Clamp

A technology of fixtures and fixtures, which is applied in the direction of grinding workpiece supports, etc., can solve the problems of affecting working conditions, limited use, splashing, etc., and achieve the effects of reducing external dimensions, safe and stable gas supply, and suppressing splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

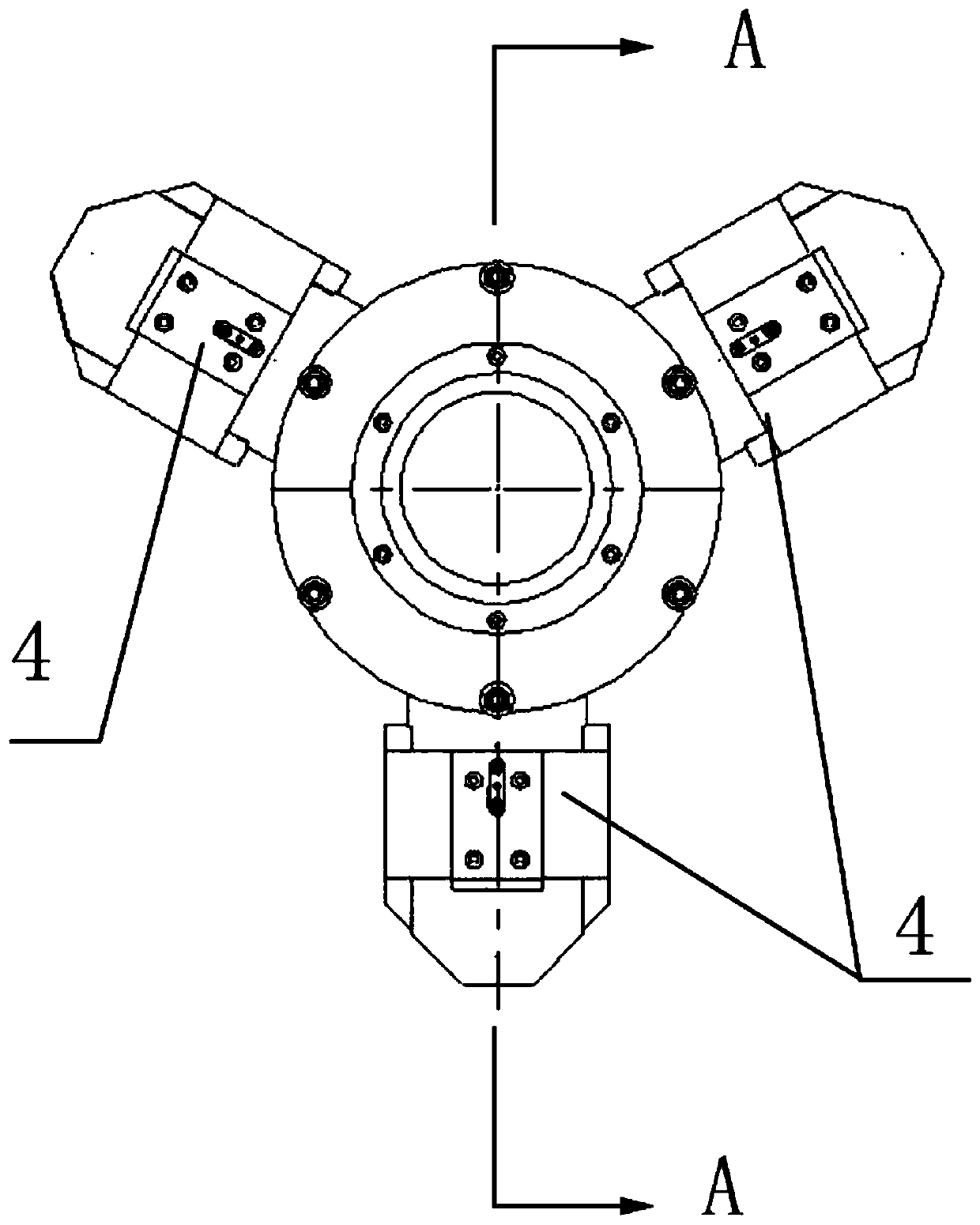

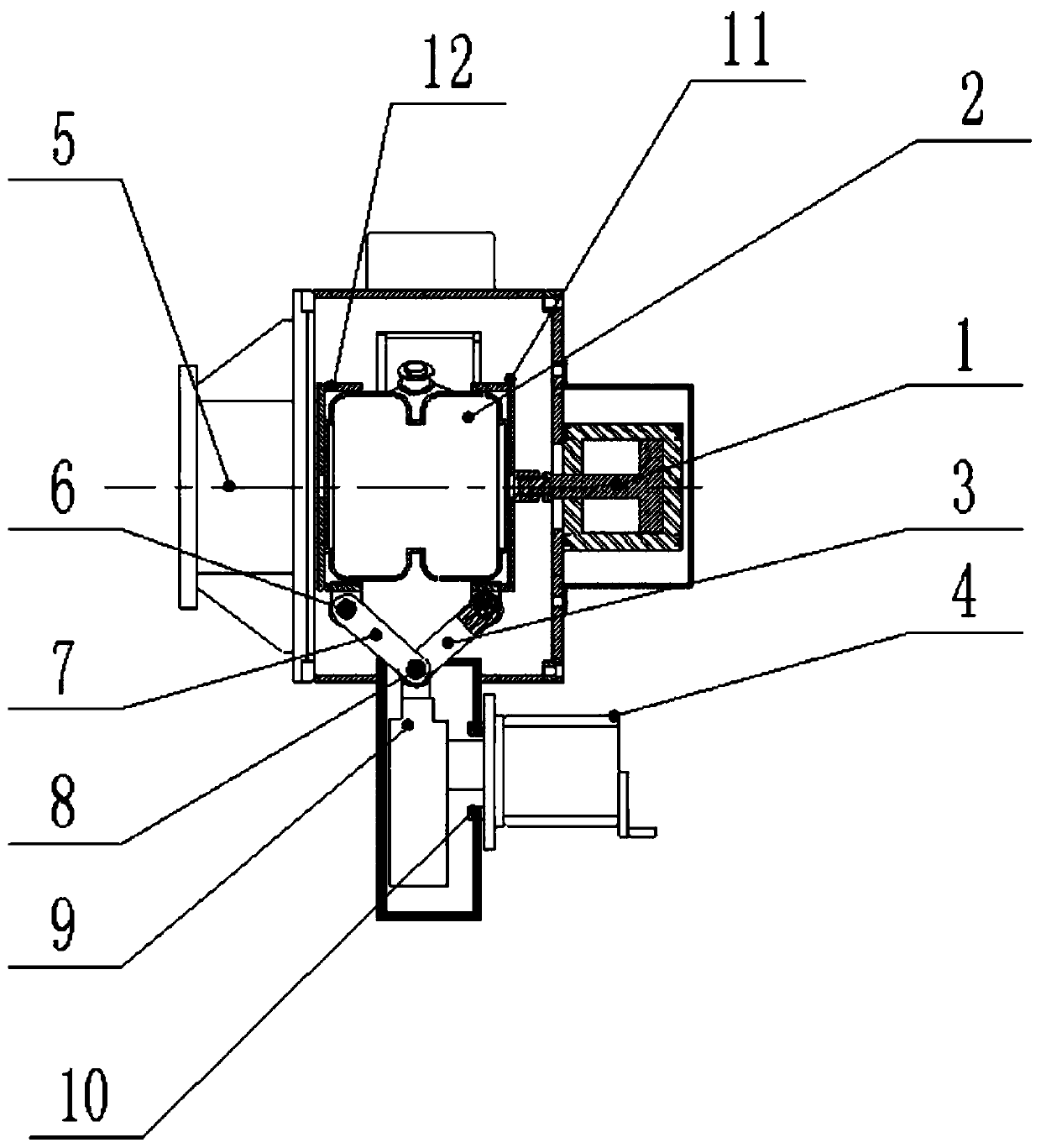

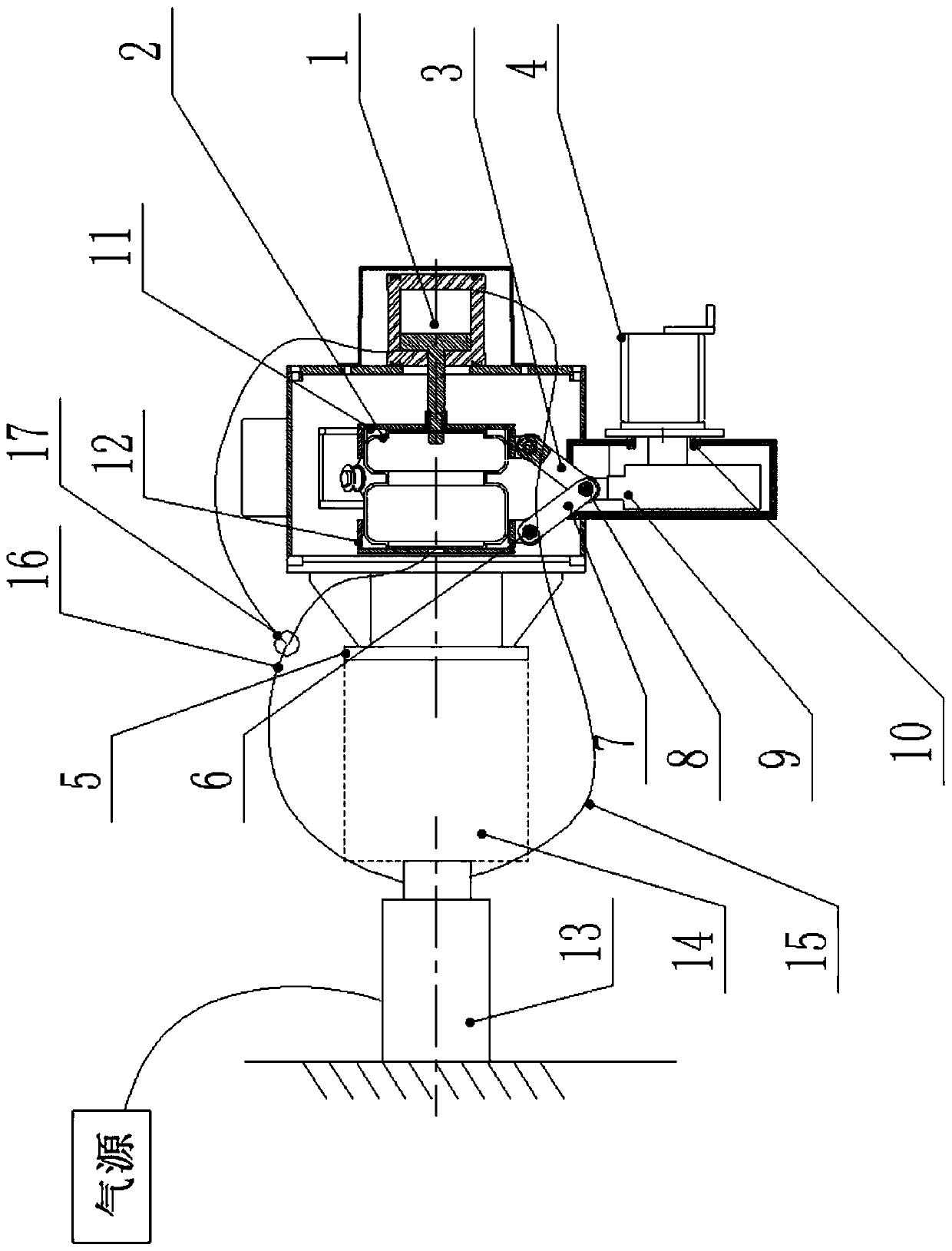

[0030] figure 1 It is the front view of the fixture in Embodiment 1 of the present invention; figure 2 The clamp provided for the present invention is along the figure 1 Sectional view of plane A-A in the center; image 3 It is a diagram of the working state of the fixture in Example 1 of the present invention when the workpiece is replaced. Such as figure 1 , figure 2 and figure 2 As shown, Embodiment 1 of the present invention provides a clamp, which includes a body, a cylinder assembly 1 , an airbag 2 , a reversing transmission device, a clamping assembly, an airbag top plate 11 and an airbag base 12 . The body is provided with an airbag 2 and a cylinder assembly 1, and a number of reversing transmission devices and a number of clamping assemblies are arranged on the circumference of the body. Any clamping assembly is connected to the airbag top plate 11 and the airbag base through the corresponding reversing transmission device 12 connections.

[0031] In this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com