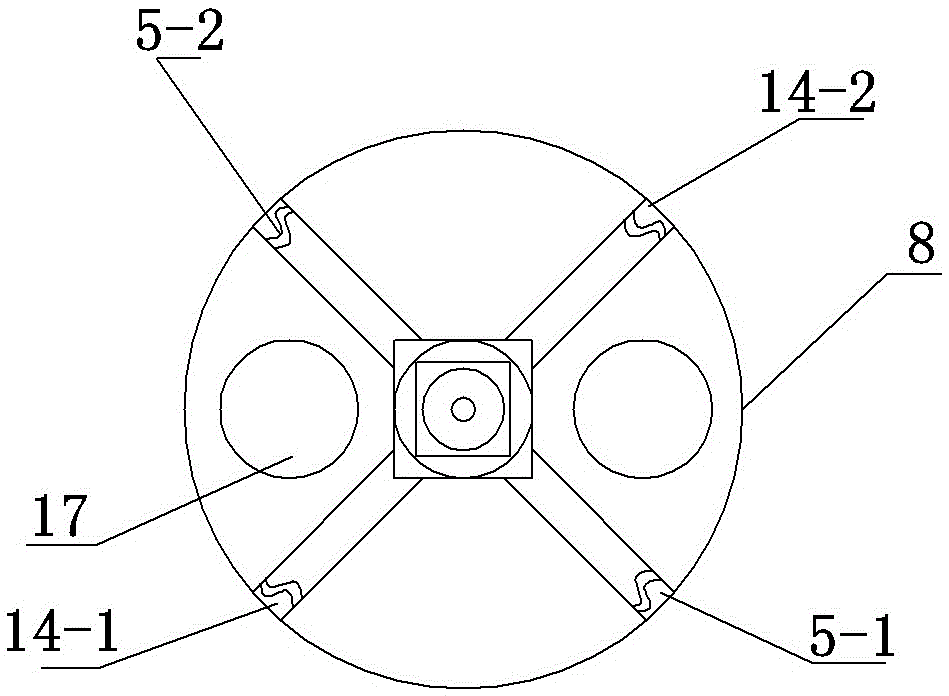

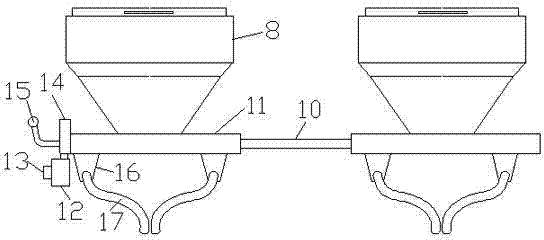

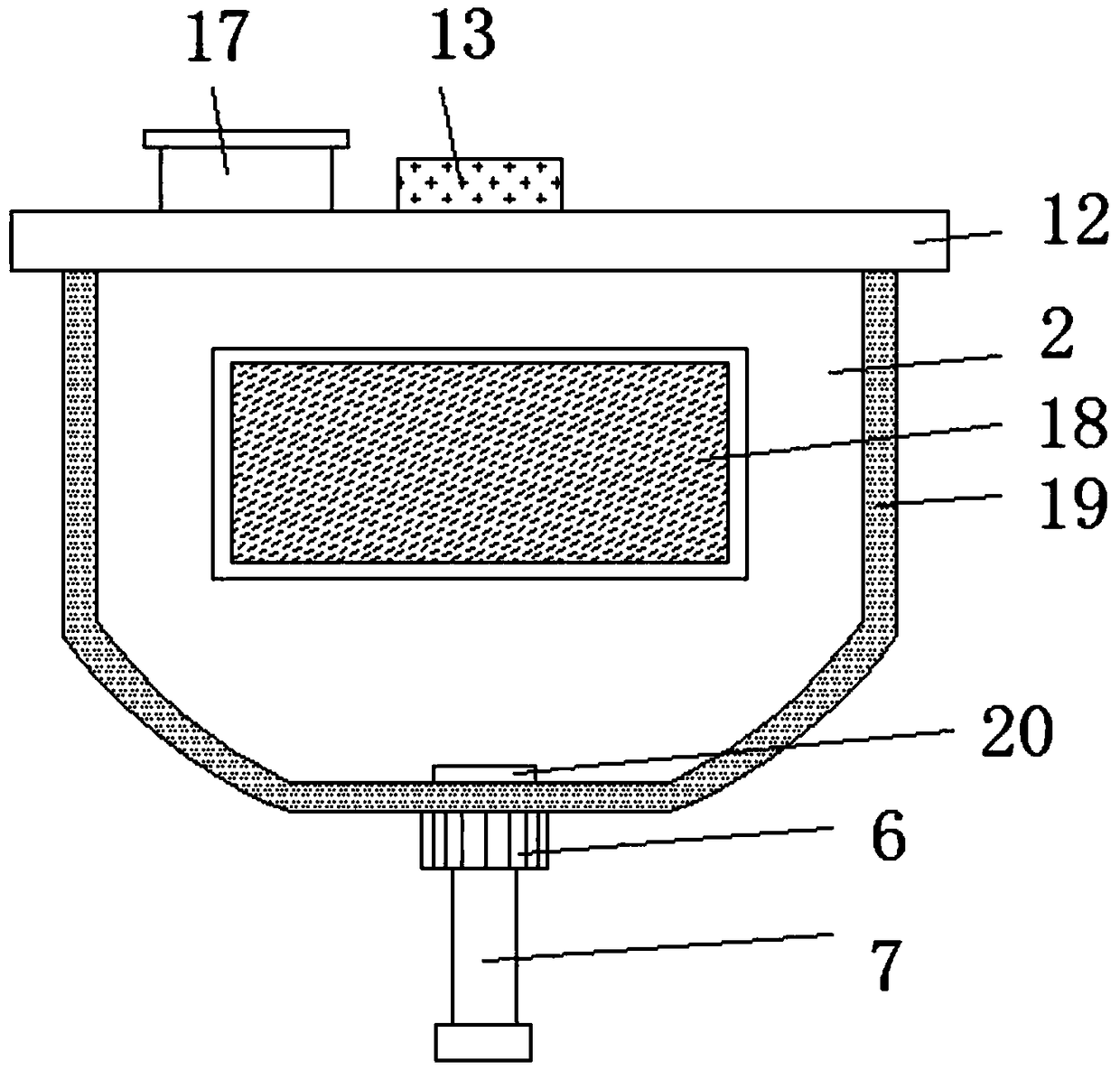

Conical mixer

InactiveCN105833754AWell mixedHigh mixing precisionRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention provides a conical mixer which is simple in structure. The problem that raw materials are nonuniform in mixing, low in mixing accuracy and low in efficiency can be solved effectively. The conical mixer comprises a barrel, a feeding port is arranged at the upper end of the barrel, a discharging valve is arranged at the bottom end of the barrel, the barrel is conical, a double-helical-band stirrer, a screw-helical-band stirrer and a front double-hinge small-paddle stirrer which are mutually independent are arranged in the barrel and combined in the same through a same spindle.

Owner:WUXI PROFESSIONAL COLLEGE OF SCI & TECH

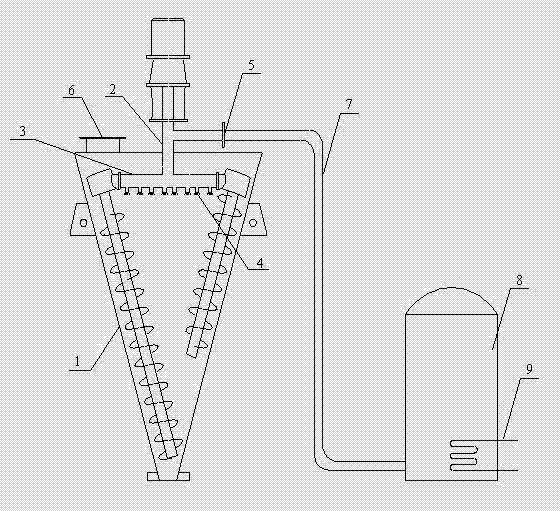

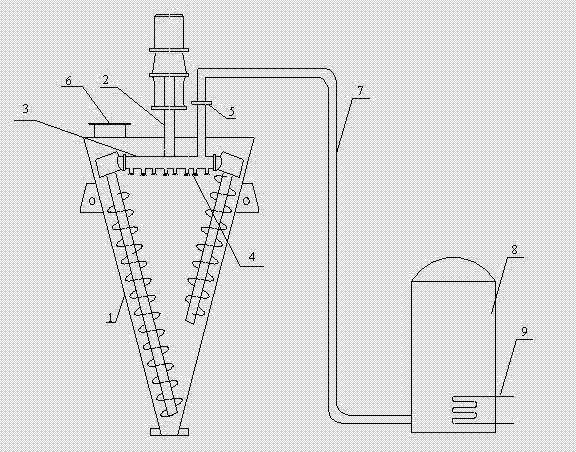

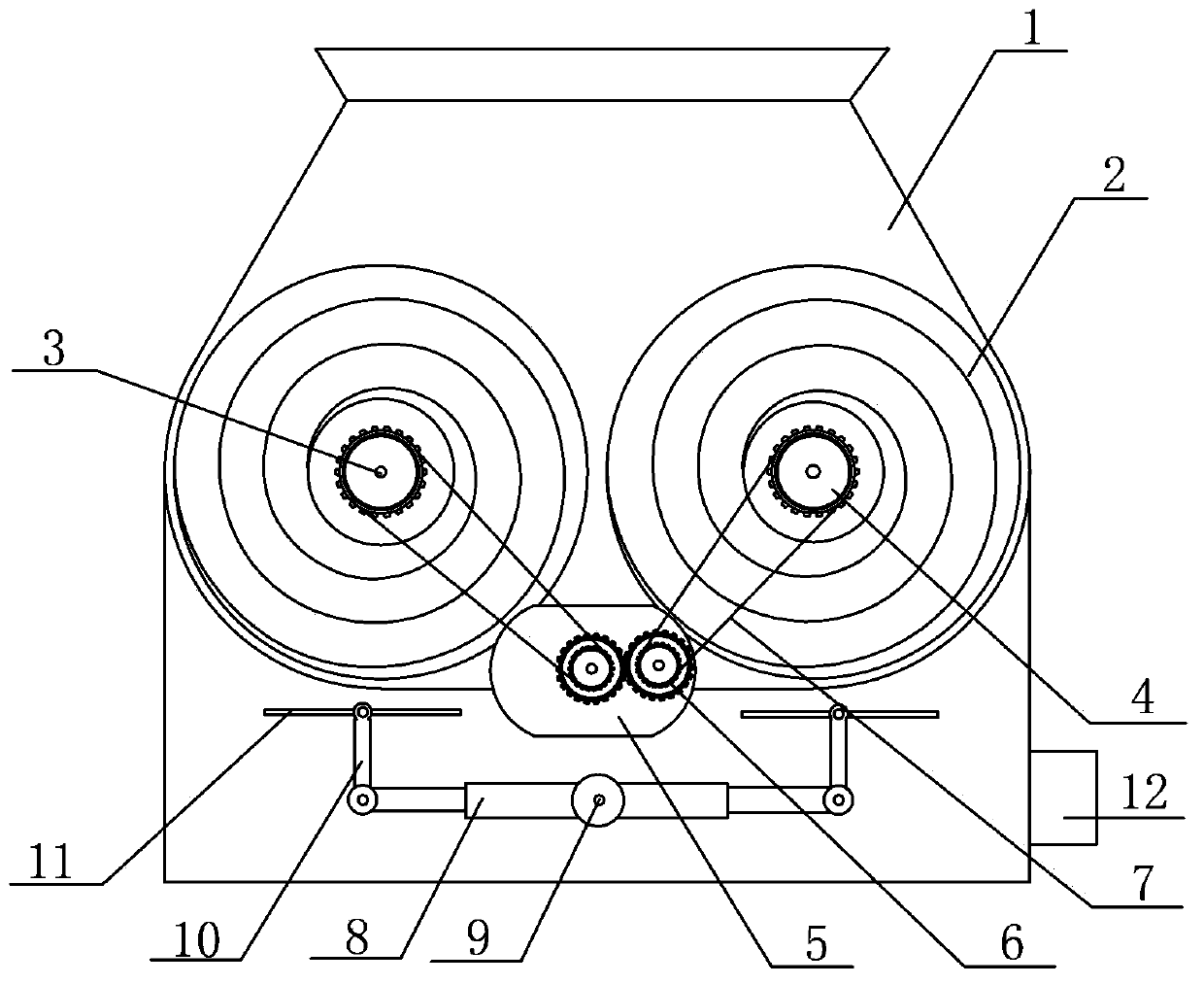

Twin-spiral mixer

InactiveCN102814131AMix well and evenlySimple structureRotary stirring mixersMixer accessoriesProcess engineeringEnergy consumption

The invention relates to a mixing apparatus, specifically to a twin-spiral mixer. The twin-spiral mixer comprises a cylindrical shell and a rotating shaft. A horizontal tumbler which is connected with the rotating shaft is arranged inside the cylindrical shell. The cylindrical shell is provided with a liquid feed inlet which is connected with a storage tank through a pipeline. A heat coil is arranged inside the storage tank. The twin-spiral mixer has a simple structure and can be used to heat a liquid material according to an actual situation. In addition, by the adoption of a spray device, all-around full uniform mixing of a solid material and a liquid material can be realized. Mixing precision is high as well as the mixing efficiency. Therefore, energy consumption is reduced to some extent. The twin-spiral mixer is easy to popularize and use.

Owner:广饶彤鑫工贸有限公司

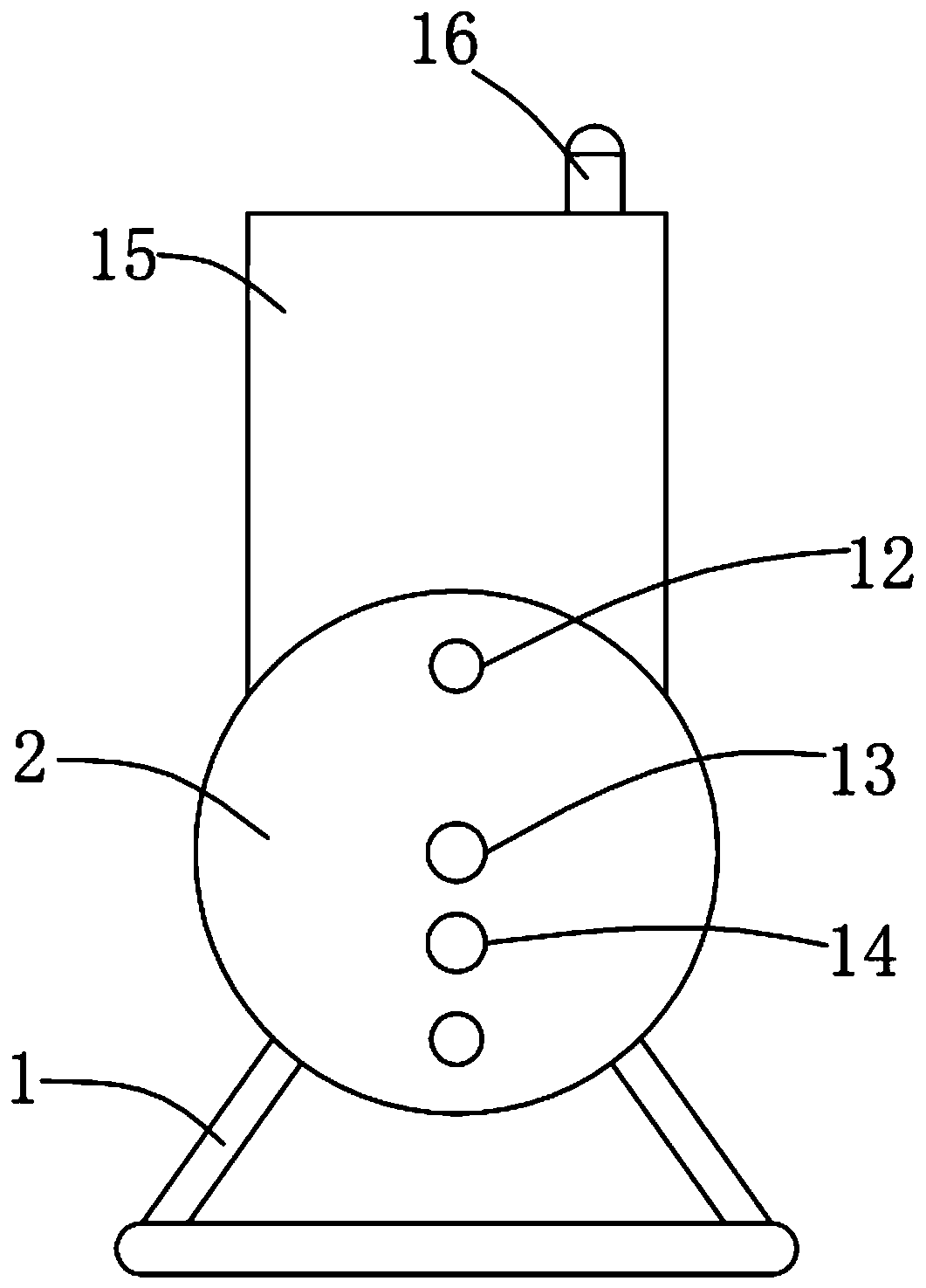

Laser mixed gas preparation device

ActiveCN113786769AAvoid shakingPrevent leakageRotary stirring mixersMixer accessoriesEngineeringGas holder

The invention provides a laser mixed gas preparation device which comprises a mounting mechanism, a mixing device is mounted at the top of the mounting mechanism, a driving mechanism is mounted in the mixing device, the mixing device comprises an outer pipe and an inner pipe, the inner pipe is fixedly mounted in the outer pipe, a plurality of gas inlets are formed in the peripheral side of the inner pipe, and a plurality of gas outlets are formed in the peripheral side of the inner pipe. A first air storage tank and a second air storage tank are connected to the outer pipe, a flow guiding device is installed in the inner pipe, two air inlet mechanisms are symmetrically installed on the flow guiding device, a plurality of sealing devices are installed between the outer pipe and the inner pipe, one end of a connecting device is connected with the outer pipe, and the other end of the connecting device is connected with a collecting device. And a fixing device is mounted in the connecting device. The mixing device, the driving mechanism and the flow guide device are combined, so that gas in the gas storage tank I and the gas storage tank II is premixed in the mixing device, the mixing quality is improved, and the mixing precision can be ensured.

Owner:PERIC SPECIAL GASES CO LTD

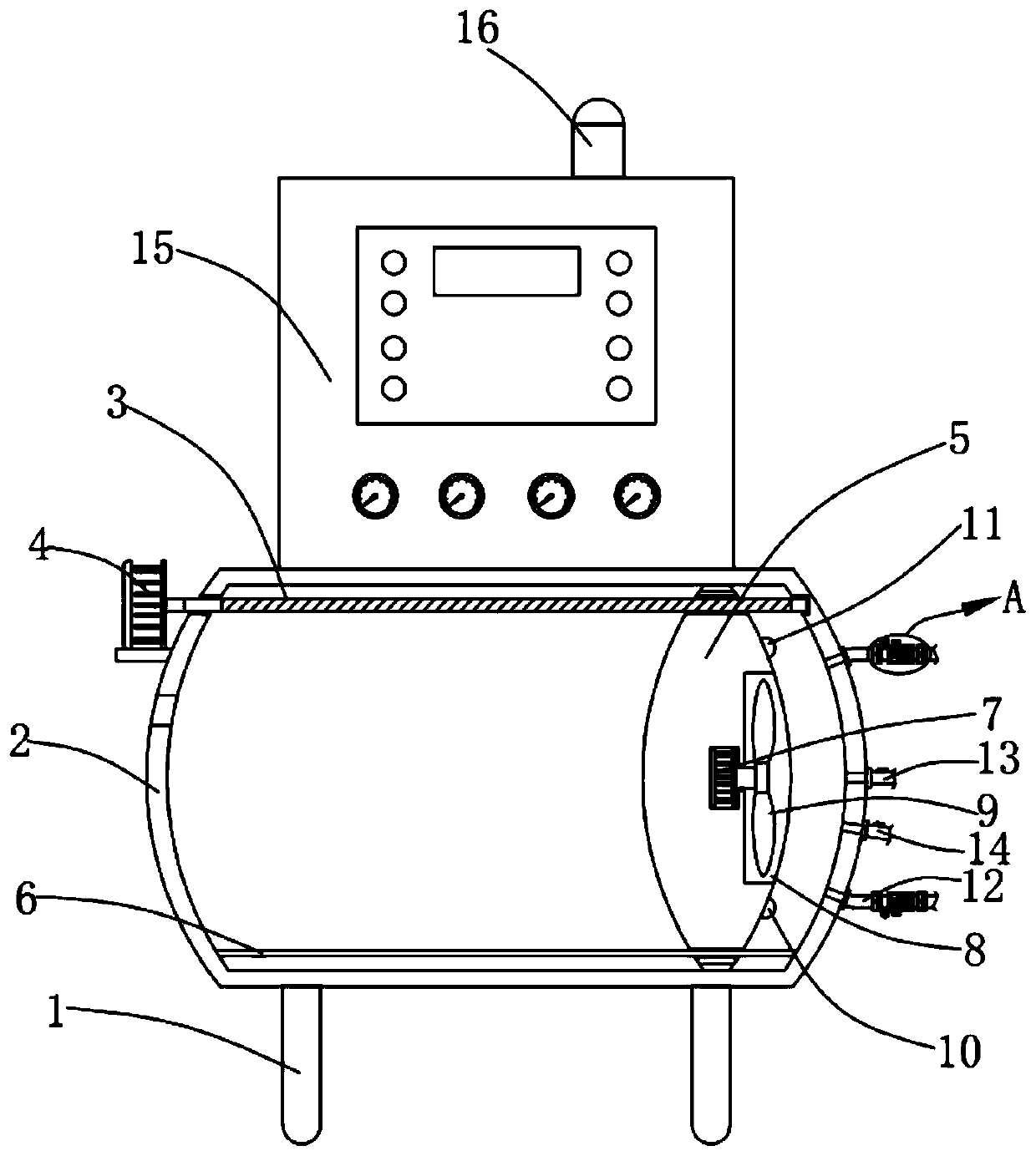

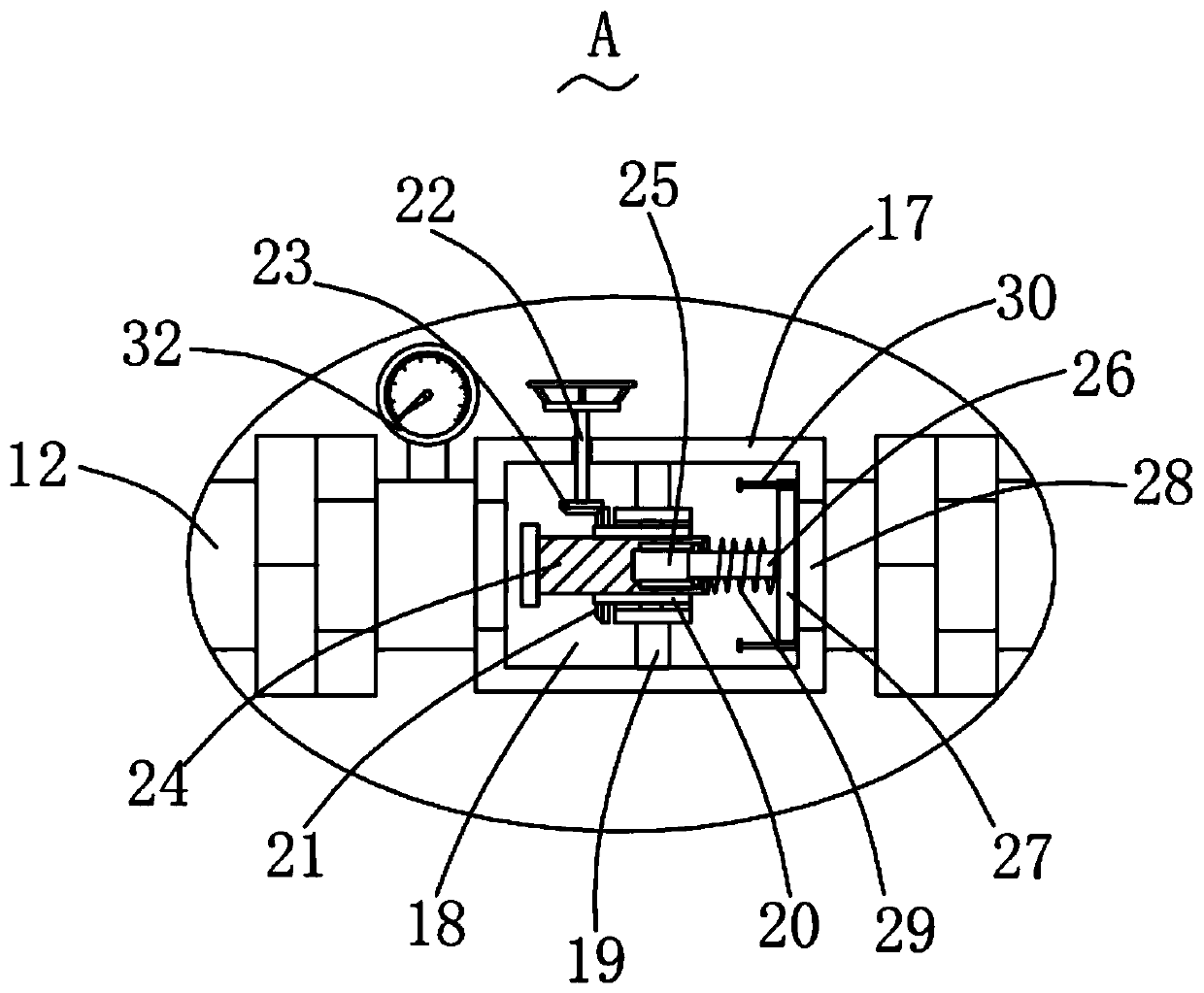

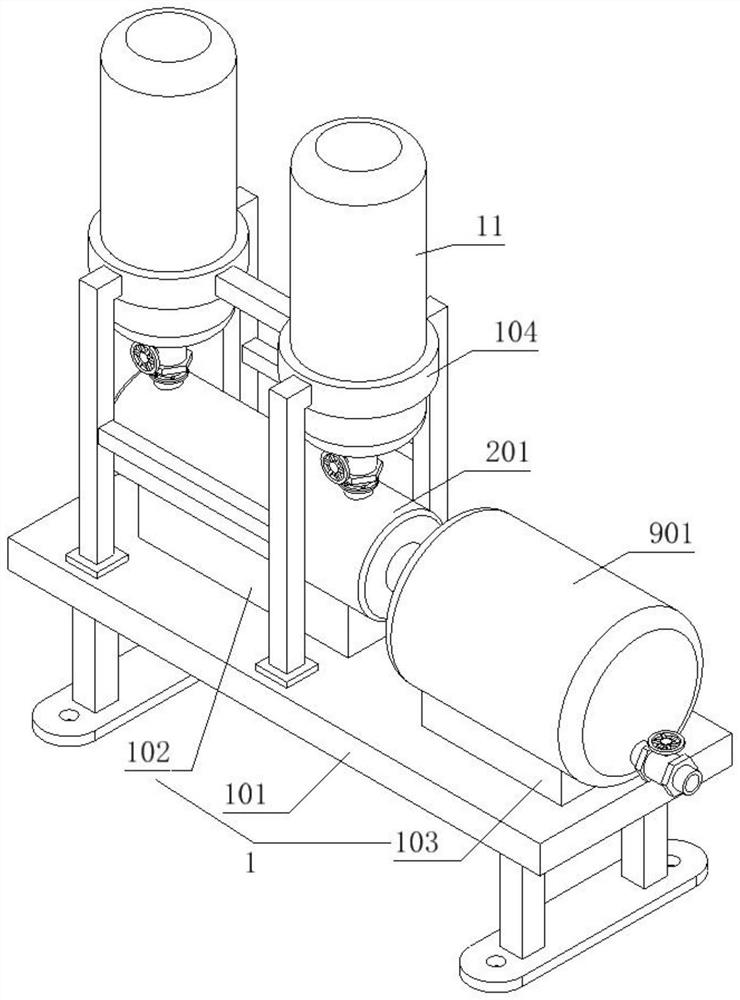

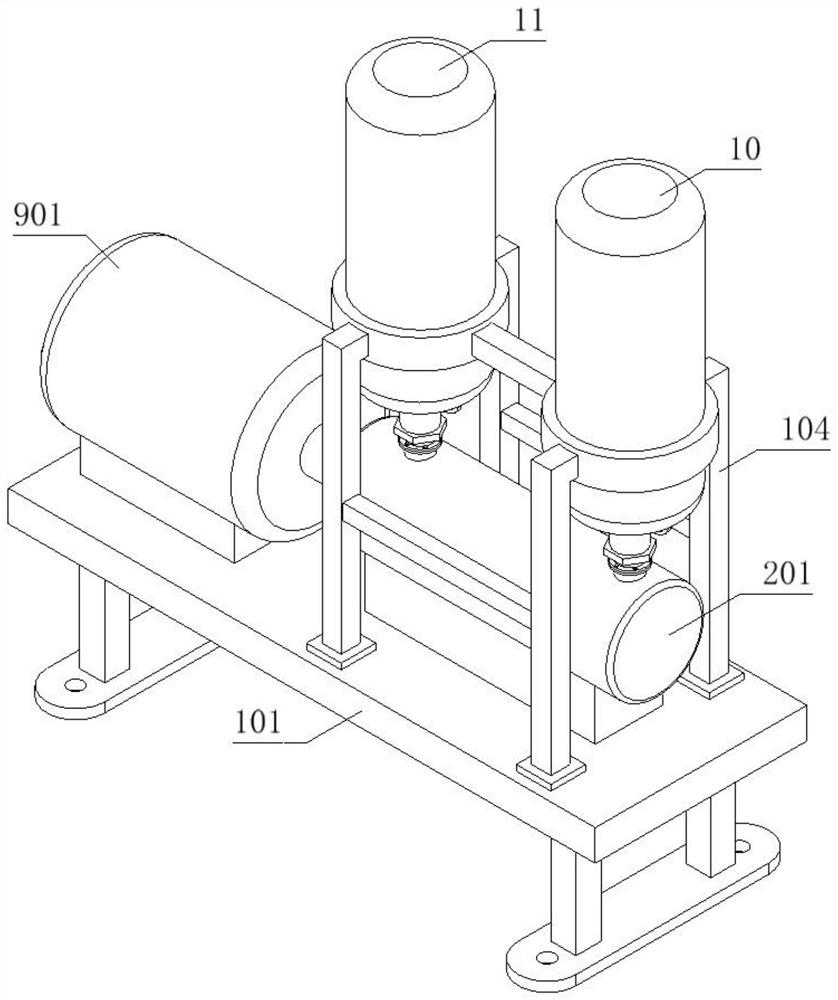

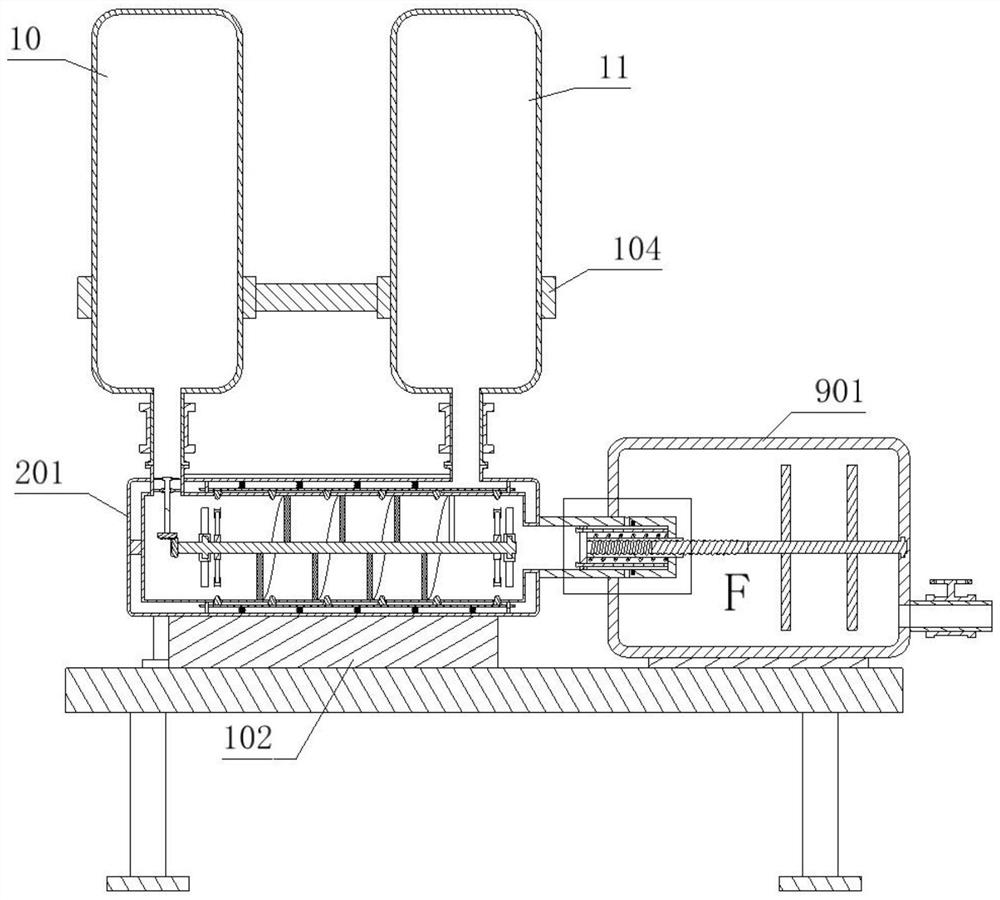

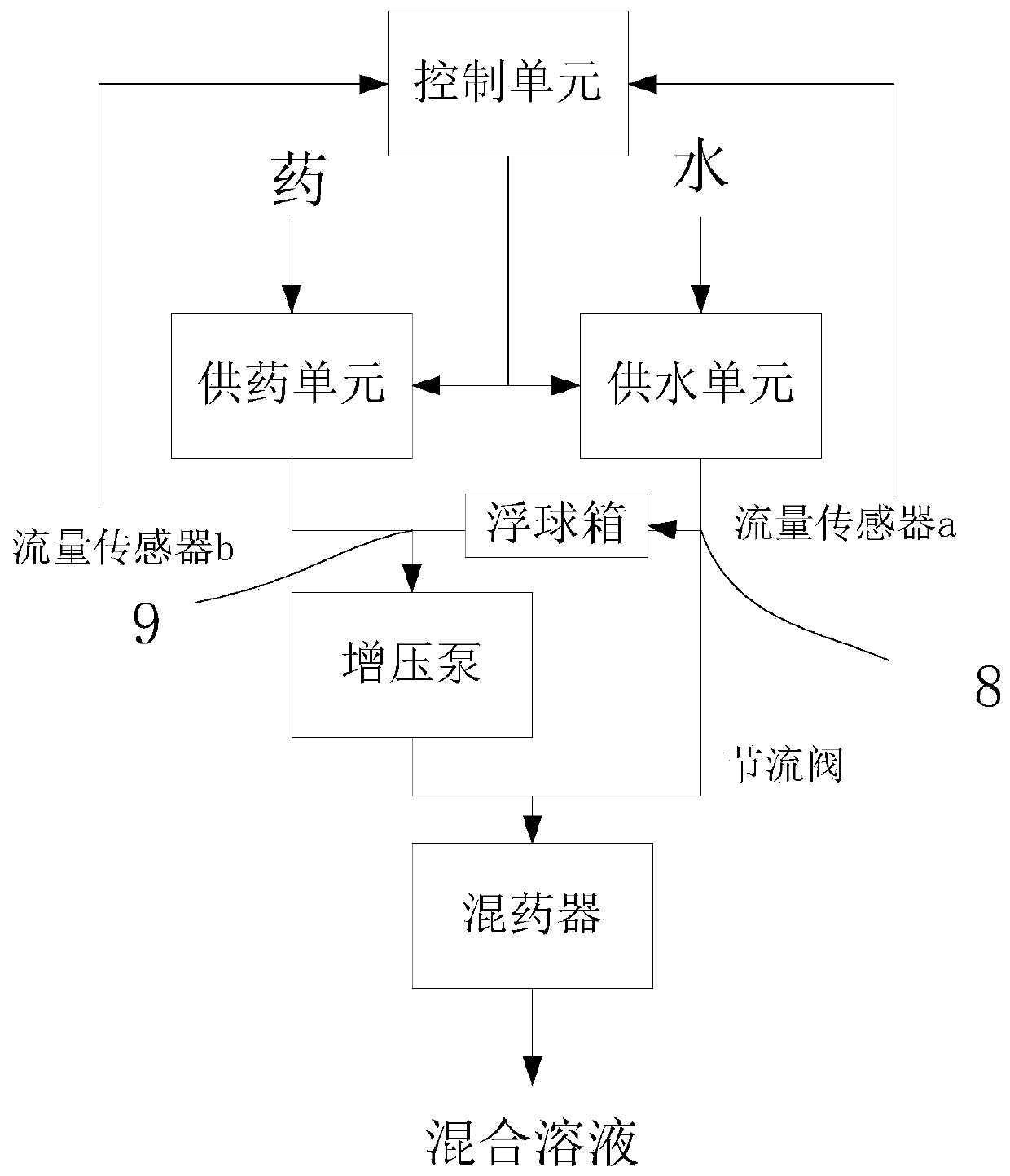

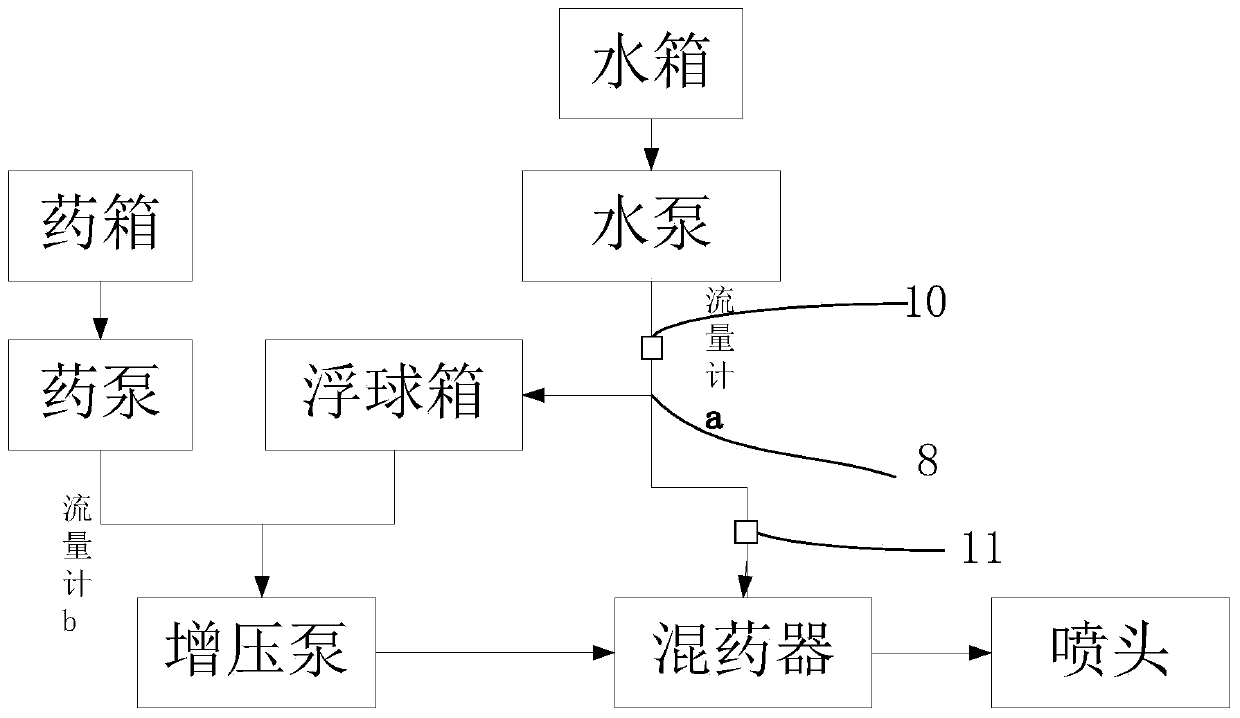

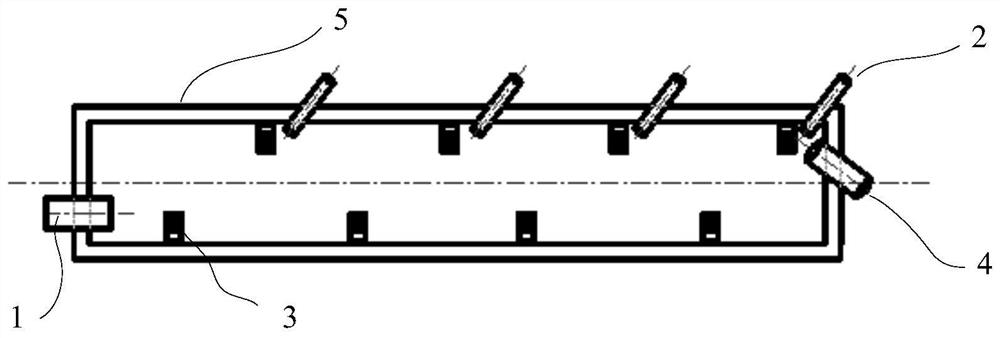

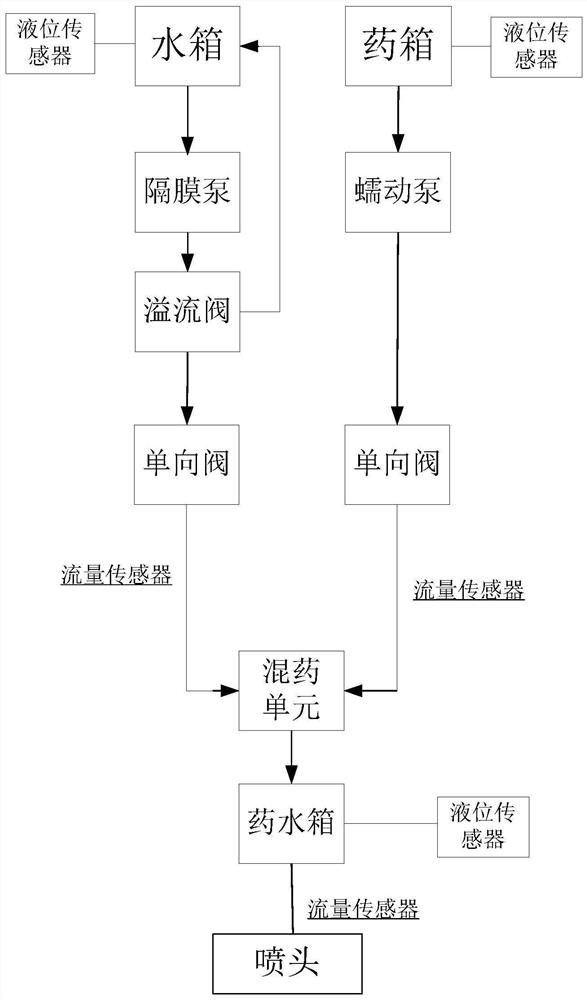

High-pressure injection type drug mixing device

PendingCN110102198AHigh mixing precisionLower requirementFlow mixersTransportation and packagingHigh pressureWater supply

The invention discloses a high-pressure injection type drug mixing device. The device comprises a water supply unit, a drug supply unit, a float tank, a booster pump and a drug mixer, wherein the drugsupply unit is connected with a drug injection port of the drug mixer through the booster pump, the water supply unit is connected with a water injection port of the drug mixer, and the water supplyunit also premixes a drug output by the drug supply unit with water output by the float tank through the communication of the float tank with a drug outlet port of the drug supply unit and an inlet ofthe booster pump. The high-pressure injection type drug mixing device has the advantages that the precision of drug mixing is high, the range of drug mixing is large, and the economy is good; on thebasis of meeting the requirements of large-scale drug mixing and high-precision drug mixing, the resources can be saved, and the environment is protected.

Owner:HUNAN AGRICULTURAL UNIV

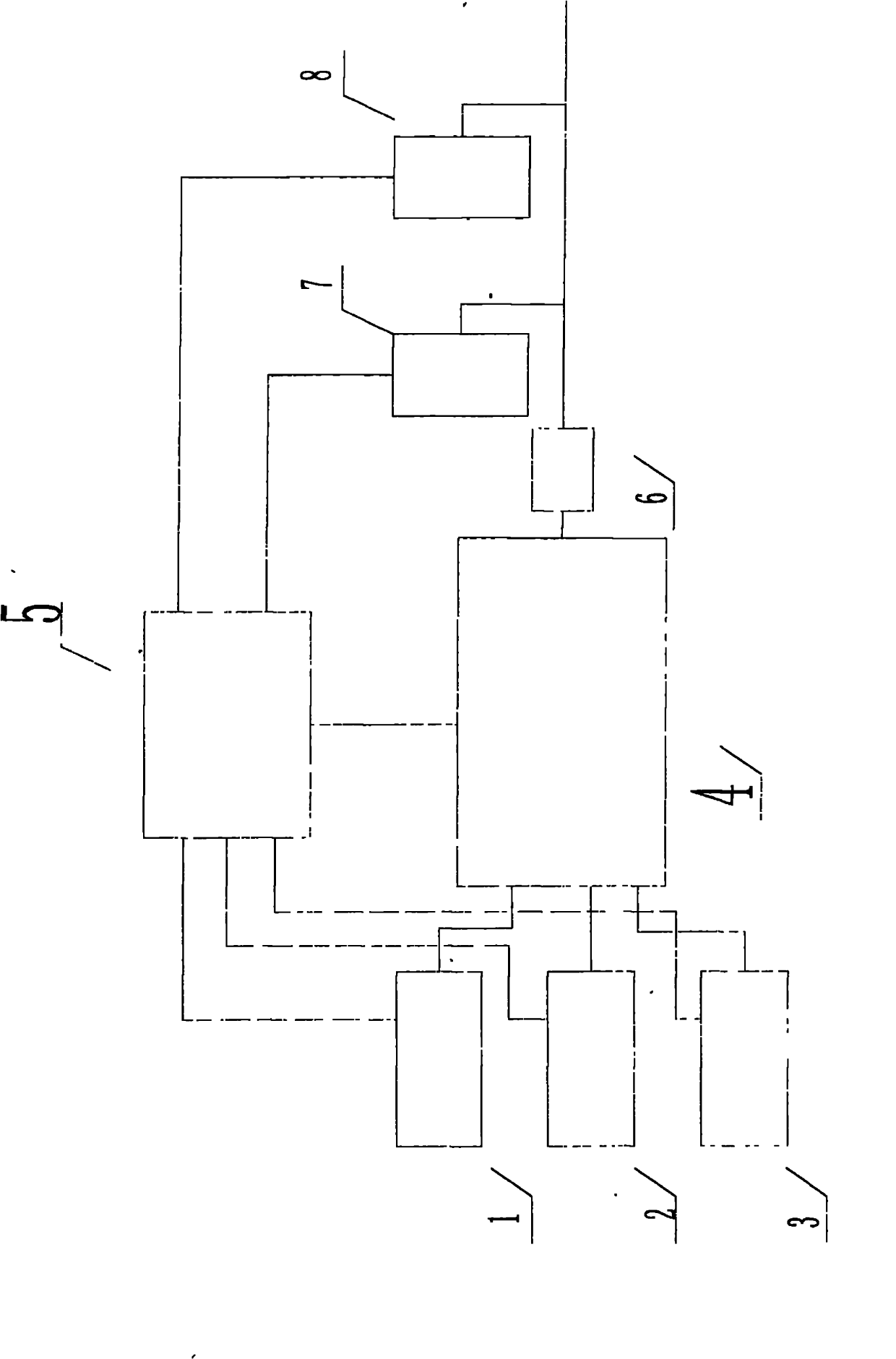

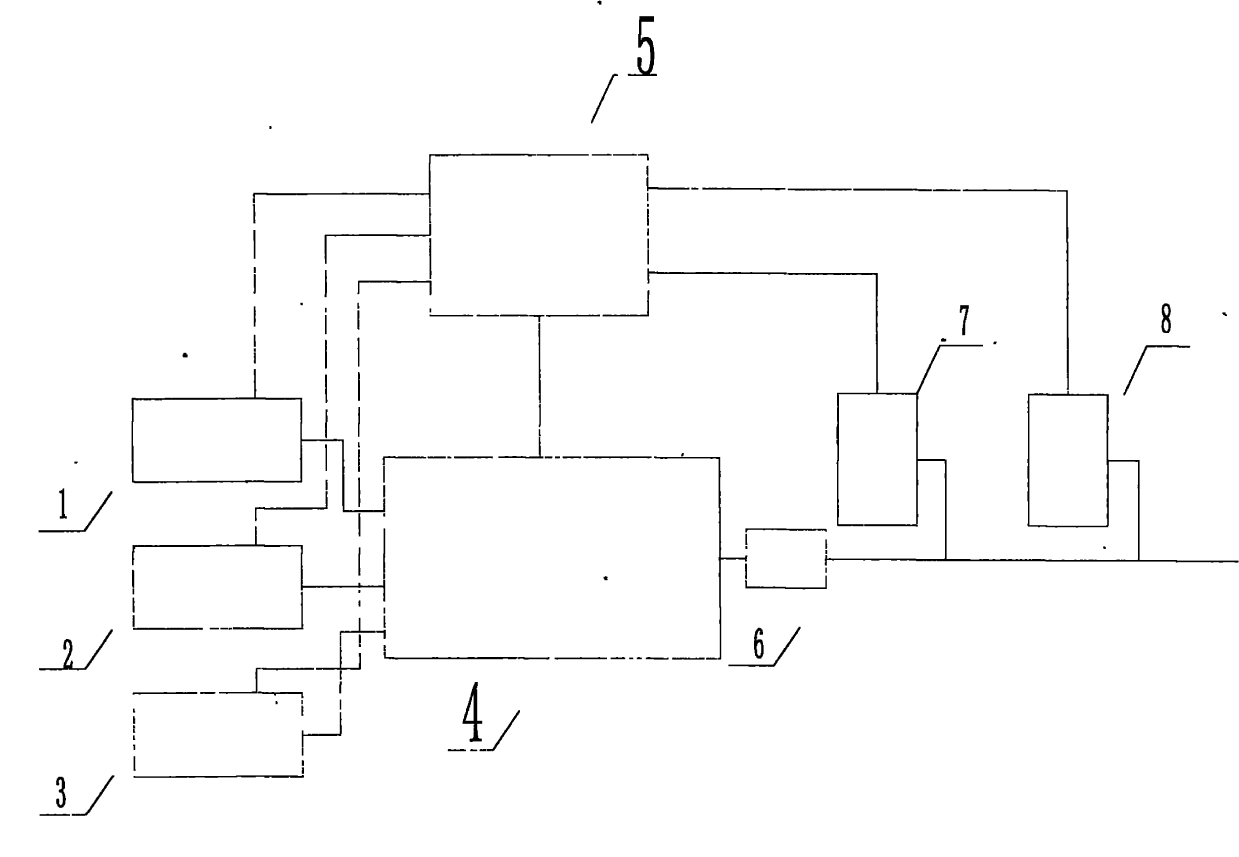

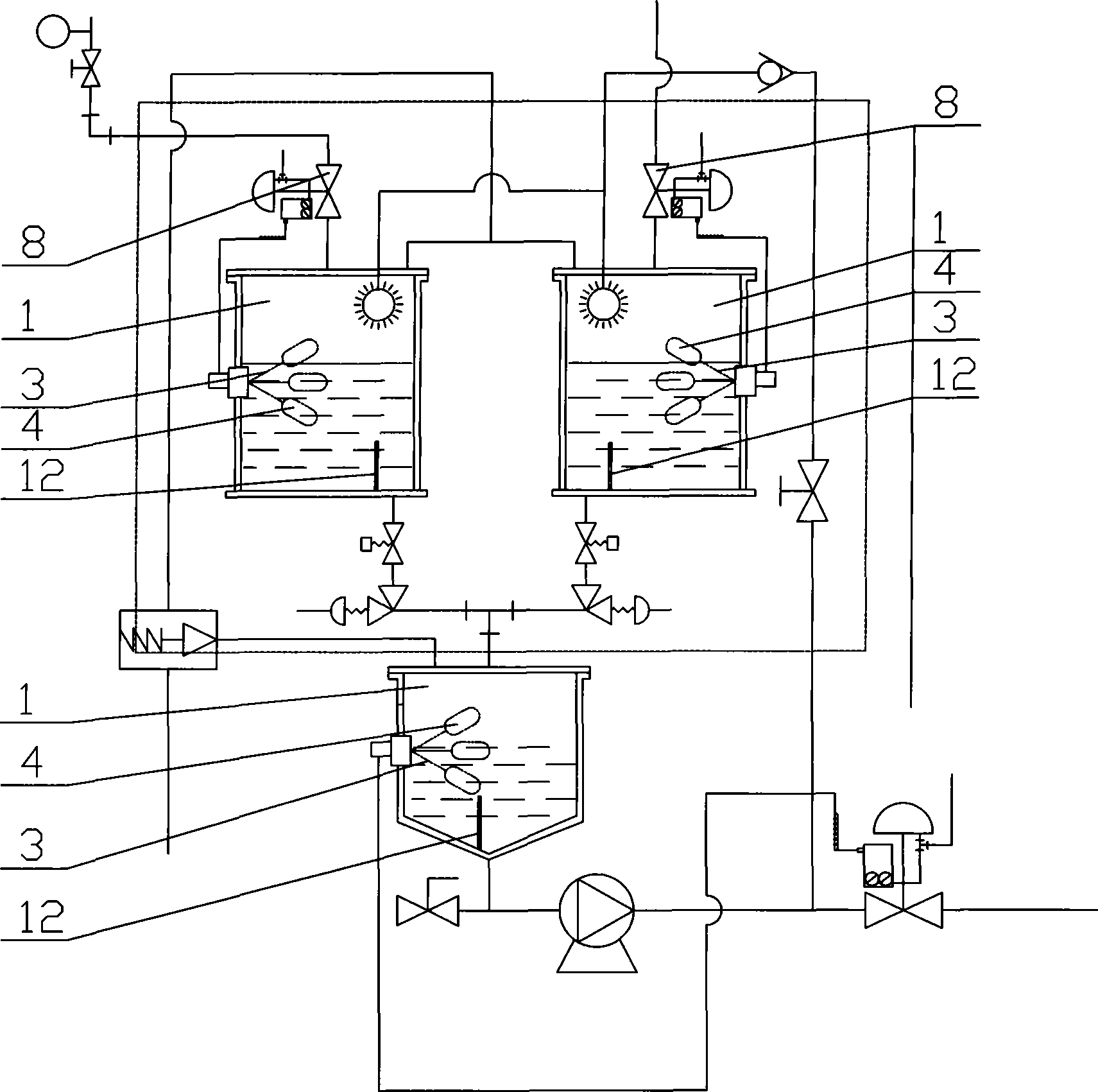

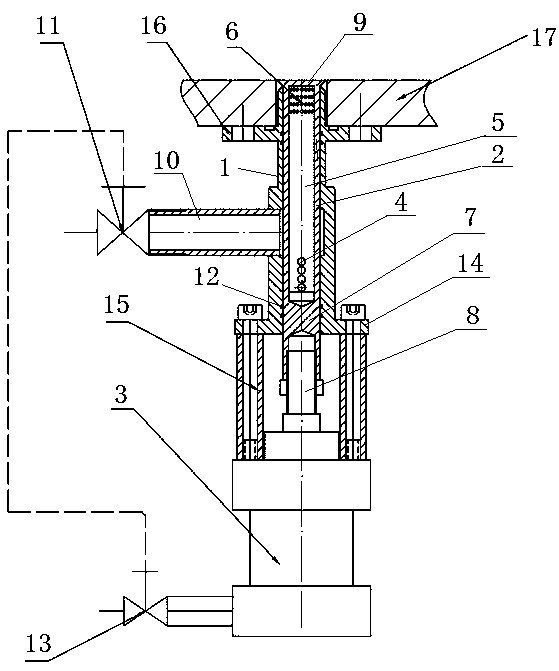

Blending device

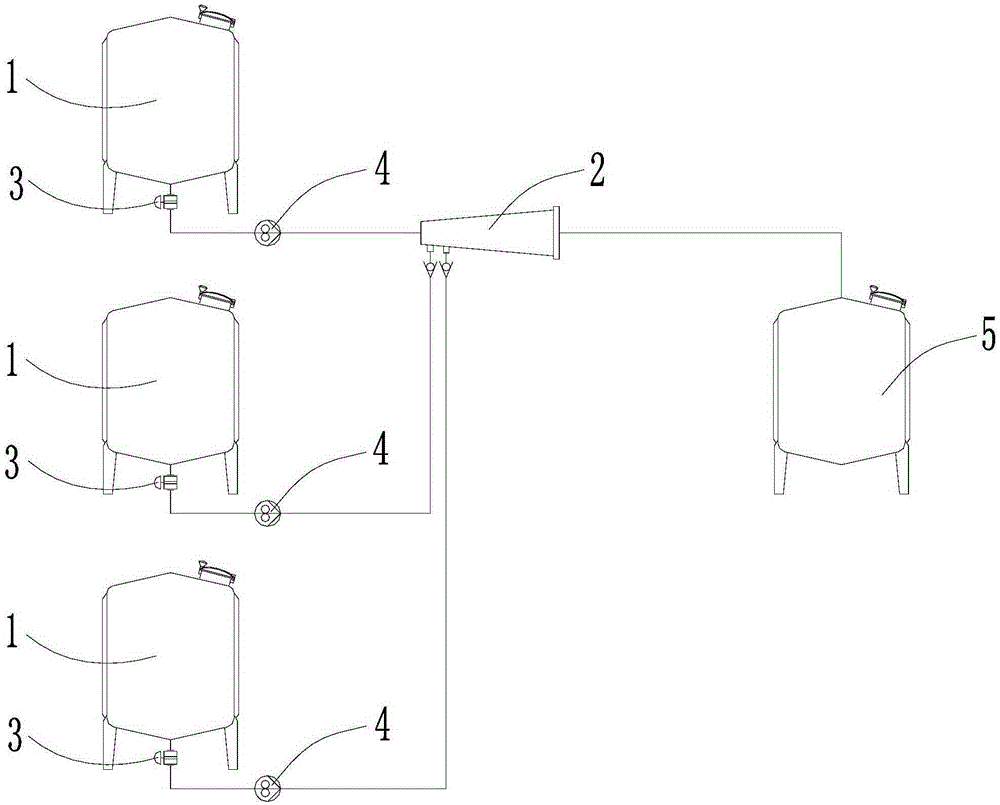

InactiveCN102553469AAdaptableHigh mixing precisionGaseous fuelsMixer accessoriesProcess engineeringCoal

The invention discloses a blending device. The blending device comprises a low-concentration coal bed gas pipe (1), a high-concentration coal bed gas pipe (2), an air pipe (3), a gas blender (4), a controller (5), a mixed gas pipe (6), an oxygen analyzer (7) and a caloric value meter (8), wherein one side of the gas blender (4) is respectively connected with the low-concentration coal bed gas pipe (1), the high-concentration coal bed gas pipe (2) and the air pipe (3); the other side of the gas blender (4) is connected with the mixed gas pipe (6); the controller (5) is respectively connected with the low-concentration coal bed gas pipe (1), the high-concentration coal bed gas pipe (2), the air pipe (3) and the gas blender (4); and the gas blender (4) and the controller (5) are respectively connected with the oxygen analyzer (7) and the caloric value meter (8). The blending device is high in adaptability and blending precision, and suitable for blending two or more kinds of coal bed gas with different caloric values, and blending two or more kinds of gases.

Owner:吴裕仁

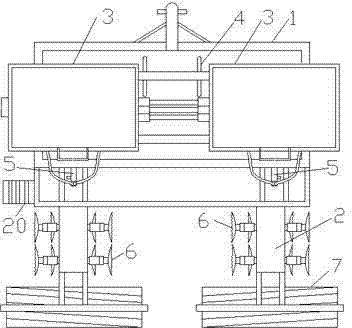

Intertillage fertilizer applicator

InactiveCN104509240ARealize the function of fertilizer compoundingEasy to operateSpadesPloughsCircular discAgricultural engineering

An intertillage fertilizer applicator mainly comprises a main frame, front brackets and fertilizing mechanisms, wherein plough disc blades and furrow plows are mounted on the main frame, a plurality of disk gangs and raking fliers are mounted on the front brackets, the fertilizing mechanisms comprise two fertilization boxes fixed on the main frame, three fertilizer chambers are arranged in each fertilization box, the fertilizer chambers are wide in the upper part and narrow in the lower part, a spiral discharging mechanism is arranged at the bottoms of the fertilization boxes, the spiral discharging mechanism comprises spiral discharging rollers arranged at the outlets of the bottoms of the fertilizer chambers, an oil pump, a speed control valve, a motor and a control rod, the spiral discharging rollers are connected with the motor, the spiral discharging rollers are arranged in the discharging grooves in the outlets at the bottoms of the fertilizer chambers, the bottoms of the discharging grooves are connected with material mixing grooves, and the bottoms of the material mixing grooves are connected with discharging pipes. The intertillage fertilizer applicator provided by the invention has the following benefits: the fertilization boxes can allow adjustment and replacement to different compound fertilizers according to different tillage requirements, the fertilizer compound mixing function of a cultivator is achieved, and the intertillage fertilizer has the advantages that the operation is convenient, the compound mixing accuracy is high, and the operating efficiency is high.

Owner:SHANDONG TIANSHENG MACHINERY

Liquid level control apparatus of liquid storing tank of beverage mixing machine

InactiveCN101441483AHigh mixing precisionHigh accuracy of liquid level positioningLevel controlBeverage vesselsEngineeringControl valves

The invention discloses a liquid level controller for a liquid storing tank of a beverage mixing machine, which comprises the liquid storing tank, wherein one side tank wall of the liquid storing tank is provided with a hole, a lever is hinged in the hole, one end part of the lever positioned in the liquid storing tank is provided with a floating ball, the other end of the lever is provided with a displacement sensor, the hole wall of the liquid storing tank corresponding to the displacement sensor is provided with a displacement signal receiving device, and the displacement signal receiving device is connected with a liquid inlet control valve through an electric apparatus control device. The liquid level controller has the advantages of high liquid level positioning precision, convenient control, capability of improving the mixing precision of a mixer, and product quality guarantee.

Owner:SUZHOU HUAYU FEILING PACKING MACHINERY

A kind of preparation method of high voltage lithium cobalt oxide cathode material

ActiveCN109326781BSolving the problem of segregation of distributions at the microscopic scaleSimplify complexitySecondary cellsPositive electrodesPhysical chemistryMaterials science

The invention discloses a preparation method of a high-voltage lithium cobalt oxide positive electrode material: (1) three cobalt tetroxide containing a doping element M, a lithium source, an oxide containing a doping element M', a grain refiner and a flux mixing to obtain a primary mixture; (2) sintering and crushing the primary mixture to obtain a primary sintered powder; (3) mixing the primary sintered powder and the coating to obtain a secondary mixture; (4) The secondary mixture is sintered and pulverized to obtain a lithium cobalt oxide cathode material. The doping of the present invention is divided into two methods of pre-blending and dry mixing to solve the problem of segregation of doping elements in the product on a microscopic scale; the coulter type mixing technology is used to solve the problem of segregation of different substances during mixing; the grain refiner Combining with flux to synthesize materials with mixed morphology; adopting technologies such as doping element surface crystallization catalysis and cladding; the performance of high-voltage lithium cobalt oxide is significantly improved.

Owner:HUNAN CHANGYUAN LICO CO LTD

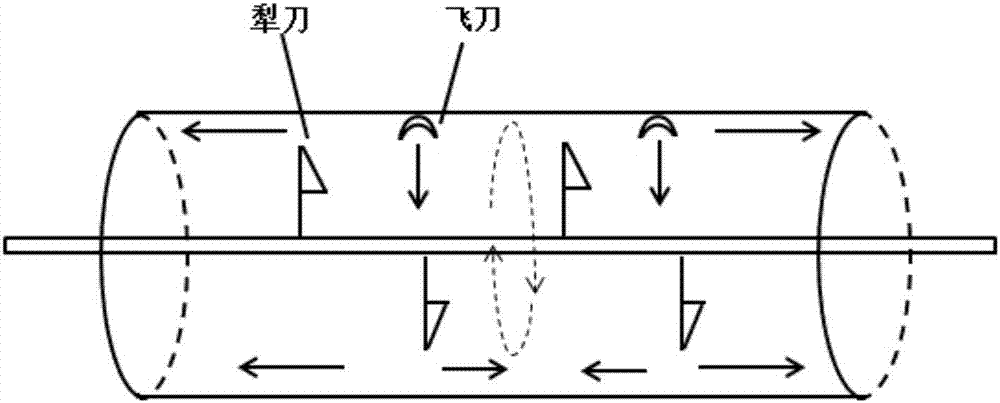

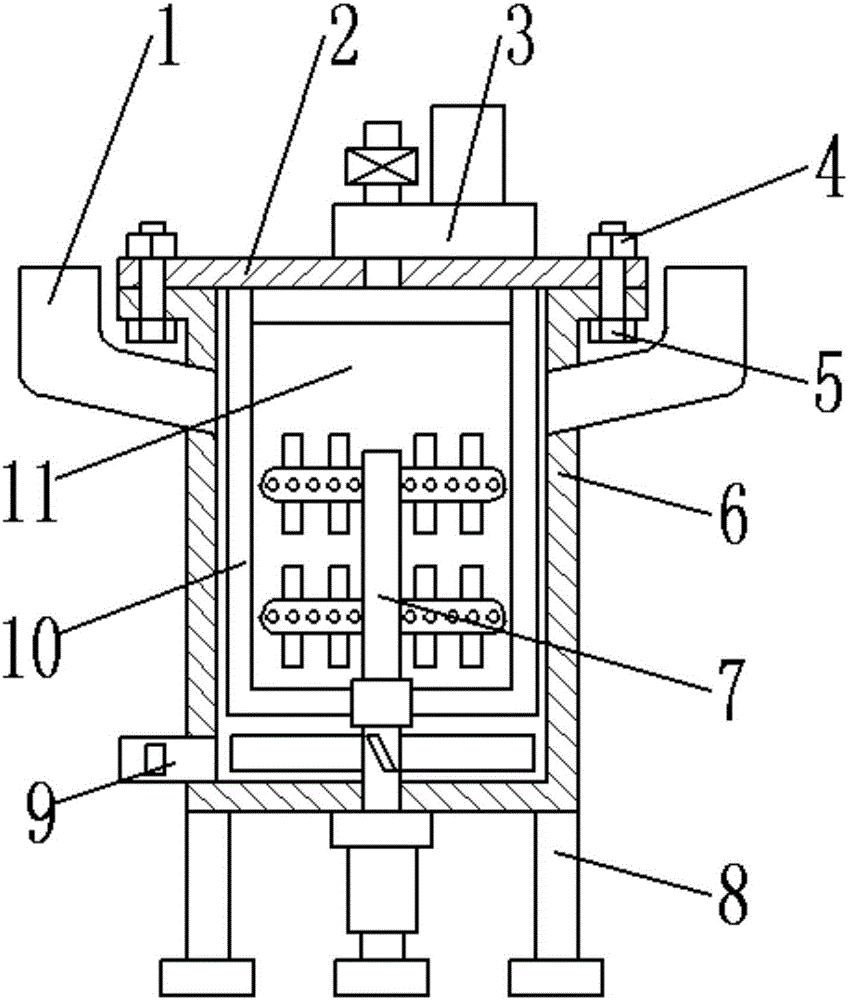

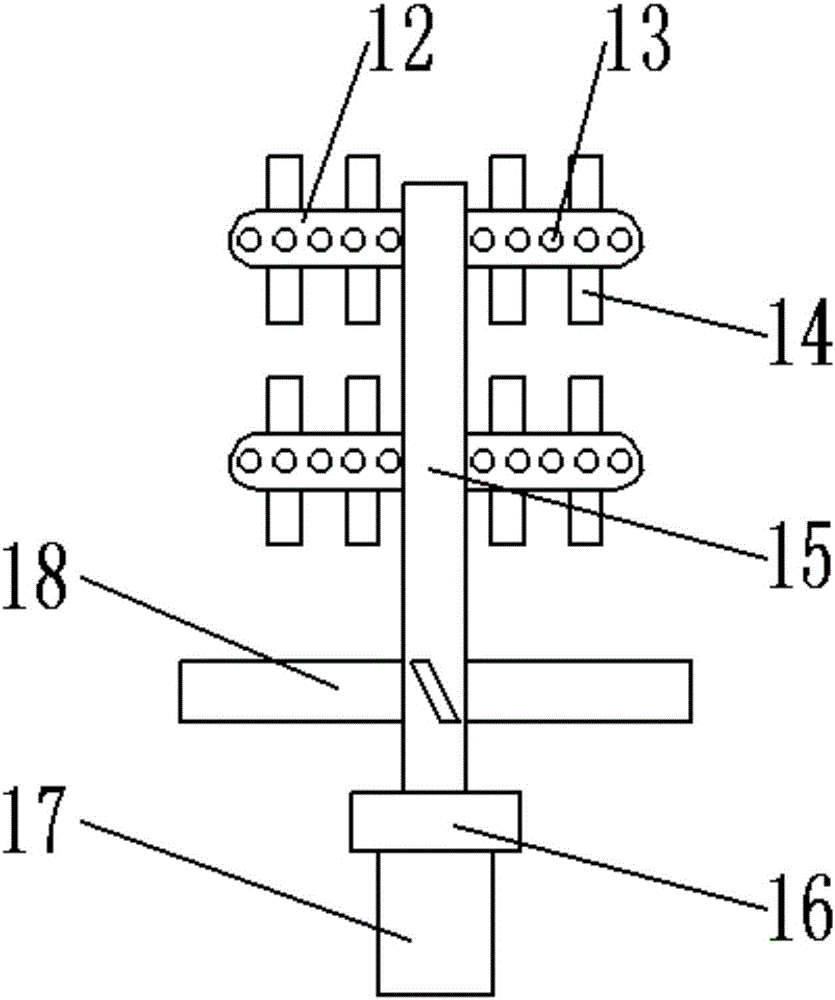

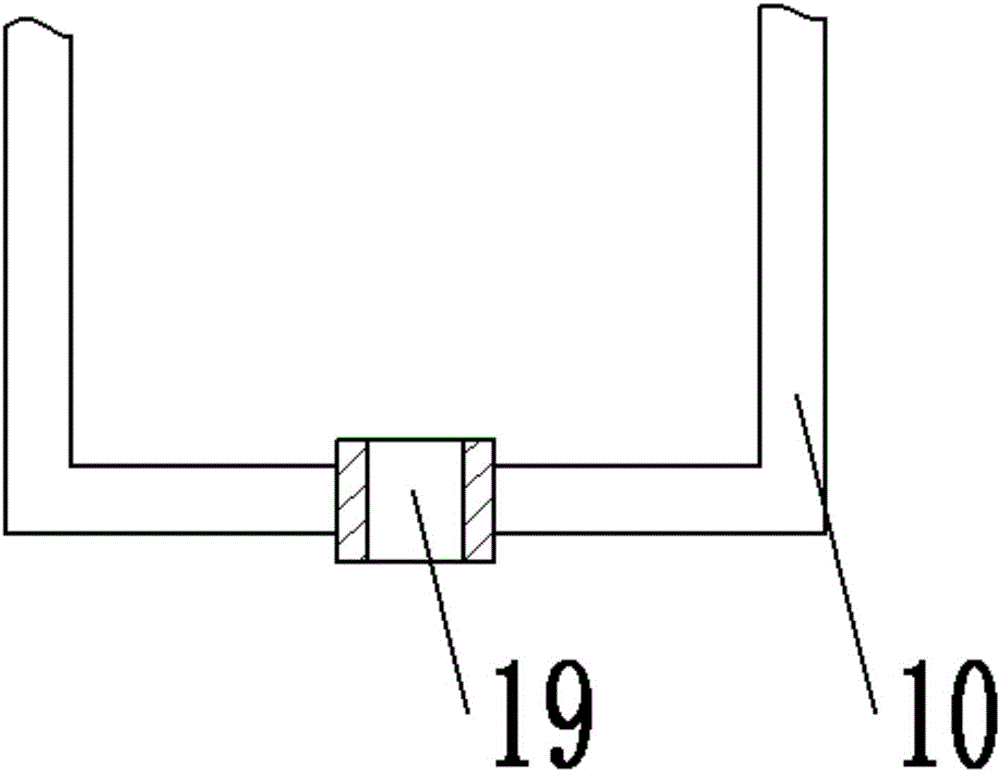

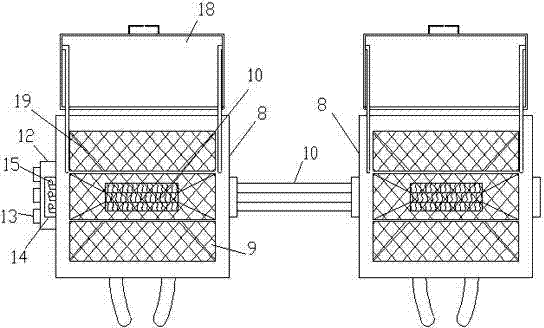

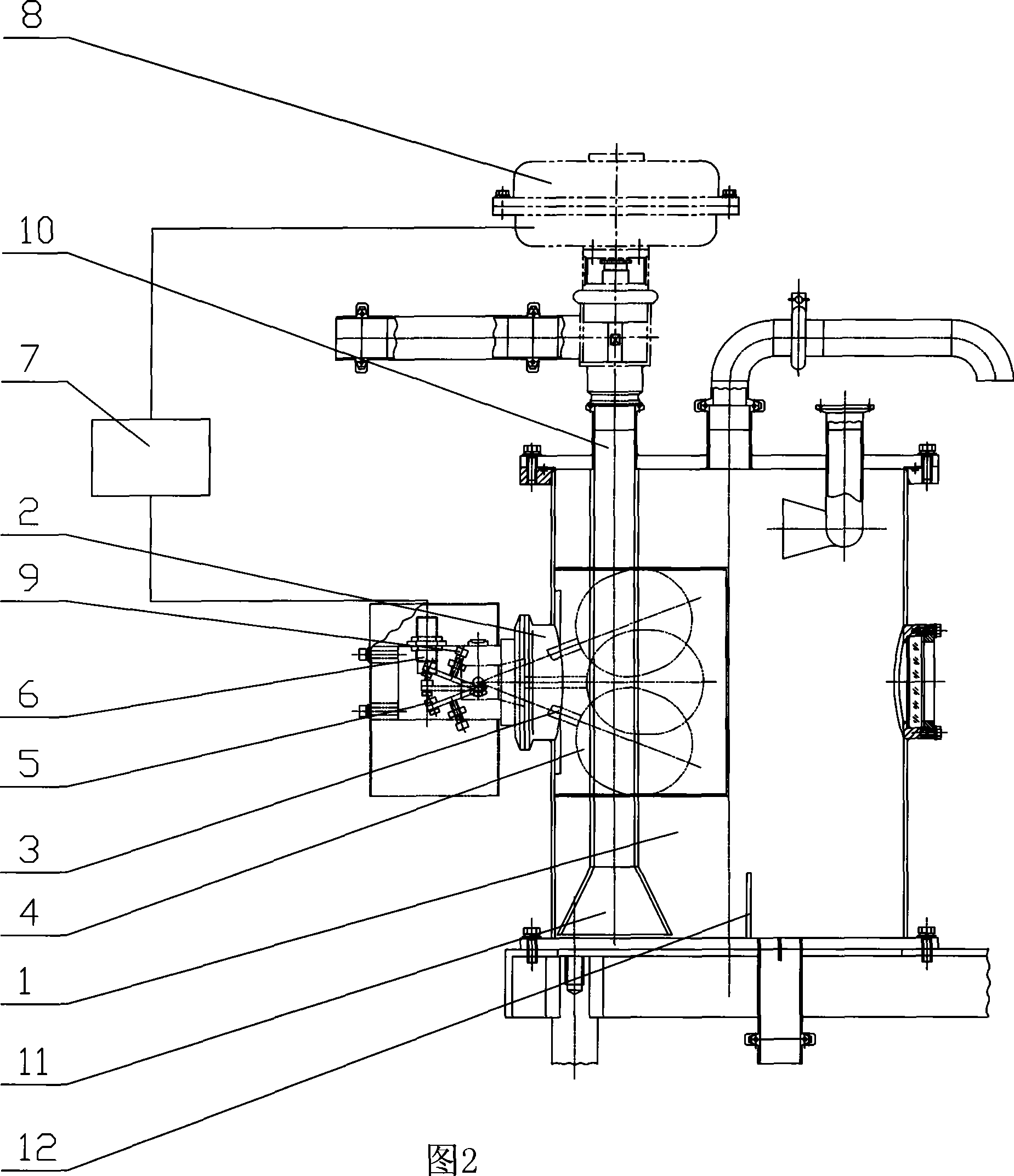

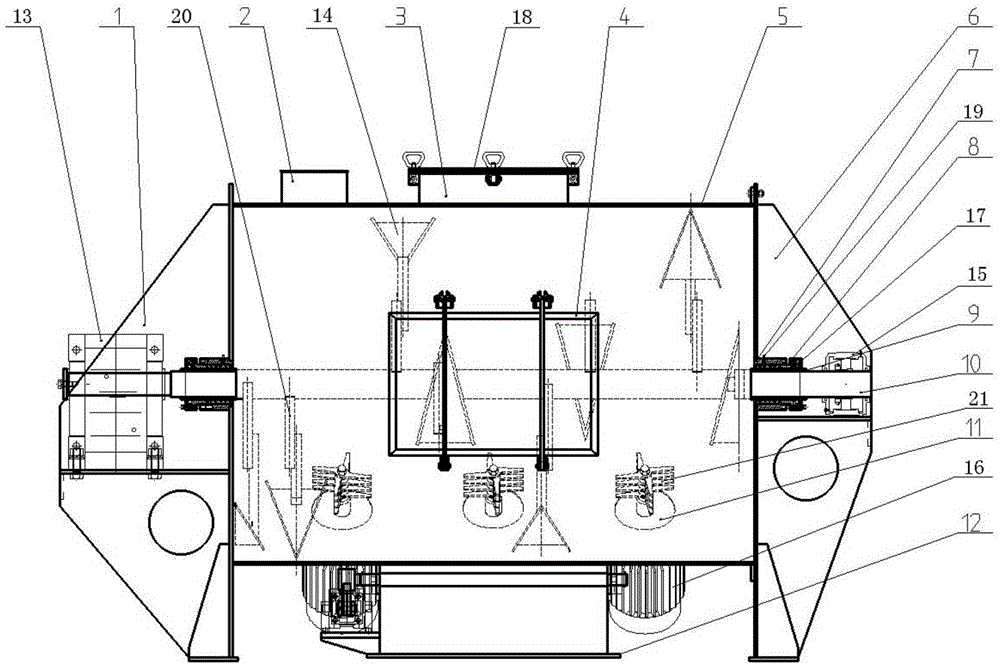

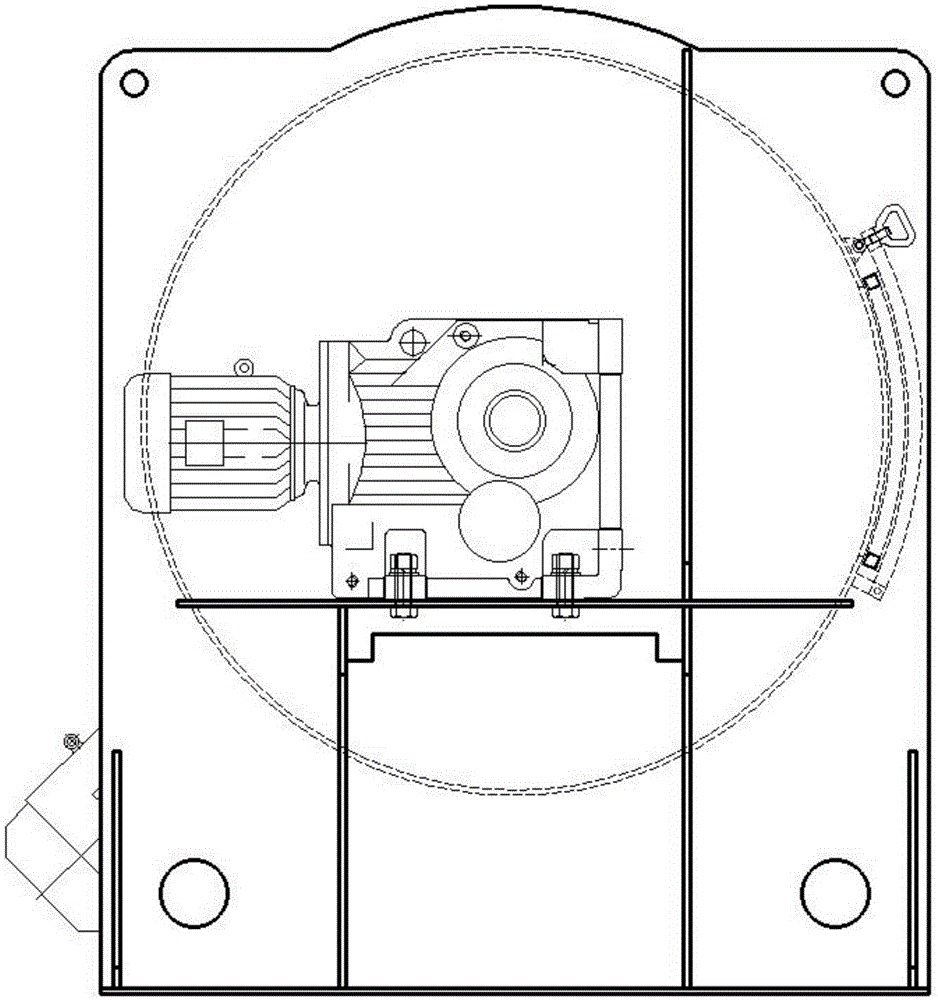

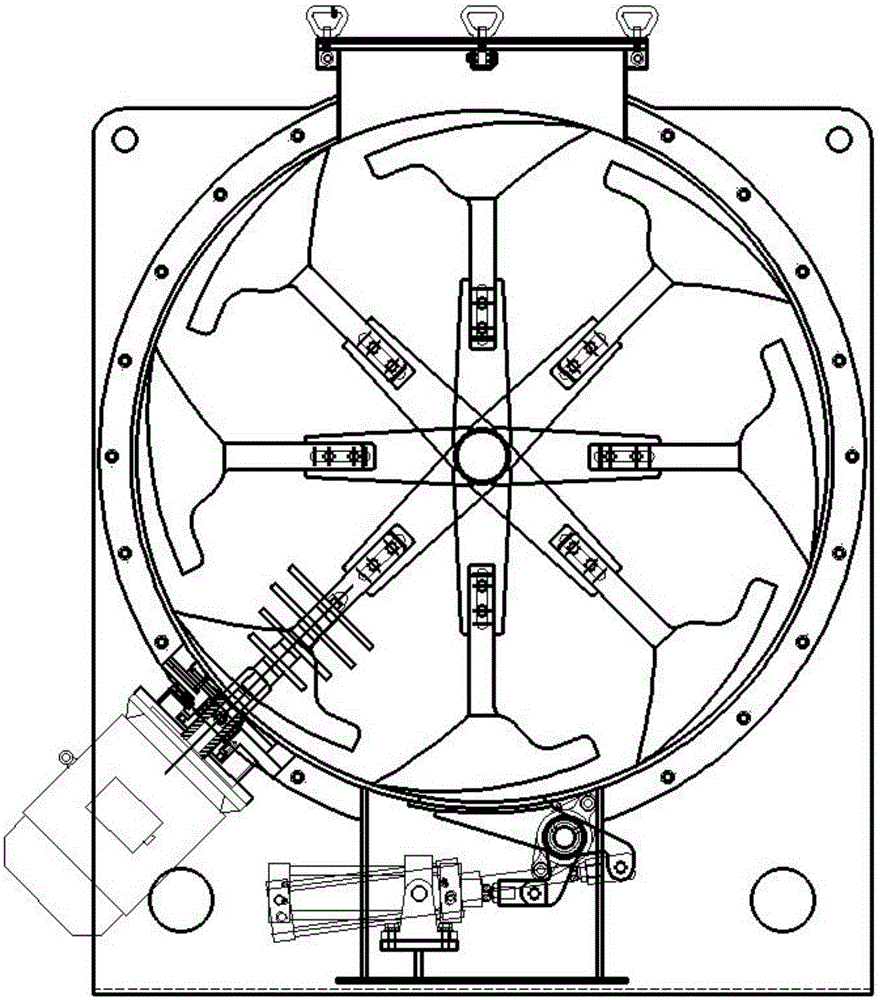

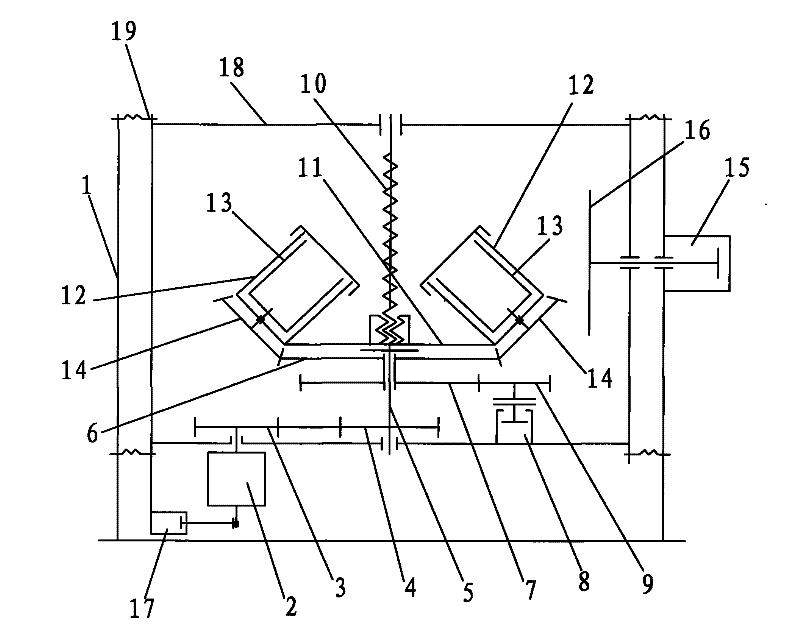

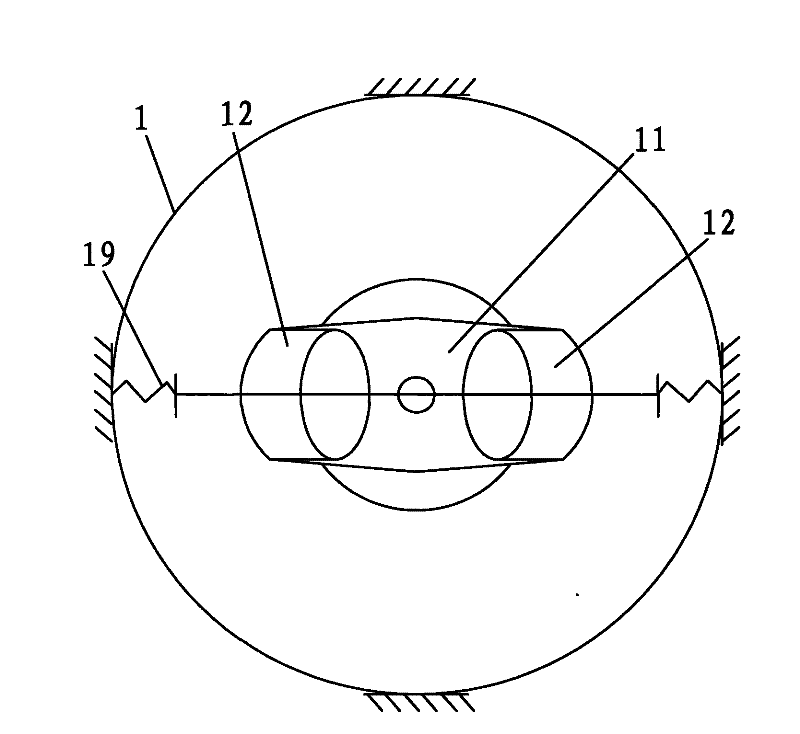

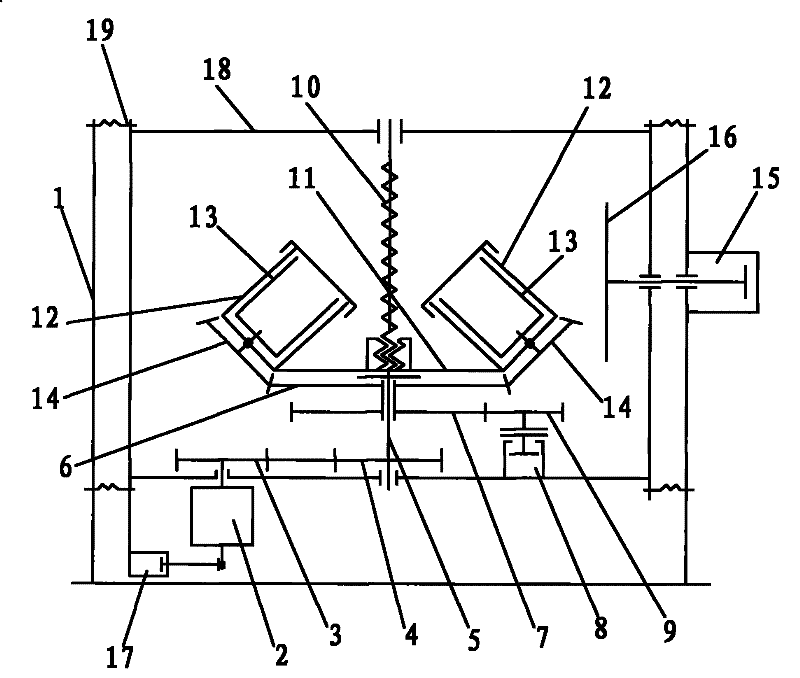

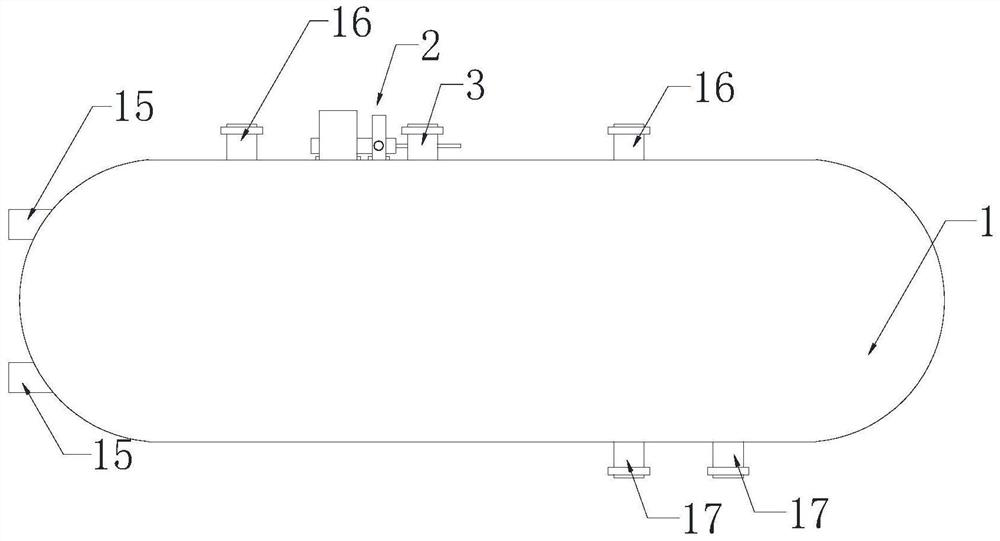

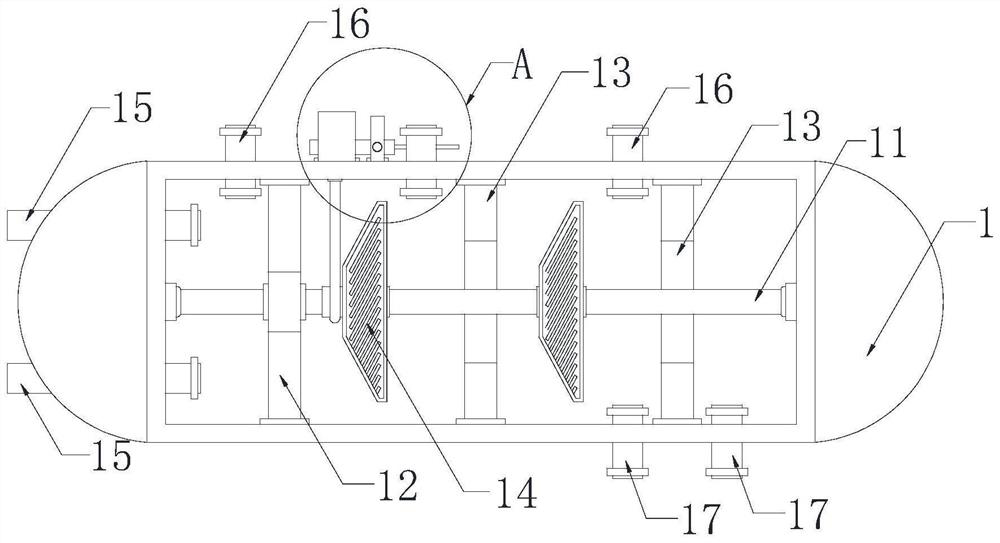

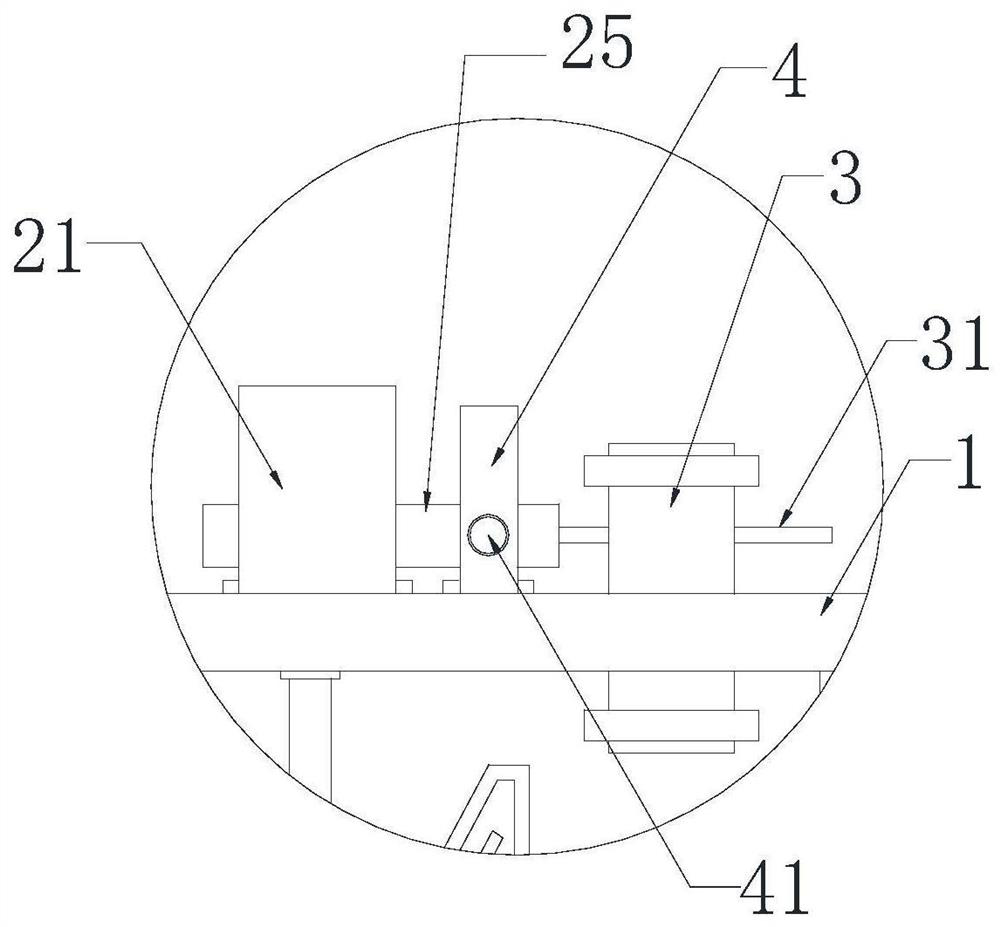

Coulter type mixing machine

InactiveCN105396480AHigh mixing precisionWide adaptabilityRotary stirring mixersGrain treatmentsWall plateEngineering

The invention relates to a coulter type mixing machine which comprises a cylindrical barrel, a speed reducing motor, a spindle, a group of coulters and multiple groups of fly cutter devices. The speed reducing motor is fixedly installed on a left wallboard, and a bearing block is fixedly installed on a right wallboard. Packing boxes and packing box pressing covers are arranged in the middle of the ends of both the left wallboard and the right wallboard connected with the barrel and are assembled together. One end of the spindle is connected to the speed reducing motor, the other end of the spindle is connected to the bearing block, and the adjacent coulters of the group of coulters are staggered in the axial direction of the spindle on the spindle located in the barrel. All the coulters are perpendicular to the axis of the spindle. Each fly cutter device comprises a fly cutter blade and a fly cutter motor, the fly cutter blade is connected to a rotating shaft of the fly cutter motor and arranged in the barrel, and the fly cutter motor is positioned on the outer portion of the barrel. The top of the barrel is provided with a feeding port, and the bottom of the barrel is provided with a discharging port. The mixing machine is quick in mixing speed, low in energy consumption and high in mixing accuracy.

Owner:JIANGSU DUOYUAN MACHINERY CO LTD

Novel electric feed mixing blender

InactiveCN103464023AIngenious designWell mixedFeeding-stuffRotary stirring mixersEngineeringThrough transmission

The invention discloses a novel electric feed mixing blender, which is characterized in that a housing is internally equipped with screw panel-carrying bearings respectively on the left and the right, single-layer gears are respectively installed at the outer ends of the two bearings, a motor is installed outside the housing, double-layer gears are respectively arranged on the right side of a motor rotation shaft and on the rotation shaft, the outer gears of the two double-layer gears are interlocked, the inner gears are respectively connected to the single-layer gears on the left and the right through chains, hydraulic rods are fixed on a rotation shaft seat, the other ends of the hydraulic rods are in connection with discharge plates through transmission rods, a distribution box is installed on the right side of the housing and is connected to the motor and the hydraulic rods through a wire. With the above settings, the novel electric feed mixing blender provided in the invention has the advantages of high mixing efficiency, low energy consumption, and high mixing precision, and can save energy and improve product quality at the same time.

Owner:SHANDONG YITAI SCI & TECH

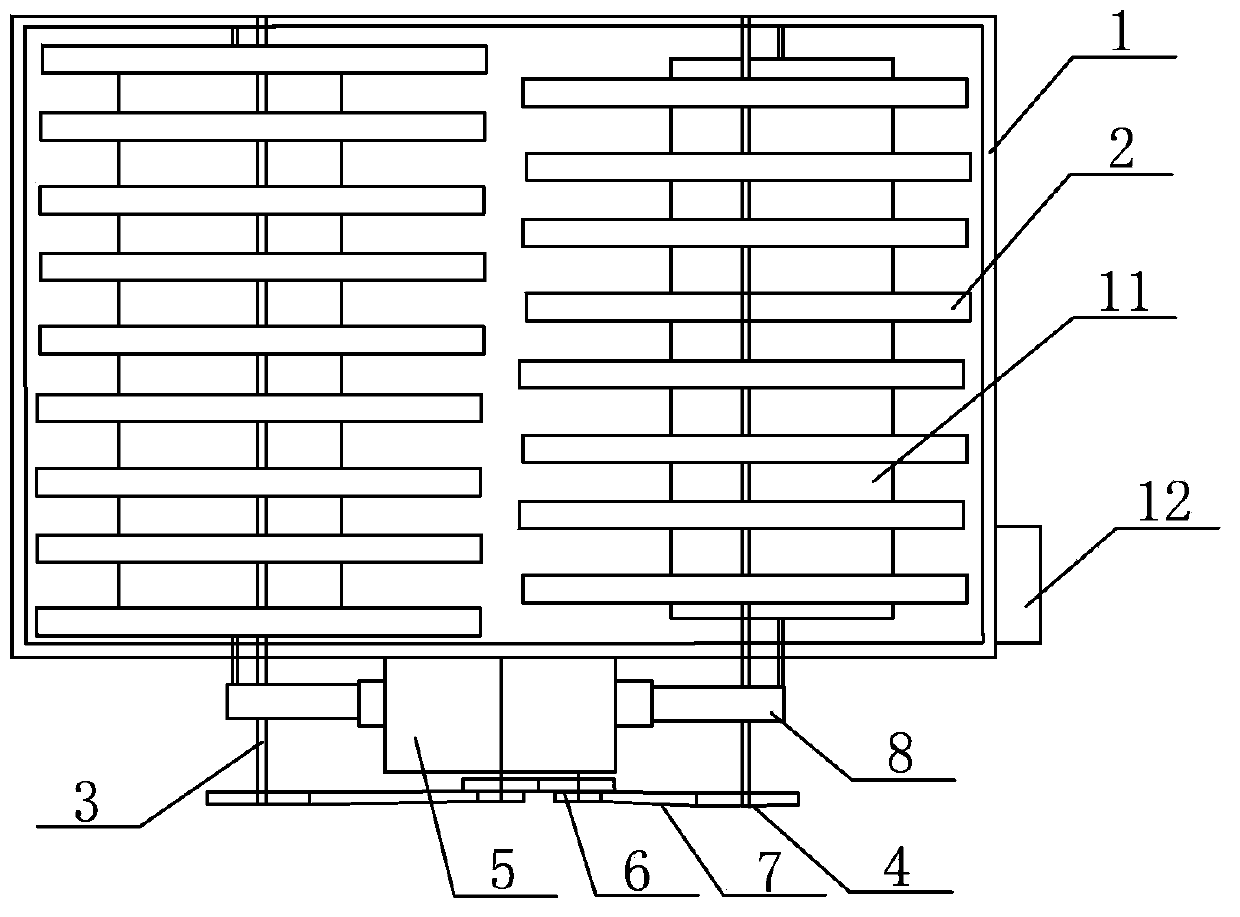

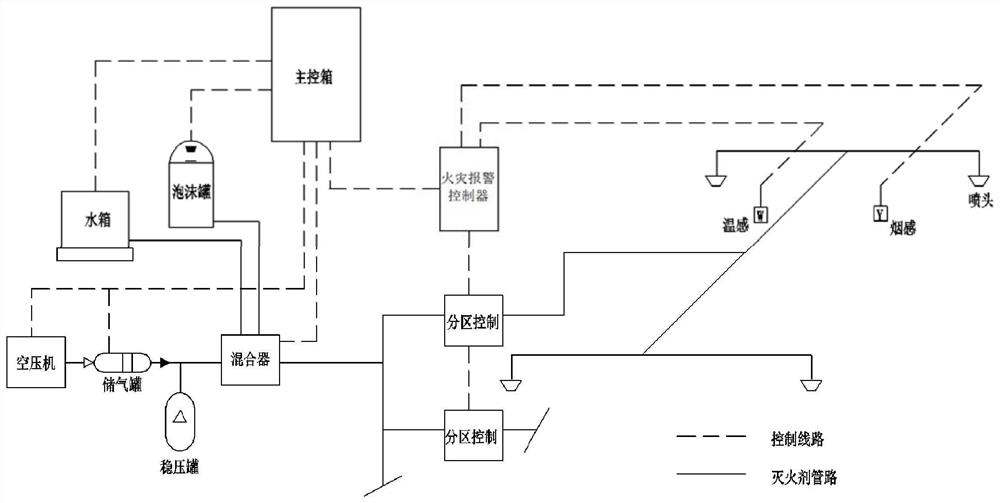

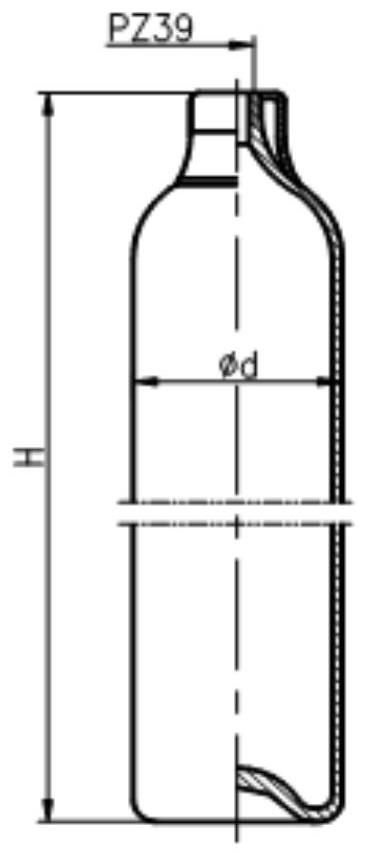

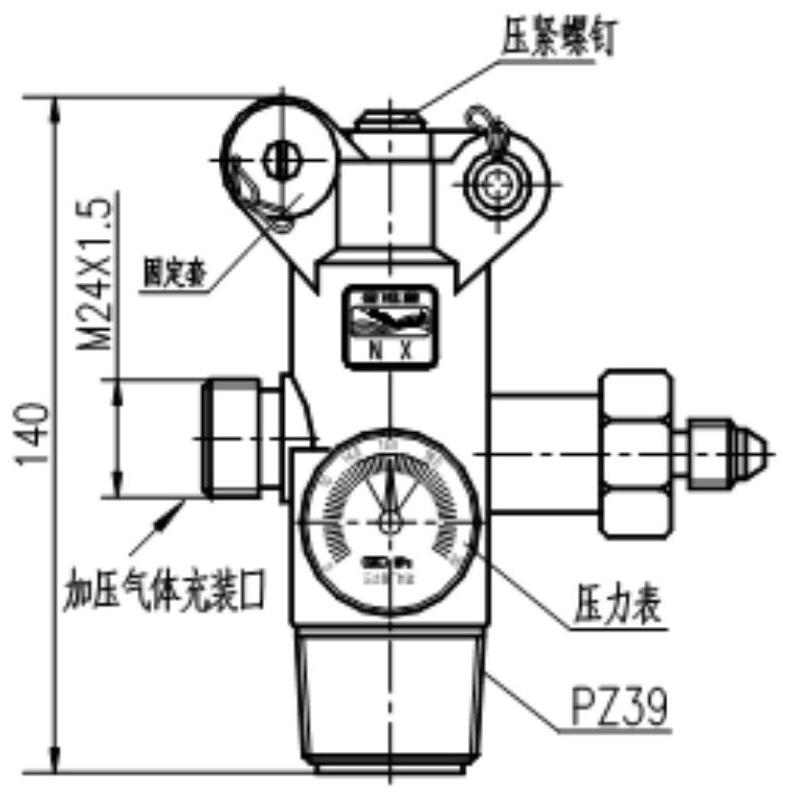

Compressed air foam water mist fire extinguishing system for urban integrated transformer substation cable trench

PendingCN114534142AFire fastSimple structureSignalling system detailsFire rescueTransformerFire - disasters

The compressed air foam water mist fire extinguishing system for the urban fusion type transformer substation cable trench comprises a fire monitoring device, a fire alarm controller, a main controller, a compressed air foam water mist device, a partition control valve and a fire extinguishing nozzle, the fire monitoring device is used for collecting fire information in a cable trench of an urban integrated transformer substation and sending the fire information to the fire alarm controller, and the fire alarm controller judges whether a fire occurs or not according to the fire information collected by the fire monitoring device and sends fire alarm information to the main controller. After receiving fire alarm information, the main controller controls the compressed air foam water mist device to generate foam water mist fire extinguishing liquid, and meanwhile, controls the partition control valve of a fire area to be opened; the foam water mist fire extinguishing liquid is sprayed into a cable trench of an urban fusion type transformer substation through a fire extinguishing nozzle in a fire area for fire extinguishing. The fire extinguishing liquid is accurately mixed and provided in real time, a fire area is rapidly covered, and rapid fire extinguishing is achieved.

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +2

Stirrer

InactiveCN101579607BAvoid pollutionEasy to take outRotating receptacle mixersTransportation and packagingLine shaftPulp and paper industry

The invention discloses a stirrer, which comprises a machine frame, wherein the machine frame is provided with a motor which is connected with a driving synchronous belt wheel through a driven synchronous belt wheel and a synchronous belt and has a main shaft which is connected with the shaft sleeve of the driven synchronous belt wheel, and the main shaft is also sleeved with integrally connectedupper and lower gears; the machine frame is also provided with a pneumatic clutch and a transmission gear meshed with the lower gear, the surface of the main shaft is provided with threads, a socket platform is sleeved on the threads, a revolution tank and a rotation tank are fixed on the left and right sides of the socket platform respectively, the lower part of the rotation tank is connected with a pinion through a connecting shaft, and the pinion is meshed with the upper gear; and the machine frame is provided with an air cylinder and the front end of the air cylinder is connected with a baffle plate. The stirrer is reasonable in structure and convenient in use and can uniformly stir materials, avoid generating air bubbles, eliminate air bubbles and be used in fields of electronics, chemical, light manufacturing, food, medicine, building materials, farm chemical and the like for mixing, dispersing and other processing of materials.

Owner:佛山市恒之芯复合材料有限公司

Bottom liquid spraying device for mixing and stirring

PendingCN111298718ADoes not affect rotational movementPrevent leakageFeed devicesChemical reactionChemical reactor

The invention belongs to the technical field of chemical reactor feeding, and particularly relates to a mixing and stirring bottom liquid spraying device for preventing feeding splashing in powder andliquid mixing and stirring equipment. The device comprises a sealing bushing, a porous spraying head and an air cylinder lifting mechanism, wherein the porous spraying head is arranged in the sealingbushing, the porous spraying head is slidably connected with the inner wall of the sealing bushing, the air cylinder lifting mechanism is arranged below the porous spraying head, the lifting rod of the air cylinder lifting mechanism is fixedly connected with the porous spraying head, the lifting rod drives the porous spraying head to move up and down in the sealing bushing, and the porous spraying head is provided with a liquid inlet for conveying a liquid. The mixing and stirring bottom liquid spraying device can effectively prevent a liquid from splashing after entering from the upper partor due to the fact that the liquid quickly enters powder, so that the working efficiency and the mixing precision are improved.

Owner:大连天马可溶制品有限公司

Mixing device for compressed air foam fire extinguishing system

Owner:ELECTRIC POWER RES INST OF STATE GRID ANHUI ELECTRIC POWER +2

Groove-shaped stirring mixing machine for pharmacy

InactiveCN108786639AHigh mixing precisionIntegrity guaranteedRotary stirring mixersTransportation and packagingPharmacyMotor drive

The invention discloses a groove-shaped stirring mixing machine for pharmacy. The groove-shaped stirring mixing machine comprises fixed frames and locking bolts, wherein a top plate is arranged at thetop ends of the fixed frames; a Y-160M 2-2 stirring motor is arranged at the center of the top plate, and the output end of the Y-160M 2-2 stirring motor is connected with a rotary main shaft; the fixed frames are provided with a mixing groove; a bearing seat is arranged at the center of a sealing cover; screw rods are arranged between one end of a curved stirring rod and the rotary main shaft; both ends of the screw rods are connected with the curved stirring rod and the rotary main shaft by welding; the center of the top end of the mixing groove is provided with a material outlet; an electromagnetic valve is fixedly arranged on the material outlet, and is connected with a material discharge pipe; a PLC (programmable logic controller) is arranged at one end of the fixed frames. The groove-shaped stirring mixing machine has the advantage that the Y-160M 2-2 stirring motor drives the rotary main shaft to uniformly rotate, so that the material is fully mixed and uniformly shaken by thecurved stirring rod and the screw rods, and the mixing precision of the material is improved.

Owner:倪菁菁

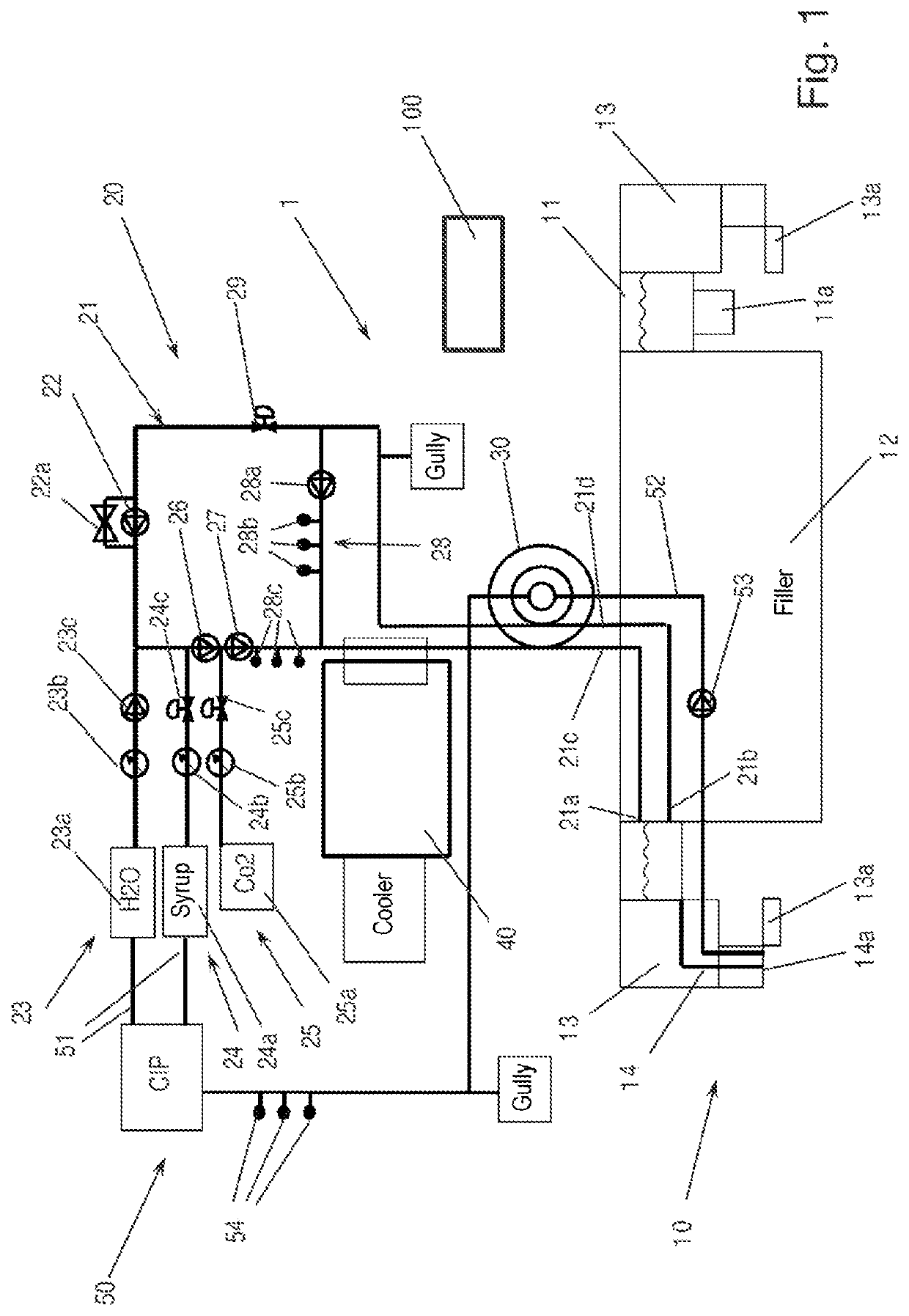

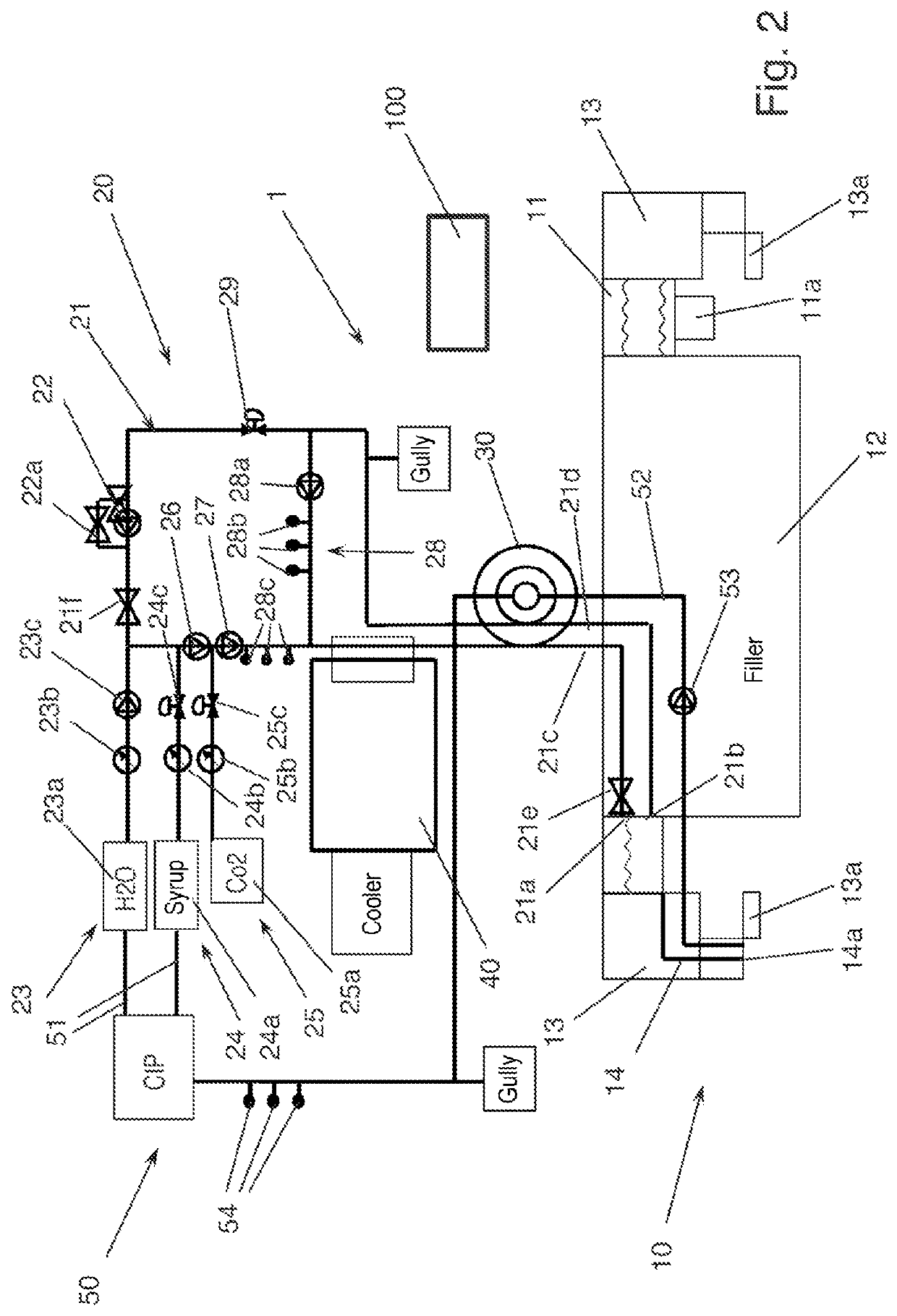

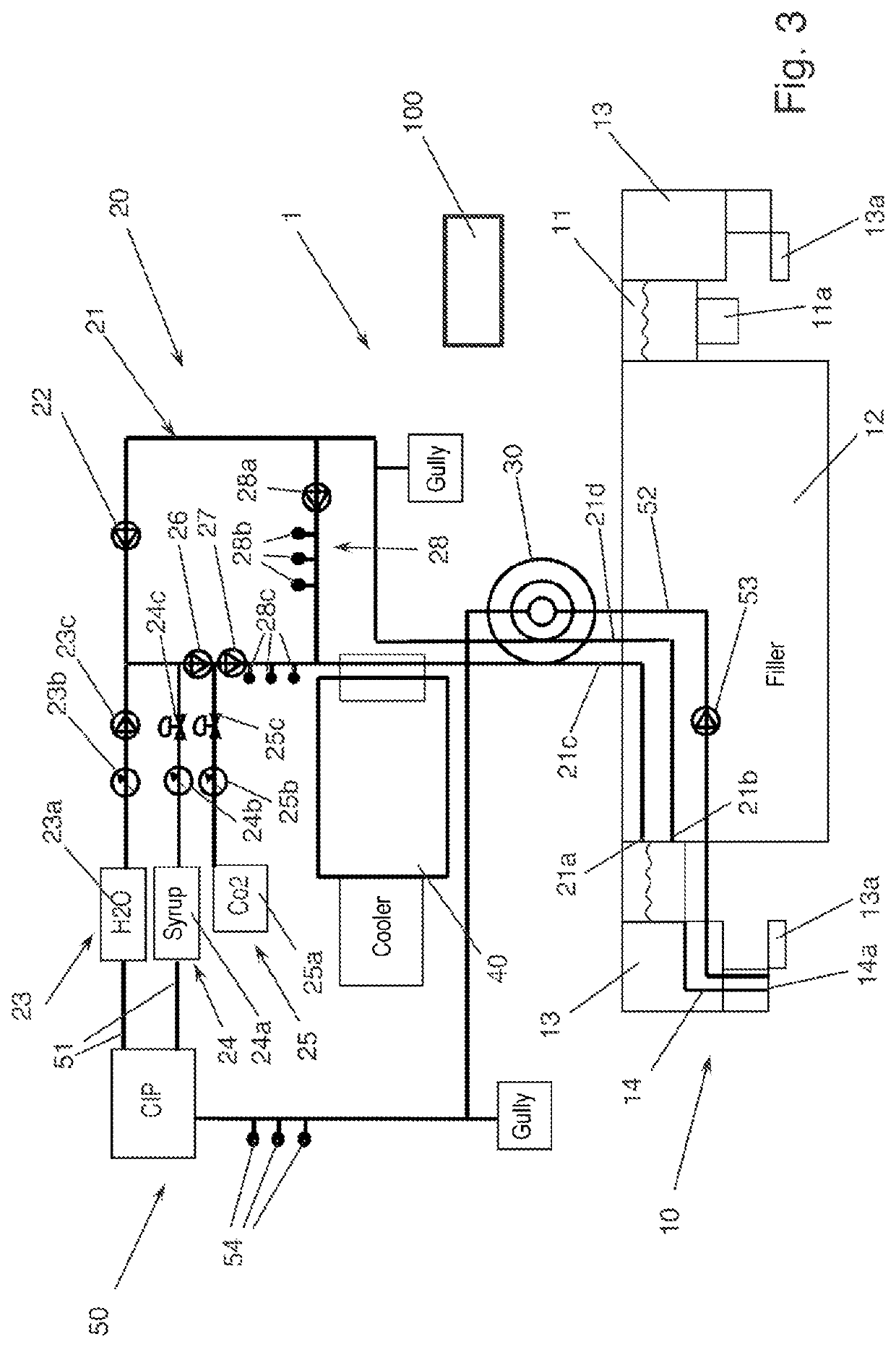

Apparatus for filling a vessel with a filling product

ActiveUS20220162049A1High mixing precisionFilling using counterpressureControlling ratio of multiple fluid flowsProcess engineeringFiller - product

An apparatus for filling a vessel with a multicomponent filling product includes a filler having at least one filling unit set up to introduce the filling product into the vessel, and a filler tank set up for intermediate buffering of the filling product and in fluid connection with the filling unit via a product conduit to supply the filling unit with the filling product; and a mixer set up to blend the filling product from at least two filling product components, wherein the mixer has a circulation conduit; and the mixer has at least one dosage branch set up to introduce one filling product component into the circulation conduit, wherein the mixer has a heat exchanger set up to adjust the temperature of the filling product in the circulation conduit.

Owner:KRONES AG

Mixing proportioning mechanism for pesticide mixing device

InactiveCN113041942AAchieve precise ratioIncrease profitTransportation and packagingMixer accessoriesGear driveGear wheel

The invention relates to a mixing proportioning mechanism for a pesticide mixing device. The mechanism comprises a lower box body, the top of the lower box body is cooperatively connected with a waste barrel, the top of the waste barrel is cooperatively connected with a roller gear, the top of the roller gear is provided with a mixing disc, a plurality of collecting boxes are arranged along the circumferential direction of the mixing disc at intervals, and the bottom of each collecting box is provided with a discharging pipe. The discharging pipes penetrate through the mixing disc, a first proportioning pipe and a second proportioning pipe are arranged on the discharging pipes, a first proportioning opening is formed in one end of the first proportioning pipe, a second proportioning opening is formed in one end of the second proportioning pipe, and the first proportioning opening and the second proportioning opening are different in size. Any discharging pipe is connected with a collecting channel, the multiple collecting channels are connected to a collecting opening, and the collecting opening communicates with the waste barrel. A transmission gear is arranged on one side of the roller gear in a matched mode, a transmission motor is arranged at the bottom of the transmission gear and can drive the transmission gear to rotate, and the transmission gear drives the roller gear to rotate in the rotating process.

Owner:佛山一本农业科技有限公司

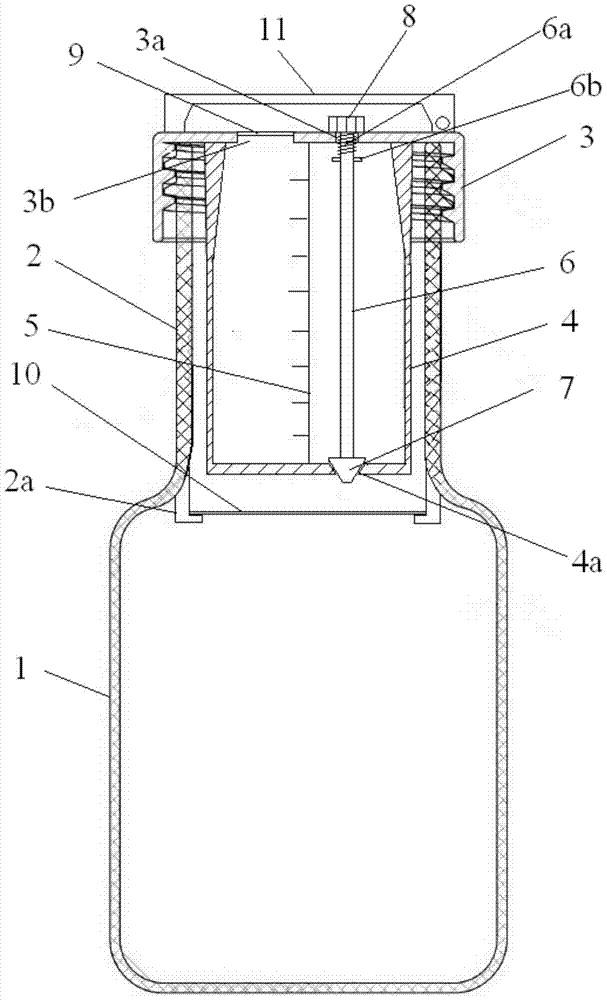

Fluorinated bottle with double liquid quantitative mixing function

ActiveCN105253450BMeet the needs of controlled quantitative mixingHigh mixing precisionClosure with auxillary devicesContainers with multiple articlesEngineeringBottle

The invention discloses a fluorinated bottle with the function of double-liquid quantitative mixing, which comprises a main bottle body and a main cover body threadedly connected with the mouth of the main bottle body; it is characterized in that the main cover body is fixed or integrally connected with The auxiliary bottle body extending into the mouth of the main bottle body, the bottle body of the auxiliary bottle body is marked with a scale, and the auxiliary bottle body is provided with a drip valve mechanism, which includes an inverted cone-shaped drip valve located at the bottom of the auxiliary bottle body. A liquid hole, a threaded hole provided on the main cover and opposite to the inverted tapered drip hole, and a control valve stem matched with the threaded hole through a threaded section, the bottom of the control valve stem is provided with an inverted cone The inverted cone-shaped valve head matched with the drip hole, and the top of the control valve stem protrudes from the main cover to fix the adjustment knob; at the same time, the main cover is provided with a liquid injection hole for the auxiliary bottle body, and the auxiliary bottle body injects liquid The hole is provided with a secondary bottle sealing film. The invention can meet the requirement of controlled quantitative mixing of liquids, and has better barrier protection between two liquids when they are not mixed.

Owner:JRB PACKING CO LTD

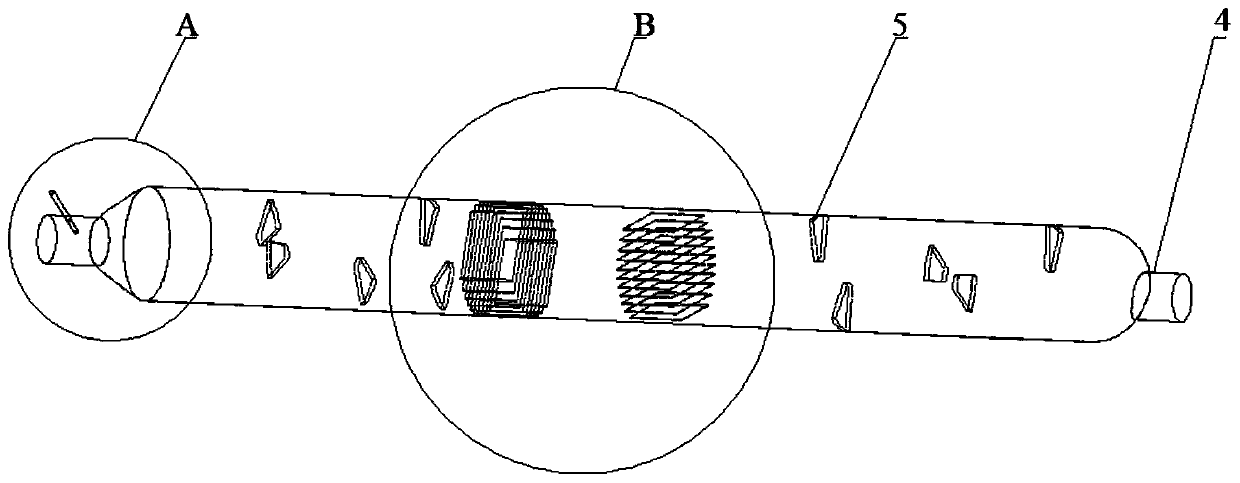

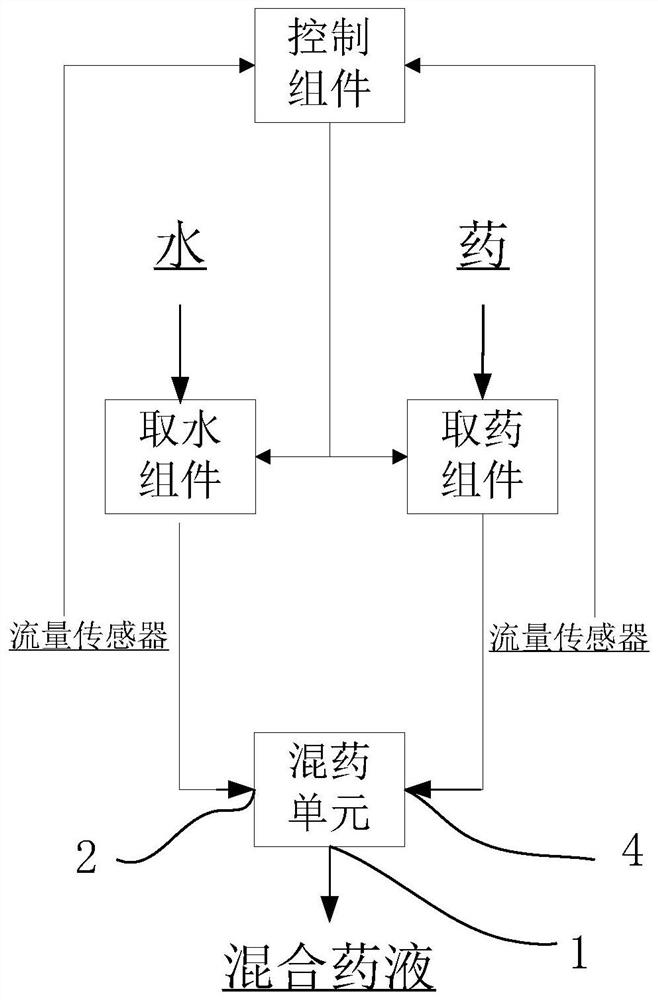

Drug mixing device and drug mixing method based on multi-point injection

ActiveCN109224904BMix evenly onlineThe ratio range is largeFlow mixersTransportation and packagingInjection portWater flow

The invention discloses a medicine mixing device and a medicine mixing method based on a multi-point injection type. The medicine mixing device comprises: a water intake assembly, a medicine intake assembly, a medicine mixing unit, and a control assembly respectively connected with the water intake assembly and the medicine intake assembly , the control component controls the water intake component and the medicine intake component to take the corresponding flow of water and medicine into the medicine mixing unit according to the ratio of water and medicine matching the crop category; the outlet pipe of the water intake component is connected to the medicine mixing unit through the water injection port, and the outlet of the medicine taking component The drug tube is connected to the drug mixing unit through more than two drug injection ports, and the water injection port is arranged at an angle to the two or more drug injection ports, so that the water flow starts from one end of the drug mixing unit and flows sequentially with the two or more drug injection ports in the drug mixing unit. The medicine flow at the medicine injection port is jetted and mixed and output from the medicine liquid outlet at the other end of the medicine mixing unit. The invention mixes water and medicine through multi-point jetting, improves the ratio precision of medicine and water, and can ensure uniform mixing.

Owner:HUNAN AGRICULTURAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com