Wire-rod and the like hot-rolling machine

A technology for hot rolling mills and wire rods, applied to metal rolling stands, metal rolling mill stands, cantilevered rolling mill stands, etc., which can solve the problems of increased number of machines and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

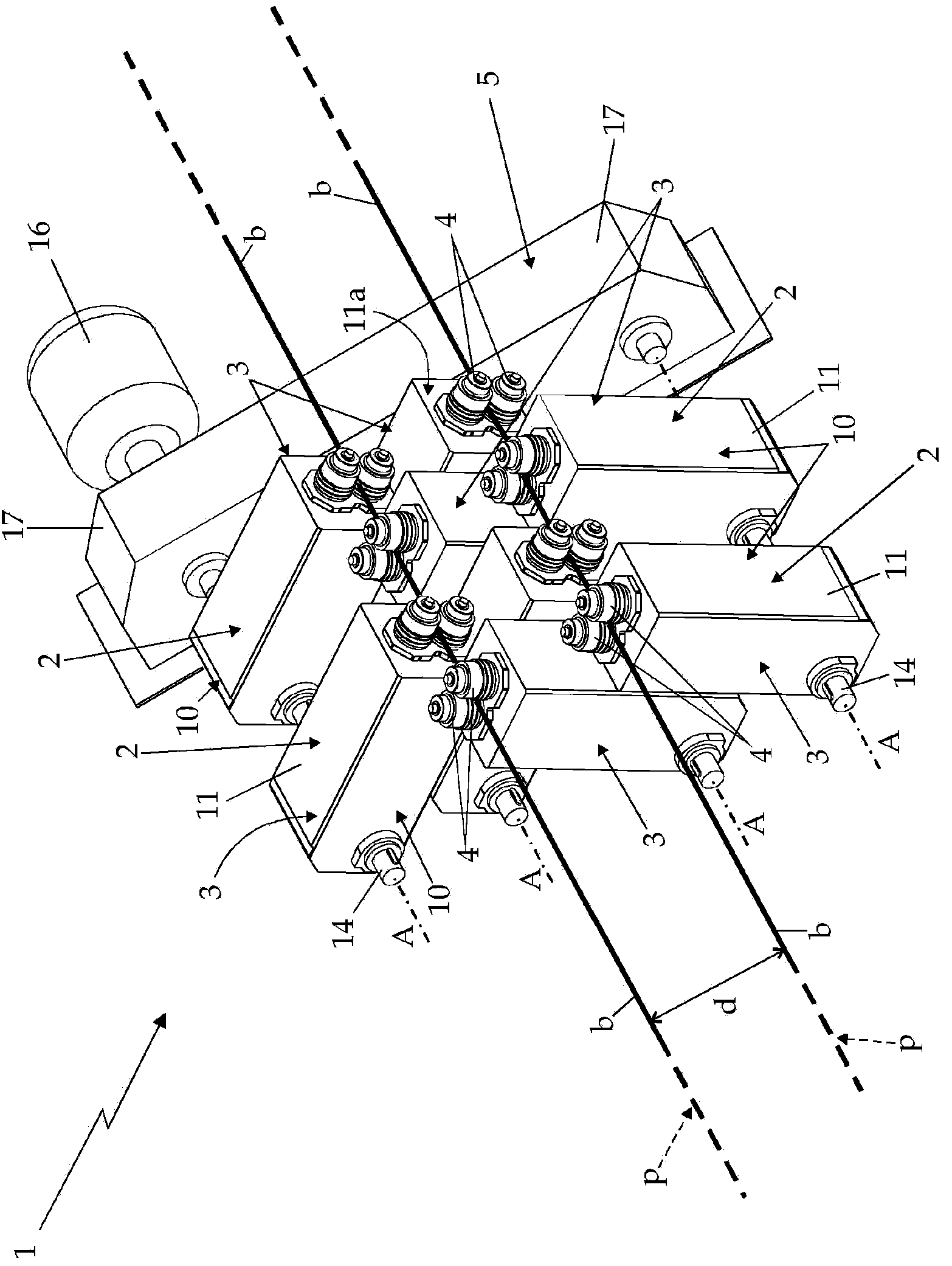

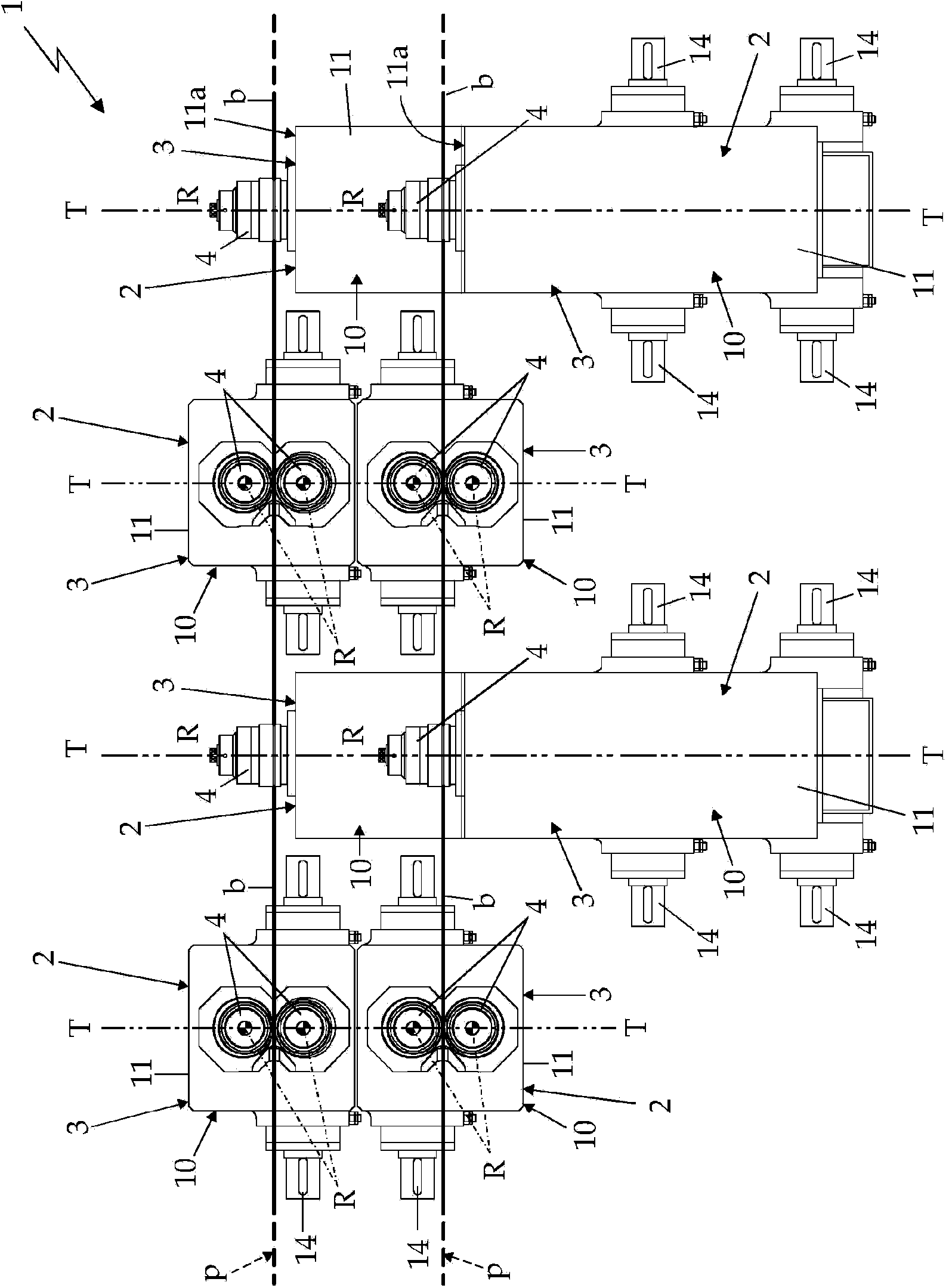

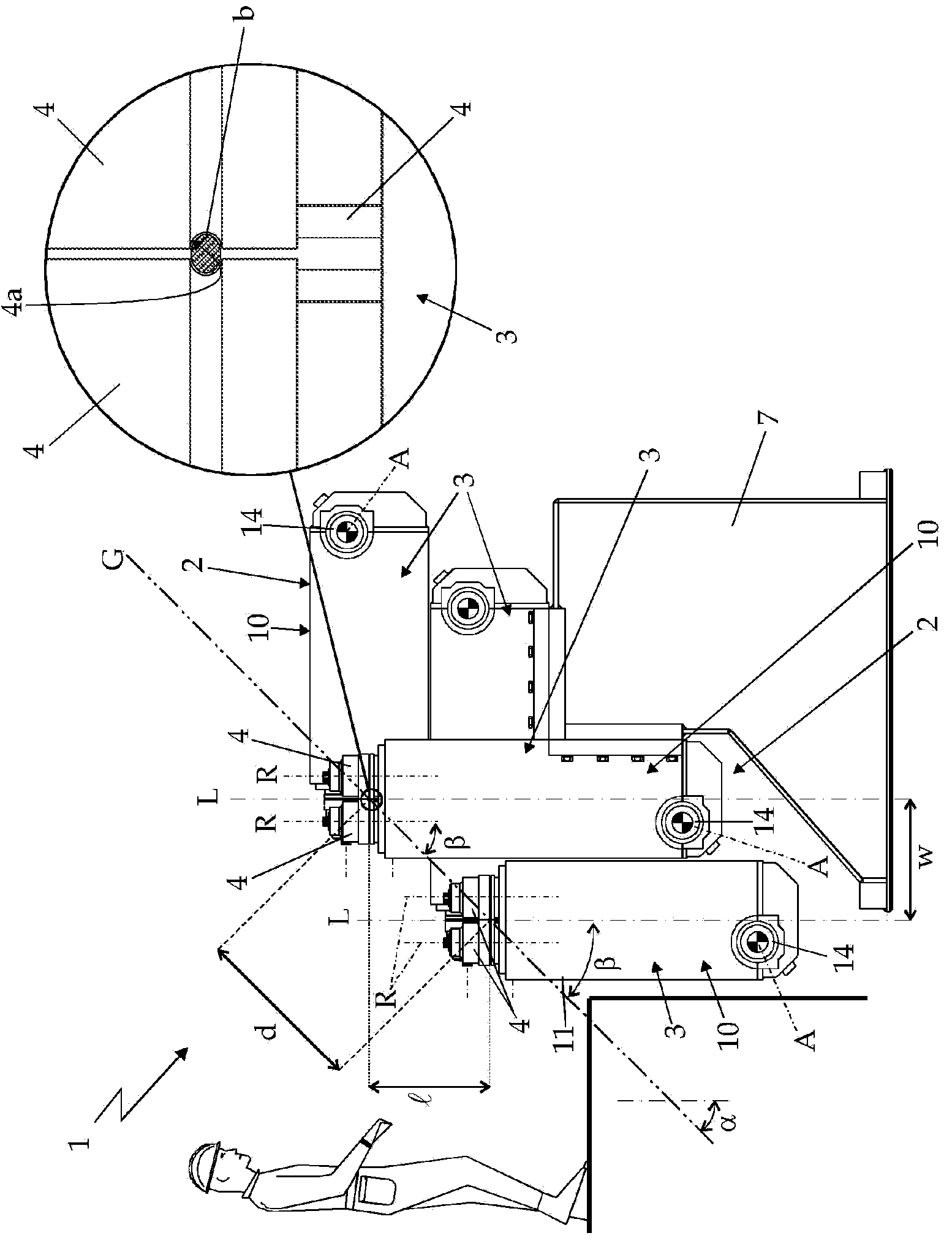

[0023] refer to figure 1 , figure 2 as well as image 3 , reference number 1 designates as a whole a machine for hot rolling two metal wires b or similar semi-finished products in parallel and at high temperature, this hot rolling mill is particularly advantageously used for the production of wires for reinforced concrete.

[0024] More specifically, the machine 1 is configured to hot-roll two metal wires b in parallel, which are fed into the machine side-by-side along respective feed paths p, which are locally substantially straight and close to each other. parallel.

[0025] In other words, the feed paths p of the two wires b lie on the same lying plane G and are arranged at a predetermined distance d from each other, preferably but not necessarily within a distance ranging from 0.3 meters to 3 meters.

[0026] In the example shown, in particular, the feed paths p of the two wires b extend preferably, but not necessarily, in the horizontal direction, while the lying plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com