Resin composition having laser direct-structuring function and its preparation method and use

A technology of laser direct structuring and resin composition, applied in the field of resin composition, can solve problems such as poor heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

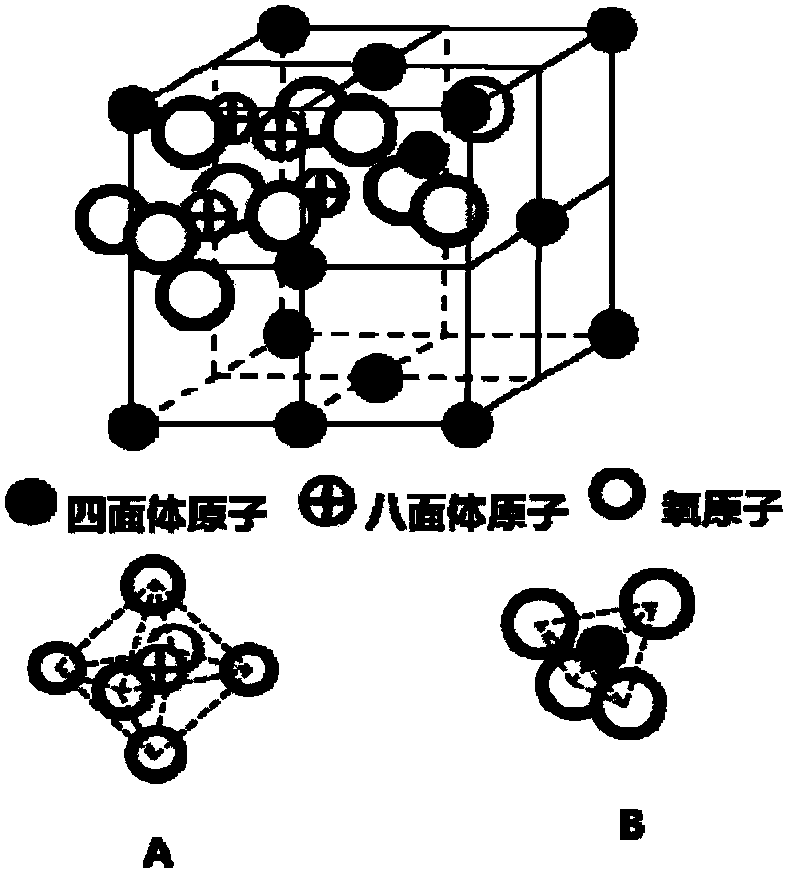

Method used

Image

Examples

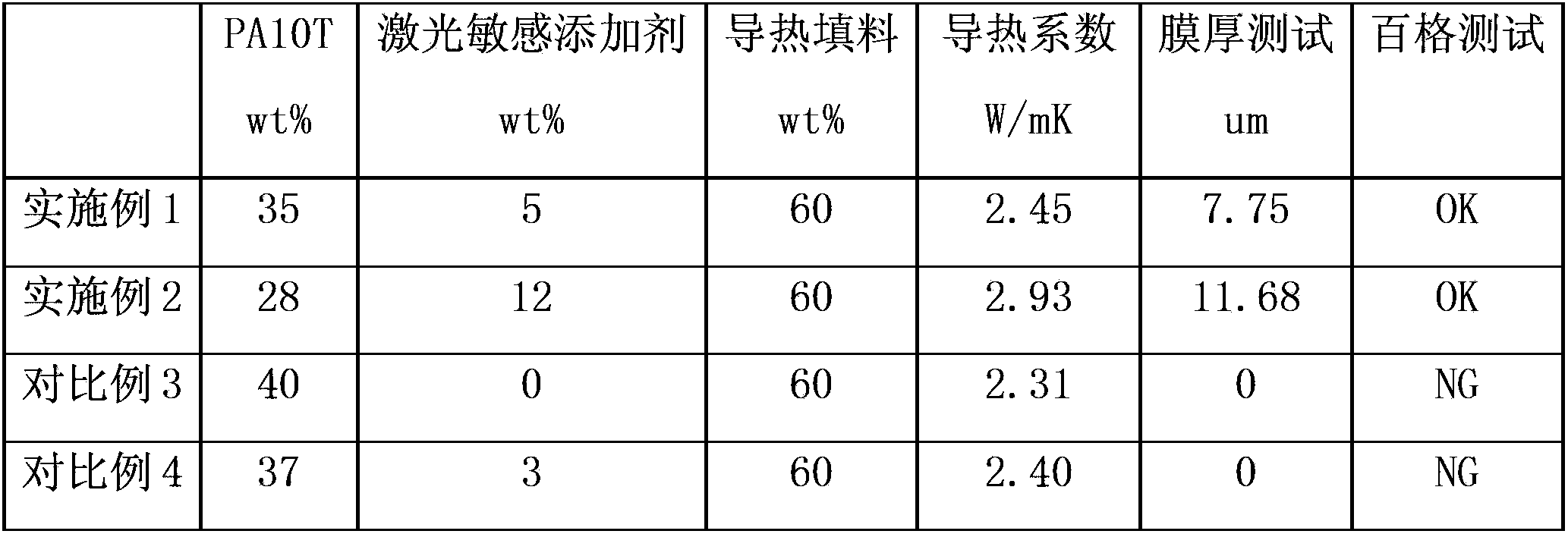

Embodiment 1

[0088] The resin matrix is made of polydecanediamide, 28wt%, the thermally conductive filler is made of boron nitride 30wt% and magnesium oxide 20wt%, the copper-manganese laser sensitive additive is 12wt%, other additives are made of nano-alumina 2wt%, glass fiber 8wt%.

Embodiment 2

[0090] Polydecanediamide 40wt% is used as the resin matrix, 30wt% boron nitride and 20wt% magnesium oxide are used as thermal conductive fillers, 0wt% copper-manganese laser sensitive additives are used, 2wt% nano-alumina is used as other additives, and 8wt% glass fiber %.

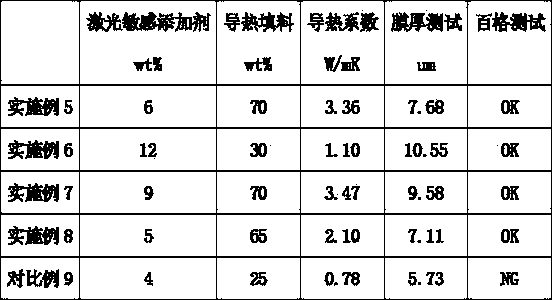

Embodiment 5

[0103] The test results show that the thermal conductivity of this material is 3.36 W / mK, the thickness of the metal film is 7.68um, and the shedding area of the metal film is less than 5% in the Baige test.

[0104] Example 6

[0105] Thermotropic liquid crystal polymer (from Kingfa Science and Technology Co., Ltd.) 58wt%, aluminum nitride 10wt%, zinc oxide 10wt%, copper-chromium laser sensitive additive 12wt%, carbon fiber 10wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com