Hydrogen energy utilization gas mixing system and hydrogen and natural gas proportioning control method

A ratio control, natural gas technology, applied in mixing methods, chemical instruments and methods, gas and gas/vapor mixing, etc., can solve the problem of slow signal feedback, no dual-gas mixing follow-up flow mixing scheme, hydrogen equipment Use safety and other issues to achieve the effect of applicability, fast and stable dynamic follow-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

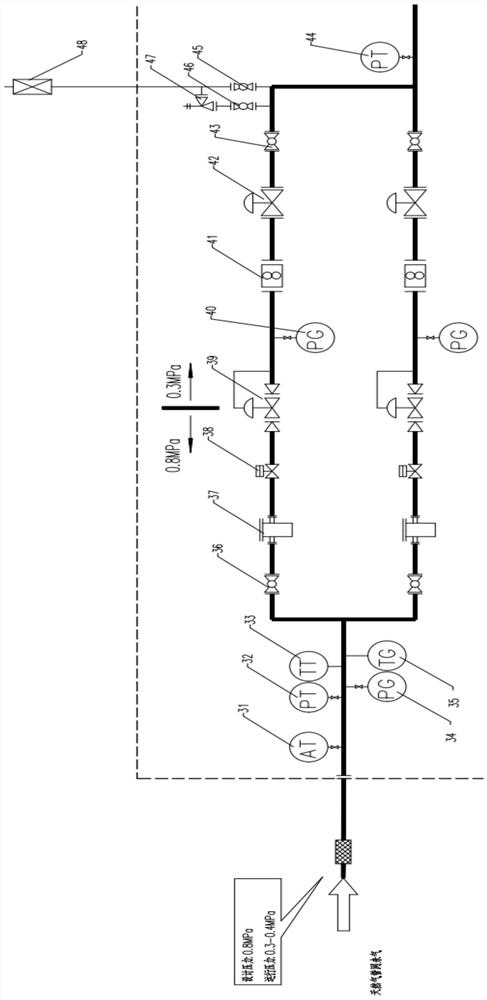

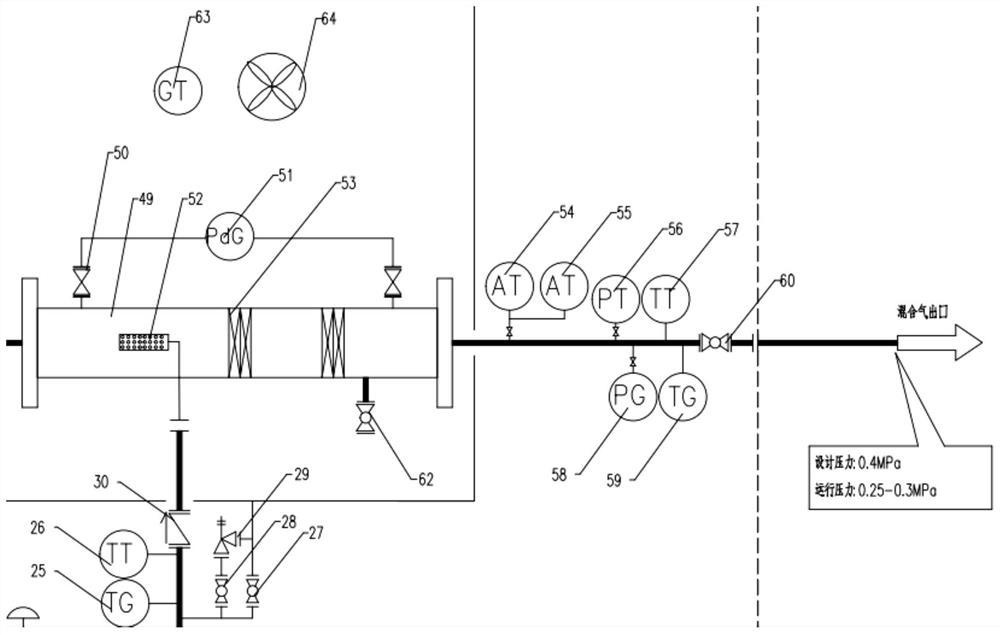

Method used

Image

Examples

Embodiment

[0084] (1) Technical parameters of gas mixing equipment

[0085] 1. Overview of device name

[0086] Gas, hydrogen blending equipment

[0087] 2. Environmental climate conditions

[0088] Annual extreme minimum temperature: -25°C;

[0089] ·Extreme maximum temperature: 36.8°C;

[0090] ·Annual average precipitation: 750mm.

[0091] 3. Temperament components

[0092] 3.1 CBM gas quality

[0093] Due to the unstable methane concentration of coalbed methane, the methane concentration is between 90% and 99%, and the rest is mainly nitrogen, oxygen, carbon dioxide, etc., and the gas contains moisture, fine coal dust, dust and other impurities, the equipment provided by the seller must meet the Temperament requirements.

[0094] 3.2 Hydrogen Gas

[0095] The hydrogen concentration is 80%-99%

[0096] 3.3 Hydrogen doping ratio

[0097] The hydrogen doping ratio is 3%-20%.

[0098] 3.4 Traffic

[0099] The hourly design flow rate of the blending equipment is 600 cubic mete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com