Preparation device of soft magnetic composite raw materials

A soft magnetic compounding, raw material technology, applied in mixers, mixers, transportation and packaging with rotating stirring devices, can solve the problems of slow compounding speed, complex structure, low mixing precision, etc., and achieve fast compounding speed, Good effect, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

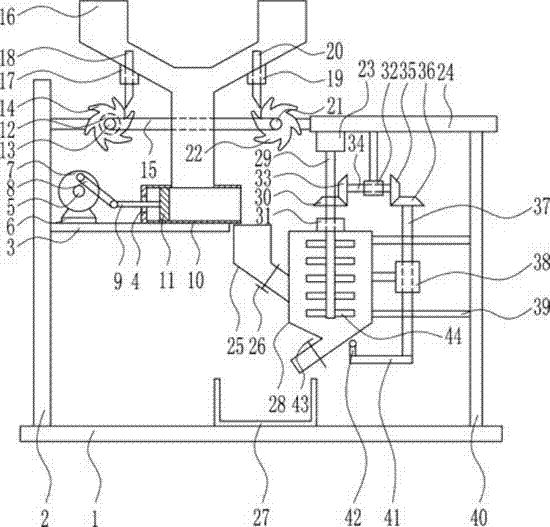

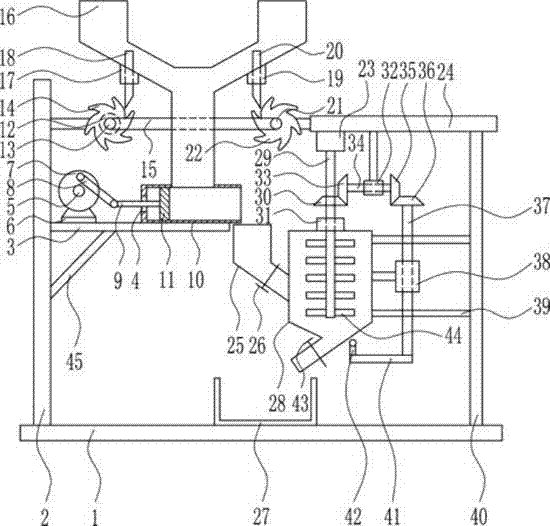

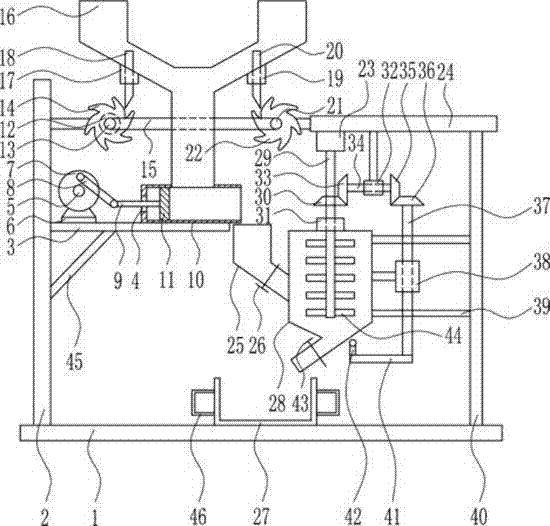

[0030] A soft magnetic composite raw material preparation device, such as Figure 1-4As shown, it includes a bottom plate 1, a left frame 2, a first fixed plate 3, a first motor 5, a mounting table 6, a turntable 7, a first connecting rod 8, a second connecting rod 9, a pushing cylinder 10, a piston 11, The second motor 12, the first pulley 13, the first ratchet 14, the flat belt 15, the Y-shaped feed hopper 16, the first fixed block 17, the first stop rod 18, the second fixed block 19, the second stop rod 20. The second pulley 21, the second ratchet 22, the third motor 23, the second fixed plate 24, the first feed hopper 25, the first electric control valve 26, the collection frame 27, the mixing box 28, the first rotating shaft 29, First bevel gear 30, first bearing seat 31, second bearing seat 32, second bevel gear 33, second rotating shaft 34, third bevel gear 35, fourth bevel gear 36, third rotating shaft 37, third bearing seat 38. Fixed rod 39, right frame 40, connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com