Monolithic hurricane resistant structural panels made from low density composites

a composite structure, low density technology, applied in the direction of building roofs, building components, constructions, etc., can solve the problems of roof no longer acting as a diaphragm, most susceptible to damage, loss of cladding or sheathing (tiles, shingles, etc., to achieve the effect of low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

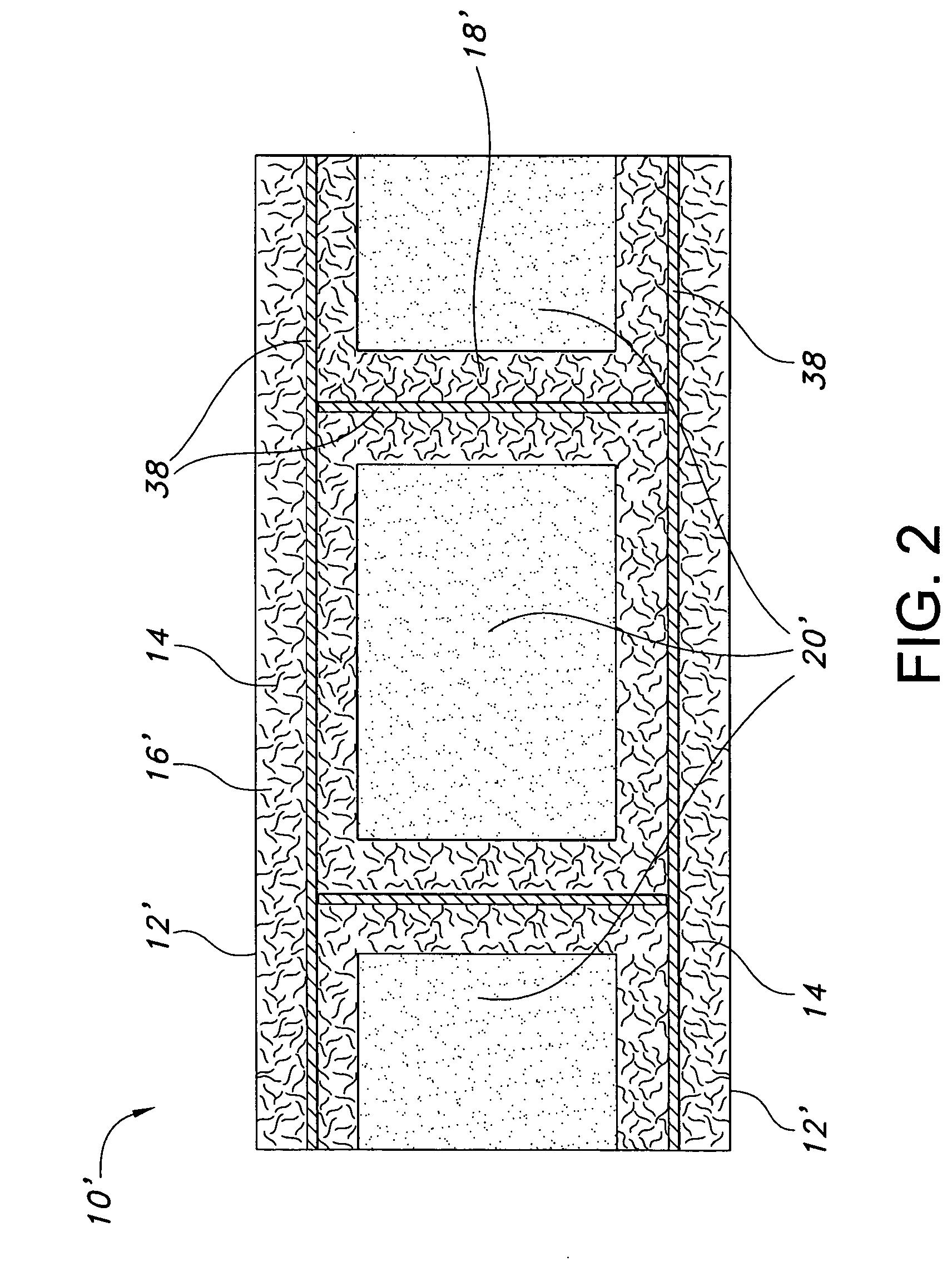

[0018] The invention will next be described with reference to the figures wherein same numerals are used to identify same elements in all figures. The figures illustrate the invention and are not intended to act as engineering or construction drawings, therefore they are not to scale and do not include all elements that may be included in such drawings, as inclusion of such elements would unduly clutter the drawings.

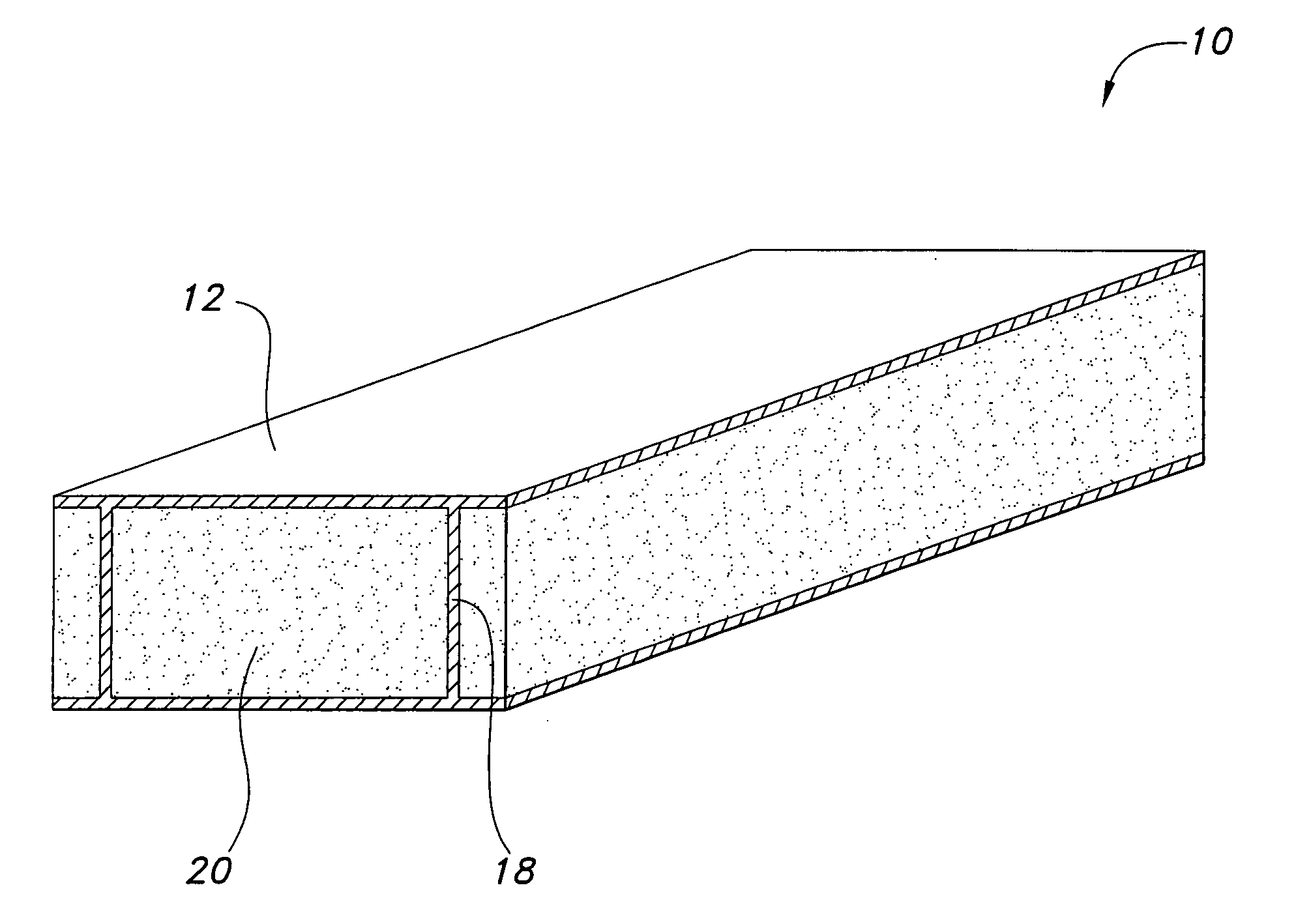

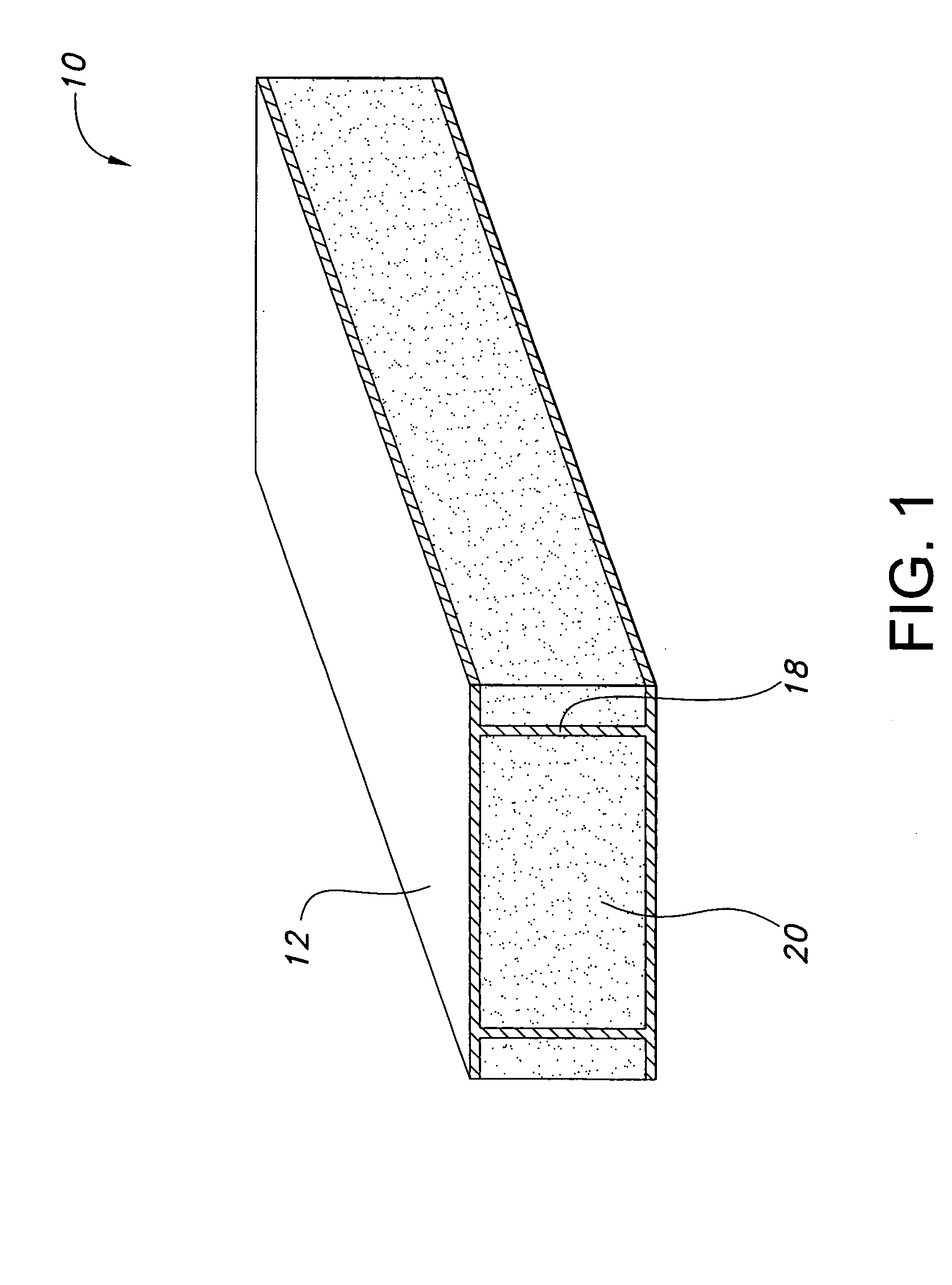

[0019] Referring next to FIG. 1 there is shown a three dimensional cross sectional view of a panel 10 constructed in accordance with this invention. The panel comprises at least two fiber-reinforcing mats 12 formed from a plurality of fibers embedded in a resin matrix. The composite structure 10 further includes a skeletal web structure 18 connecting the fiber-reinforcing mats 12 to one another in a substantially parallel configuration. Closed-cell foam core 20 is sandwiched between the fiber-reinforcing mats 12.

[0020] Many natural fibers, including, but not limited to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| loss modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com