Lubrication system

A lubricant and lubricant replenishment technology, applied in the field of lubrication systems, can solve the problems of expensive operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

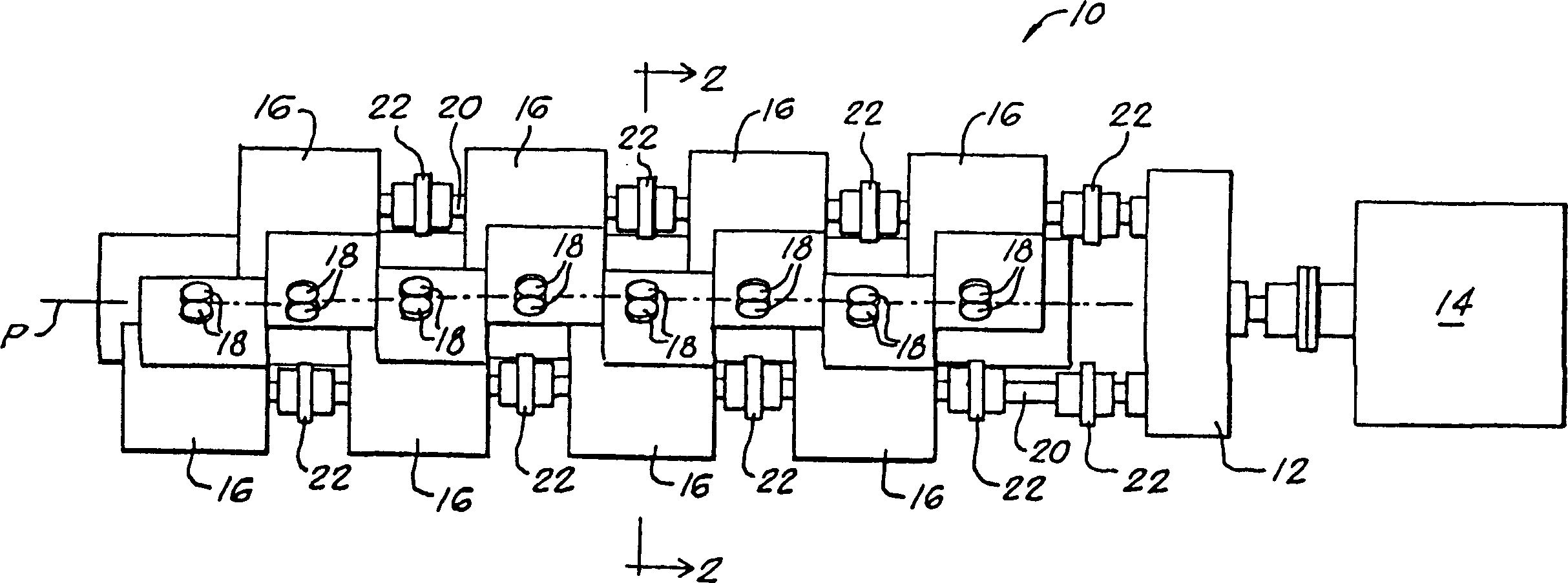

[0015] first reference figure 1 , 10 in the figure represents a high-speed finish rolling module. The module is powered by a drive motor 14 via a geared speed increaser 12 .

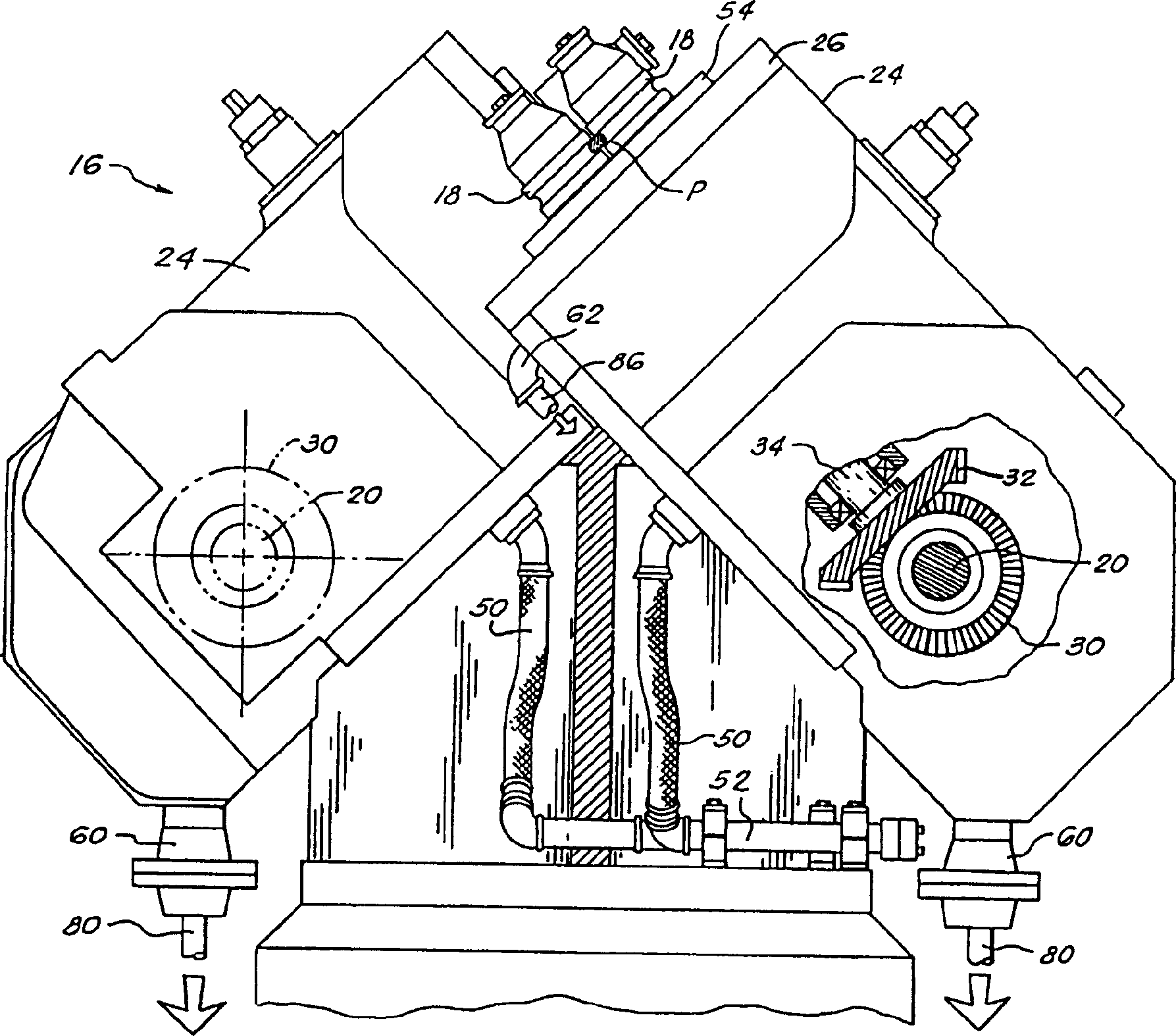

[0016] Refer again figure 2 , 3 and 5, it can be seen that the module comprises a row of rolling stands 16 arranged staggered on both sides of the pass line P. The rolling mill stand has cantilevered work roll pairs 18 staggered with a difference of 90° for twist-free rolling of the product. The rows of mill stands on each side of the rolling line are mechanically connected to each other and to the speed increaser 12 via the overall shaft sections 20 interconnected by couplings 22 .

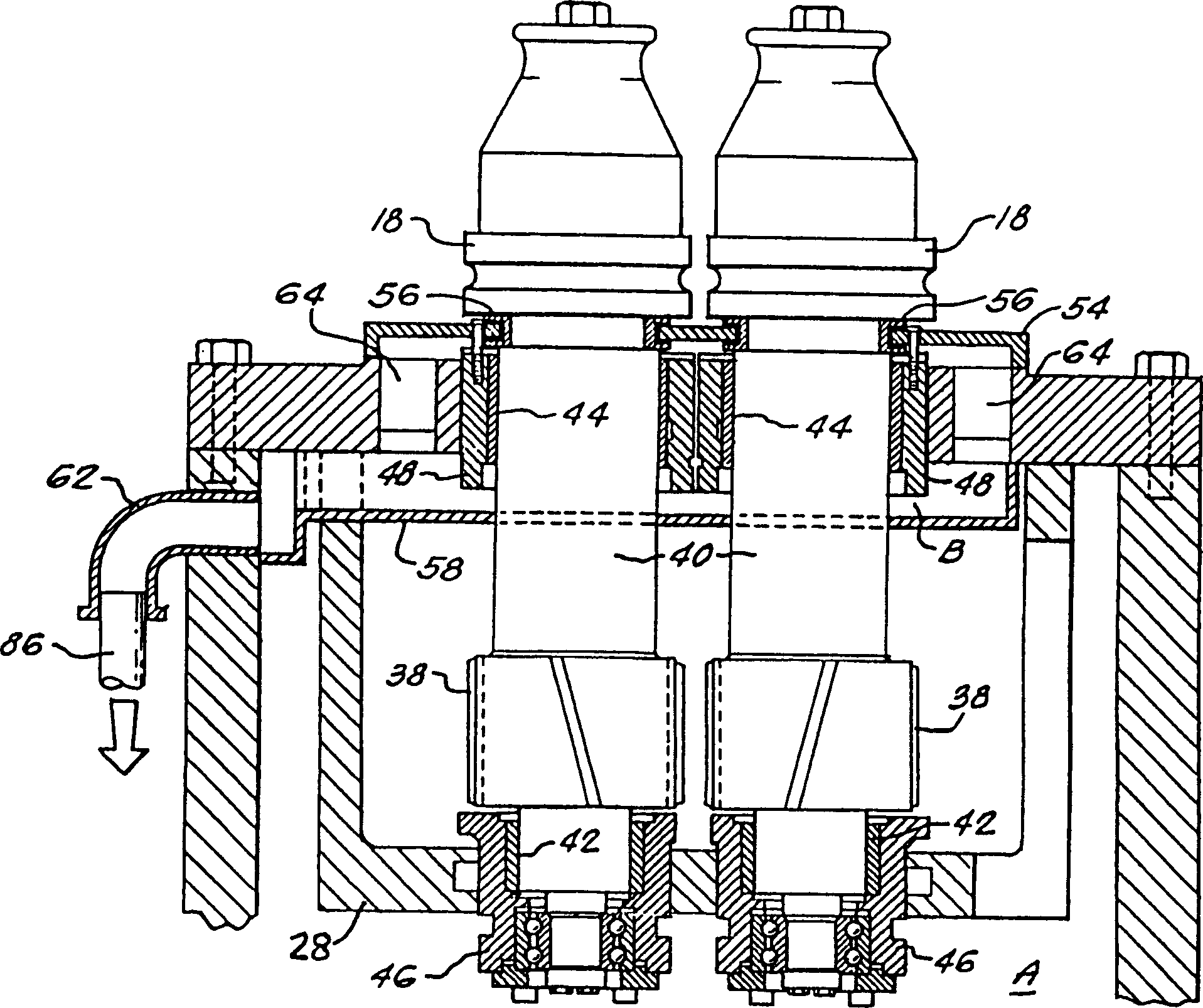

[0017] Each mill stand 16 includes a frame 24 closed at its upper end by a front cleat 26 which supports a side frame body 28 projecting inwardly through the opening. In each frame 24 , each main shaft section 20 carries a helical gear 30 which cooperates with a mating helical gear 32 on one of a pair of parallel driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com