Compact cantilever rolling mill and a method of producing a metallic product

一种金属制品、轧机的技术,应用在轧机领域,能够解决支撑辊受力高、角度不合适、悬臂式轧机不能操控轧制力等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

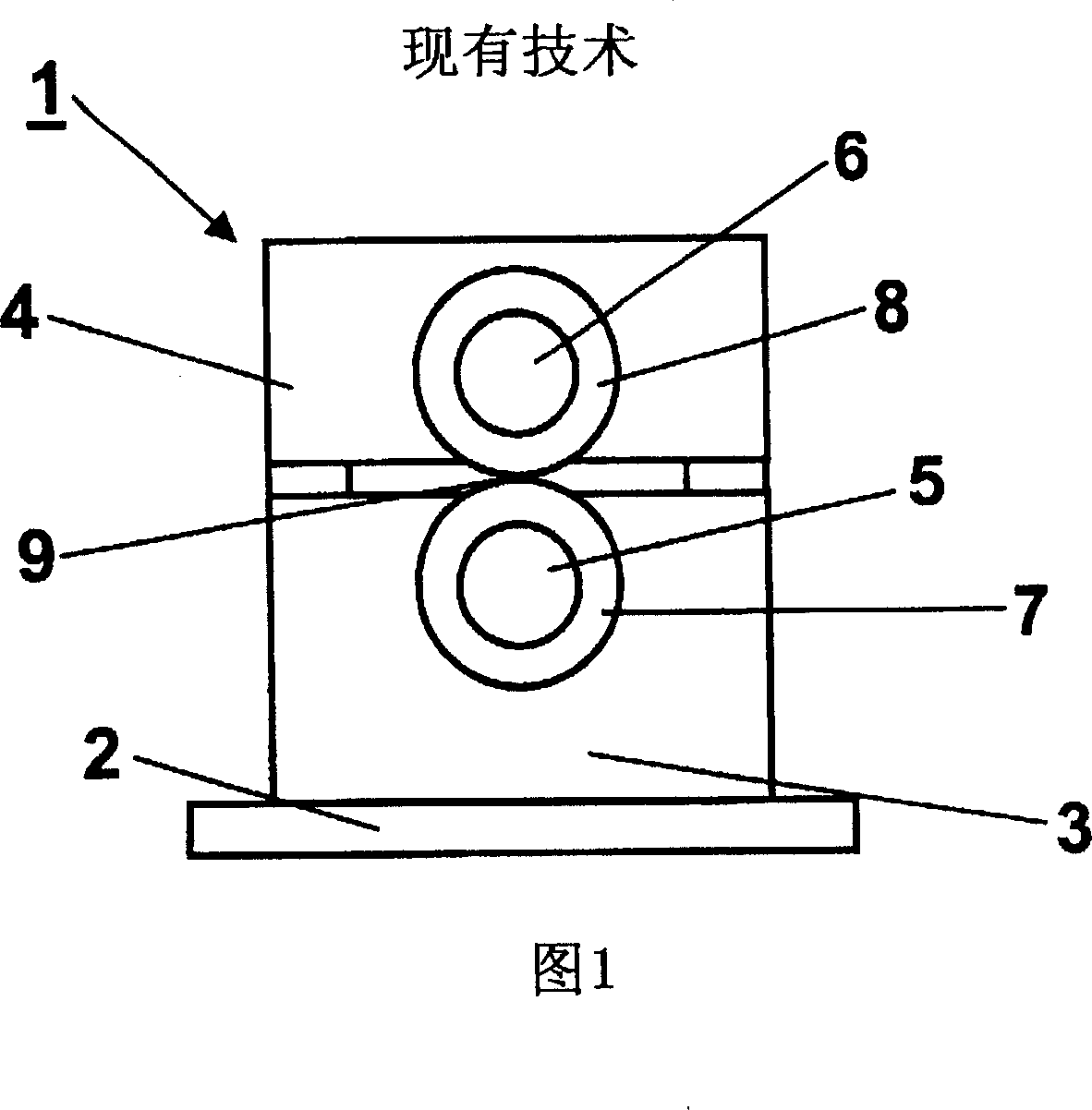

[0021] Figure 1 is a simplified representation of the components of a typical cantilever rolling mill 1 according to the prior art. The rolling mill 1 comprises a base 2 supporting a lower roll housing 3 . The lower roll frame 3 supports the upper roll frame 4 . A lower roll shaft 5 and an upper roll shaft 6 are mounted on the roll stands 3 and 4 . Mounted on the roller shafts 5 and 6 are ring rollers 7 and 8 between which a nip 9 is formed.

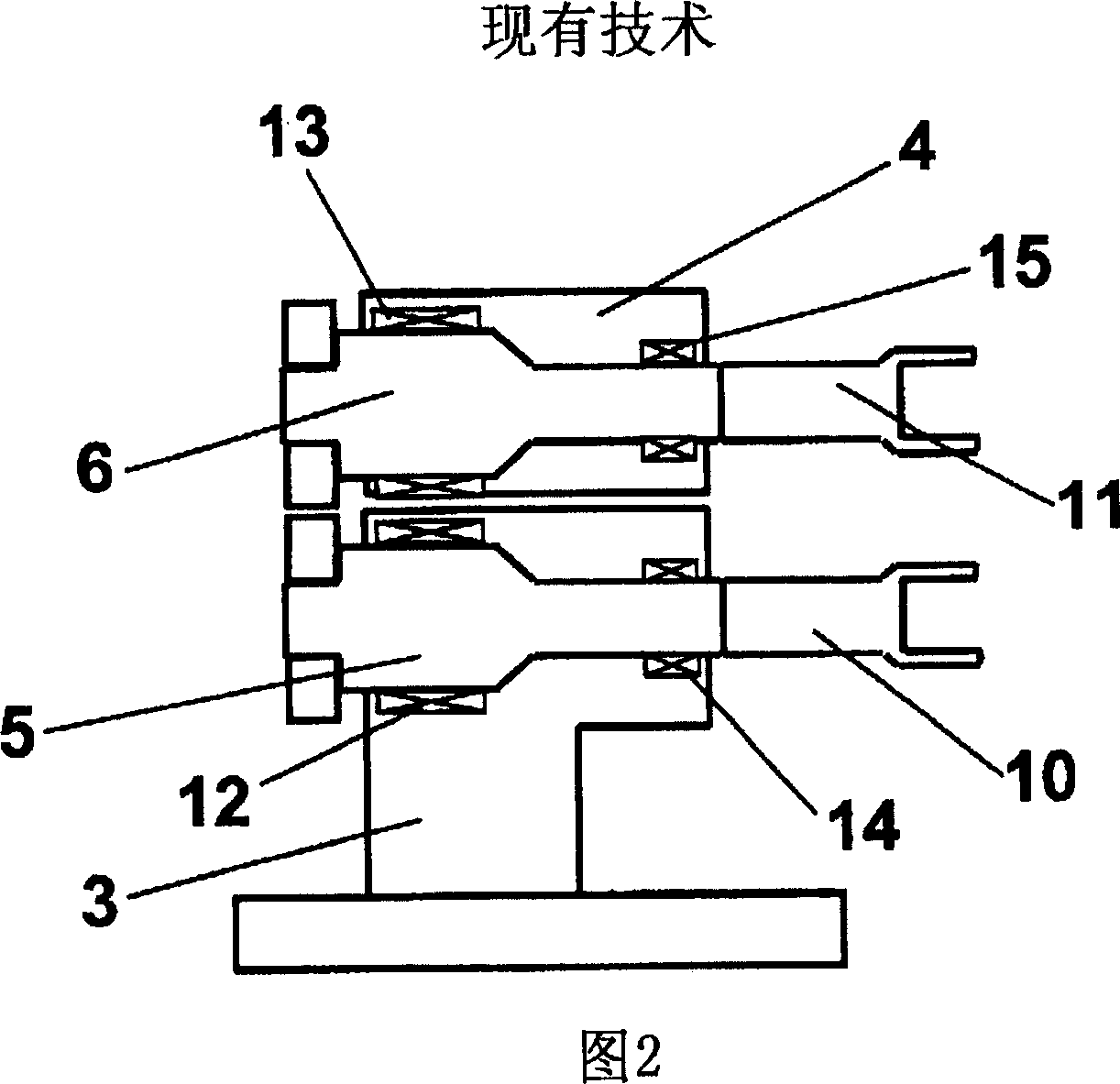

[0022] FIG. 2 is another view of the prior art cantilever rolling mill of FIG. 1. FIG. The roll shafts 5 and 6 respectively have drive ends 10 and 11 at the ends for driving the rolling mill with a drive motor. The roll shafts 5 and 6 are mounted on the roll frames 3 and 4 by heavy main bearing assemblies 12 and 13 and lighter bearing assemblies 14 and 15 which are located closer to the drive ends 10 and 11 of the roll shafts. The heavy main bearing assemblies 12 and 13 carry the major part of the rolling forces. The lighter bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com