Preparation method of high-voltage lithium cobalt oxide cathode material

A cathode material, lithium cobalt oxide technology, applied in the direction of positive electrodes, battery electrodes, active material electrodes, etc., can solve the problems of increased side reactions, degradation of cycle performance, easy cracking, etc., to achieve uniform distribution and product performance improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

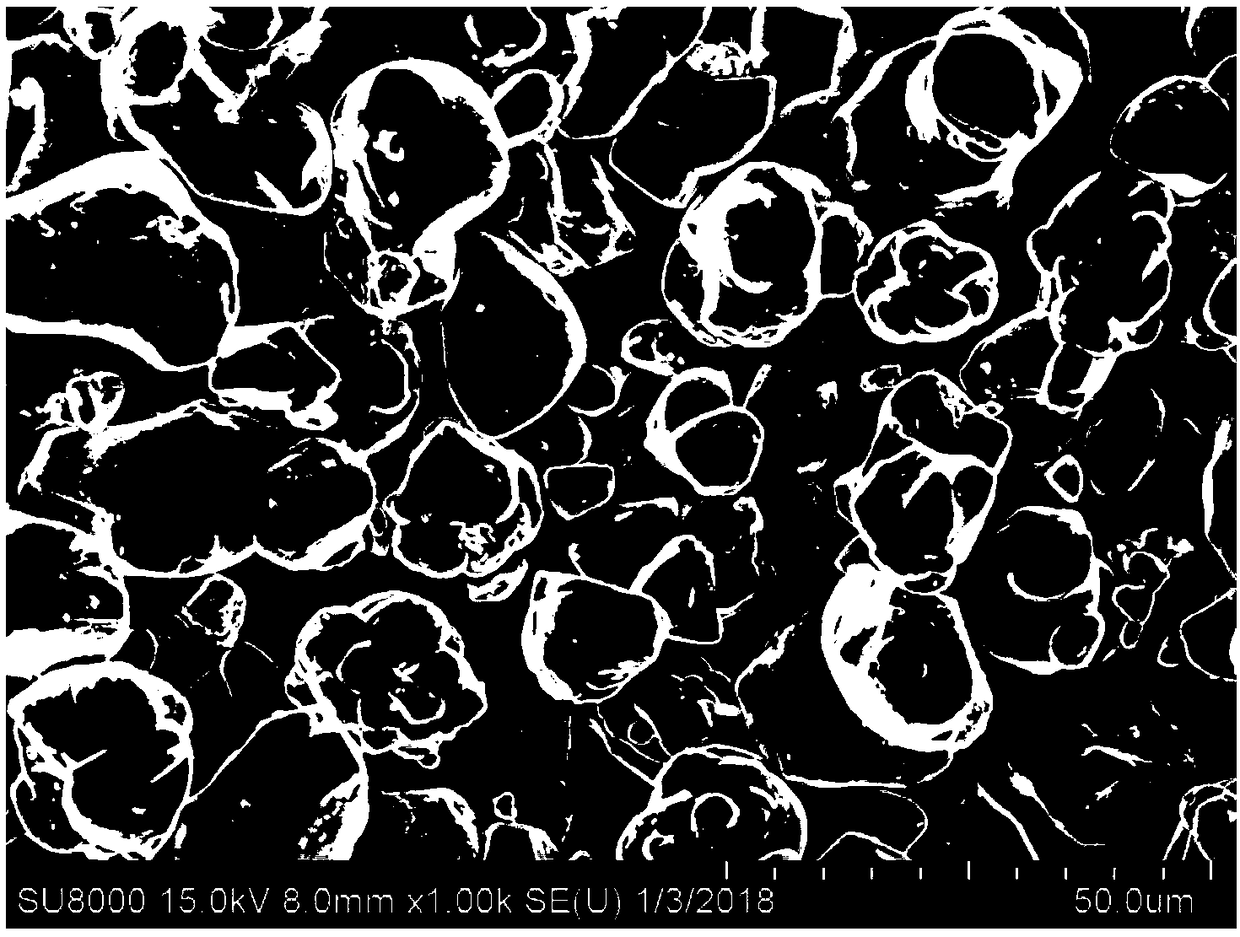

Embodiment 1

[0064] A preparation method of the high-voltage lithium cobaltate positive electrode material of the present invention, comprising the following steps:

[0065] (1) Cobalt tetroxide, lithium carbonate, lanthanum oxide, grain refiner TiO 2 and flux Mg(OH) 2 Carry out batching, adopt coulter type mixer to mix, obtain primary mixture; wherein the amount of the Al metal element doped in the tricobalt tetroxide is 0.50wt% of the lithium cobalt oxide cathode material weight, the lithium element in the lithium carbonate and the cobalt in the tricobalt tetroxide The molar ratio of the elements is n(Li):n(Co)=1.07:1, the doping amount of La is 0.1wt% of the weight of the lithium cobalt oxide cathode material, and the grain refiner TiO 2 The addition amount is 0.1wt% of lithium cobalt oxide cathode material weight, flux Mg(OH) 2 The addition amount is 0.2wt% of the weight of the lithium cobaltate positive electrode material; Cobalt tetroxide uniformly doped with Al ions is prepared by...

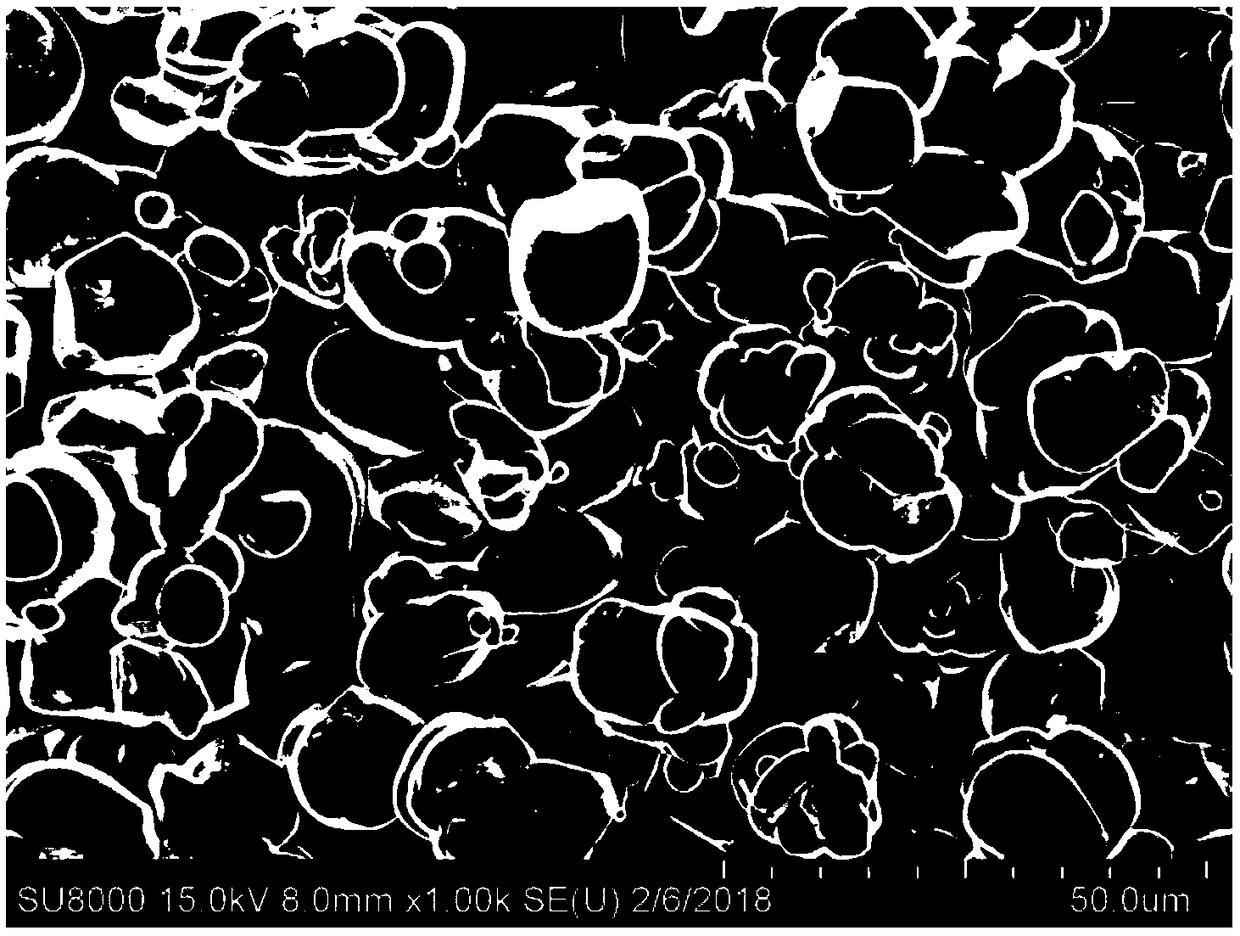

Embodiment 2

[0082] A preparation method of the high-voltage lithium cobaltate positive electrode material of the present invention, comprising the following steps:

[0083] (1) Cobalt tetroxide, lithium carbonate, aluminum oxide, and grain refiner TiO are uniformly doped with Zr ions 2 and flux Mg(OH) 2 Carry out batching, adopt coulter type mixer to mix, obtain primary mixture; Wherein, the amount of the Zr metal element doped in tricobalt tetroxide is 0.50wt% of the weight of lithium cobalt oxide cathode material, the lithium element in lithium carbonate and tricobalt tetroxide The molar ratio of the cobalt element is n(Li):n(Co)=1.06:1, the doping amount of Al is 0.1wt% of the weight of the lithium cobalt oxide cathode material, and the grain refiner TiO 2 The addition amount is 0.1wt% of lithium cobalt oxide cathode material weight, flux Mg(OH) 2 The addition is 0.1wt% of the weight of the lithium cobaltate positive electrode material; the preparation method of the used cobalt tetro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com