Magnetic suspension superconductive steel rolling machine

A magnetic levitation, rolling mill technology, applied in the direction of cantilever rolling mill stand, metal rolling stand, metal rolling mill stand, etc., can solve problems such as lack of innovation in technological improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

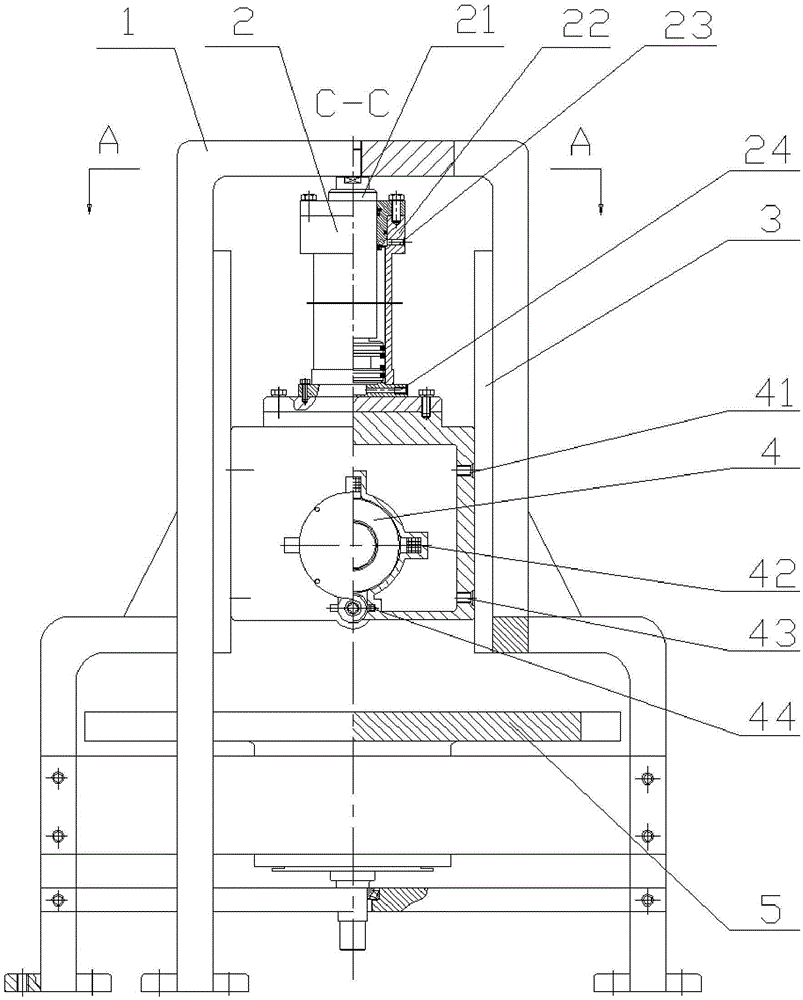

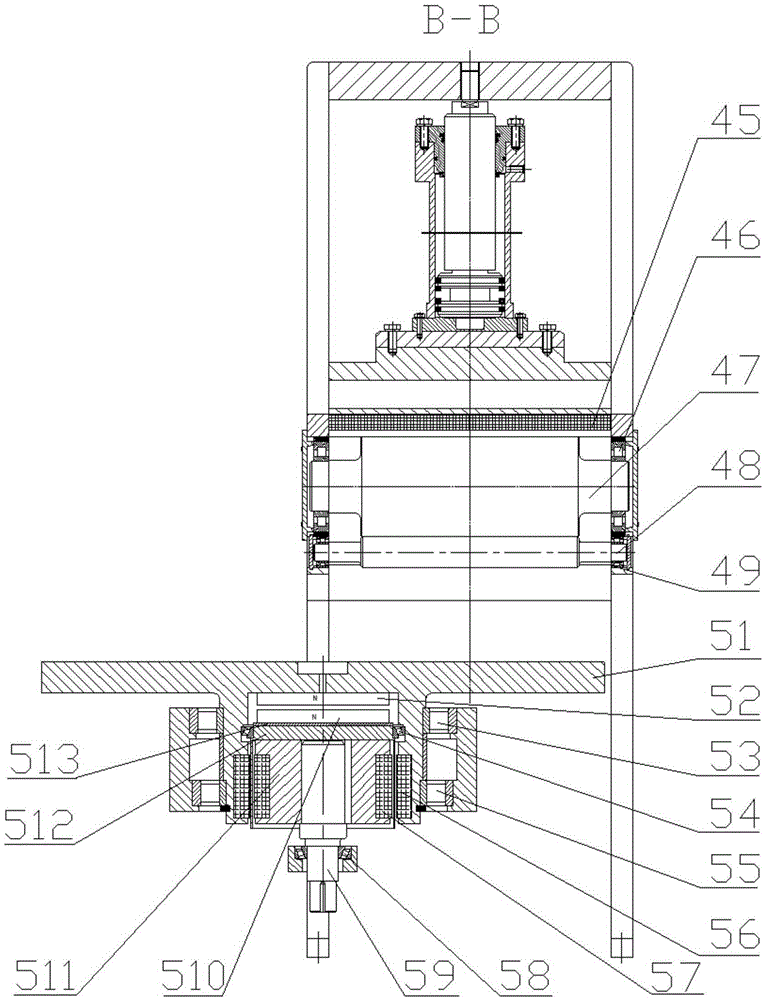

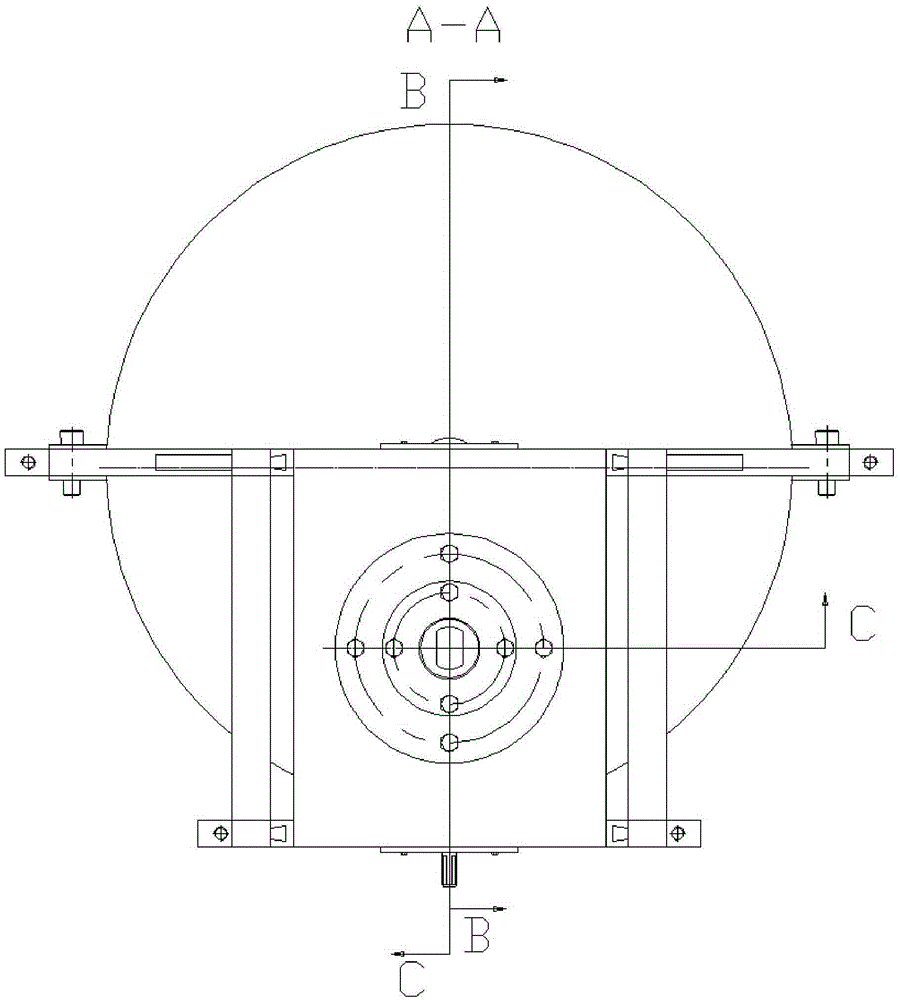

[0019] like figure 1 , figure 2 , image 3 , Figure 4 Shown 1, a kind of magnetic levitation superconducting rolling mill, comprises frame 1, hydraulic cylinder 2, guide rail 3, upper rolling mechanism 4, magnetic levitation rolling platform 5, described hydraulic cylinder 2 is composed of piston 21, cylinder block 22, It is composed of retracting oil inlet 23 and rolling oil inlet 24, which are connected to the upper part of frame 1 by thread through piston 21, cylinder body 22 is connected with upper rolling mechanism 4, and oil is fed into rolling oil inlet 24 to push hydraulic cylinder 2 to drive The upper rolling mechanism 4 presses the steel plate to be rolled along the guide rail 3, returns to the oil inlet 23 to feed oil, and pushes the hydraulic cylinder 2 to drive the upper rolling mechanism 4 to retreat from the rolled steel plate along the guide rail 3; the symmetrical guide rail 3 is fixed on the frame 1 on both sides; it is characterized in that the upper ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com