High-voltage spinel and lithium nickel manganese oxide anode material and method for preparing same

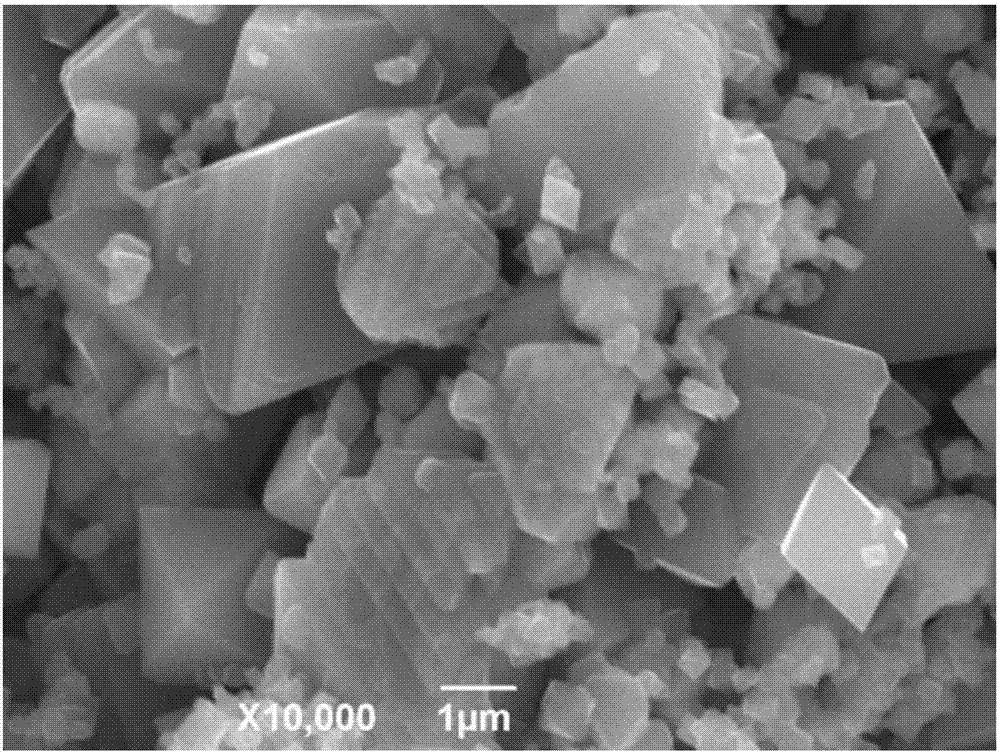

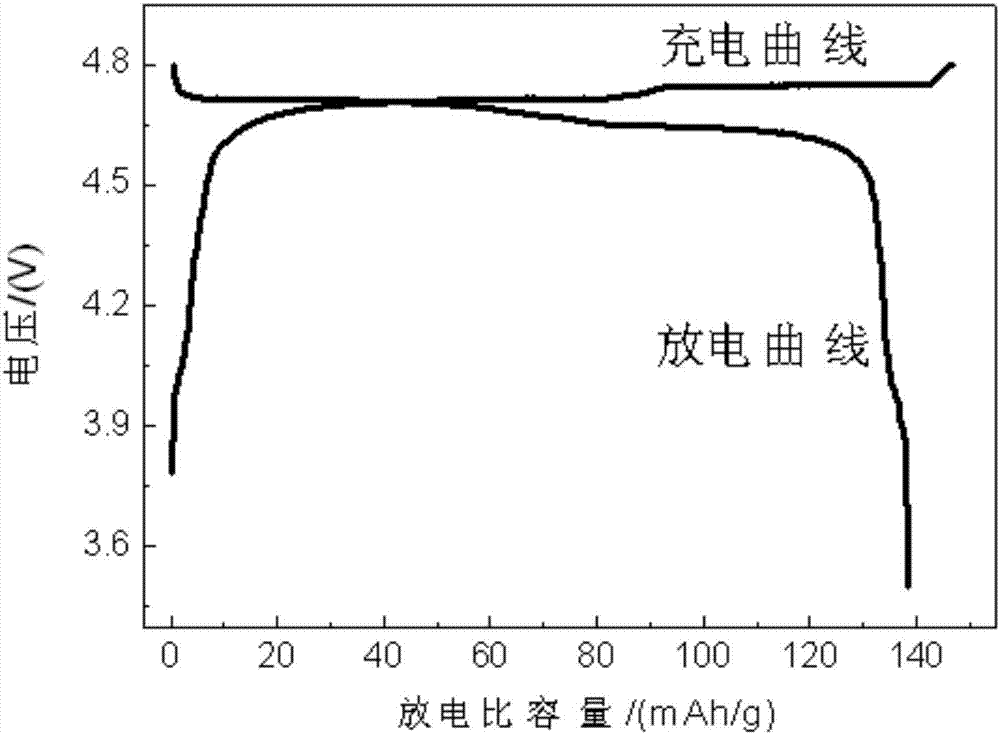

A technology for lithium nickel manganese oxide and positive electrode materials, which is applied in the field of high-voltage spinel lithium nickel manganese oxide positive electrode materials and its preparation, can solve the problems of uneven mixing of trimanganese tetraoxide and low product capacity, and achieve uniform distribution, The effect of product capacity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A preparation method of the high voltage spinel lithium nickel manganese oxide positive electrode material of the present invention comprises the following steps:

[0060] (1) Lithium carbonate and nickel-aluminum co-doped trimanganese tetroxide are compounded according to the element molar ratio of n(Li):n(Mn)=0.70:1, and mixed uniformly by a plow mixer to obtain a mixed material;

[0061] (2) Sintering the mixed material to obtain lithium nickel manganese oxide positive electrode material.

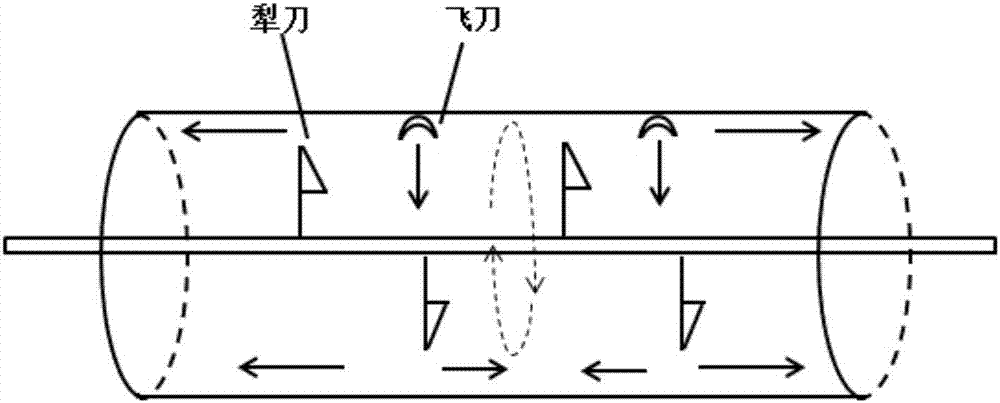

[0062] In this embodiment, the coulter type mixer includes a cylinder body, a transmission mechanism, a coulter and a flying knife; when mixing and stirring, the coulter is made to make a circular motion to divide the material into two directions to form a two-way material flow, and the coulter on both sides The diverted materials cross each other to form convection. When the materials flow through the high-speed flying knife, they are sheared and thrown by the blades of the high-...

Embodiment 2

[0075] A preparation method of the high voltage spinel lithium nickel manganese oxide positive electrode material of the present invention comprises the following steps:

[0076] (1) Lithium carbonate and nickel-aluminum co-doped trimanganese tetroxide are compounded according to the element molar ratio of n(Li):n(Mn)=0.67:1, and mixed uniformly by a plow mixer to obtain a mixed material;

[0077] (2) Sintering the mixed material to obtain lithium nickel manganese oxide positive electrode material.

[0078] In this embodiment, the coulter type mixer includes a cylinder body, a transmission mechanism, a coulter and a flying knife; when mixing and stirring, the coulter is made to make a circular motion to divide the material into two directions to form a two-way material flow, and the coulter on both sides The diverted materials cross each other to form convection. When the materials flow through the high-speed flying knife, they are sheared and thrown by the blades of the high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com