Production method for stainless steel two-sided composite board, roll

A production method and composite plate technology, applied in the direction of metal rolling, manufacturing tools, metal processing equipment, etc., can solve the problems of large floor area, poor organization, large equipment investment, etc., and achieve remarkable economic benefits of products and social harmony Significant benefits and broad product market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The production method of the stainless steel double-sided composite plate (coil) of the present invention is as follows:

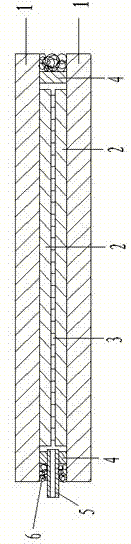

[0078] 1. If figure 1 As shown, make a one-step rolling billet:

[0079] 1.1 Surface treatment of substrate and doubler board:

[0080] The material of base plate 1 is carbon steel, and the material of double plate 2 is stainless steel. The oxide layer and oil stains on the surface of base plate 1 and double plate 2 are cleaned by pickling, sand blasting, shot blasting, grinding, etc., so that Substrate 1 and doubler board 2 exhibit metallic luster.

[0081] 1.2 Prepare file 4:

[0082] Cut carbon steel (such as Q235B) with a thickness of 12~20mm into strips. The width of the cut strips is the sum of the thicknesses of the two doubler panels 1 plus 0.3~0.5mm, and clean the surface according to the method in step 1.1.

[0083] 1.3 Weld the bar 4 on one of the substrates 1 to form a rectangular frame. The distance from the outer edge of the recta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com