Intertillage fertilizer applicator

A fertilizer applicator and fertilization box technology, which is applied to agricultural machinery and implements, shovels, plows, etc., can solve the problem of not being able to apply compound fertilizers, and achieve high work efficiency and high compounding precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

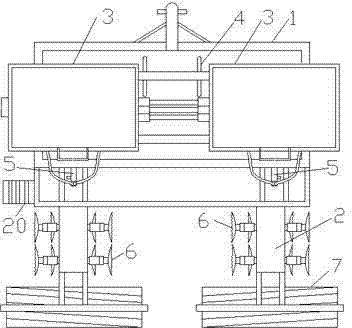

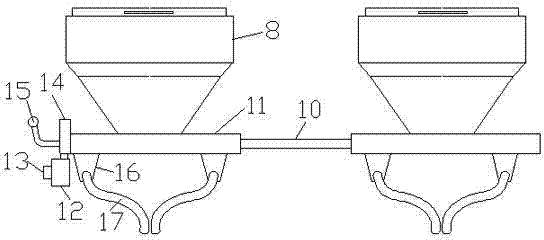

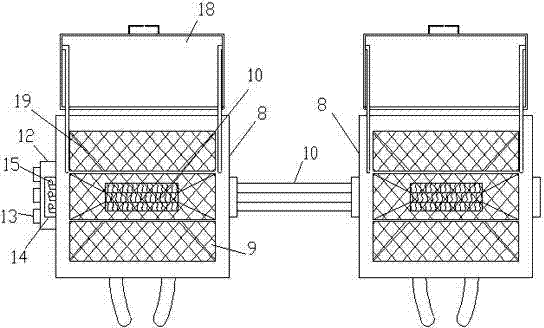

[0016] Such as figure 1 , figure 2 and image 3 As shown, a cultivating fertilizer applicator is mainly composed of a main frame 1, a front support 2 and a fertilization mechanism 3, the front support 2 is fixed in front of the main frame 1, the fertilization mechanism 3 is installed on the main frame 1, and the main frame 1 is equipped with a disc Plow blades 4 and Hua-type plow 5, several disc harrow groups 6 and rake wheels 7 are installed on the front bracket 2, and the fertilization mechanism 3 includes two fertilization boxes 8 fixed on the main frame 1, and each fertilization box 8 is internally set Three fertilizer chambers 9, the fertilizer chamber 9 is wide at the top and narrow at the bottom, and the screw discharge mechanism is arranged at the bottom of the two fertilization boxes 8, and the spiral discharge mechanism includes a spiral discharge roller 10 and an oil pump 12 arranged at the outlet at the bottom of each fertilizer chamber 9 , a speed regulating va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com