Patents

Literature

41 results about "Molded interconnect device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A molded interconnect device (MID) is an injection-molded thermoplastic part with integrated electronic circuit traces. The use of high temperature thermoplastics and their structured metallization opens a new dimension of circuit carrier design to the electronics industry. This technology combines plastic substrate/housing with circuitry into a single part by selective metallization.

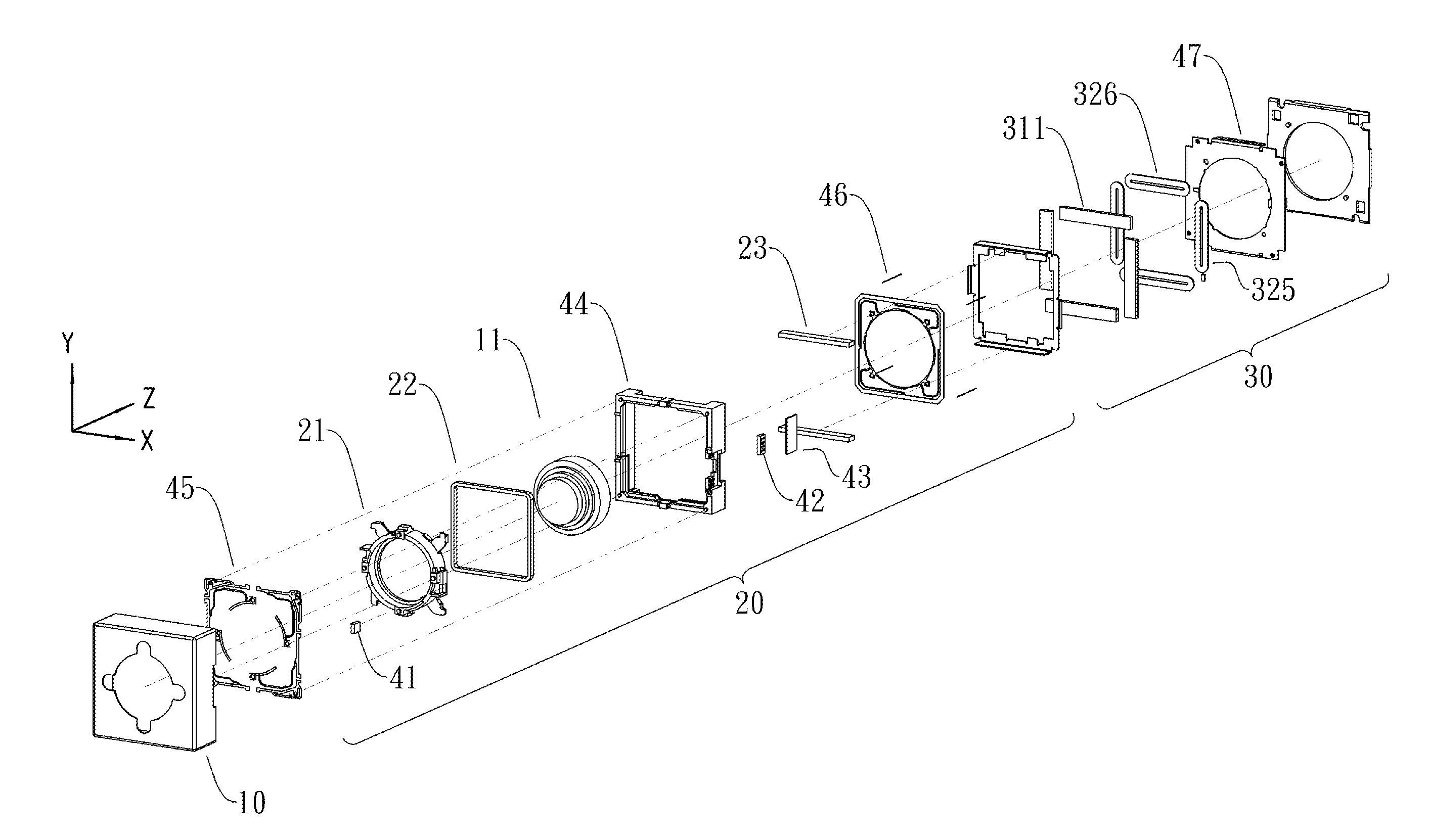

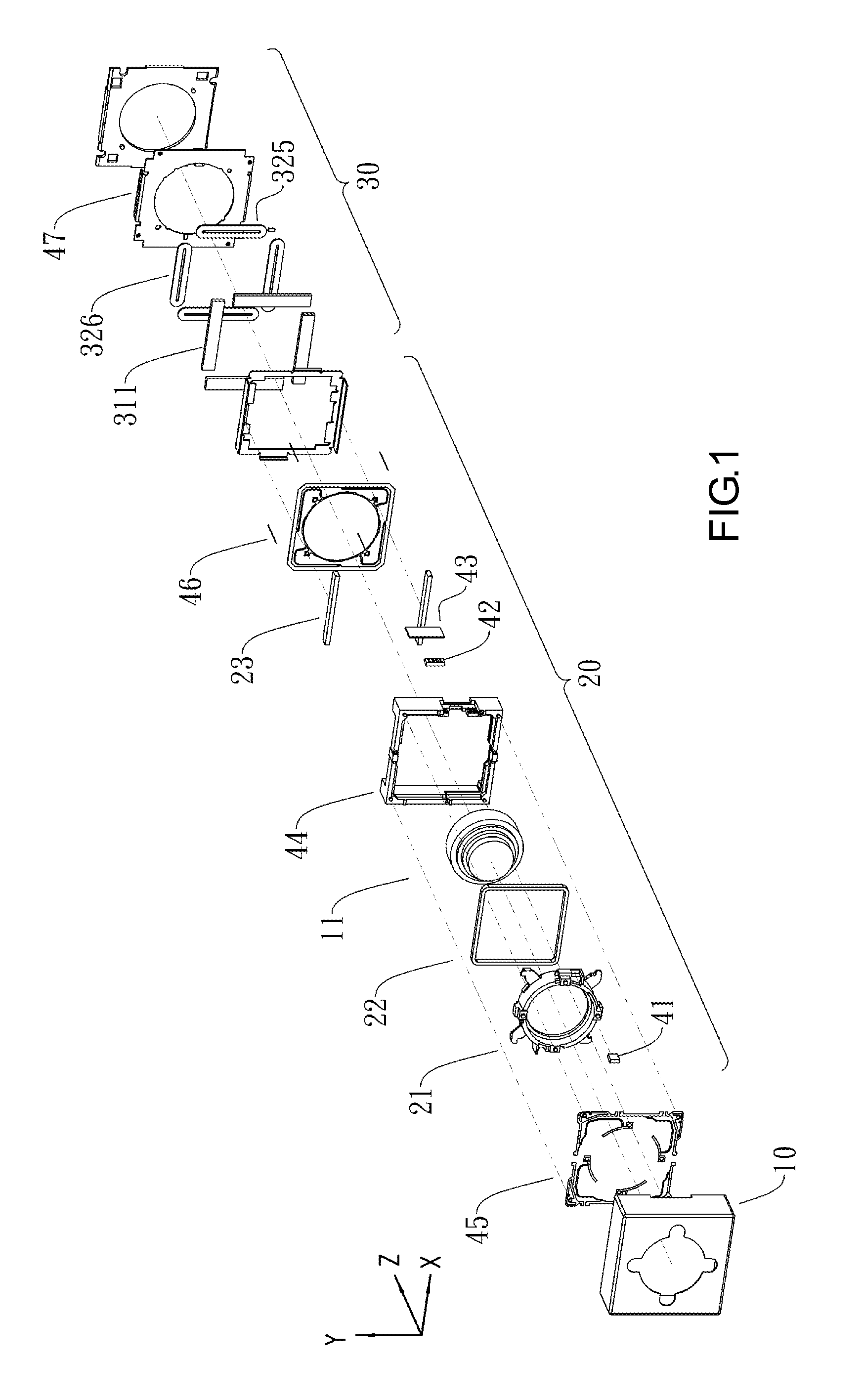

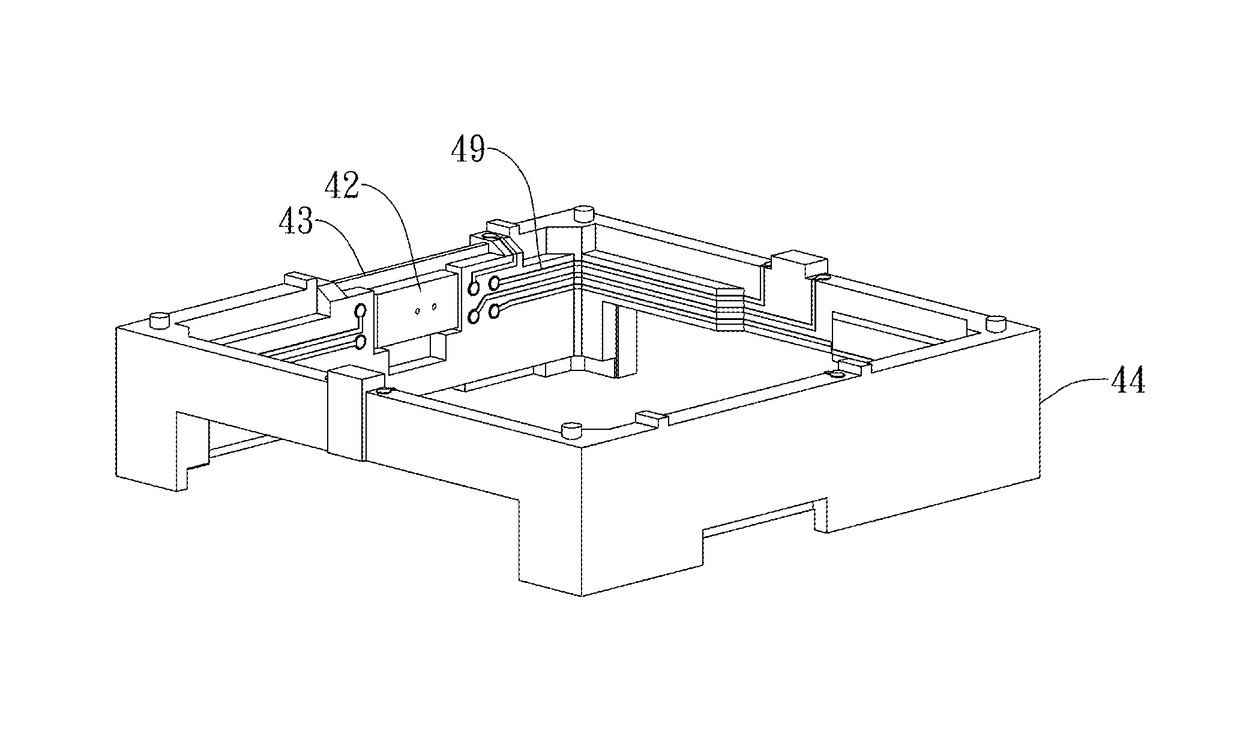

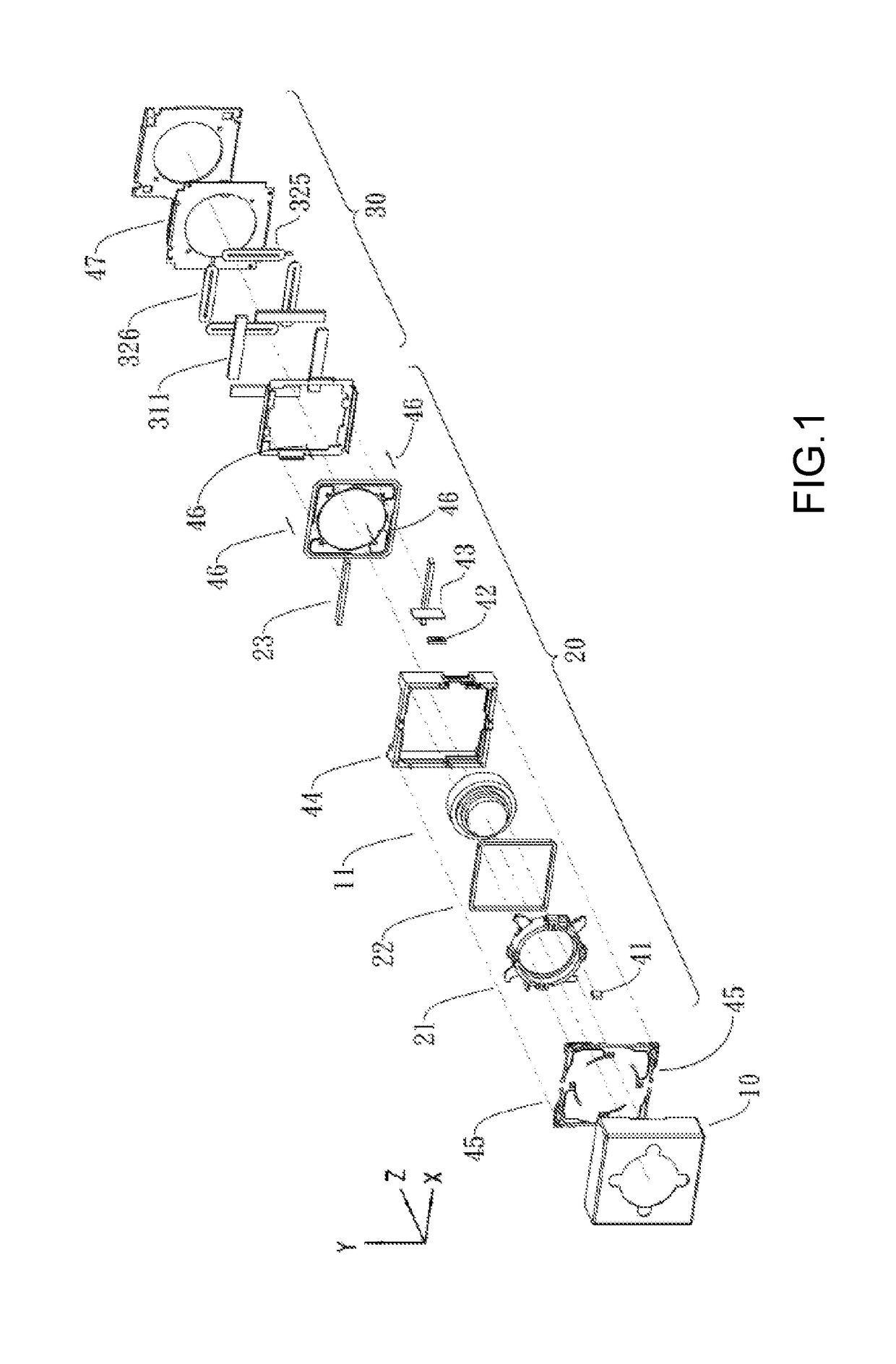

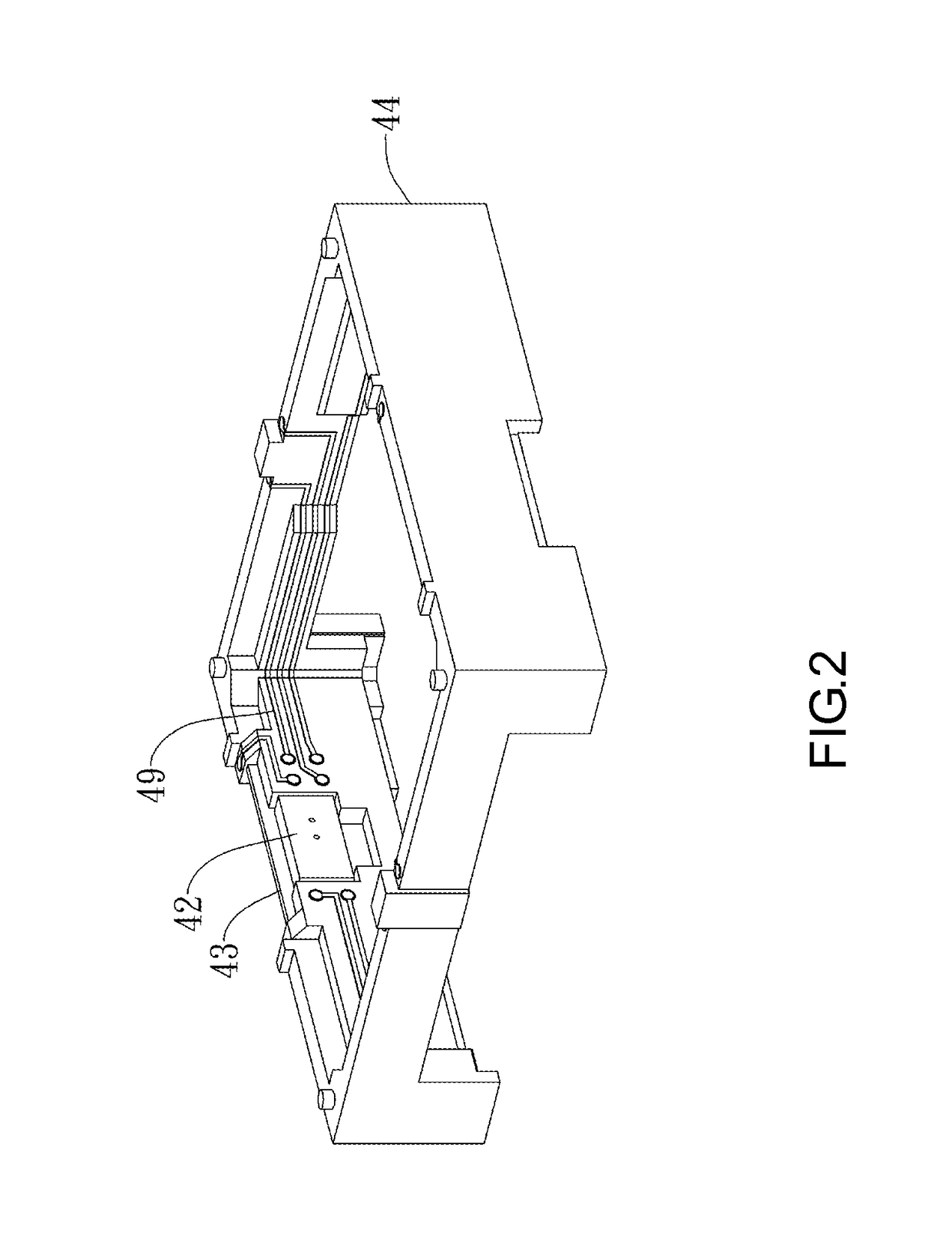

Tri-axis closed-loop Anti-shake structure

Provided is a lens driving device which includes: a lens holder including a coil; a frame for receiving the lens holder; a driving circuit board disposed below the frame; a plurality of first conductive elastic bodies disposed in a manner to keep the lens holder moving in a Z-axis direction; and a plurality of second conductive elastic bodies disposed in a manner to keep the frame moving in a direction perpendicular to the Z-axis direction. The lens driving device further comprises a plurality of electrical contact-oriented Z-axis position sensor. The Z-axis position sensor senses the motion of the lens holder in the Z-axis direction. An electronic circuit between a portion of the plurality of electrical contacts and the coil of the lens holder comprises a Molded Interconnect Device and a portion of the first conductive elastic bodies. The Molded Interconnect Device is disposed on the frame.

Owner:TDK TAIWAN

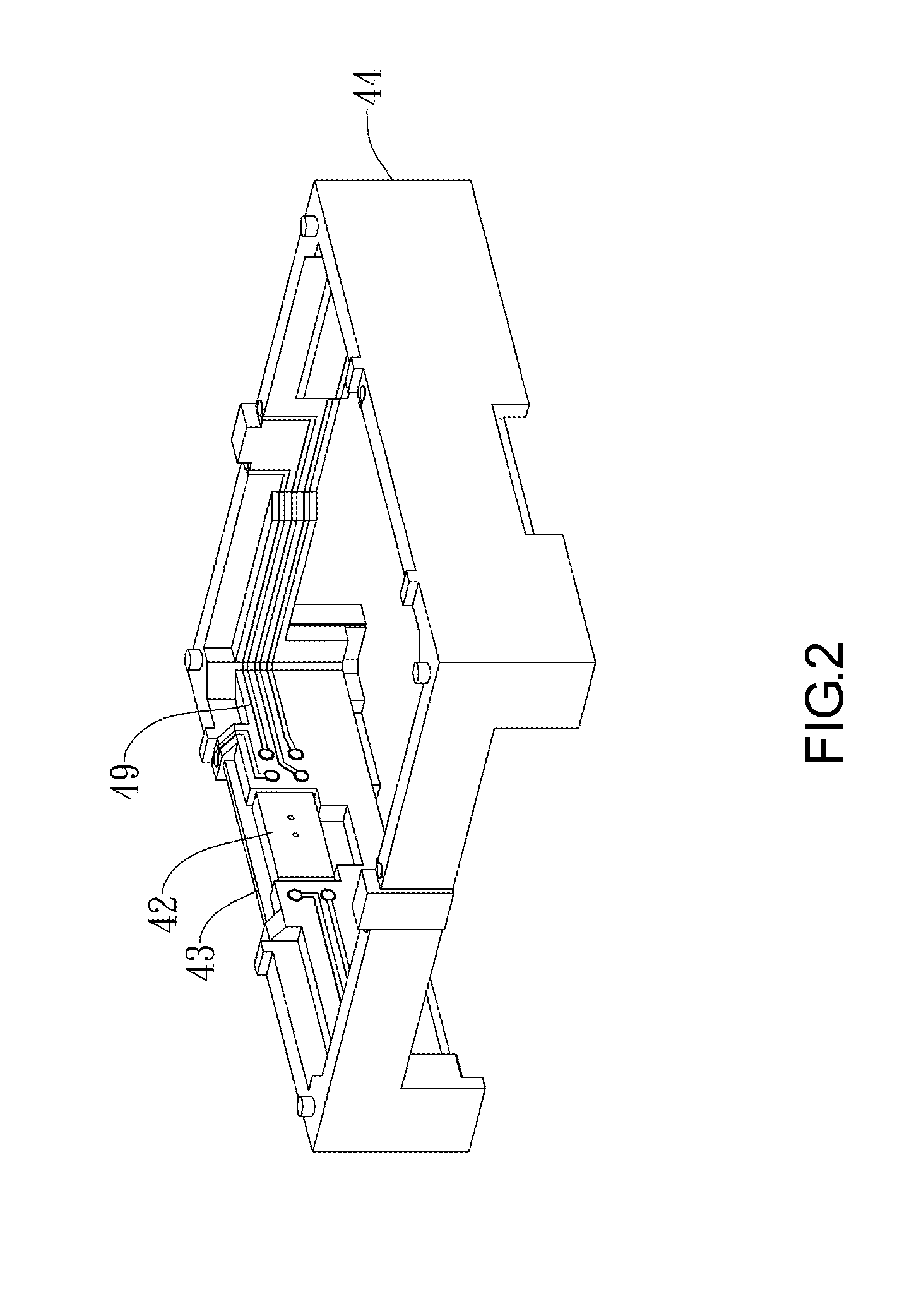

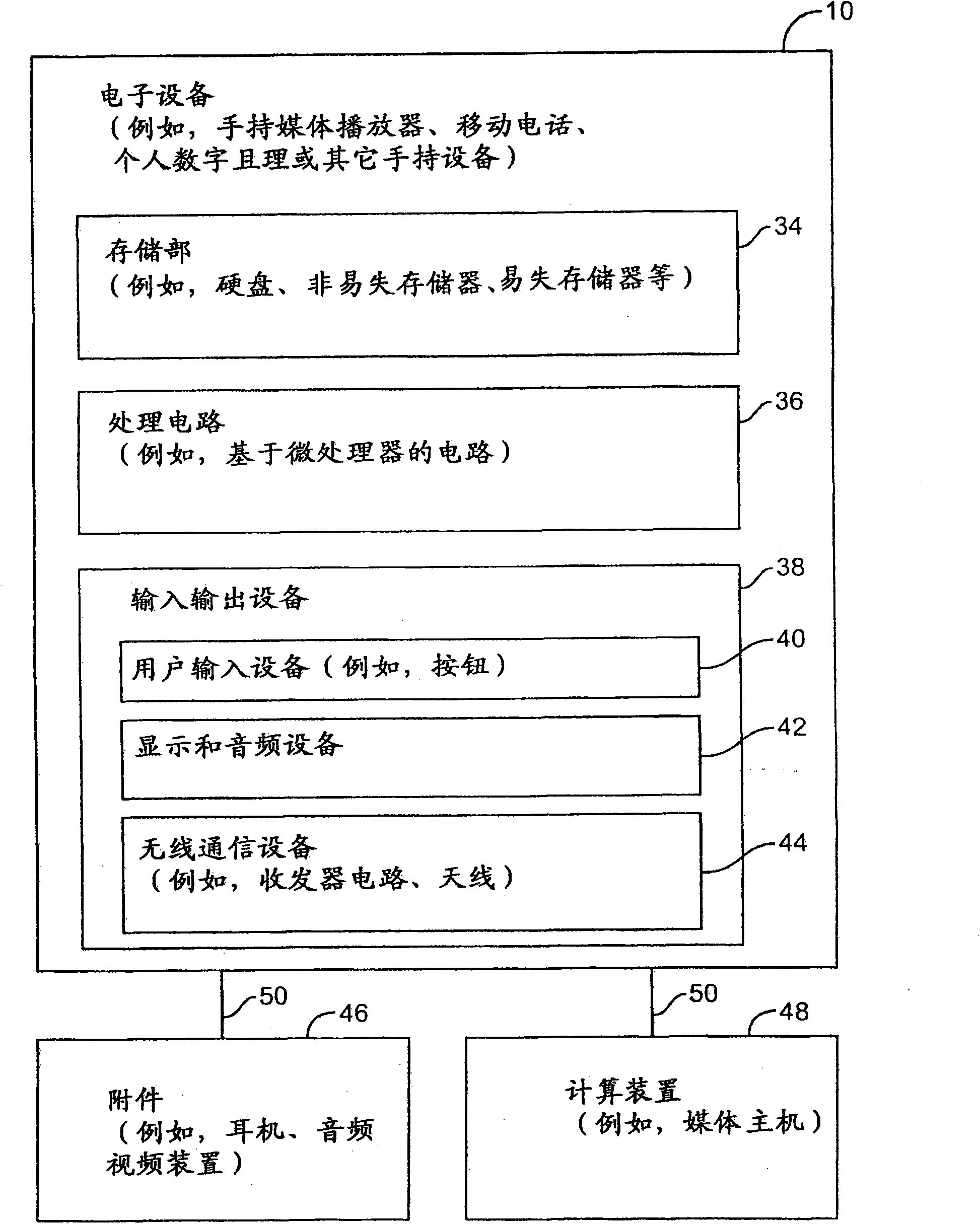

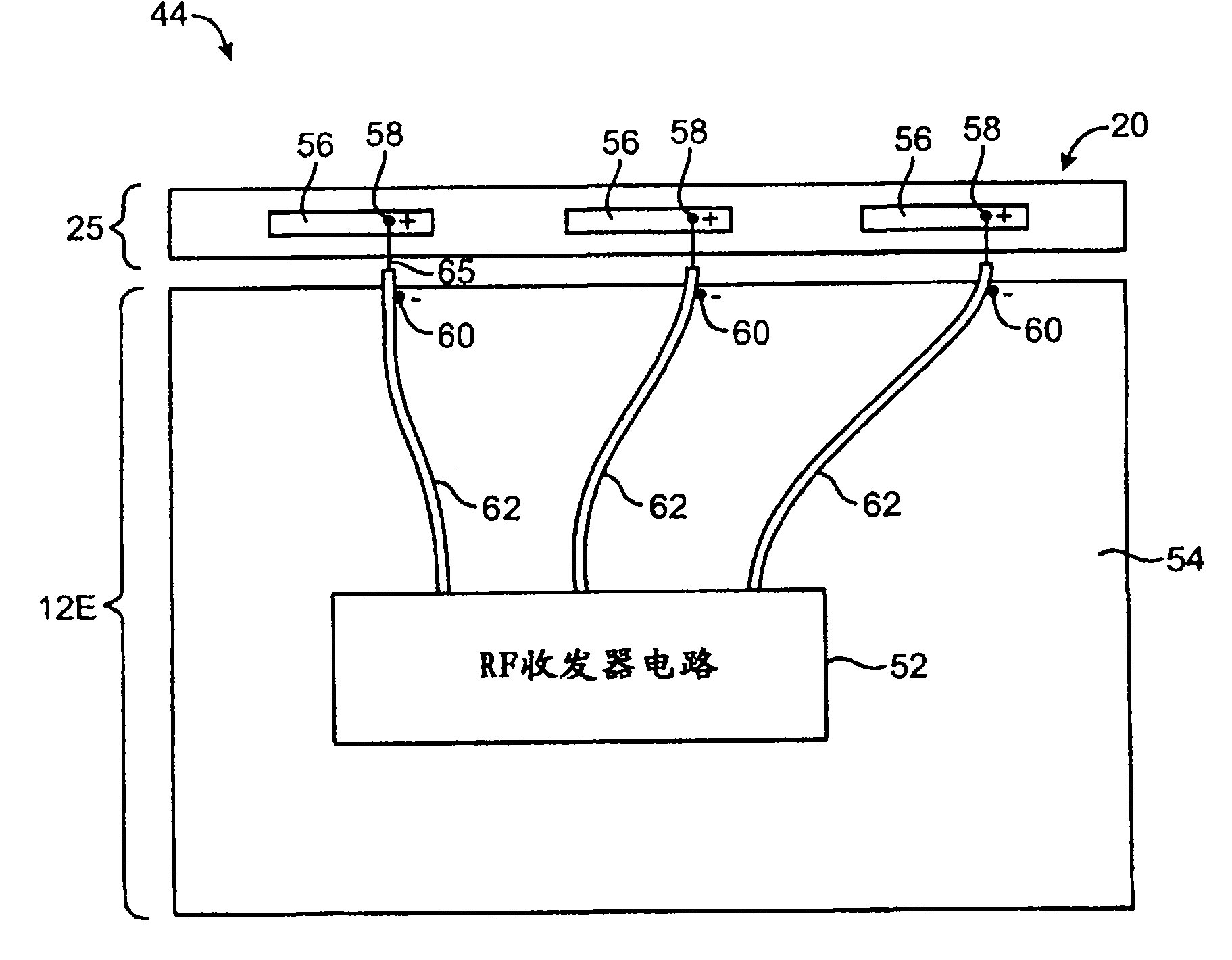

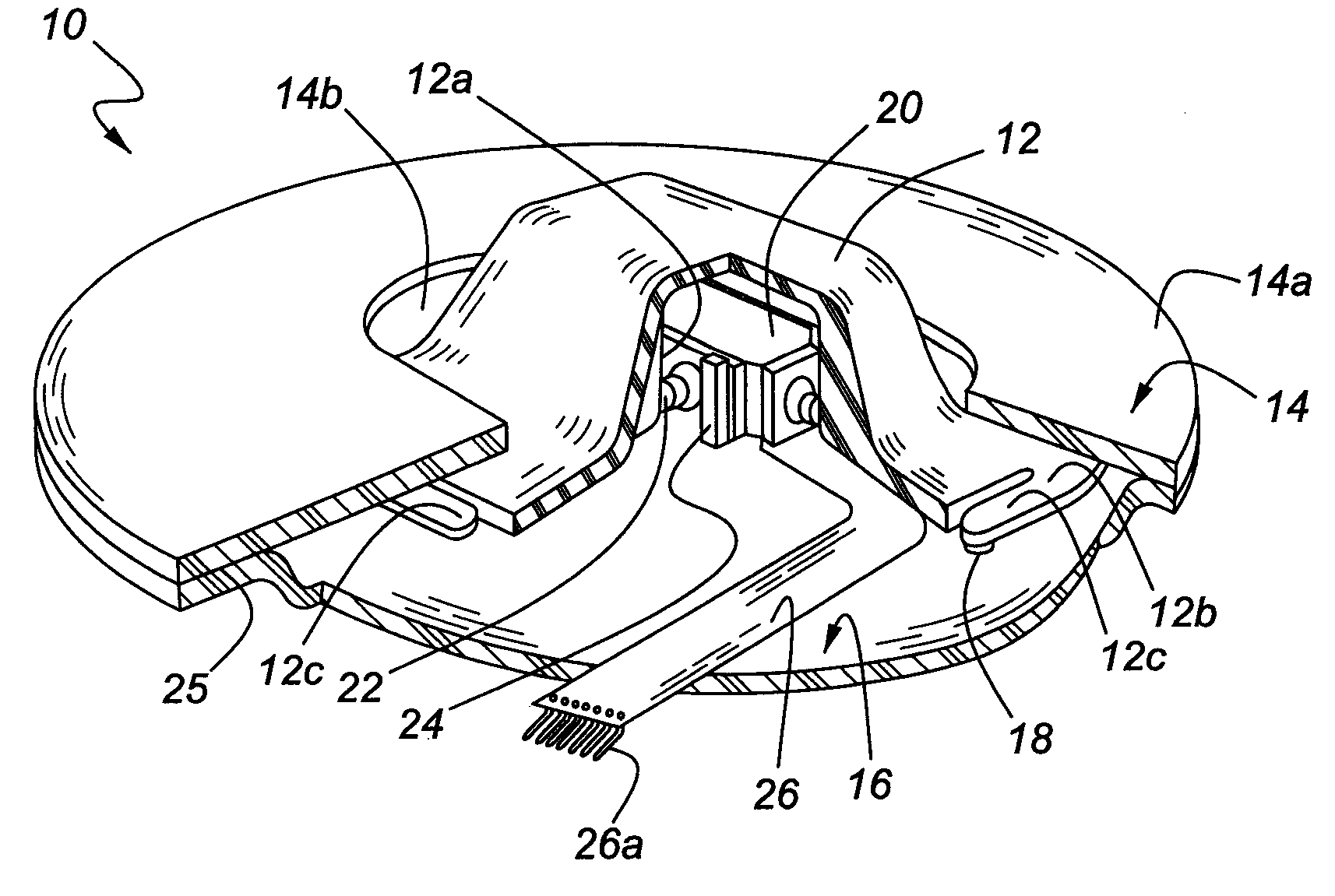

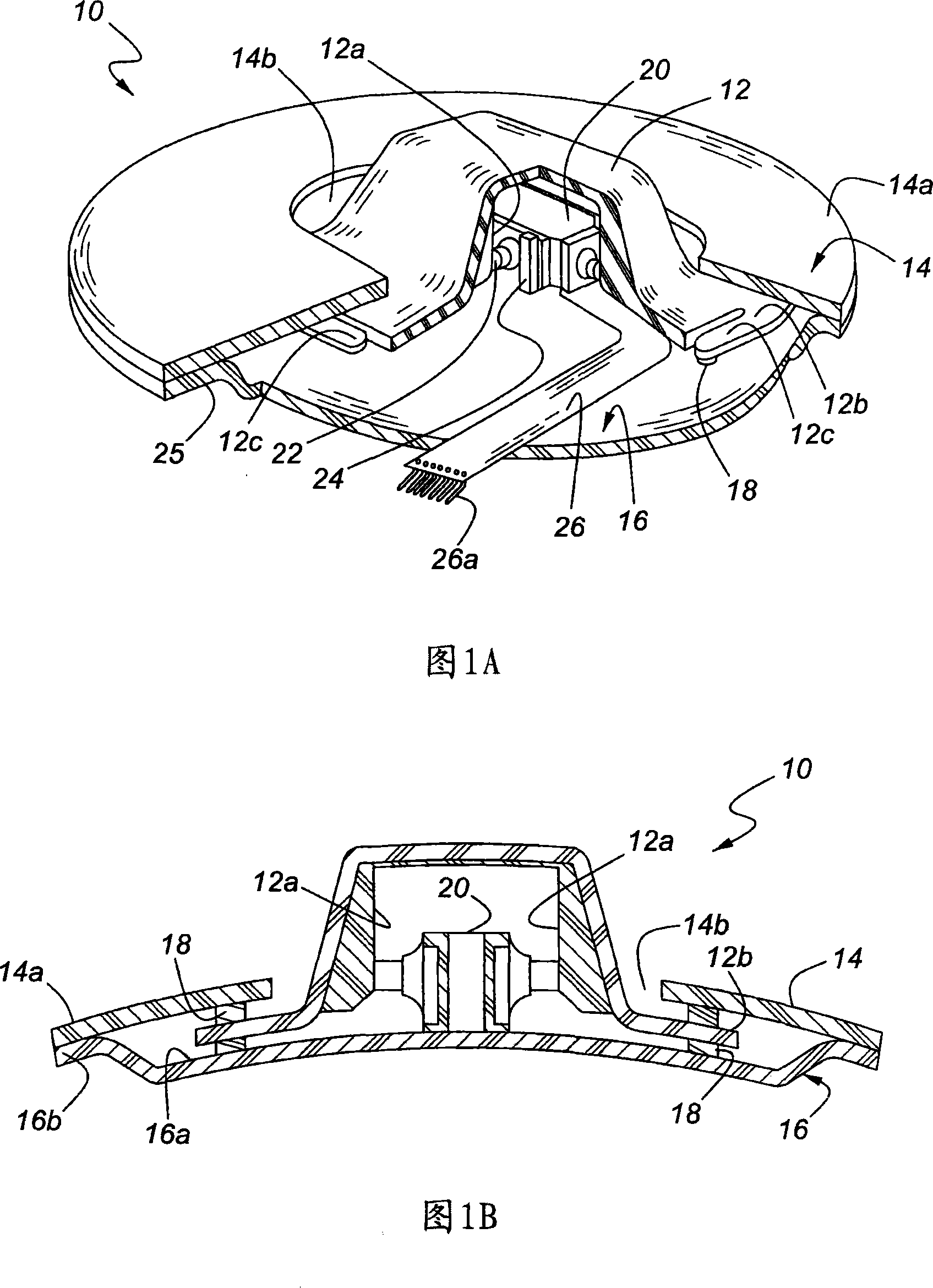

Antennas and antenna carrier structures for electronic devices

Antenna support structures and antennas are provided for wireless electronic devices such as portable electronic devices. Antenna resonating elements may be formed from conductive coatings on two-shot molded interconnect device dielectric antenna support structures. The conductive coatings may be formed from wet-plated copper or other conductive materials. The antenna support structure may have tabs that electrically connect antenna resonating elements to the case of a wireless electronic device that serves as an antenna ground plane. The antenna support structure may be curved about its longitudinal axis so that the antenna resonating elements on the support structure protrude upwards to enhance antenna performance. In a portable electronic device such as a portable computer, the antennasupport structure may be mounted within a dielectric portion of the computer housing that is located between the display portion of the housing and the base of the housing.

Owner:APPLE INC

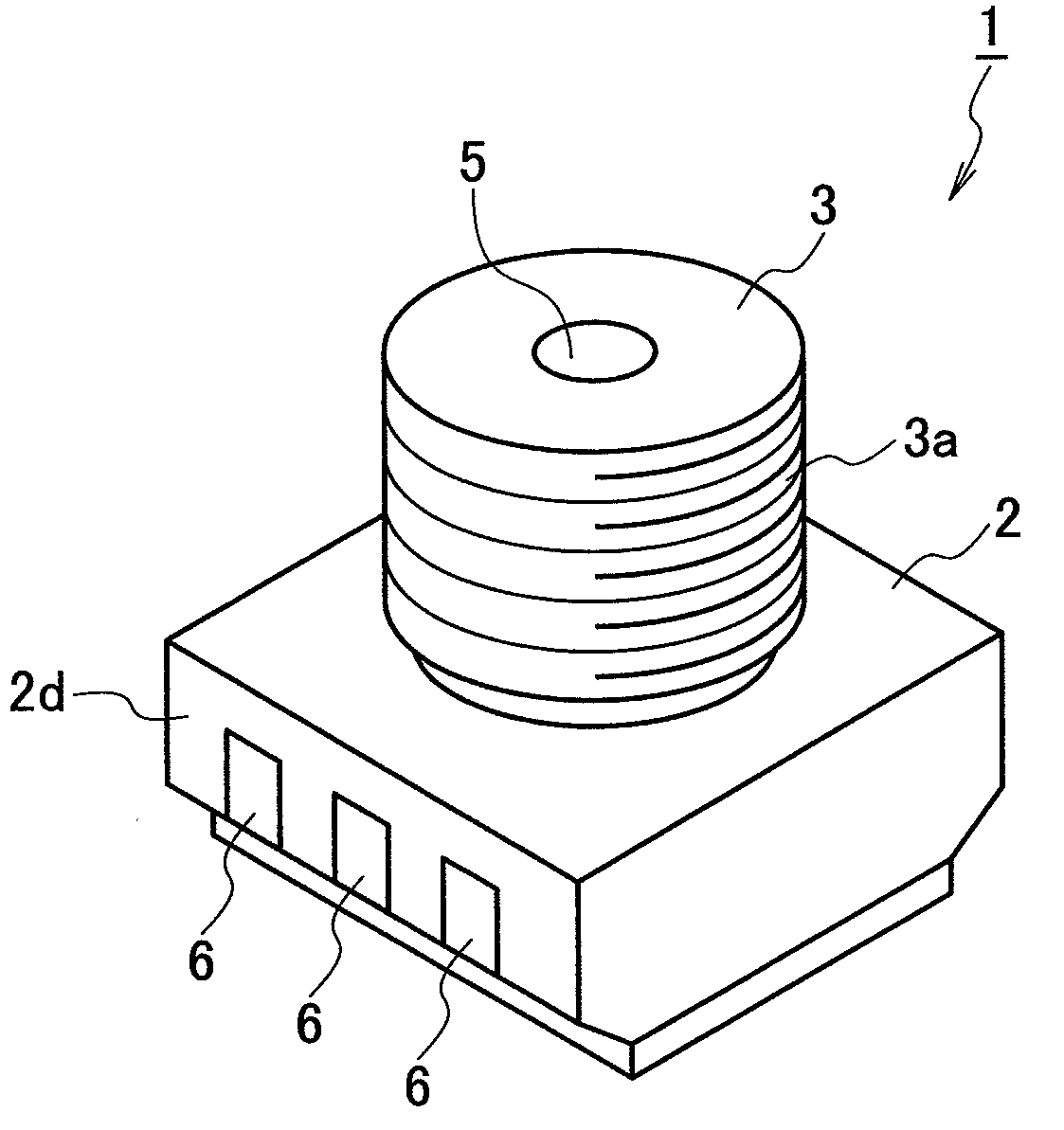

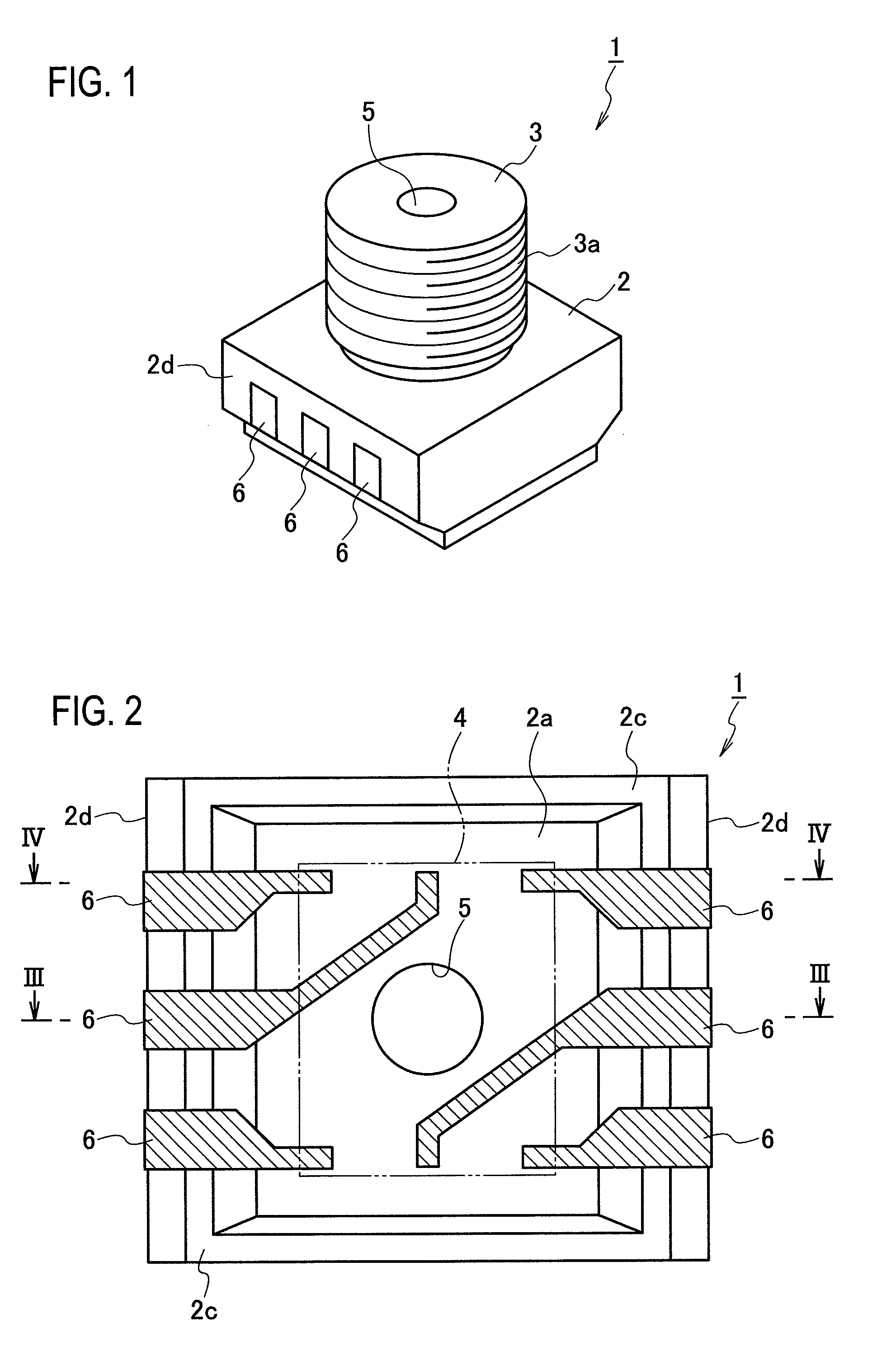

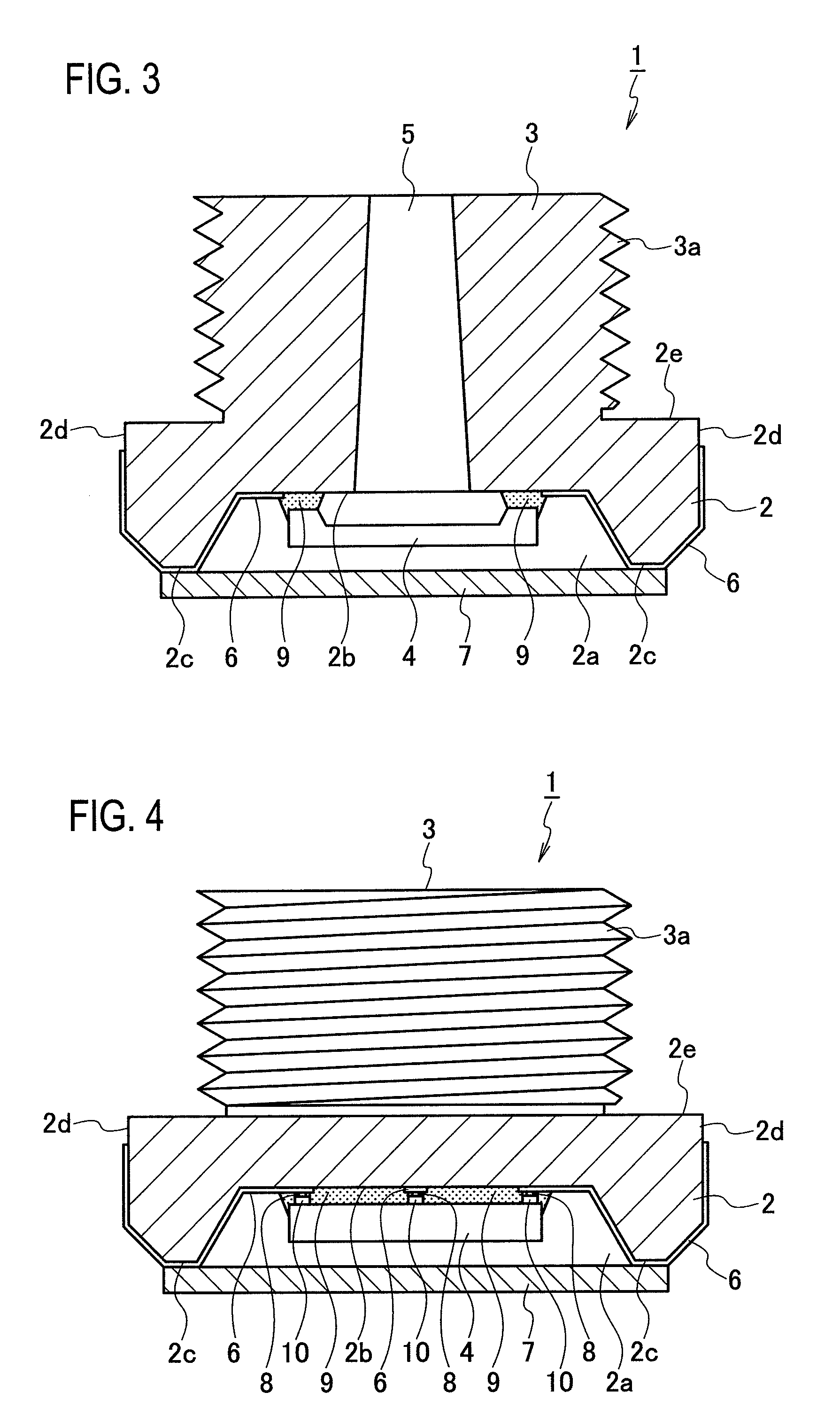

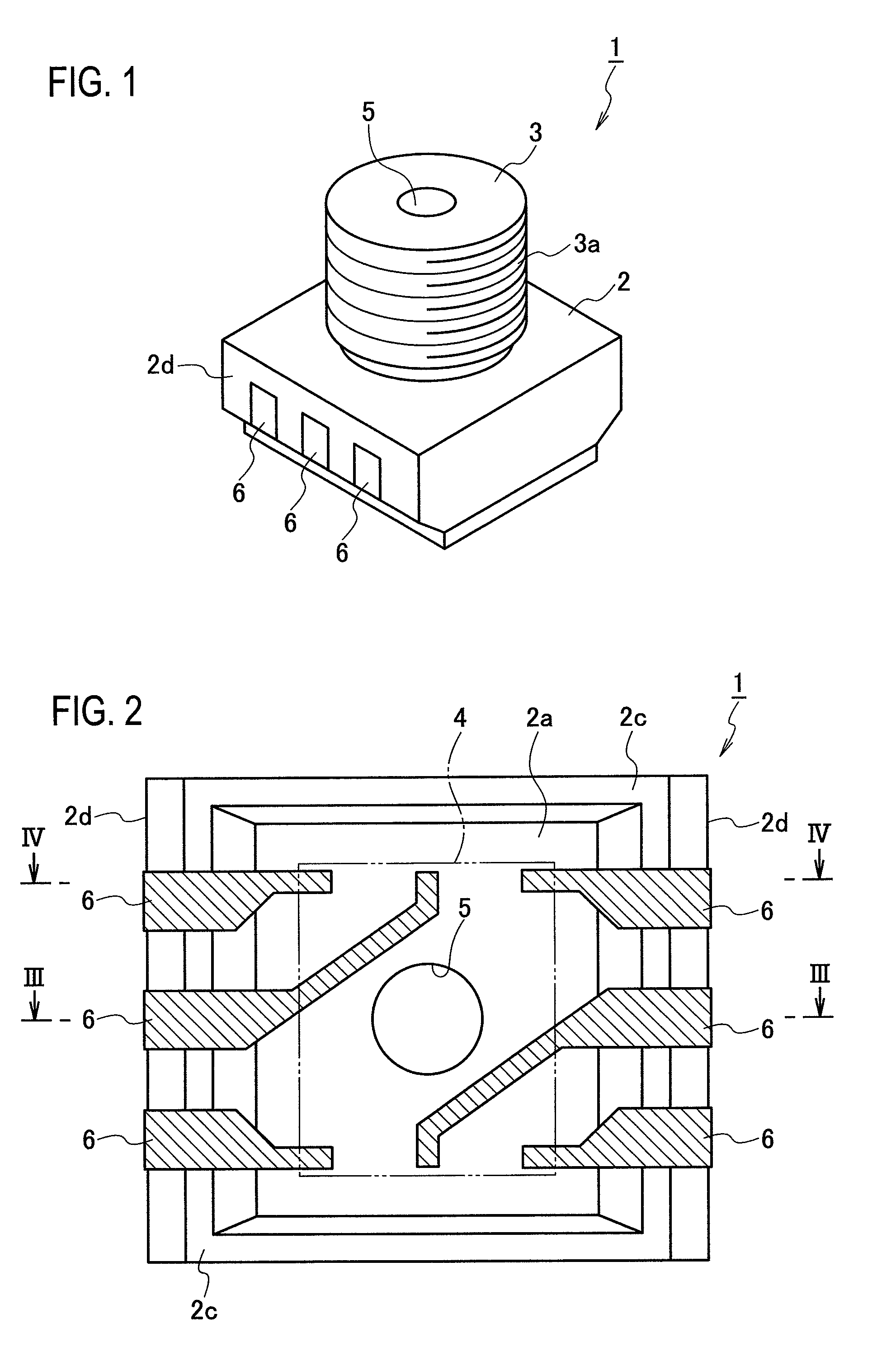

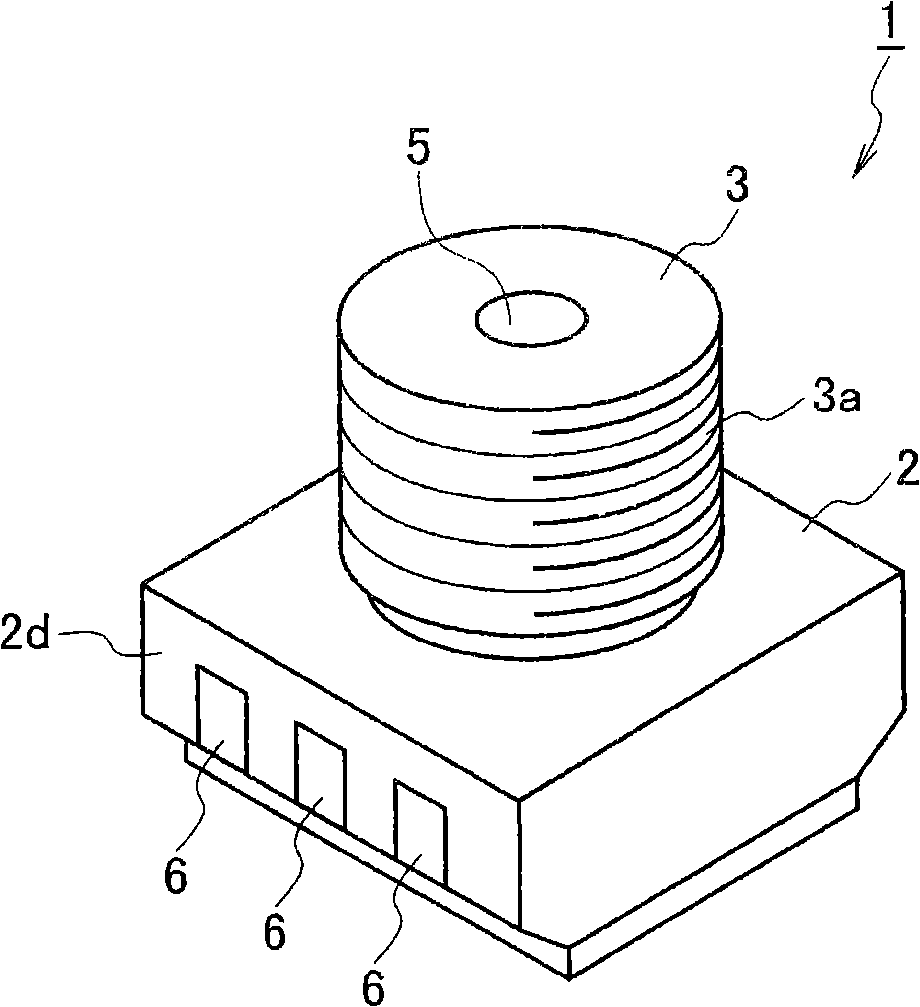

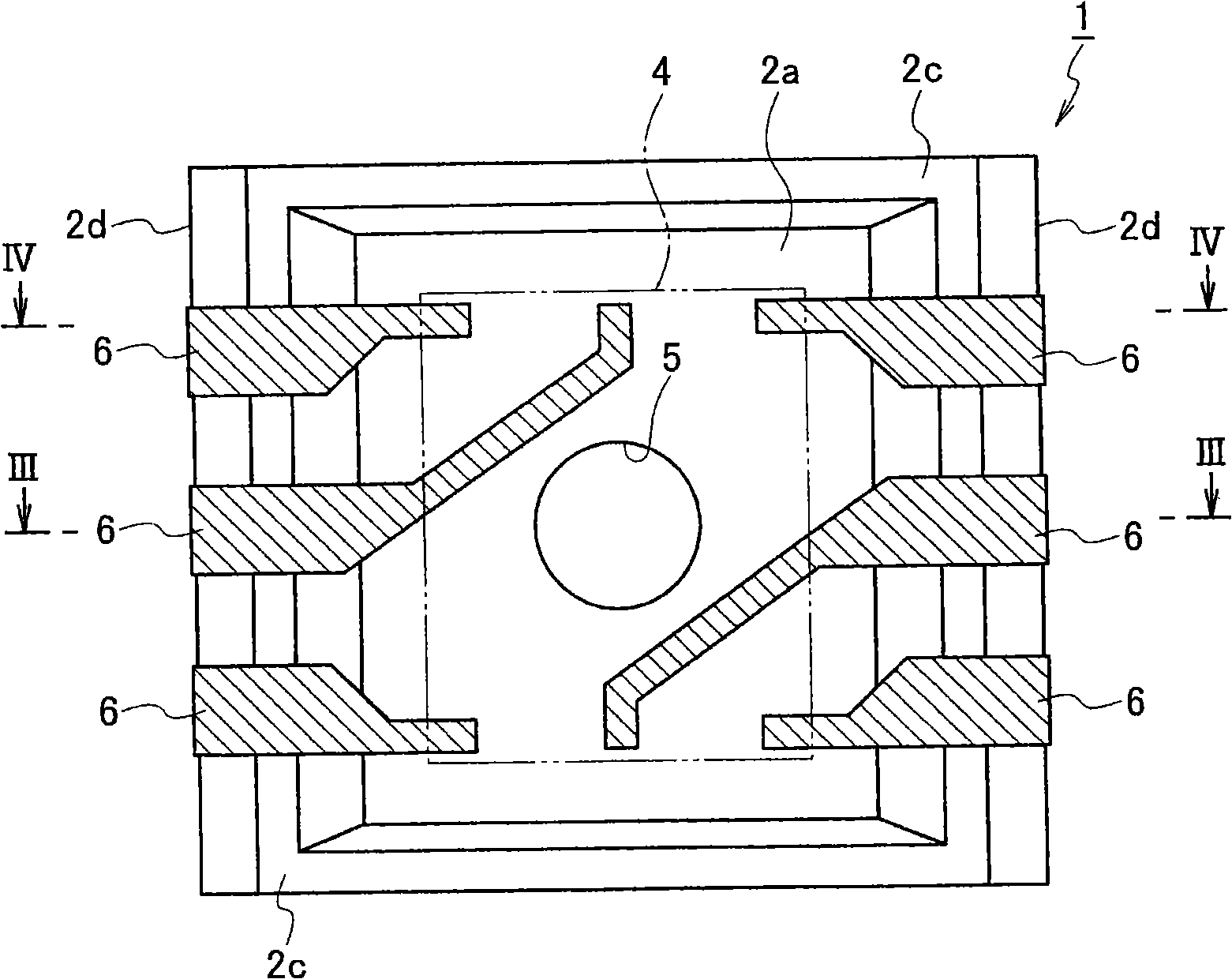

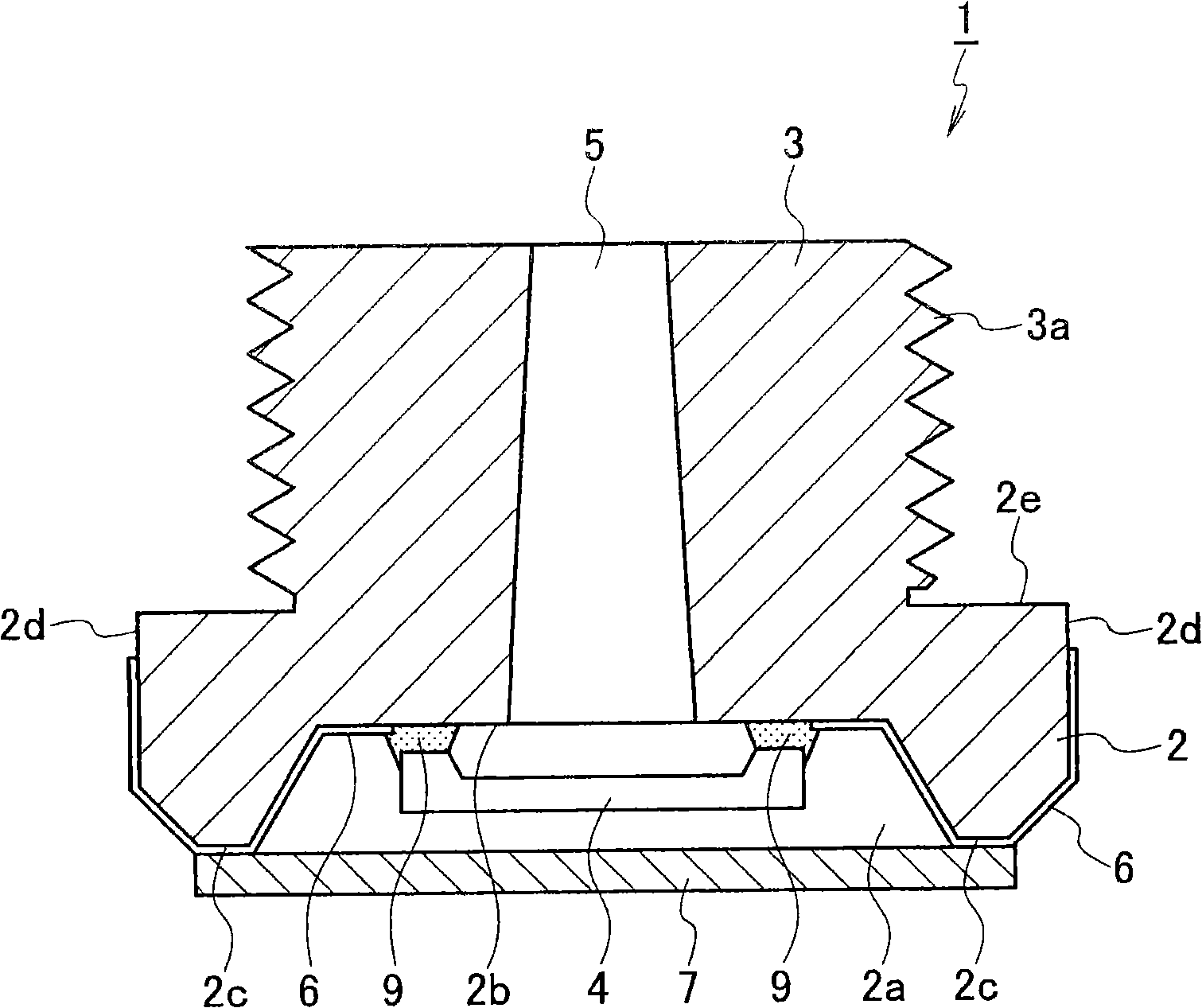

Pressure sensor

InactiveUS20090266173A1Fluid pressure measurement using capacitance variationSemiconductor devicesEngineeringPressure sensor

In a pressure sensor including a pressure detecting element in an intermediate portion or at a deep side of a through hole formed in a protrusion, a body portion (a base portion and the protrusion) is made of ceramic or an insulative resin material and molded into a predetermined shape, and the pressure sensor is constituted as a molded interconnect device in which a conductive pattern is formed on a surface thereof. Accordingly, a smaller pressure sensor can be obtained.

Owner:MATSUSHITA ELECTRIC WORKS LTD

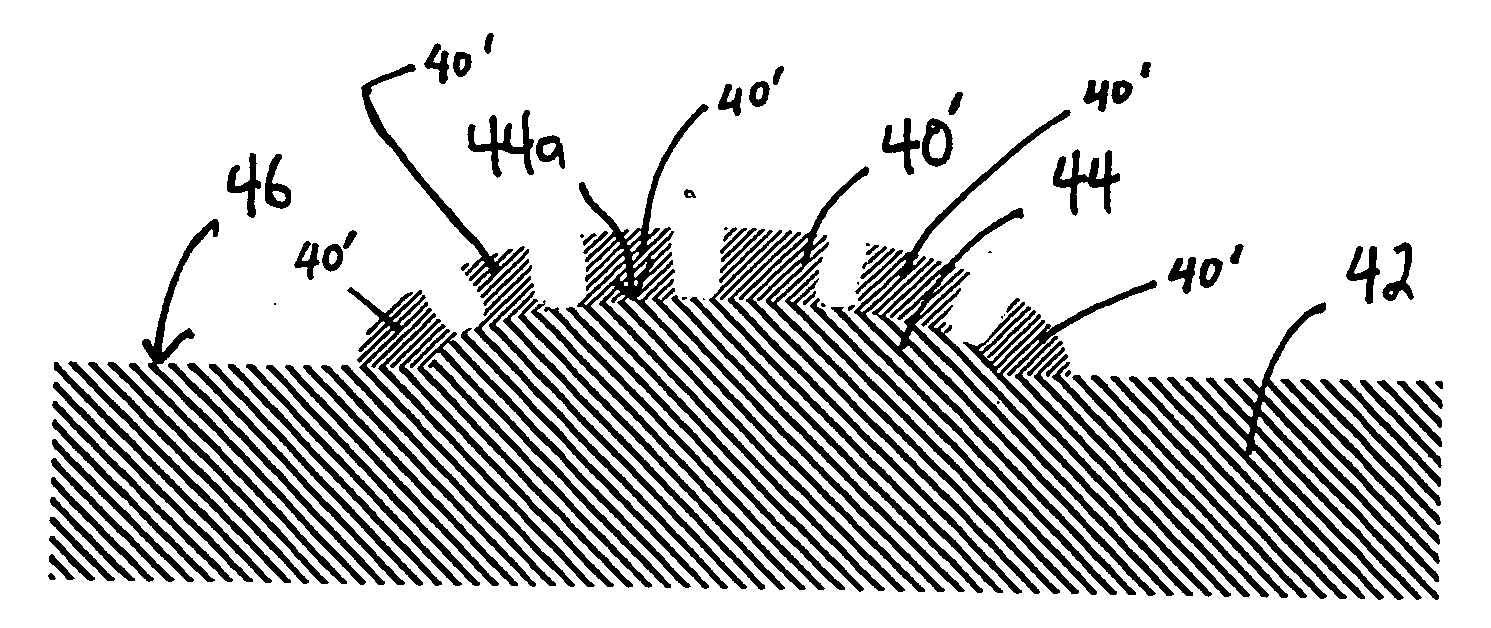

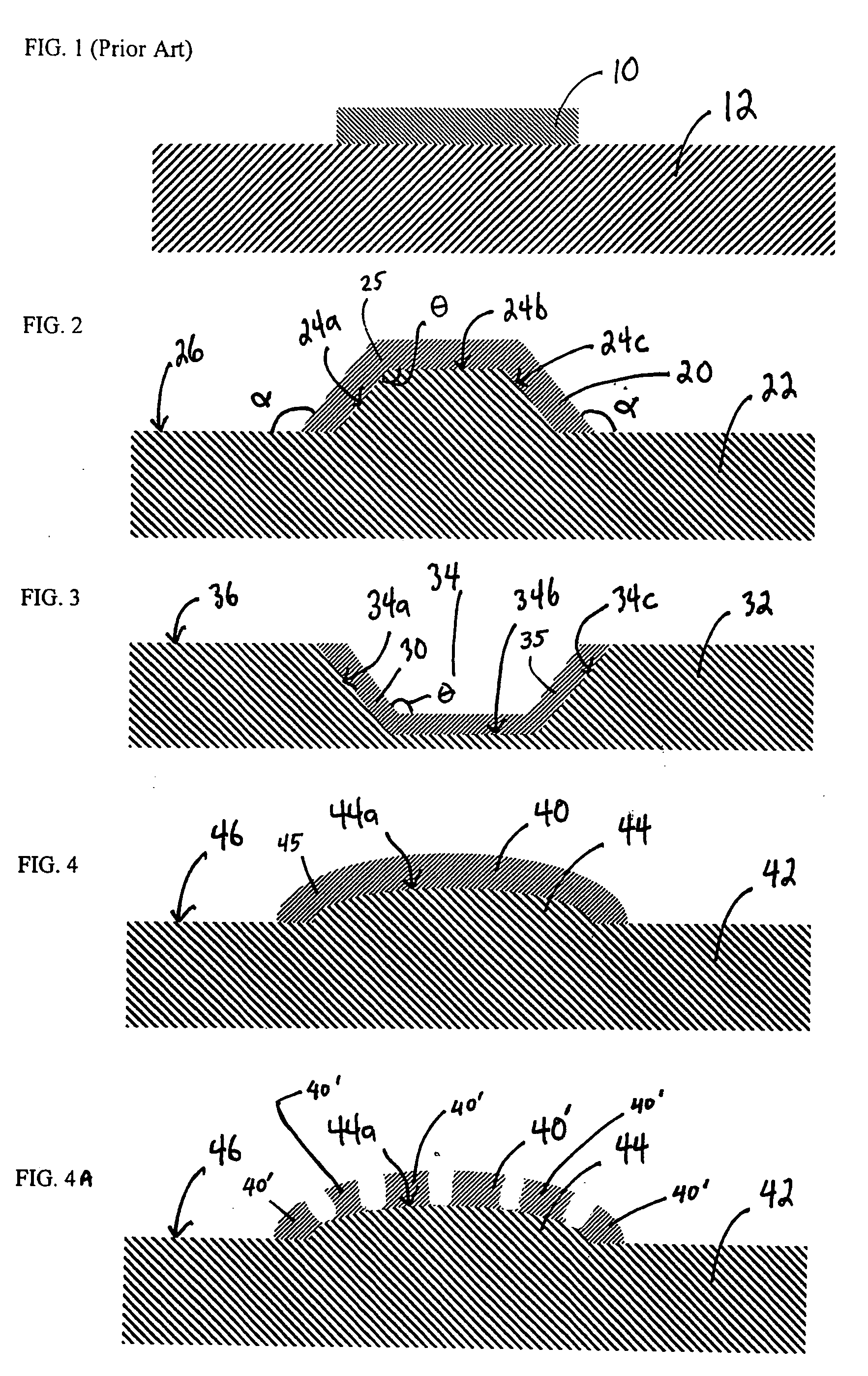

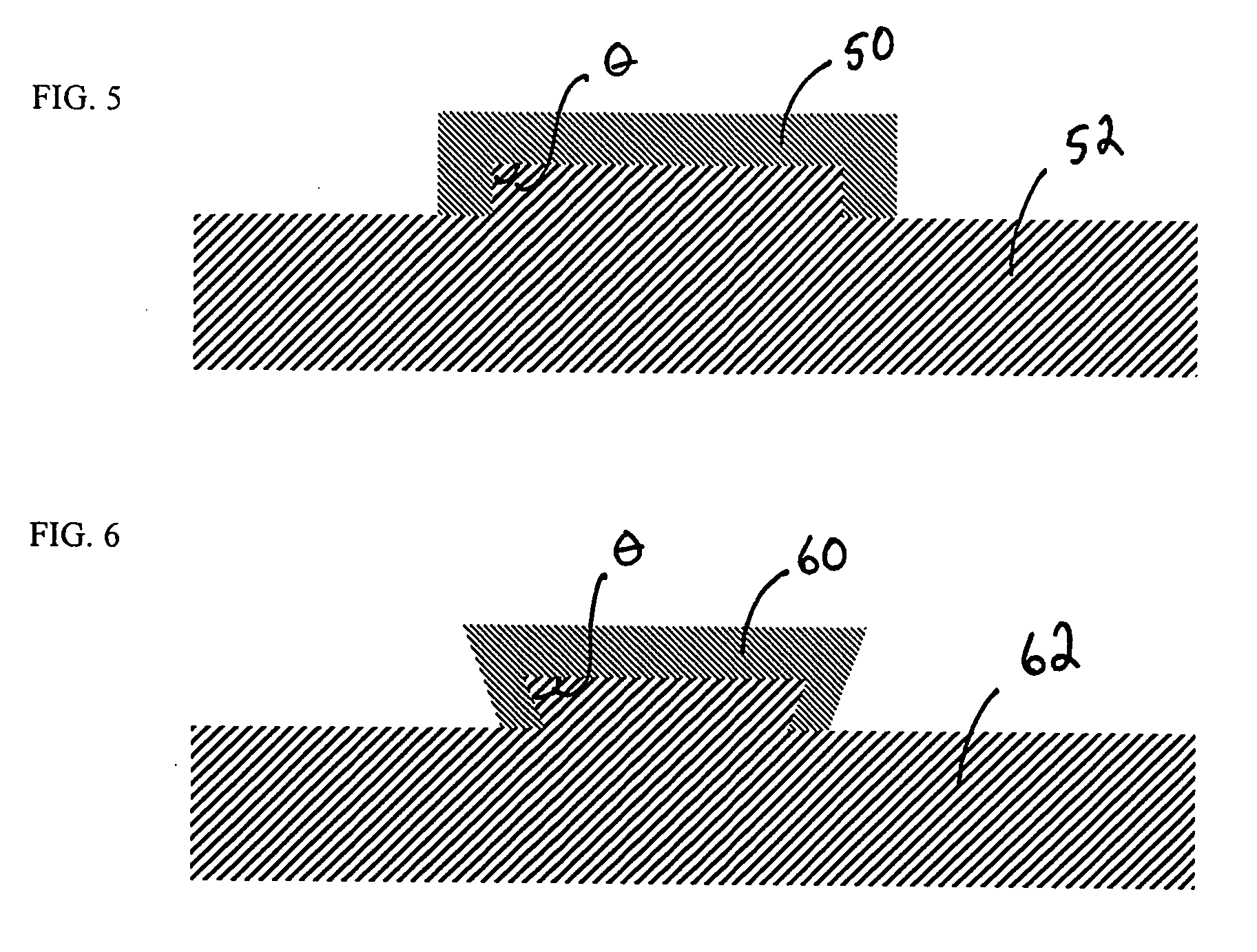

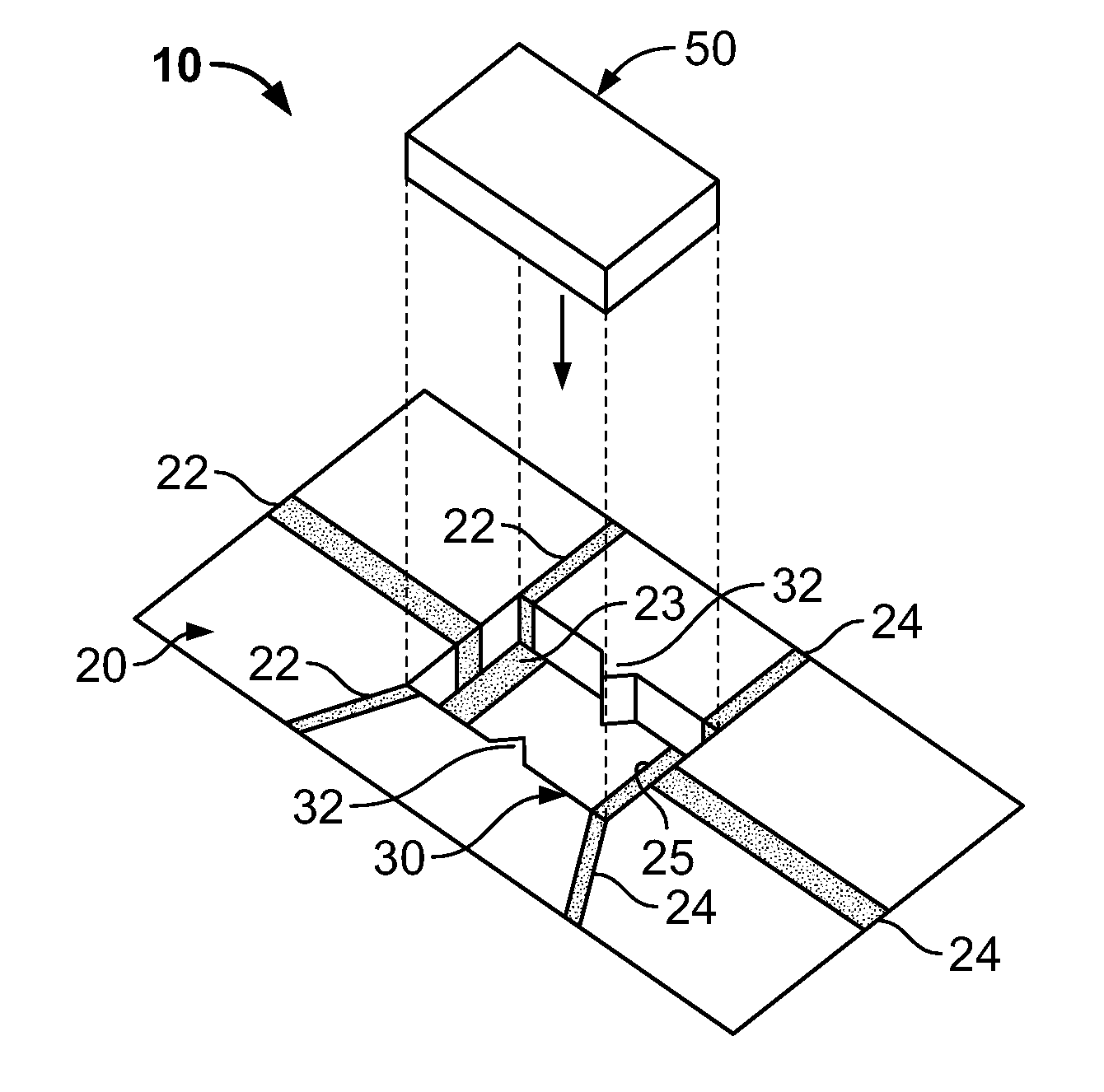

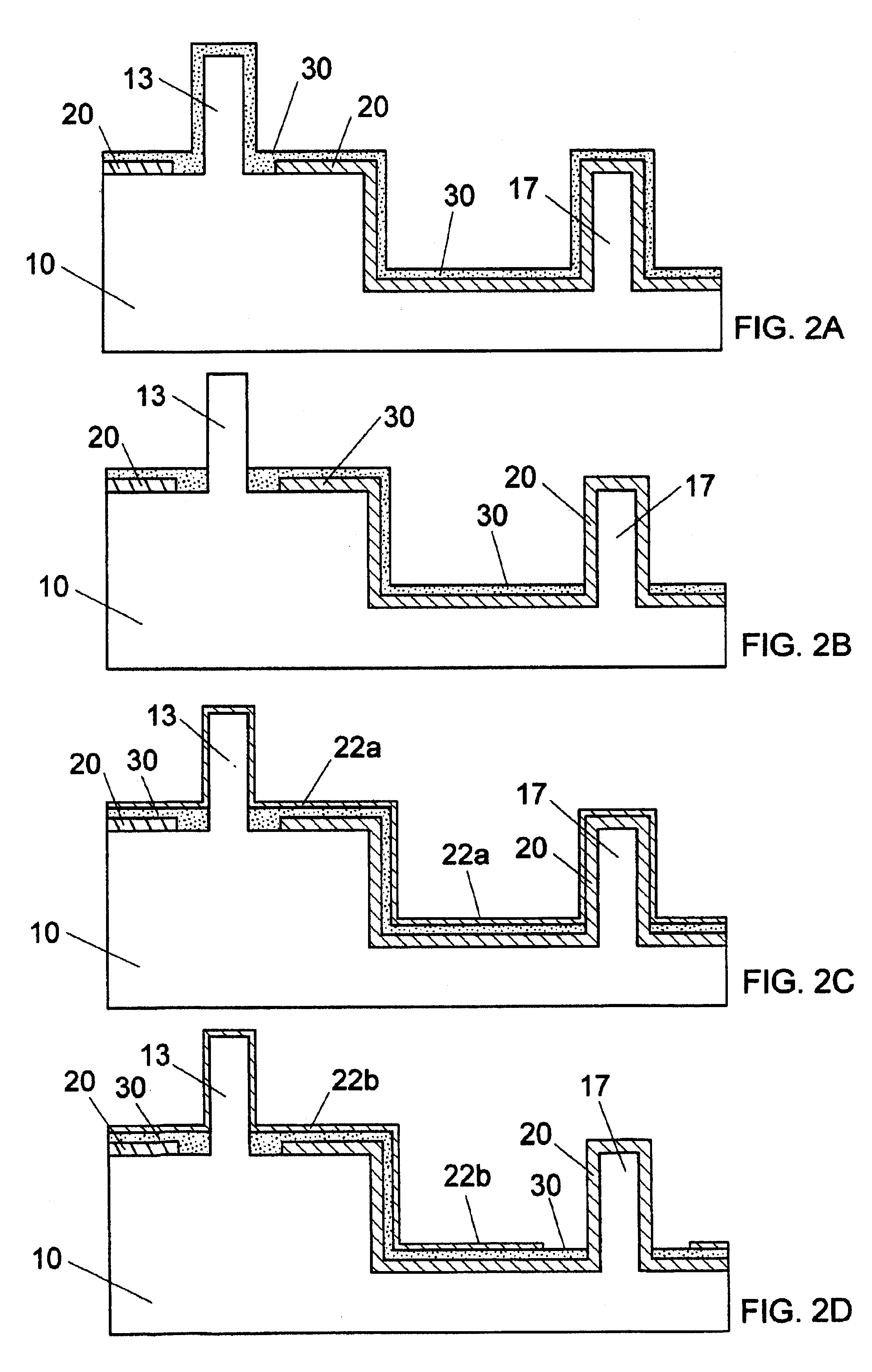

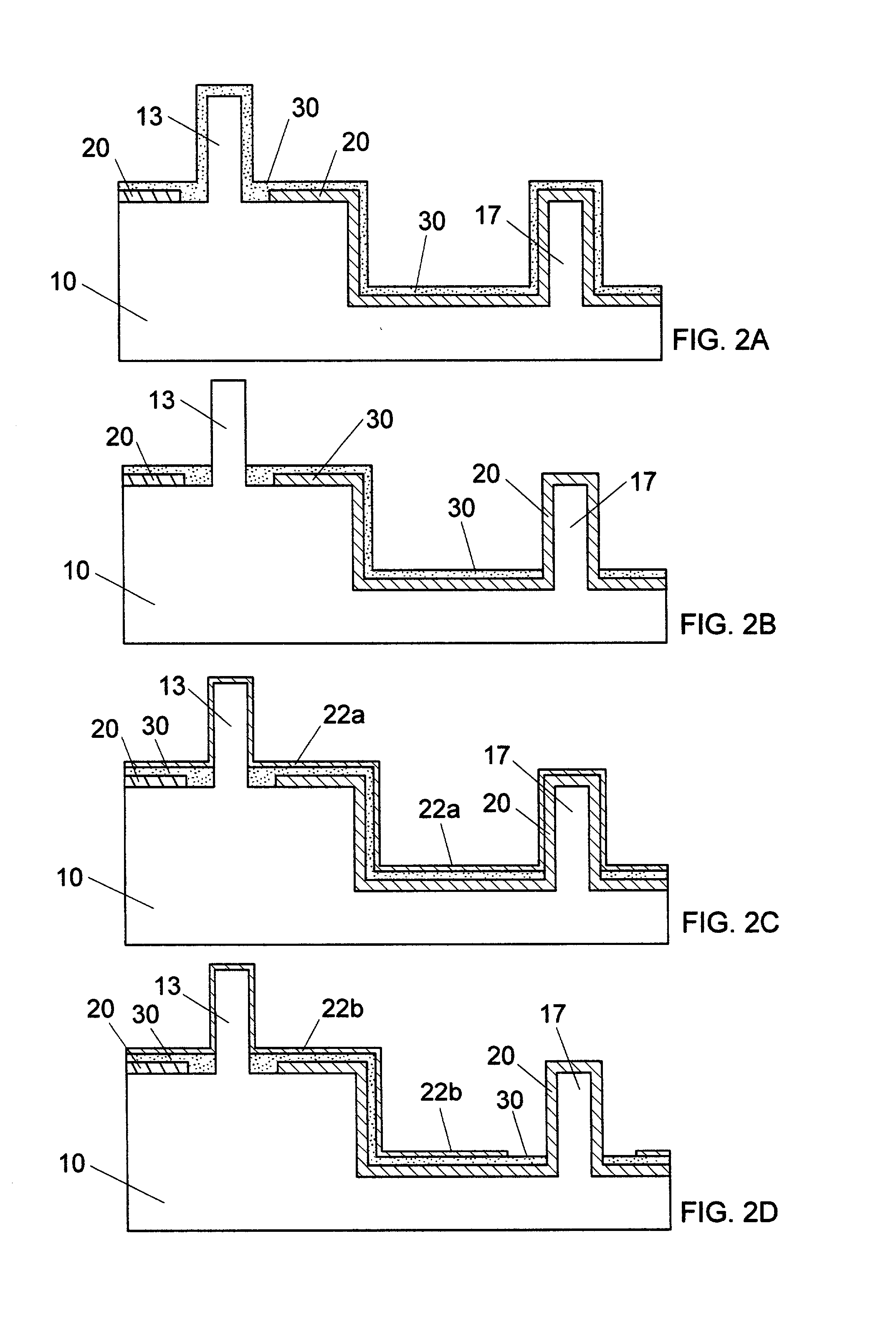

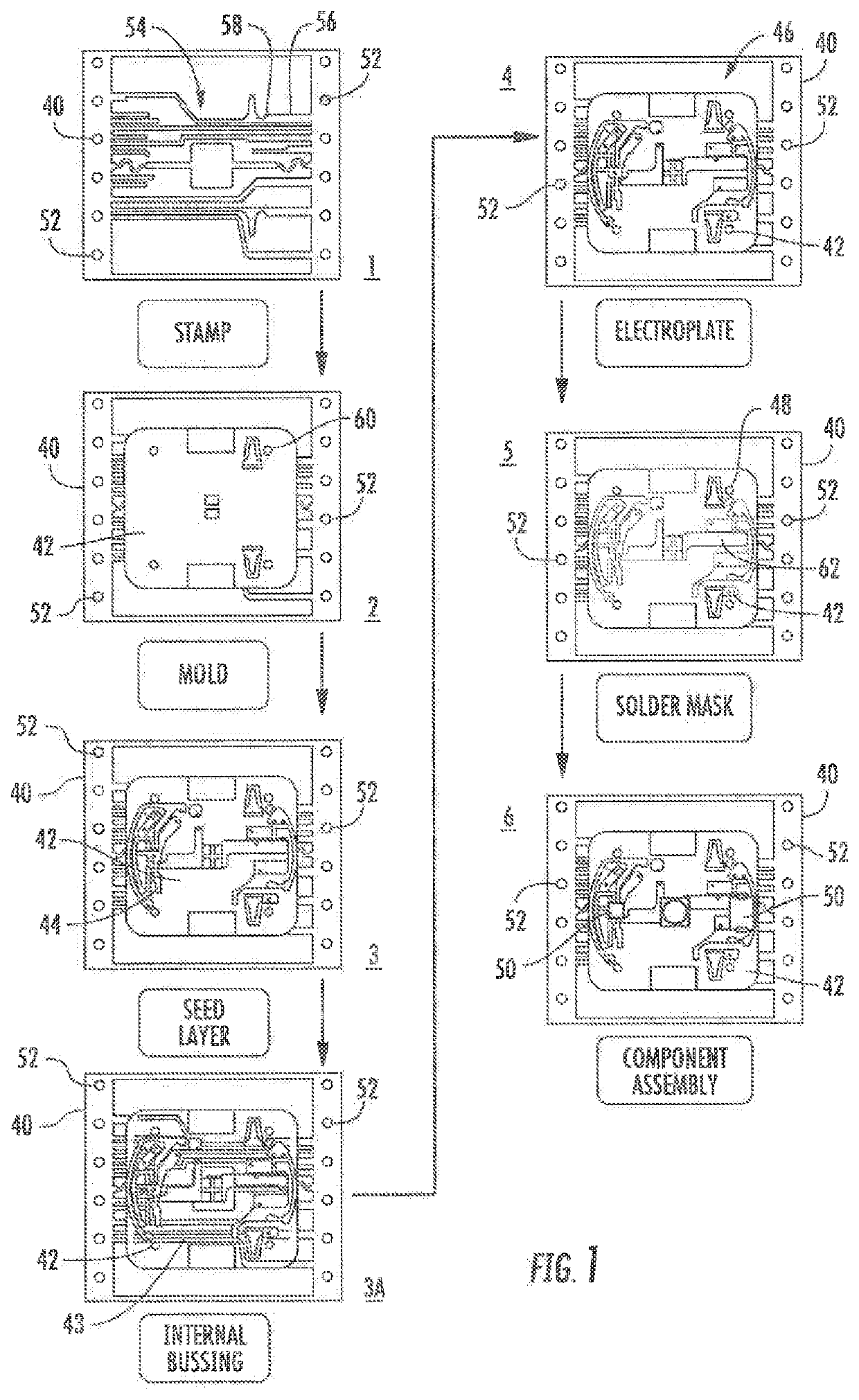

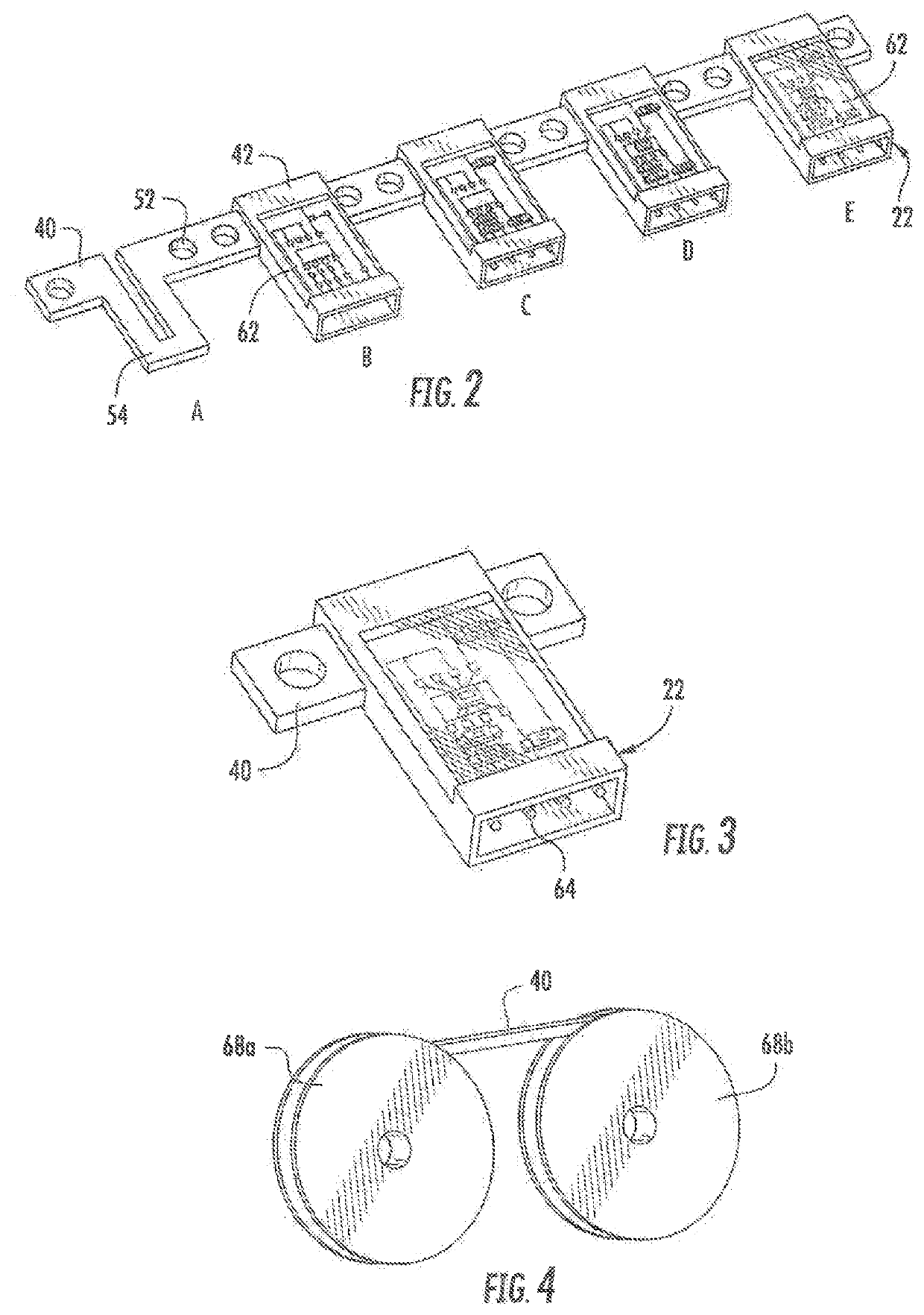

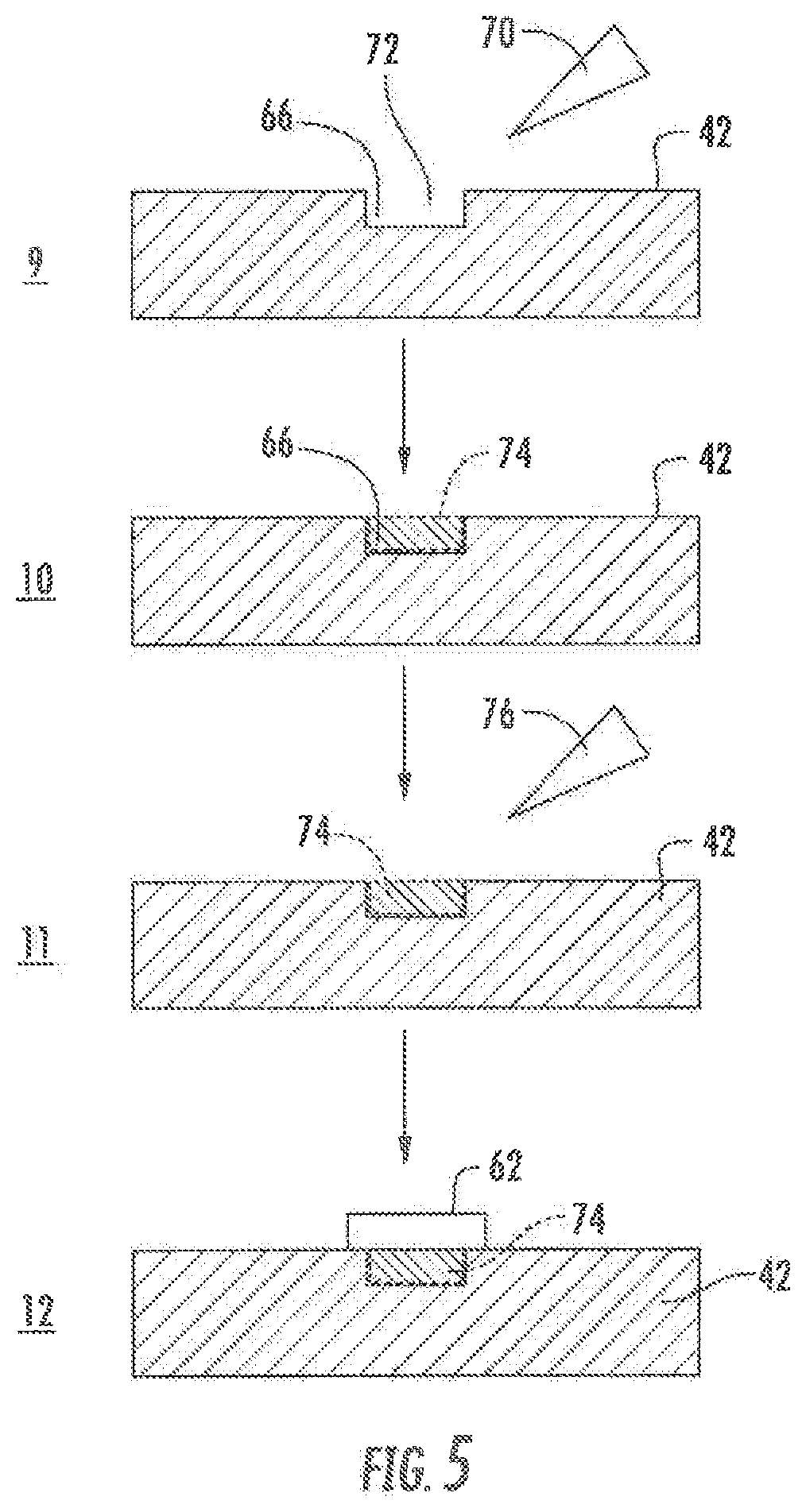

High-current traces on plated molded interconnect device

A molded interconnect device with a high-current trace and methods of making a molded interconnect device with a high-current trace are described. The molded interconnect device comprises a substrate surface and an interconnect pattern. The interconnect pattern is at least one of a rib raised from the substrate surface and a channel protruding into the substrate surface. In a first embodiment, the molded interconnect device is molded from photosensitive plastic molded in a one-shot molding process. A trace is grown on the portion of the interconnect pattern where an interconnect path has been written, either by a laser or by photolithography. In a second embodiment, the molded interconnect device is molded of plastic and the trace is grown by at least one of a mask and print-and-plate process and a mask and print-and-etch process. The trace forms at least one of an angle and a curve in cross section.

Owner:MOLEX INC

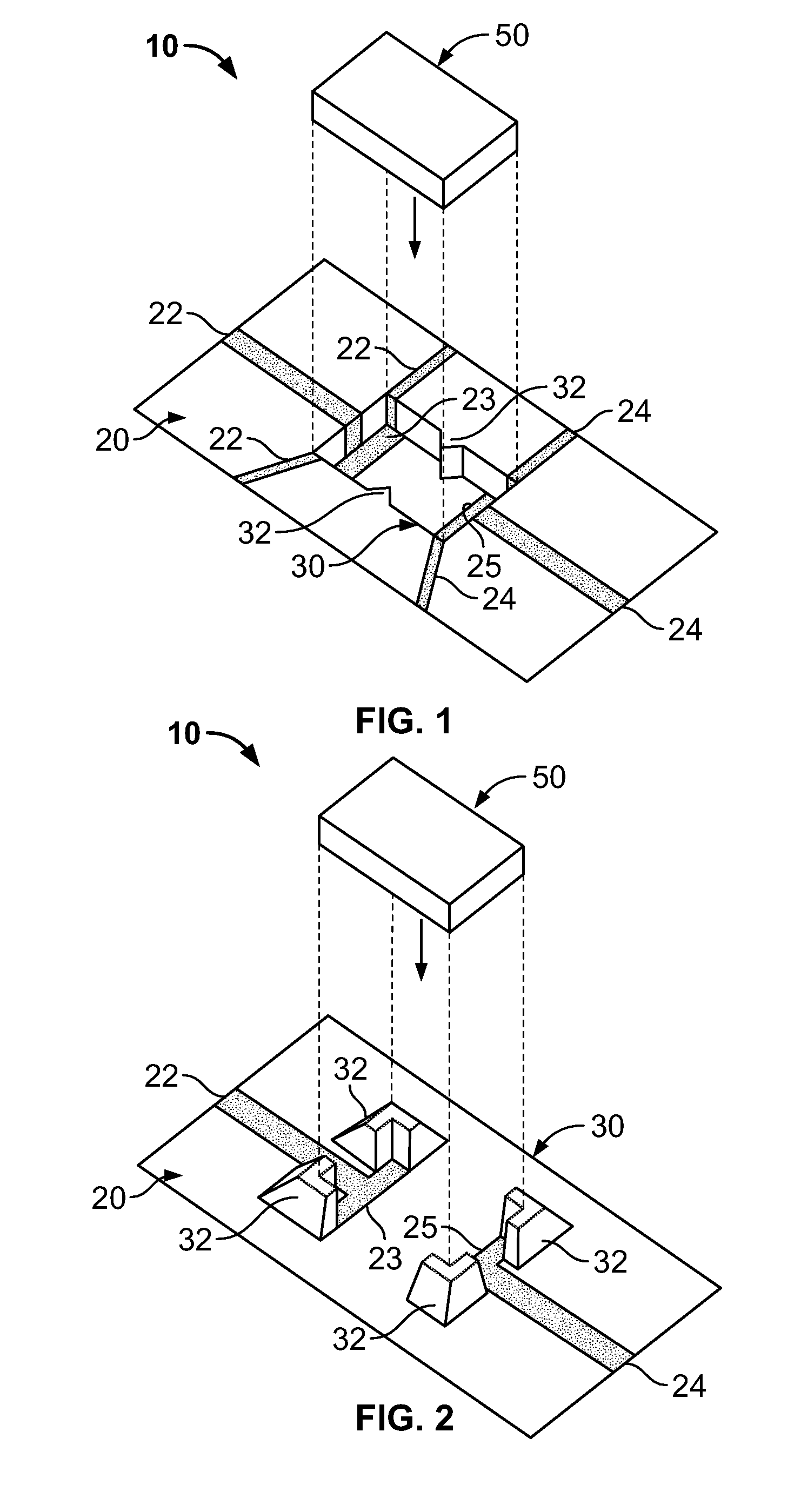

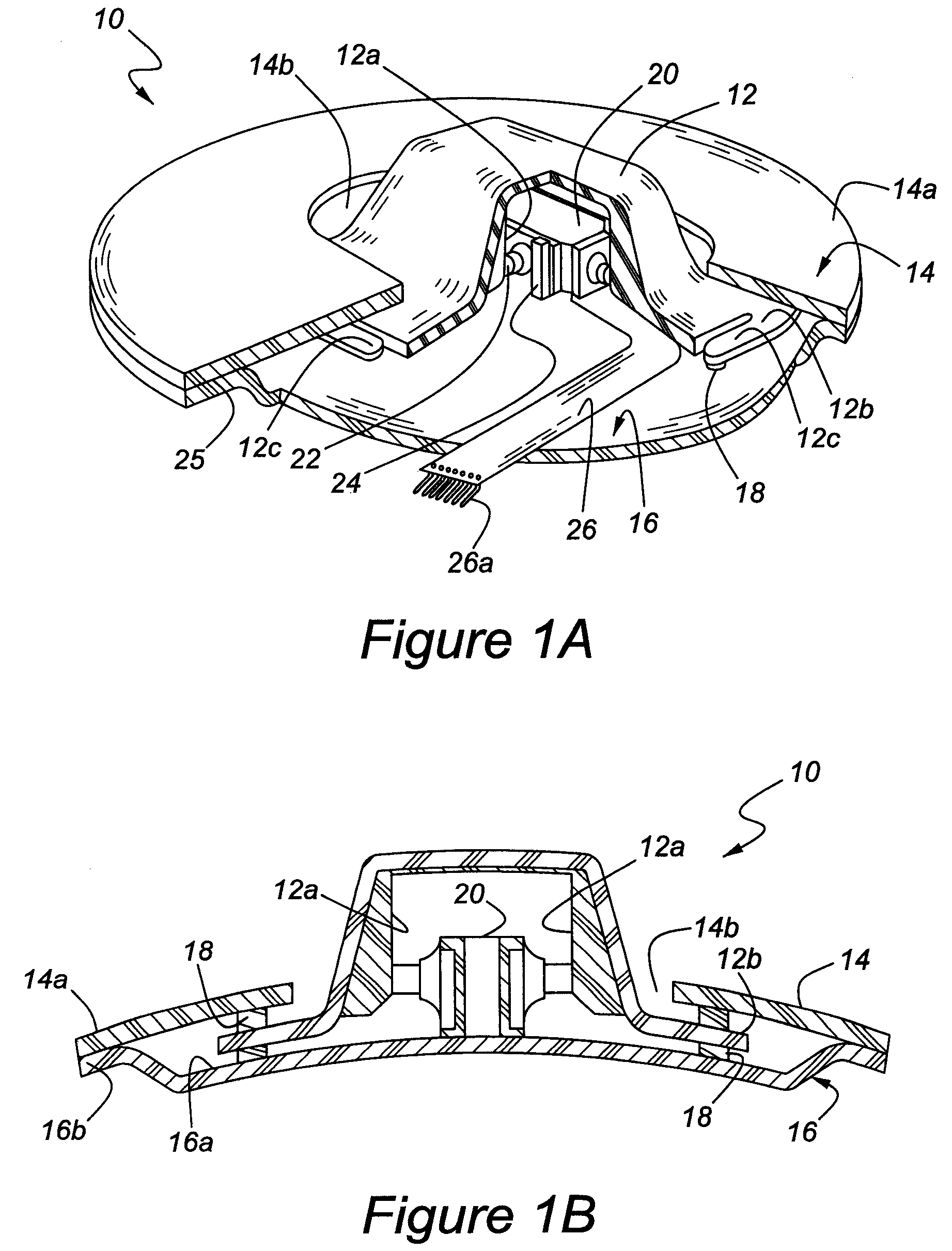

System for attaching electronic components to molded interconnection devices

InactiveUS7876577B2Printed circuit assembling3D rigid printed circuitsElectrical devicesElectrical connection

A system for connecting electrical devices to one another is provided. This system includes a horizontal or non-horizontal substrate and an anchor connected to or formed integrally with the substrate. The anchor is either a raised structure or a recessed structure, and further includes at least one retention member formed integrally with the anchor. At least one electronic component is mounted within the anchor and the at least one retention member secures the component to the substrate. At least one electrical trace is disposed on the substrate and the at least one electrical trace extends into the anchor, contacts the at least one electronic component, and forms an electrical connection between the substrate and the at least one electronic component.

Owner:TE CONNECTIVITY CORP

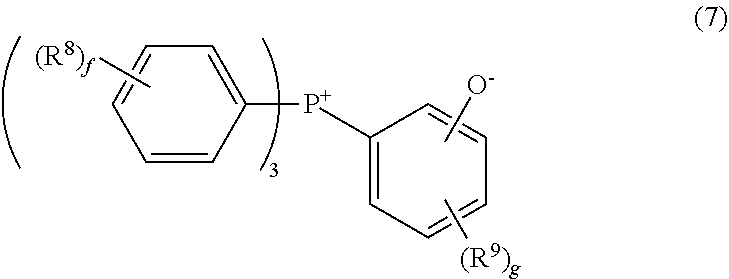

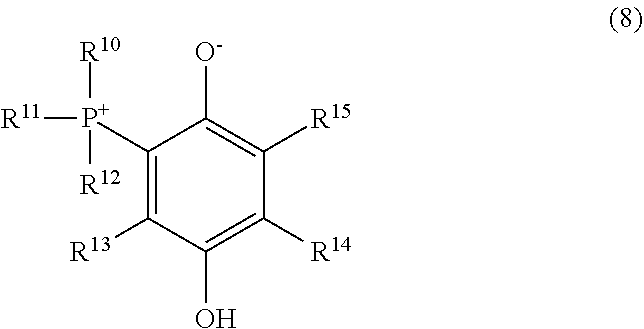

Core-shell composite inorganic metal oxides and method of preparing for prevention of thermal oxidative degradation in polymer and resin compositions

ActiveUS20150291778A1Inorganic pigment treatmentPrinted circuit aspectsThermoplasticChemical synthesis

This invention relates to products of aqueous and other chemical synthetic routes for encapsulation of a core material with an inorganic shell and finished compositions of a core-shell particulate material for application in thermoplastic, thermoset, and coatings resins prior to compounding or application or subsequent thermal processing steps. Disclosed is a composition of particles containing a shell of inorganic oxides or mixed-metal inorganic oxides and a core material of complex inorganic colored pigment, laser direct structuring additives, laser marking, or other beneficial metal oxides, metal compounds, or mixed-metal oxide materials, wherein the shell material is comprised of any single oxide or combination of oxides is taught. Preferred elements of composition for the shell are oxides and silicates of B, Ni, Zn, Al, Zr, Si, Sn, Bi, W, Mo, Cr, Mg, Mn, Ce, Ti, and Ba (or mixtures thereof). Applications may include, but are not limited to, coatings or plastic articles or materials for molded interconnect devices, durable goods, housings, assemblies, devices, and articles that are to be exposed to additional thermal processing. The resulting core-shell materials function in plastic and coatings formulations by minimizing or eliminating detrimental interactions with the resins and metal containing additives resulting in loss of mechanical properties.

Owner:SHEPHERD COLOR COMPANY +1

Pressure sensor

InactiveUS7992445B2Fluid pressure measurement using capacitance variationSemiconductor devicesEngineeringPressure sensor

In a pressure sensor including a pressure detecting element in an intermediate portion or at a deep side of a through hole formed in a protrusion, a body portion (a base portion and the protrusion) is made of ceramic or an insulative resin material and molded into a predetermined shape, and the pressure sensor is constituted as a molded interconnect device in which a conductive pattern is formed on a surface thereof. Accordingly, a smaller pressure sensor can be obtained.

Owner:MATSUSHITA ELECTRIC WORKS LTD

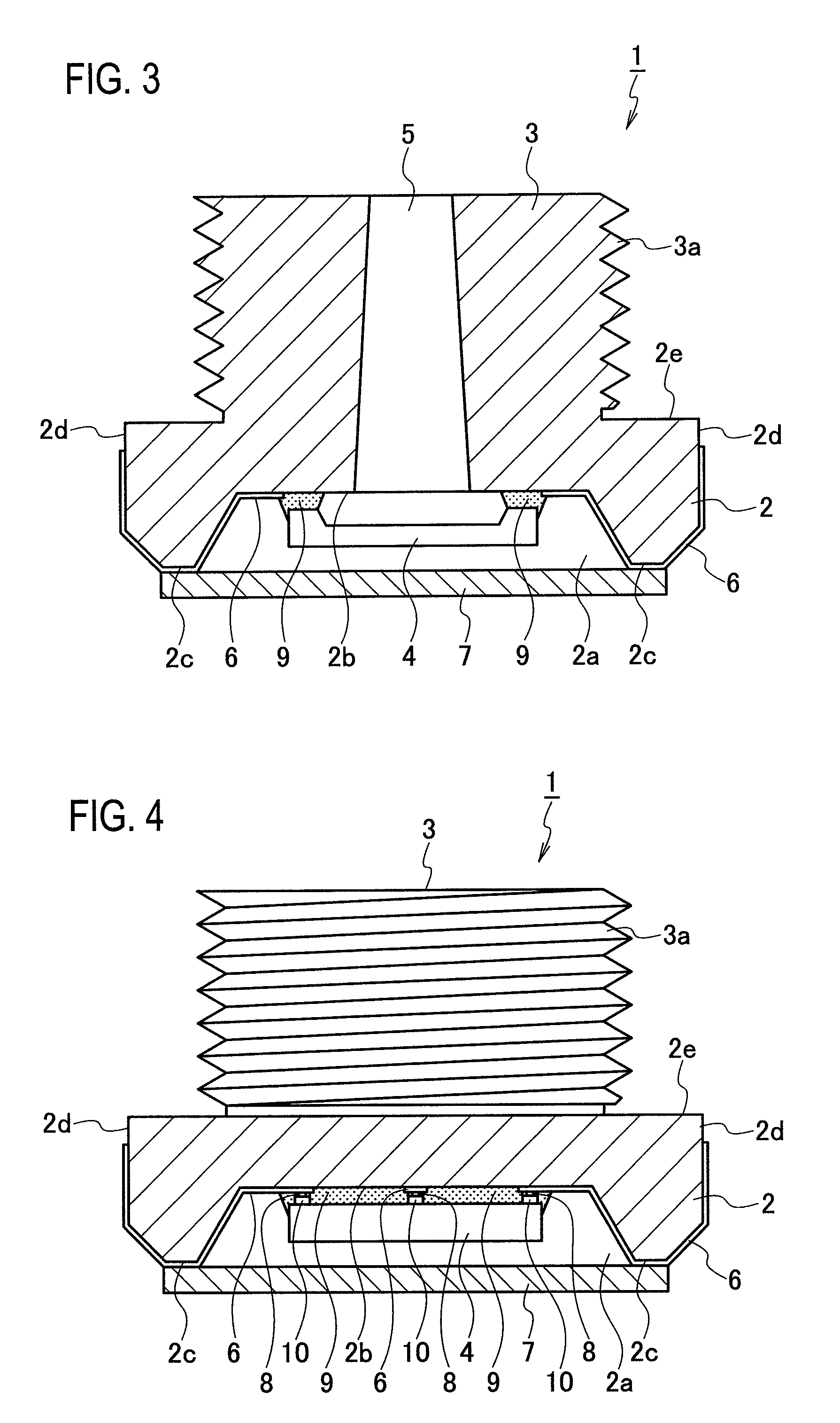

Multilayer circuit board and method of manufacturing the same

InactiveUS6833511B23D rigid printed circuitsPrinted circuit aspectsInsulation layerElectrical and Electronics engineering

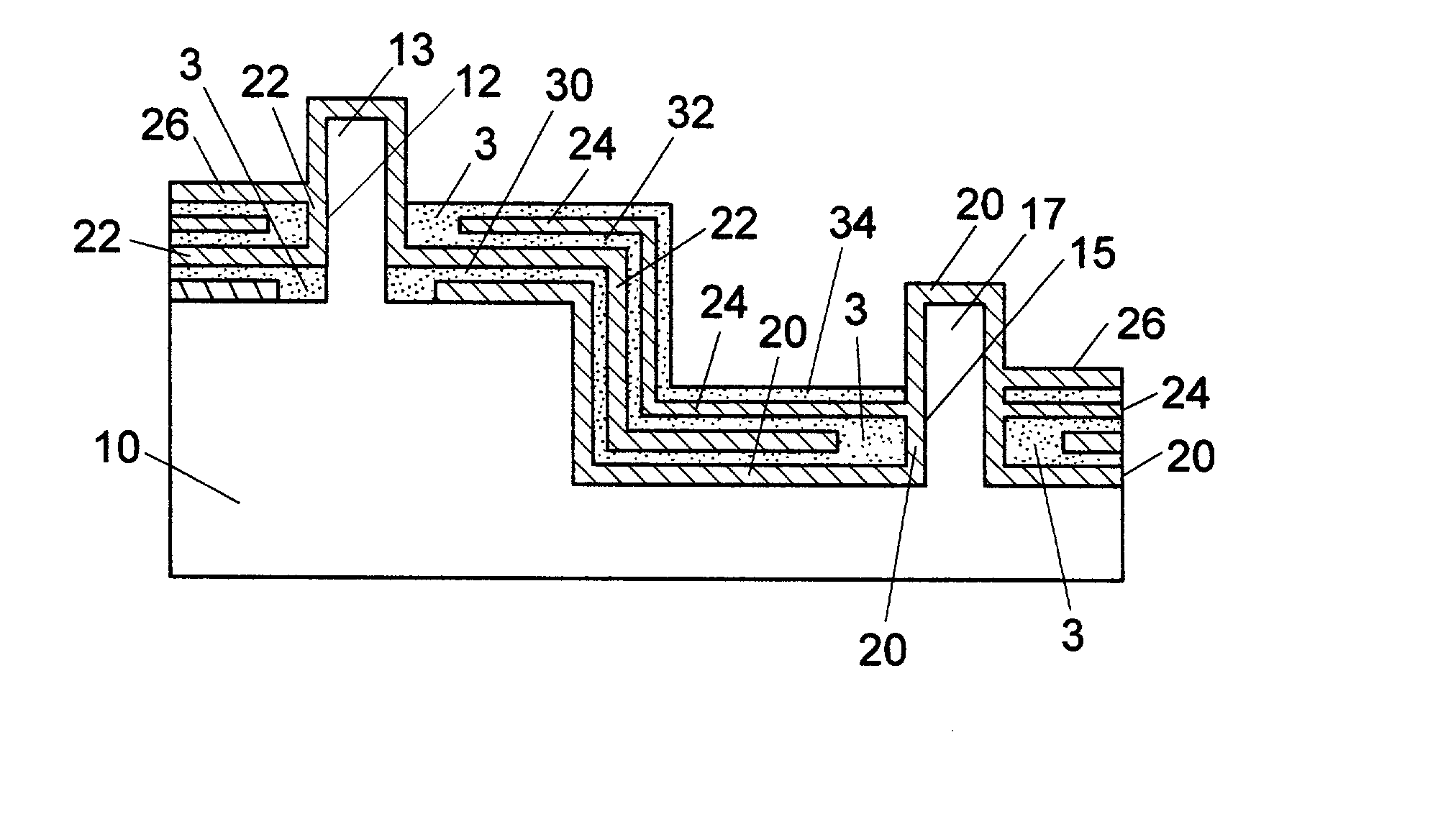

A molded interconnect device (MID) having a multilayer circuit of a reduced thickness, in which a layer-to-layer connection(s) is formed with high reliability, is provided as a multilayer circuit board. The multilayer circuit board comprises a substrate having a first surface and a second surface extending from an end of the first surface at a required angle relative to the first surface, and the multilayer circuit formed on the first surface and composed of a plurality of circuit layers. Each of the circuit layers is provided with a conductive layer having a required circuit pattern and an insulation layer formed on the conductive layer by film formation. The layer-to-layer connection of the multilayer circuit is made through a second conductive layer formed on the second surface of the substrate.

Owner:MATSUSHITA ELECTRIC WORKS LTD

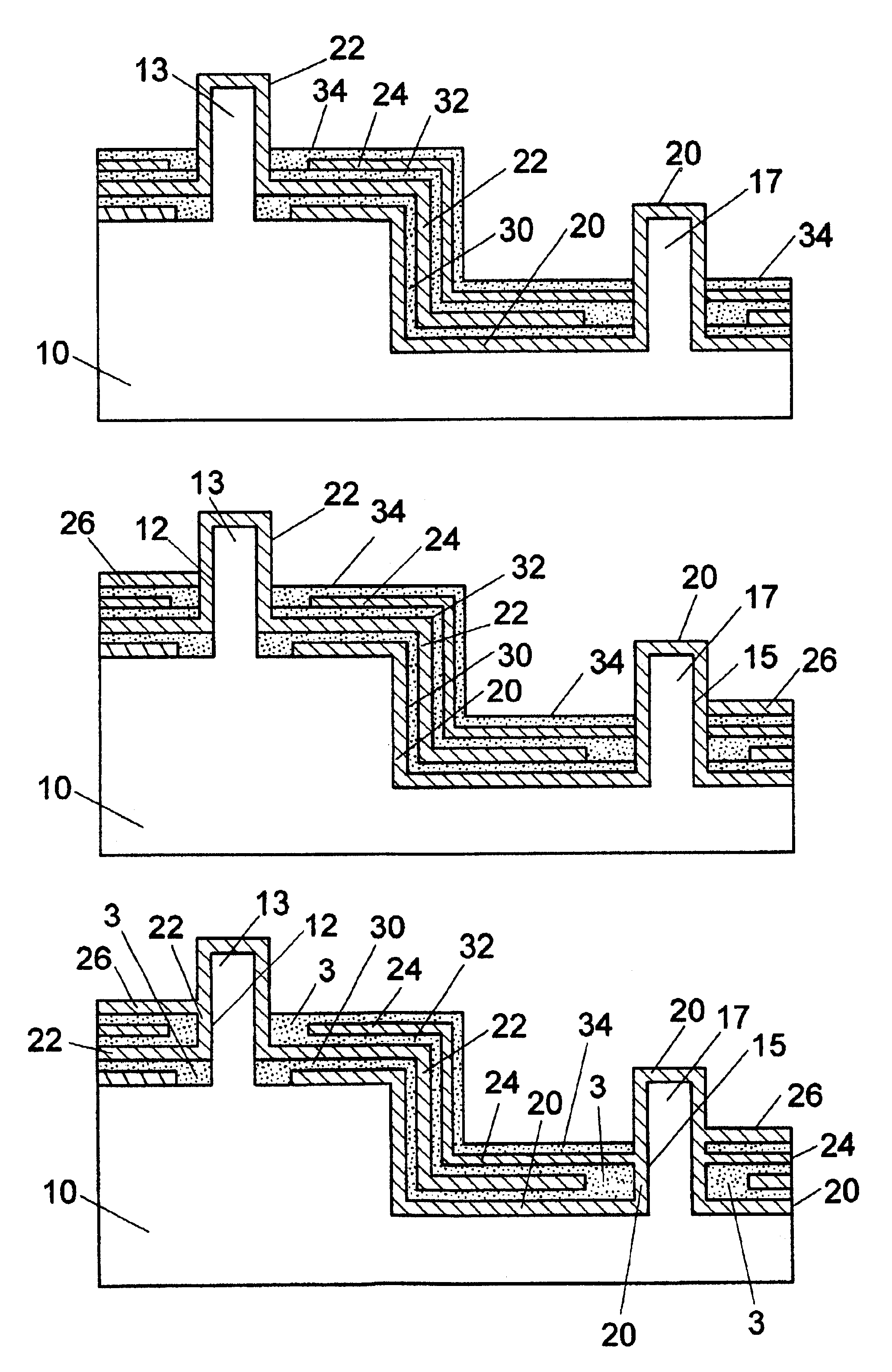

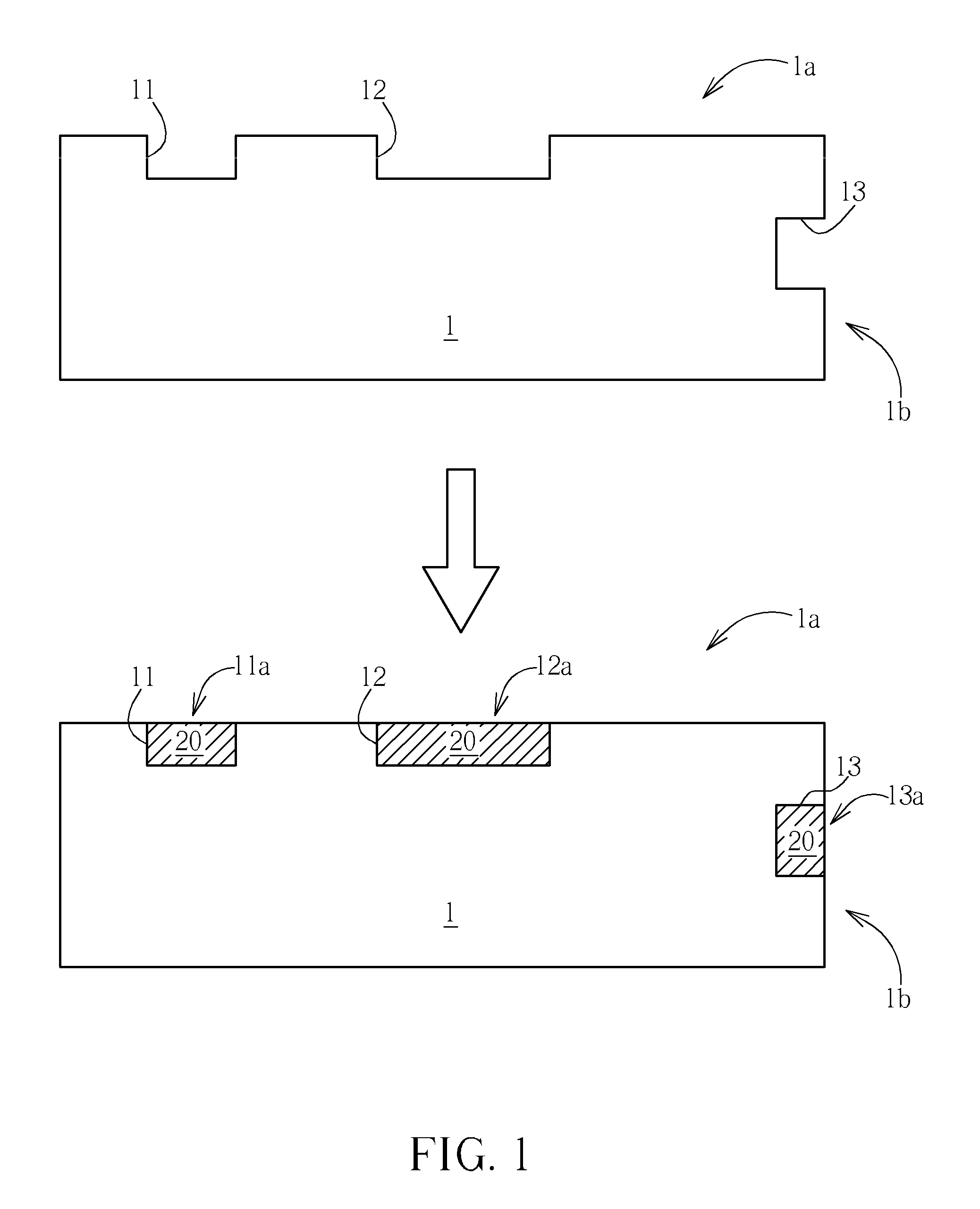

Method of making a molded interconnect device

InactiveUS8033014B2Clean and cost-effectivePrinted circuit assemblingLine/current collector detailsConductive materialsInjection moulding

Owner:UNIMICRON TECH CORP

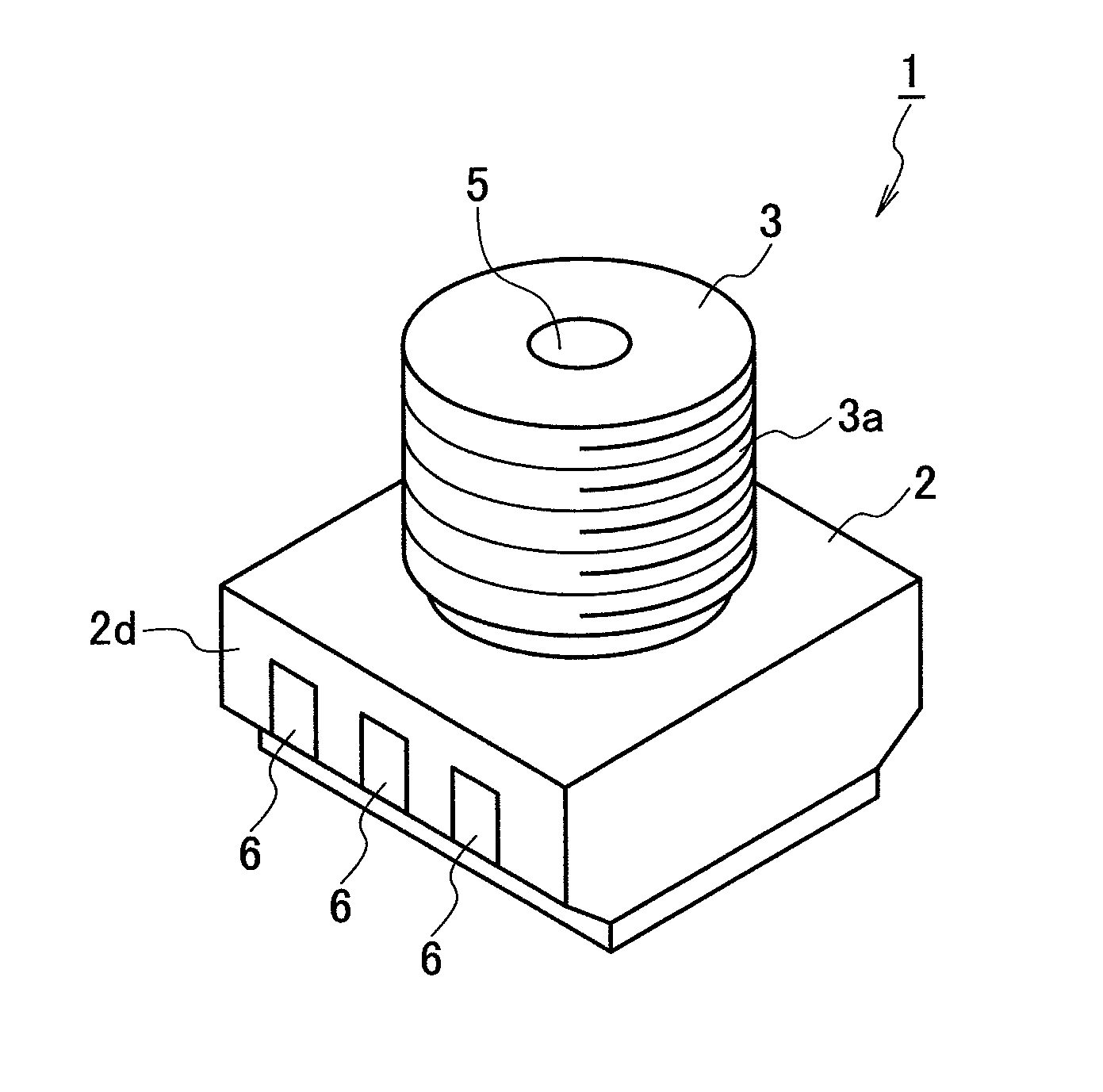

Pressure sensor

InactiveCN101517387AFluid pressure measurement using piezo-electric devicesFluid pressure measurement using ohmic-resistance variationEngineeringPressure sensor

In a pressure sensor 1 including a pressure detecting element 4 in an intermediate portion or at a deep side of a through hole 5 formed in a protrusion 3, a body portion (a base portion 2 and the protrusion 3) is made of ceramic or an insulative resin material and molded into a predetermined shape, and the pressure sensor is constituted as a molded interconnect device in which a conductive pattern 6 is formed on a surface thereof Accordingly, a smaller pressure sensor can be obtained.

Owner:PANASONIC CORP

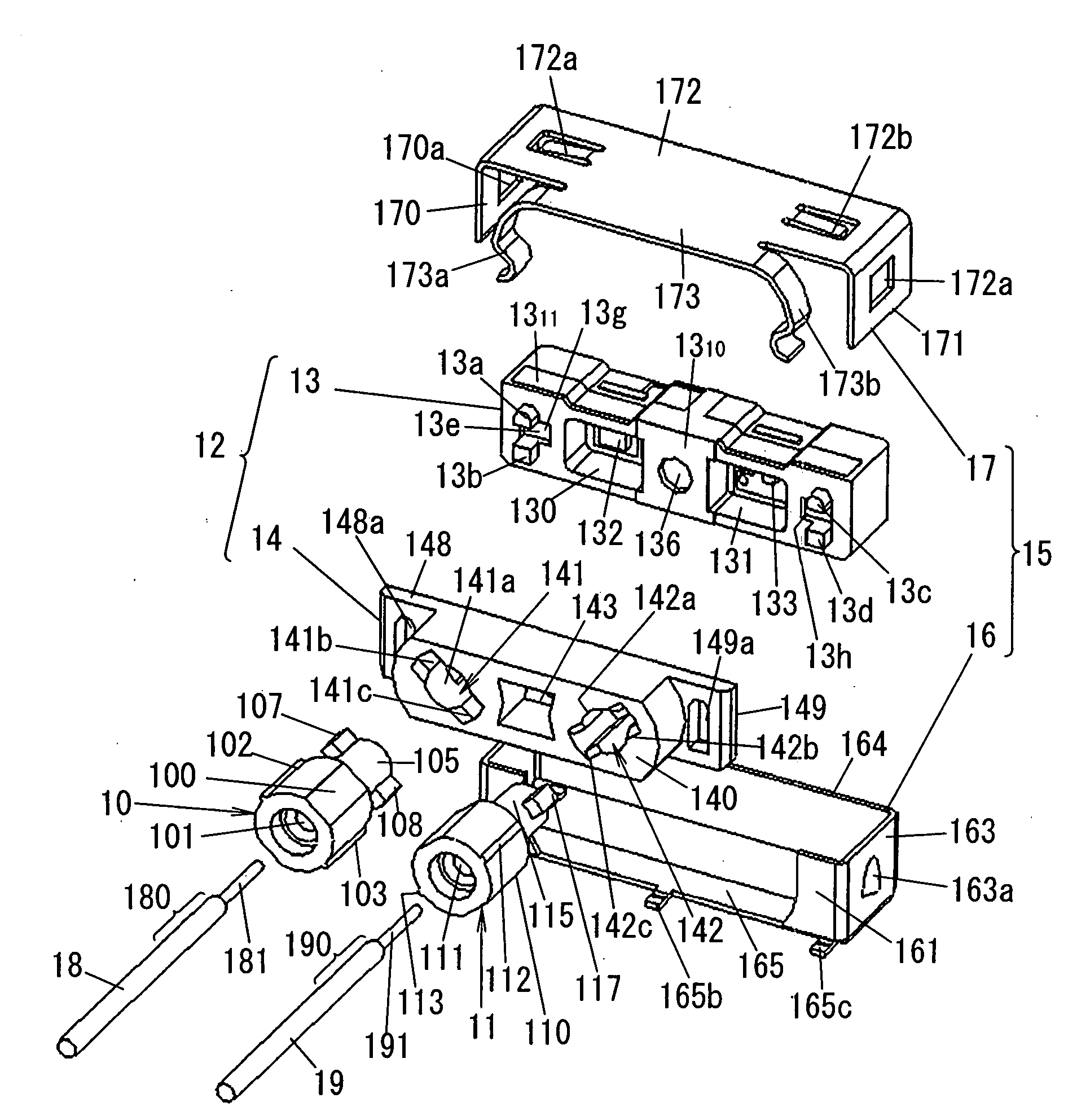

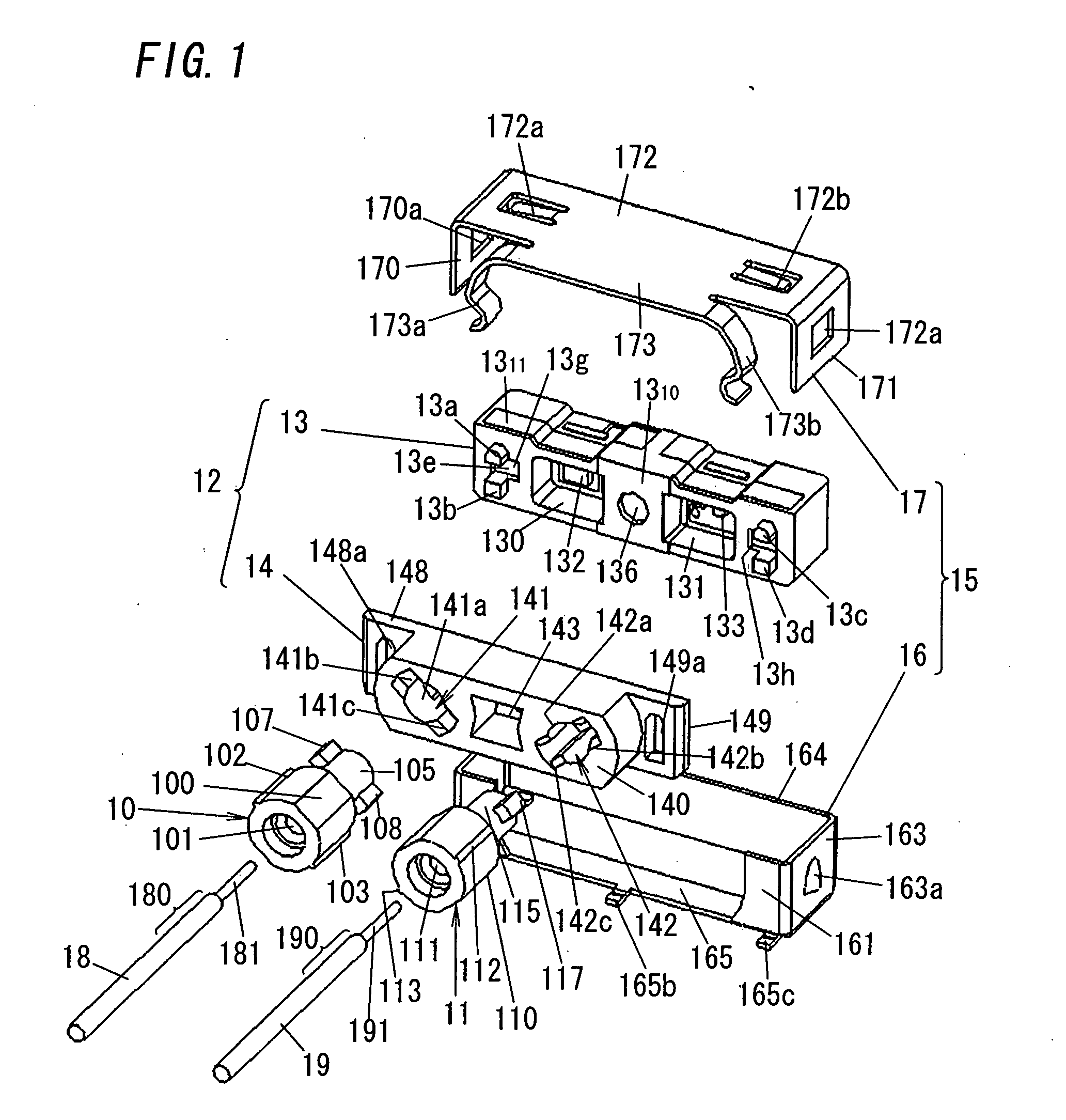

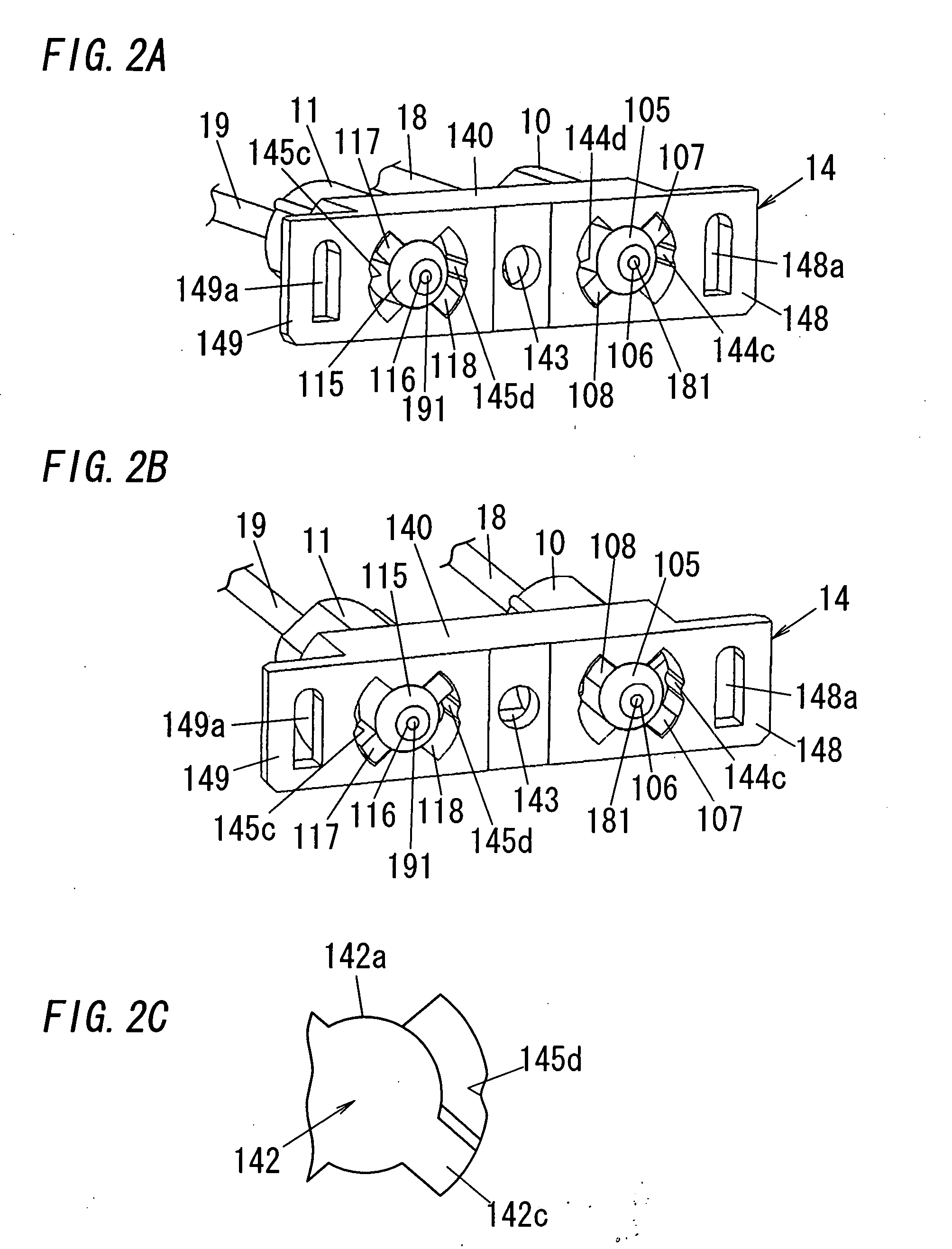

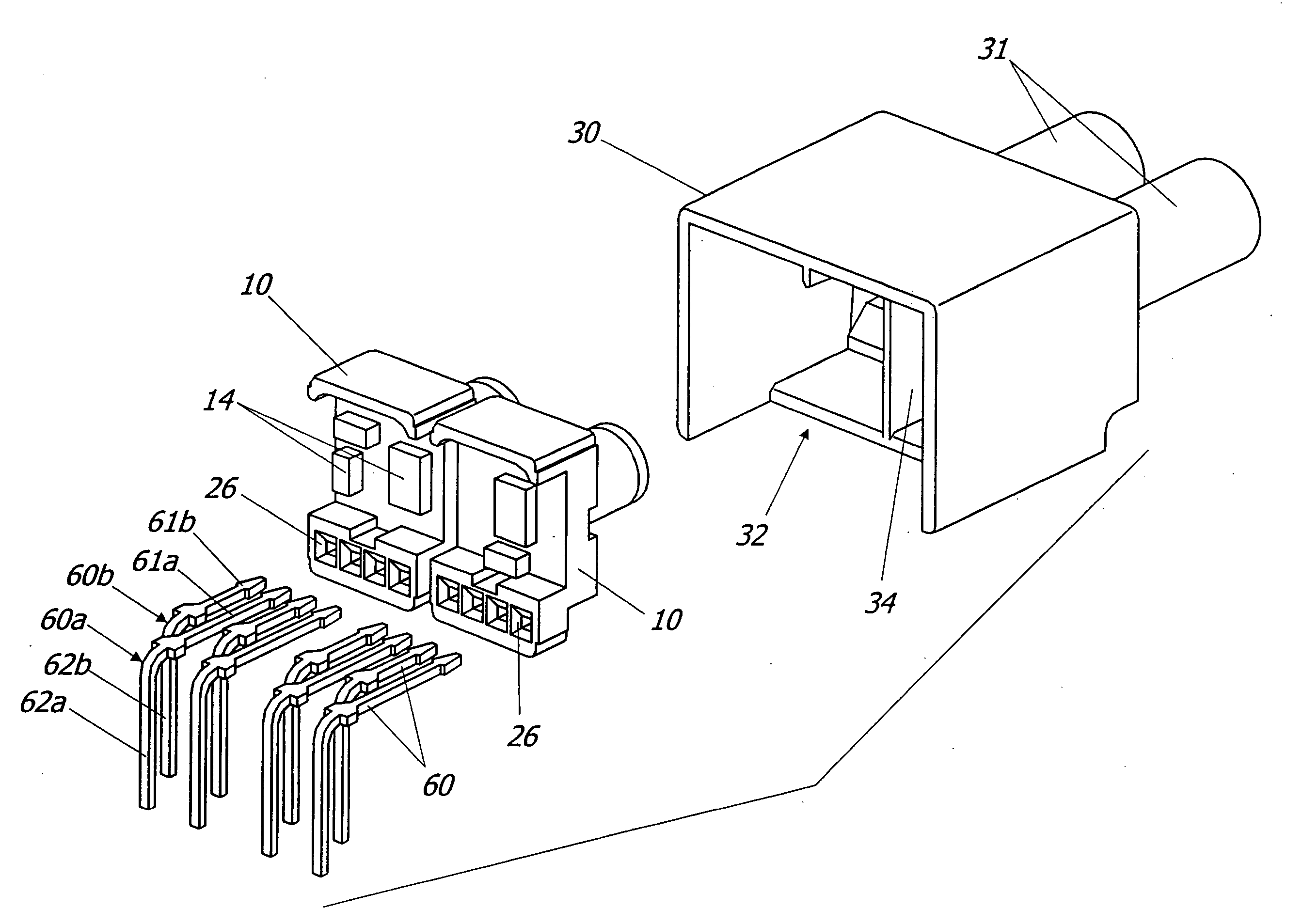

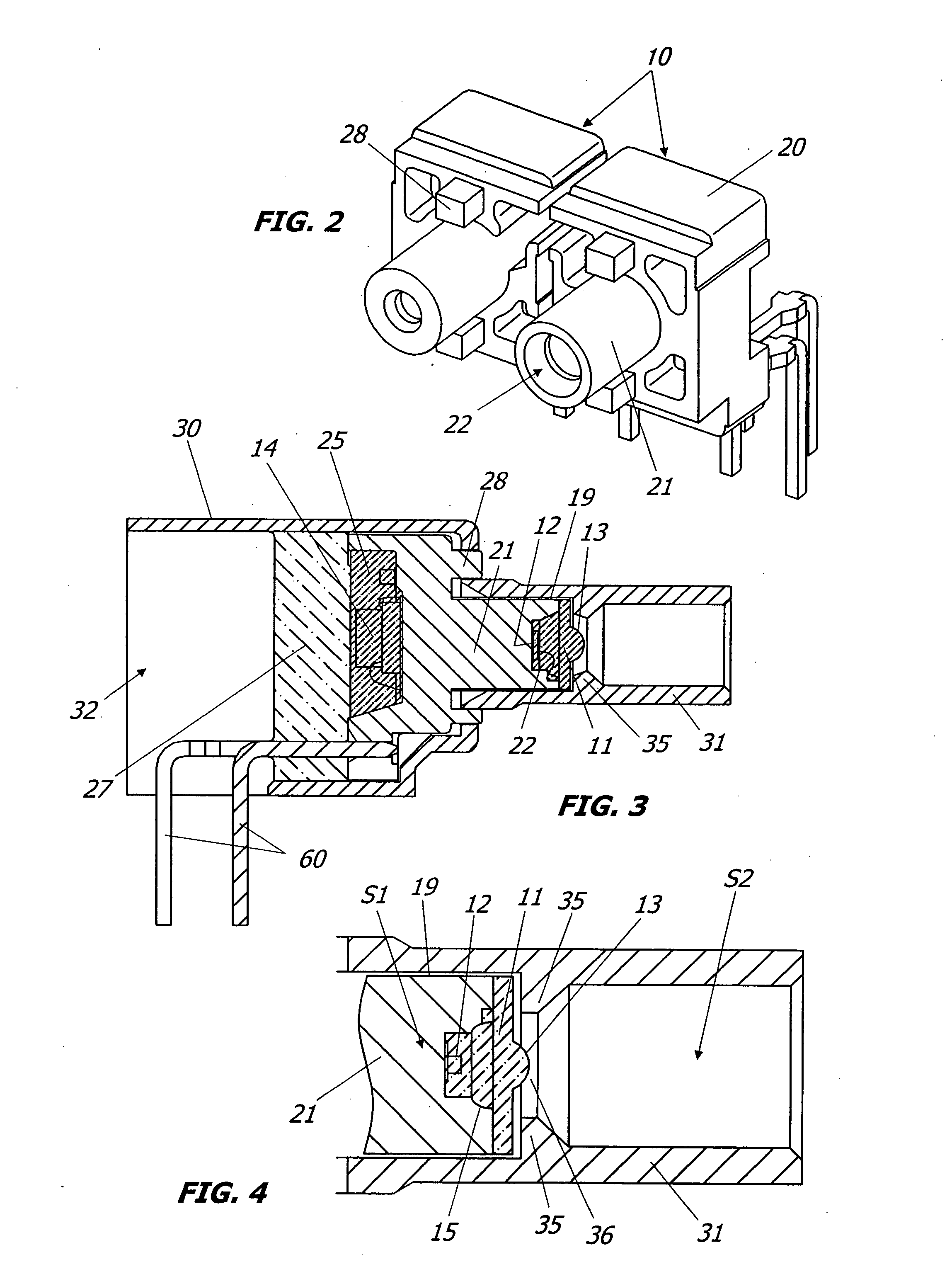

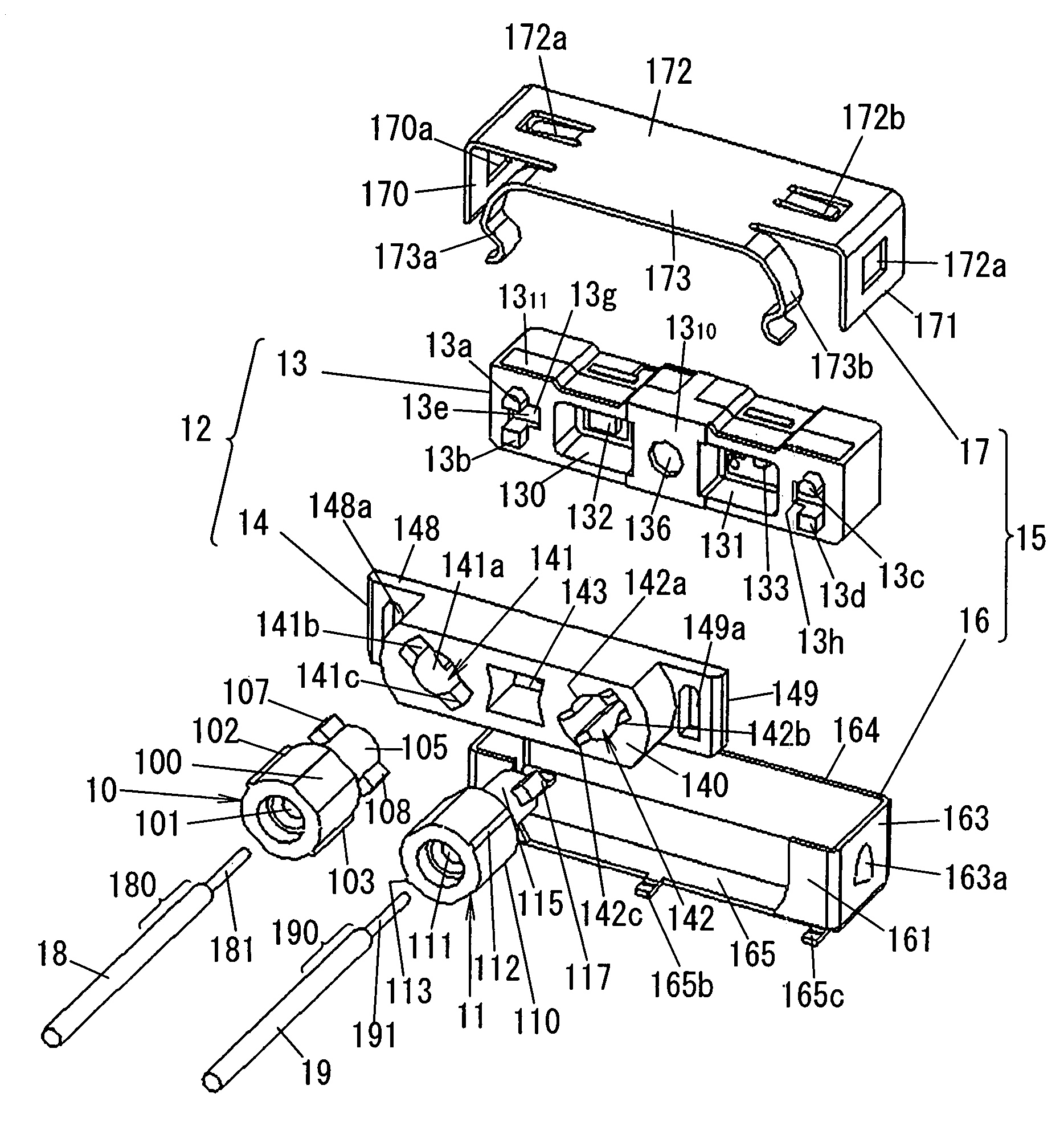

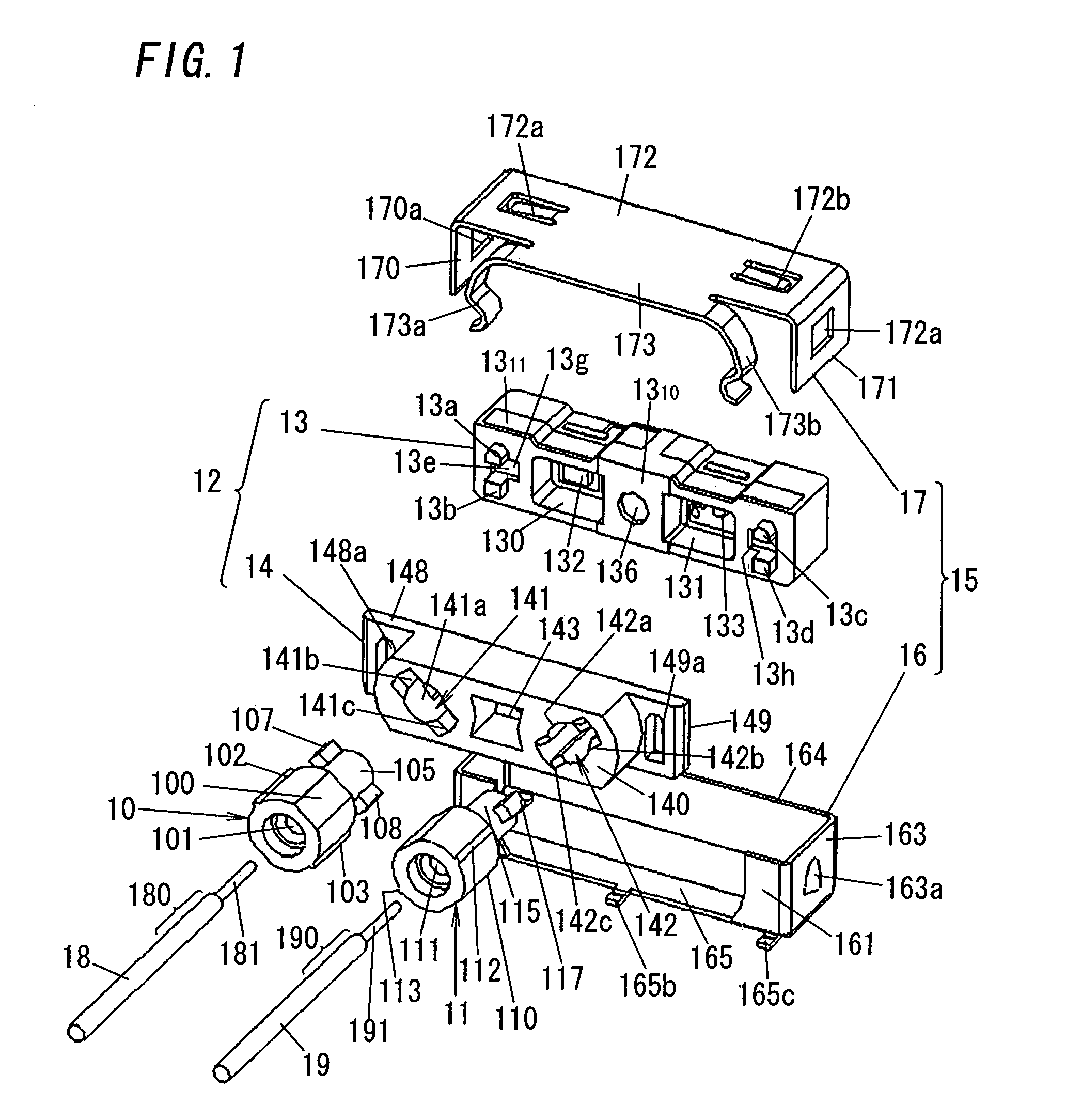

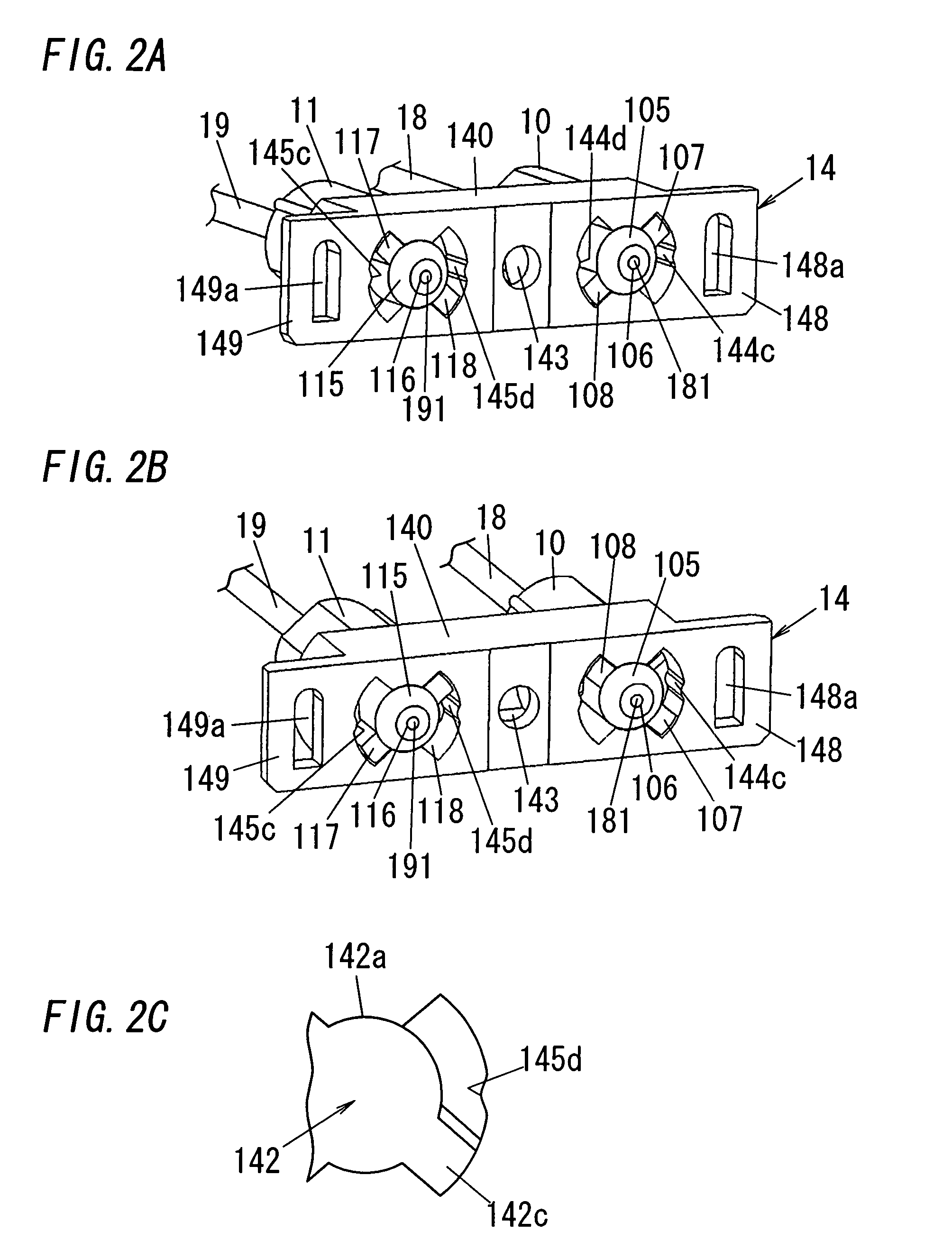

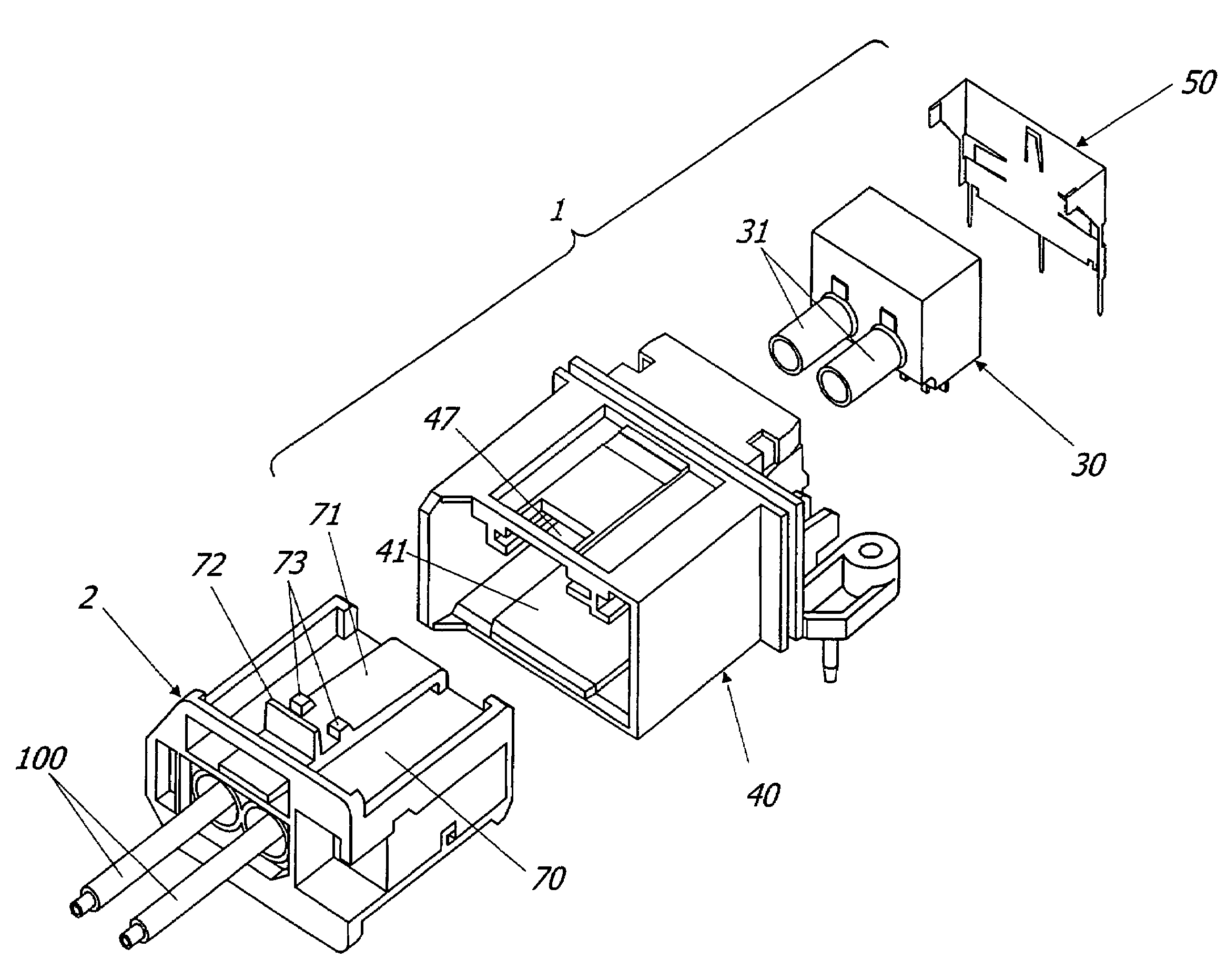

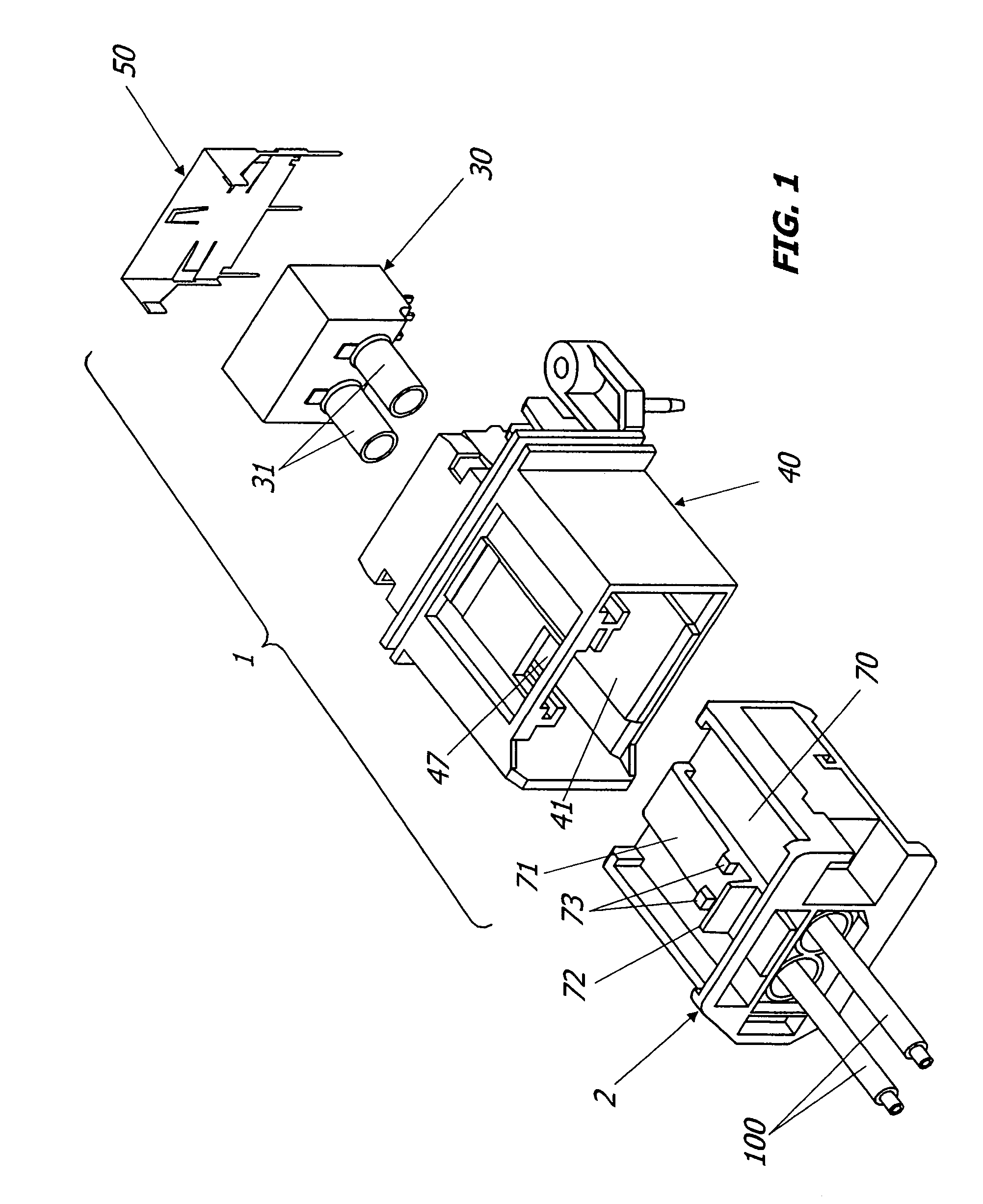

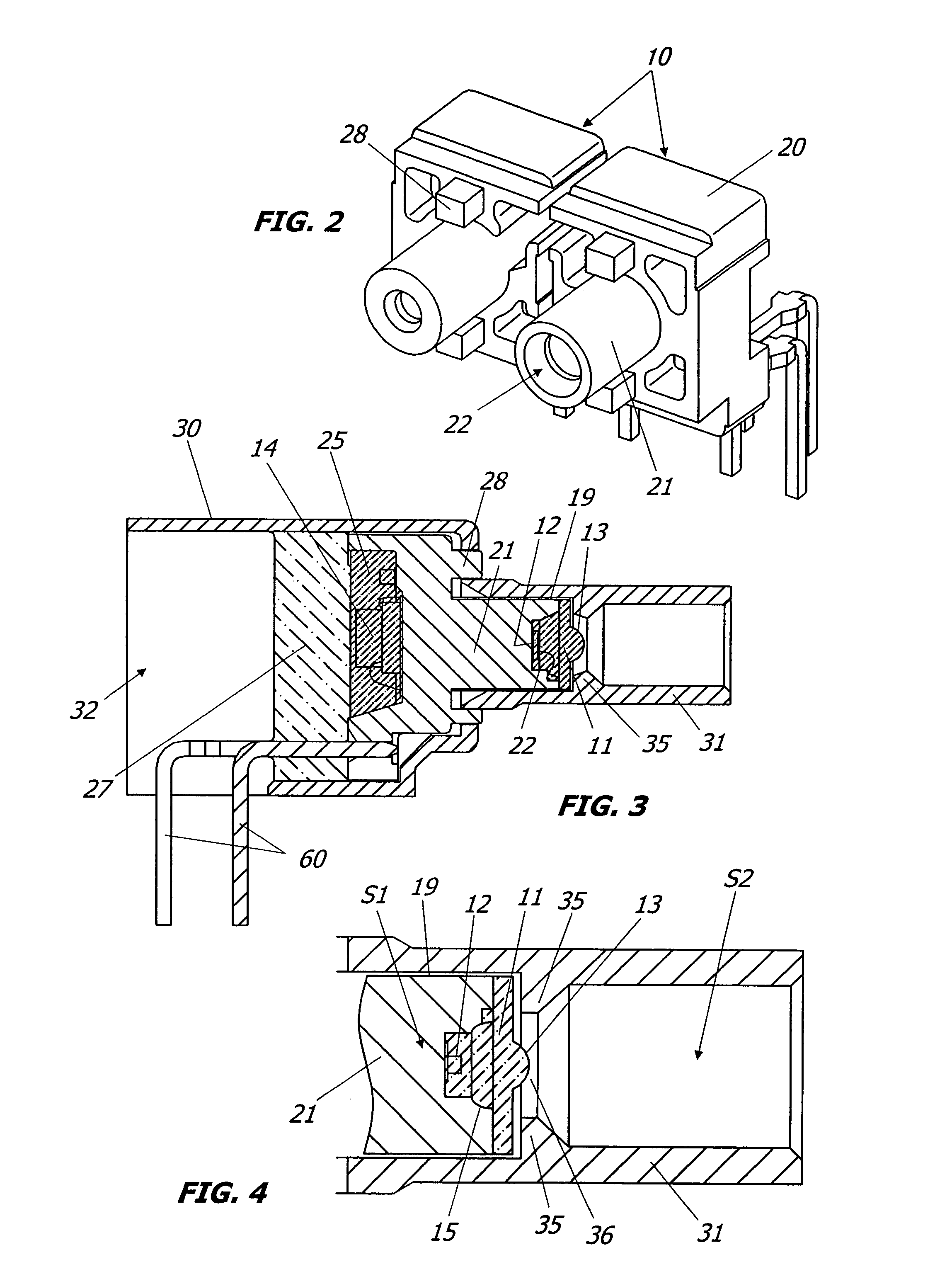

Plug-socket connector apparatus for optical fiber termination

InactiveUS20080260334A1Connection working is improvedAdd dimensionElectric connection structural associationsCoupling light guidesMechanical engineeringMolded interconnect device

Plug-socket connector apparatus for optical fiber termination comprises first and second plugs and a socket. The first and second plugs are both single ferrule plugs. The socket is a molded interconnect device and a plug holder, and includes terminals located on the bottom face of the socket, first and second bores located at one side of the socket, and first and second retainers. The retainers retain latches formed in the plugs so as to prevent the plugs from falling out of the bores and to restrict rotation angles of the plugs around the axes within predetermined rotation angle ranges, when the plugs is plugged in the bores.

Owner:MATSUSHITA ELECTRIC WORKS LTD

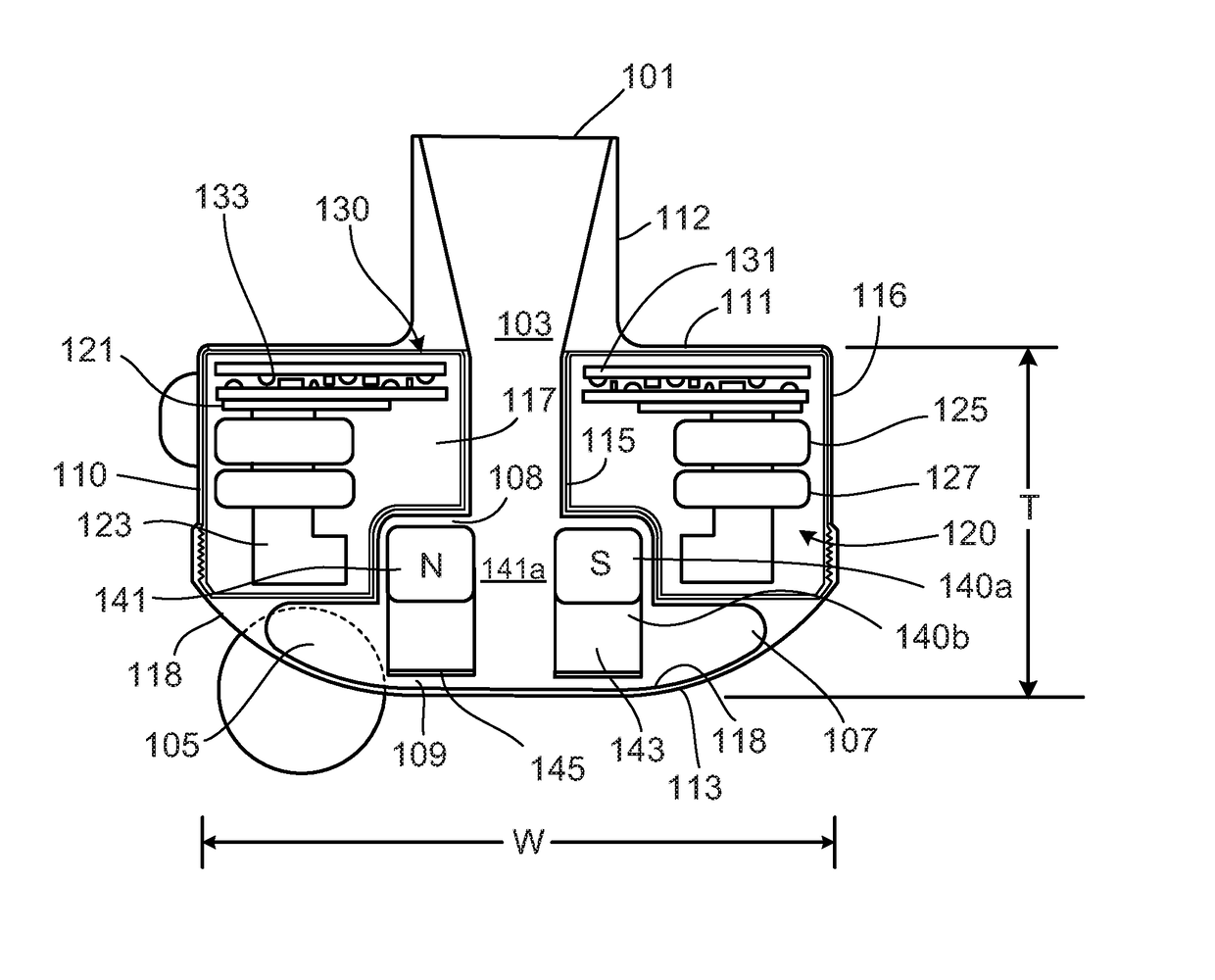

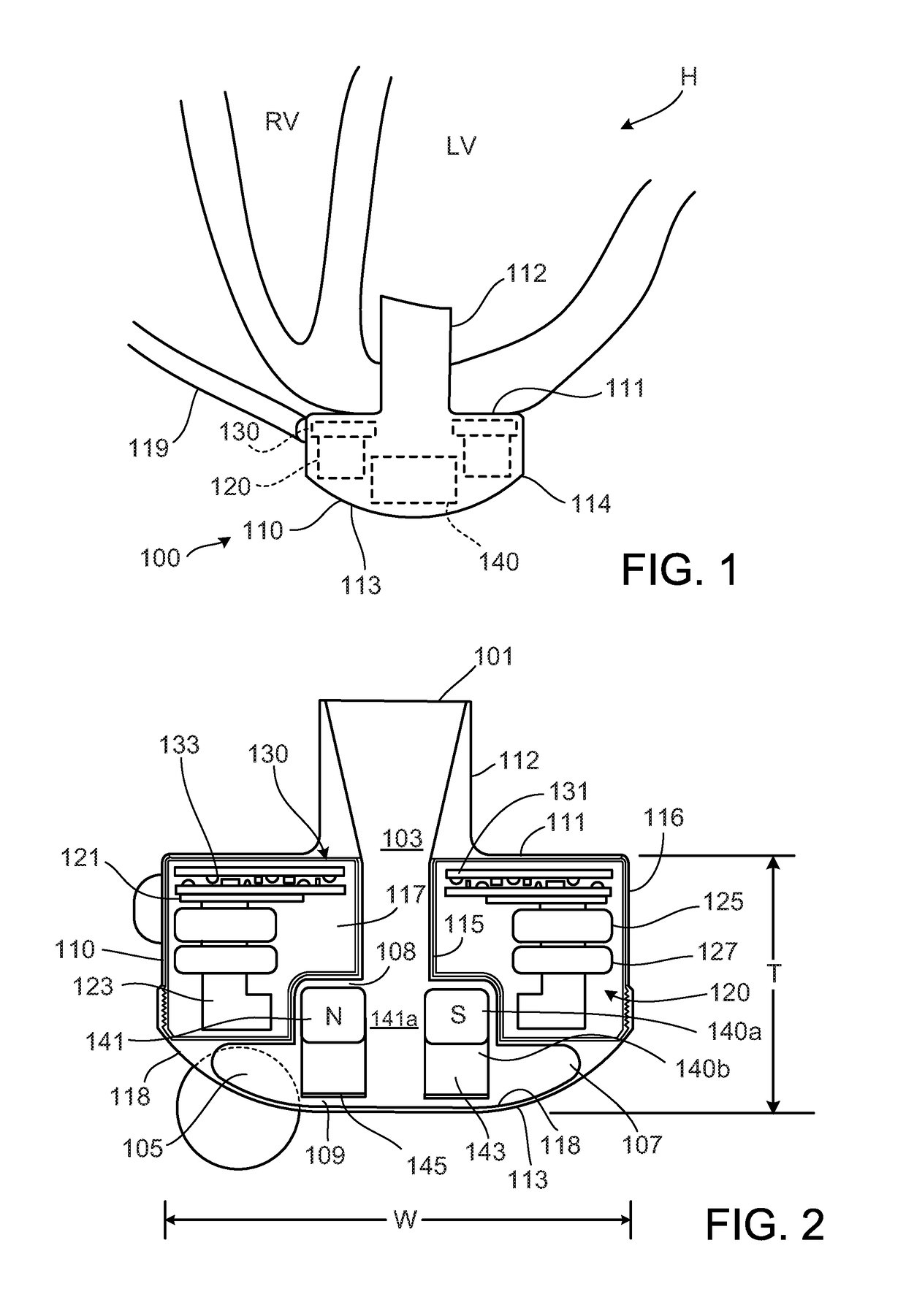

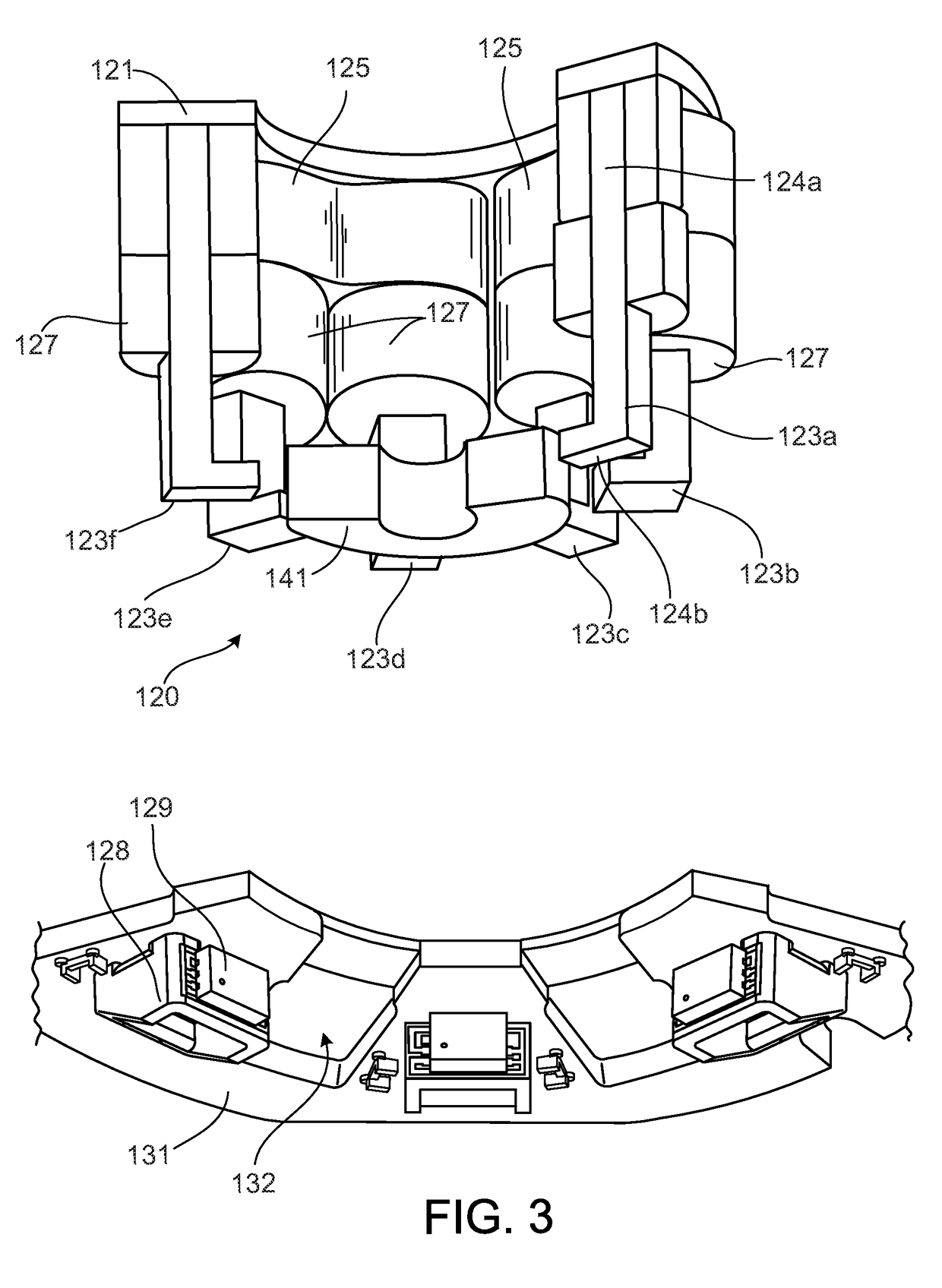

Sensor mounting in an implantable blood pump

ActiveUS20170119946A1Magnetic measurementsElectric/magnetic position measurementsBlood pumpPrinted circuit board

Owner:TC1 LLC

Multilayer circuit board and method of manufacturing the same

InactiveUS20020062987A1Insulating layers/substrates workingElectrical connection printed elementsInsulation layerEngineering

A molded interconnect device (MID) having a multilayer circuit of a reduced thickness, in which a layer-to-layer connection(s) is formed with high reliability, is provided as a multilayer circuit board. The multilayer circuit board comprises a substrate having a first surface and a second surface extending from an end of the first surface at a required angle relative to the first surface, and the multilayer circuit formed on the first surface and composed of a plurality of circuit layers. Each of the circuit layers is provided with a conductive layer having a required circuit pattern and an insulation layer formed on the conductive layer by film formation. The layer-to-layer connection of the multilayer circuit is made through a second conductive layer formed on the second surface of the substrate.

Owner:MATSUSHITA ELECTRIC WORKS LTD

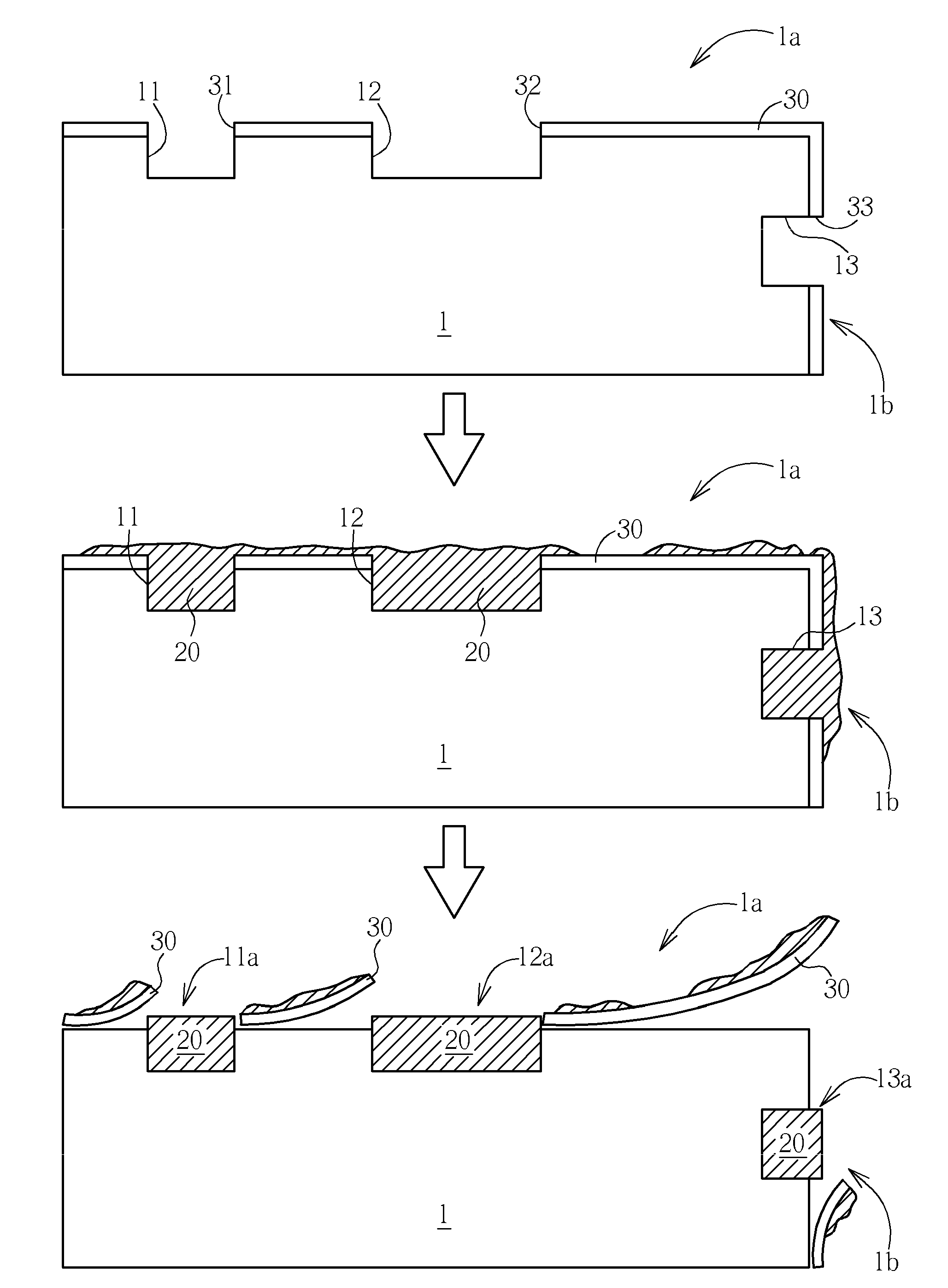

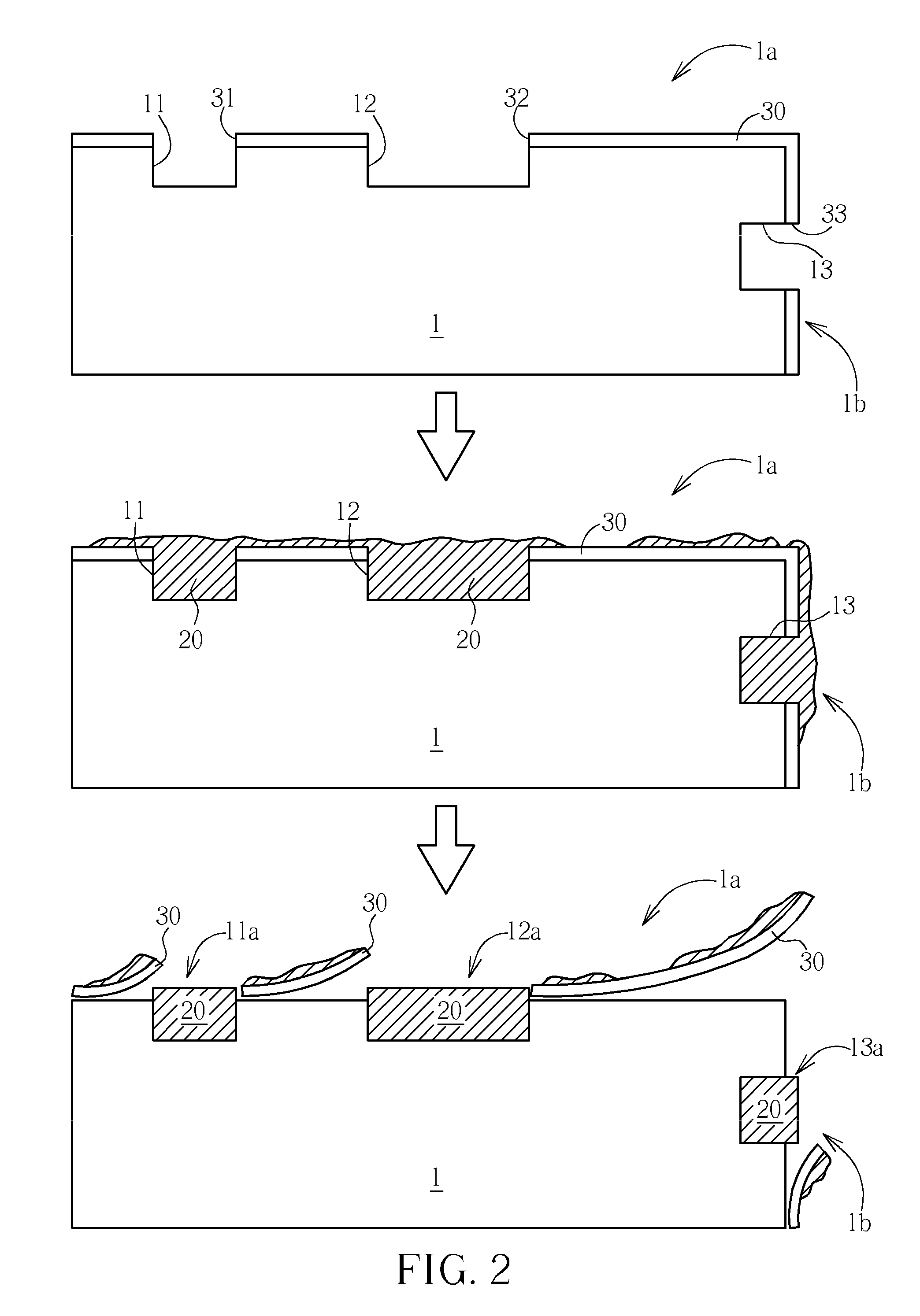

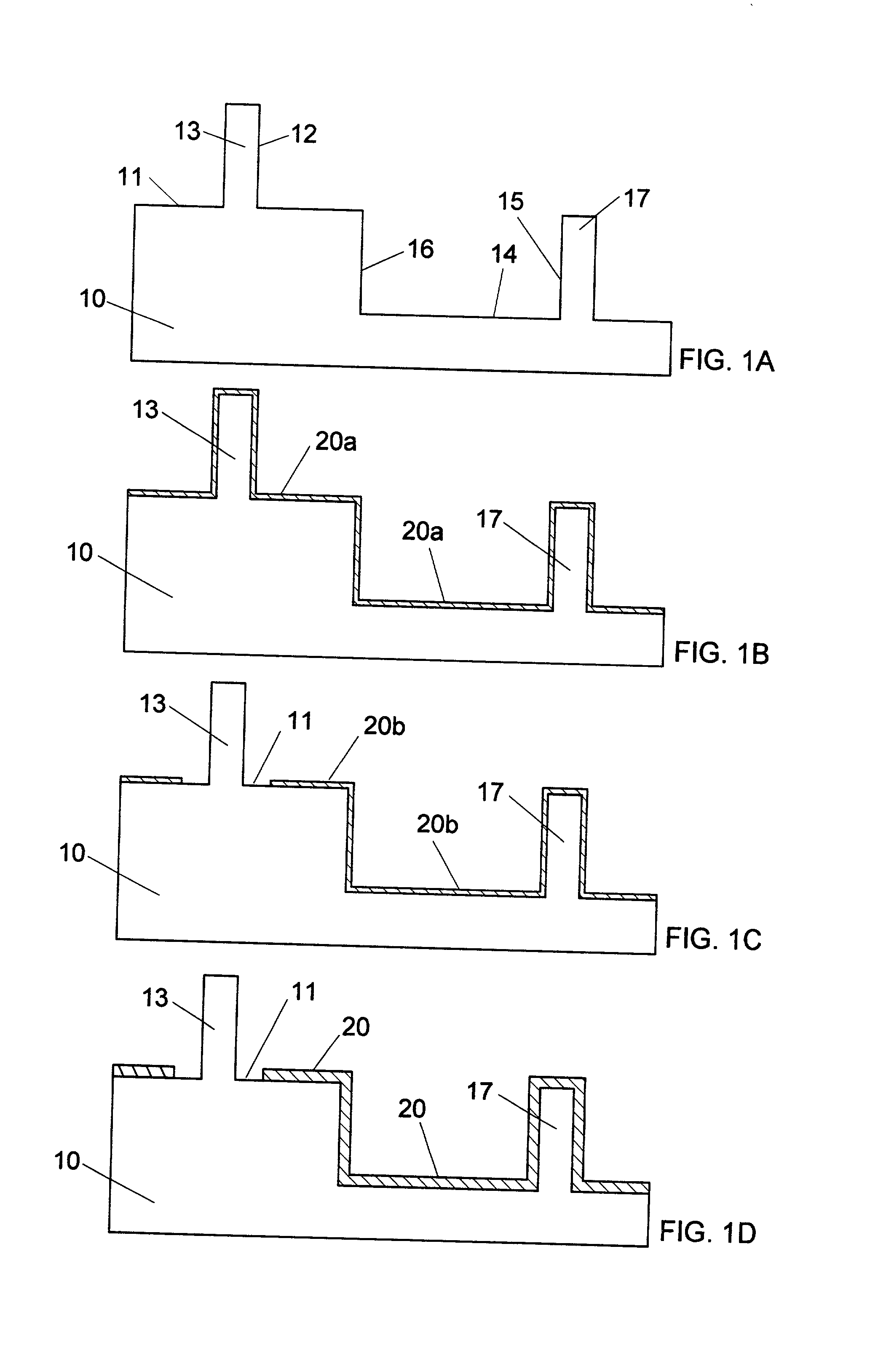

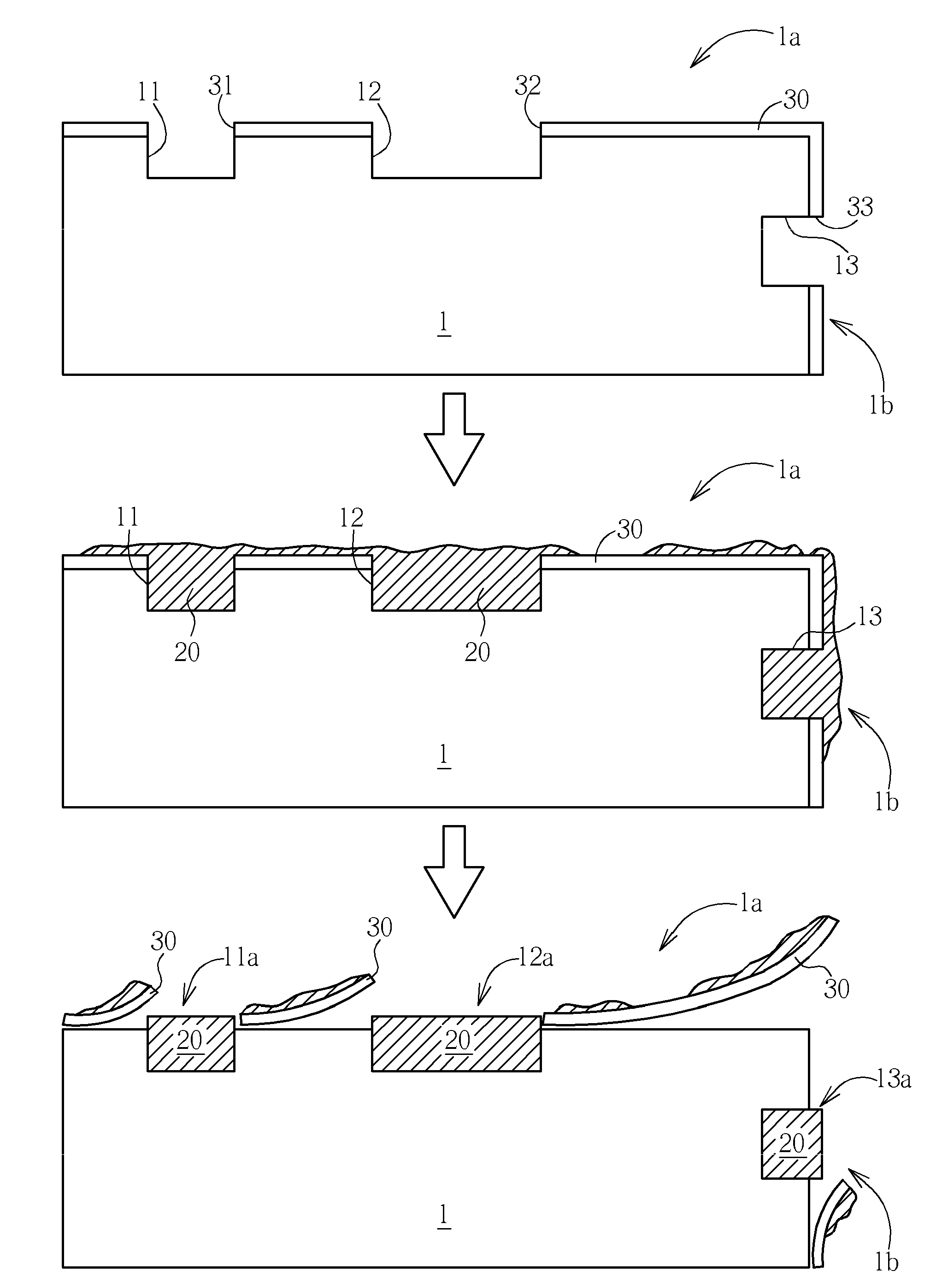

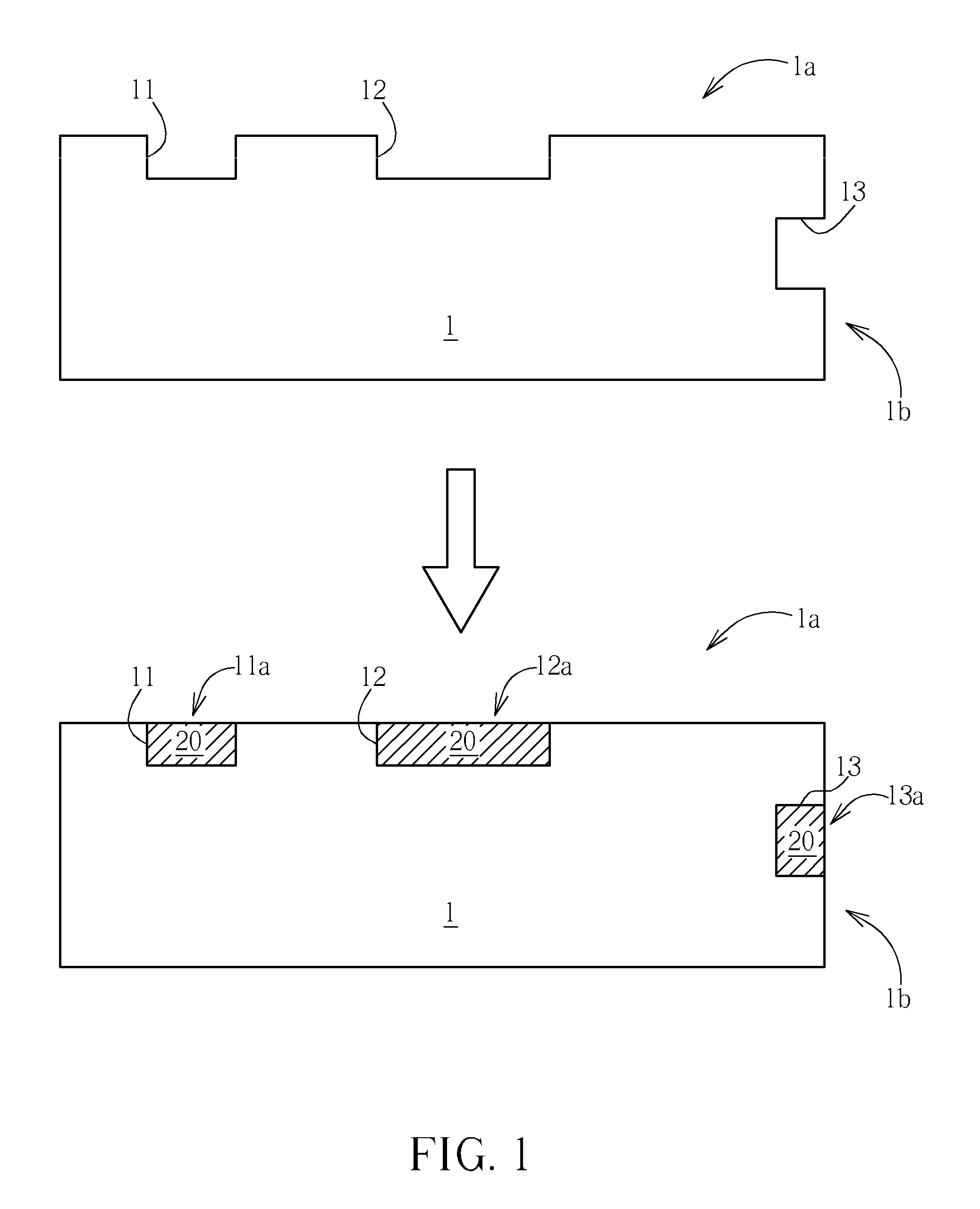

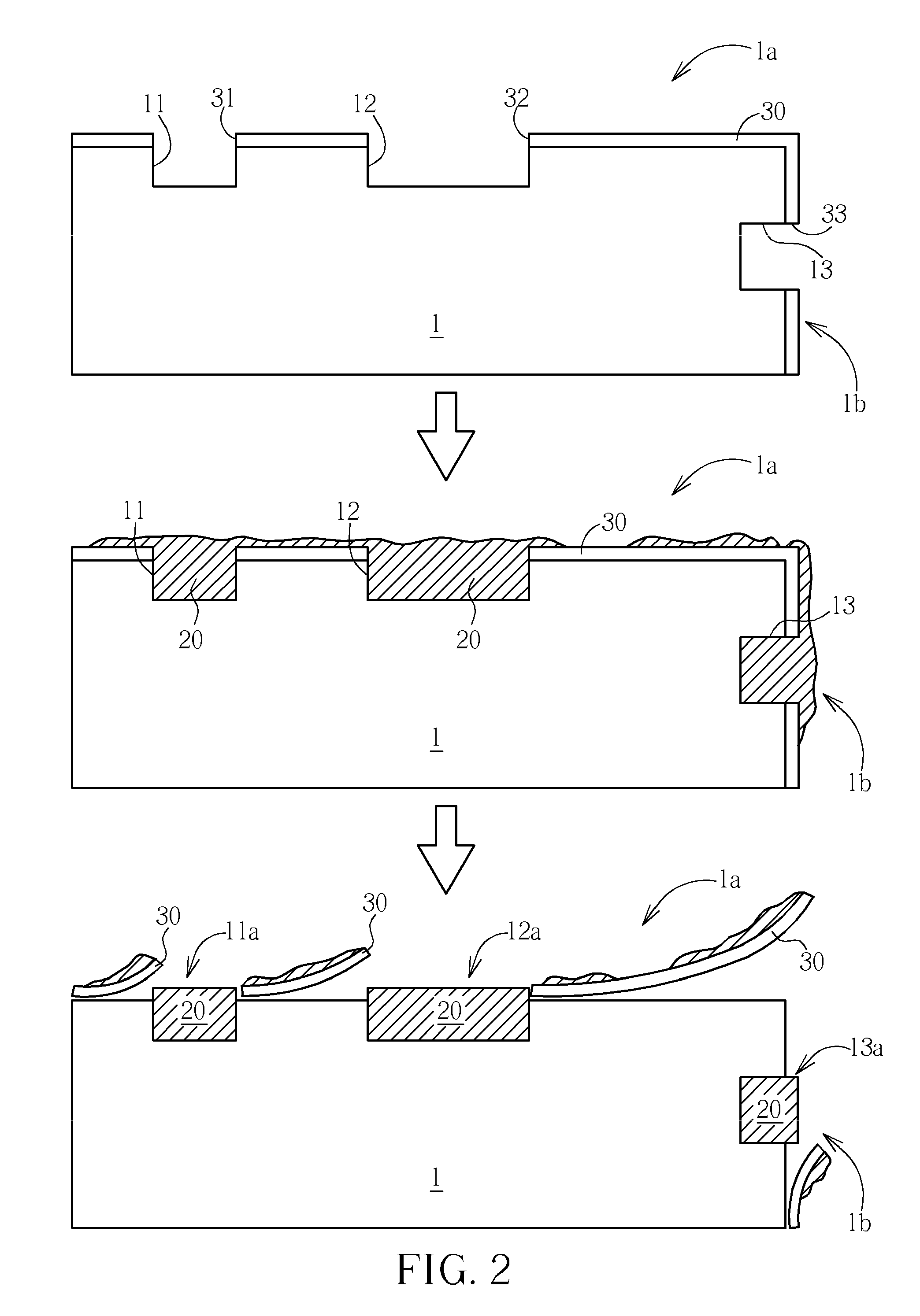

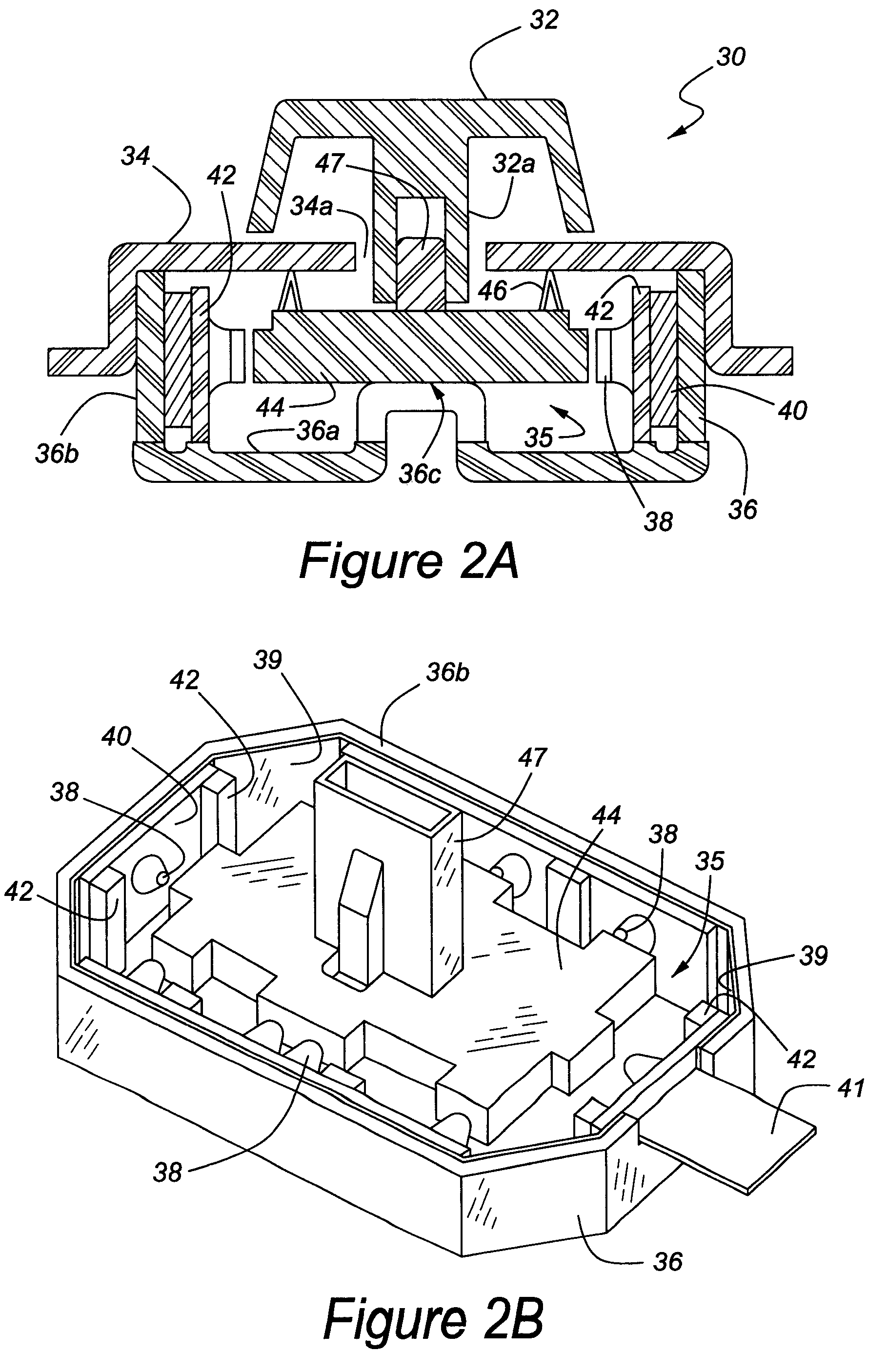

Method of making a molded interconnect device

InactiveUS20100000086A1Clean and cost-effectivePrinted circuit assemblingLine/current collector detailsShell moldingConductive materials

The present invention provides a method of making a molded interconnect device. The method includes the steps of: injection molding a plastic body having thereon at least one patterned circuit trench structure; and filling a conductive material into the patterned circuit trench structure thereby forming a circuit trace on the plastic body.

Owner:UNIMICRON TECH CORP

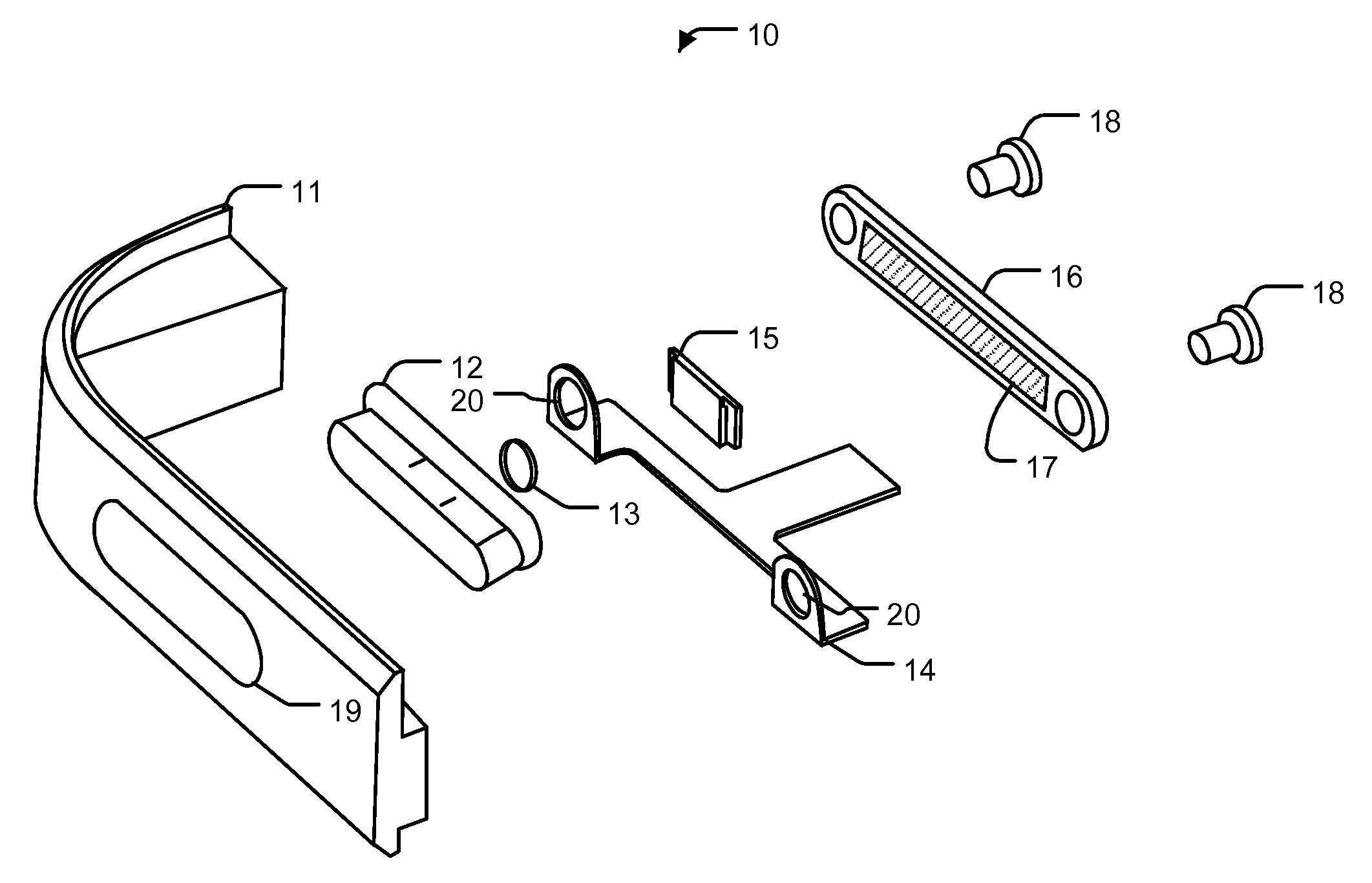

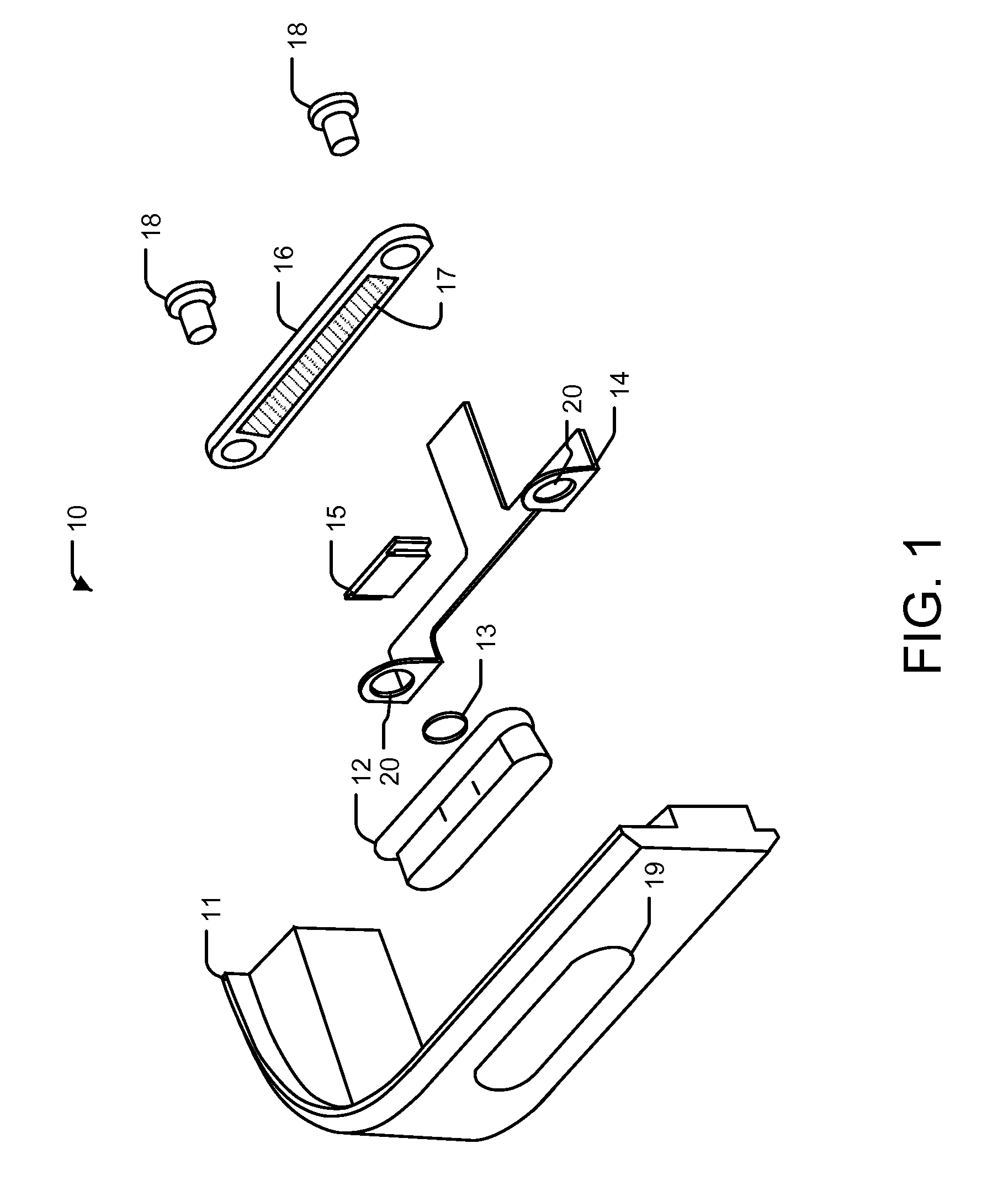

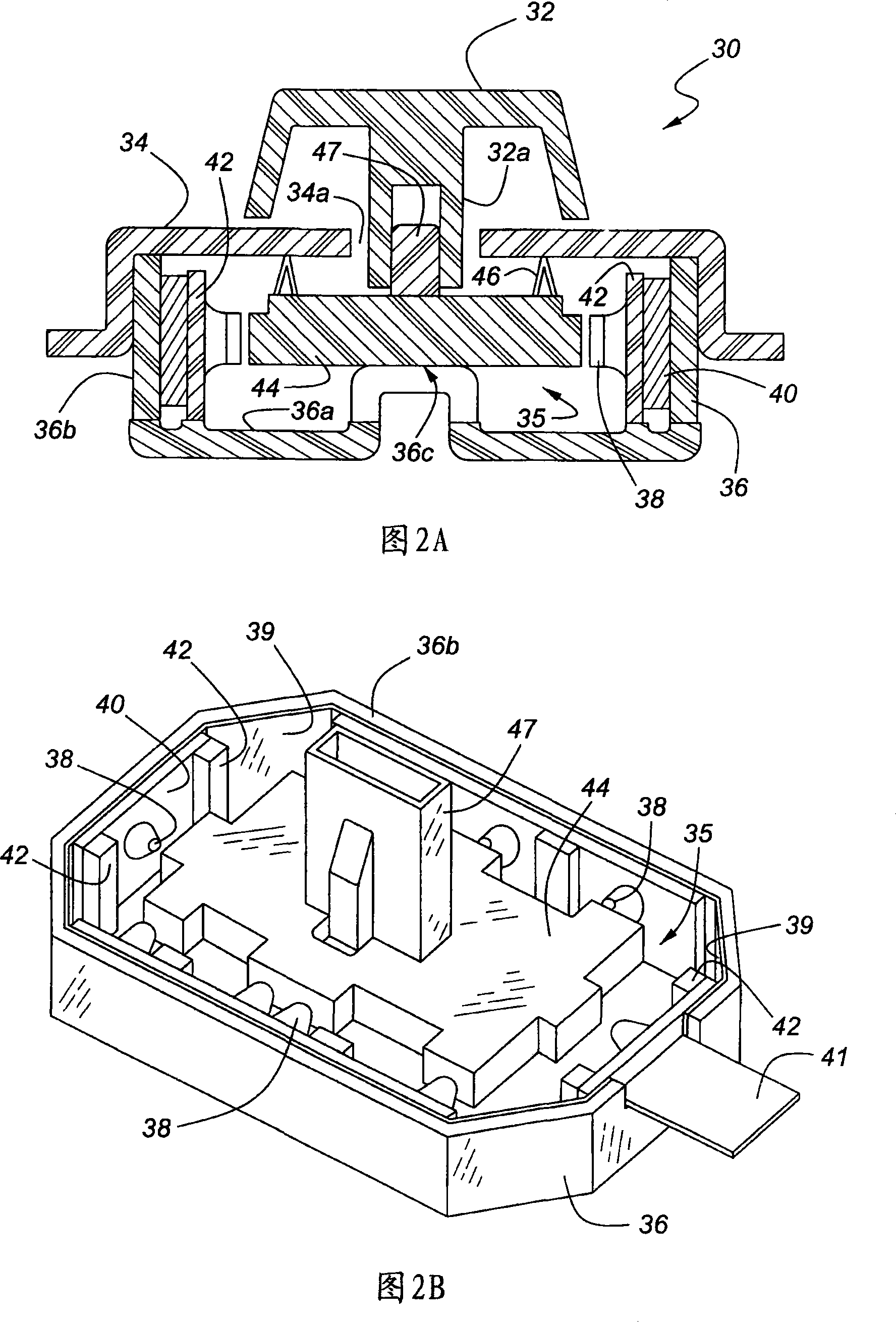

Modular molded interconnect devices

ActiveUS8981245B2Contact operating partsContact fixed to operating partFlexible electronicsPrinted circuit board

A switching subassembly includes a modular molded interconnect bracket and a switching device arranged on the modular molded interconnect bracket. The modular molded interconnect includes at least one electronic circuit trace arranged thereon configured to interconnect a portion of a flexible printed circuit board and to support a portion of the flexible printed circuit board. The switching device is configured to contact portions of the at least one electronic circuit trace.

Owner:APPLE INC

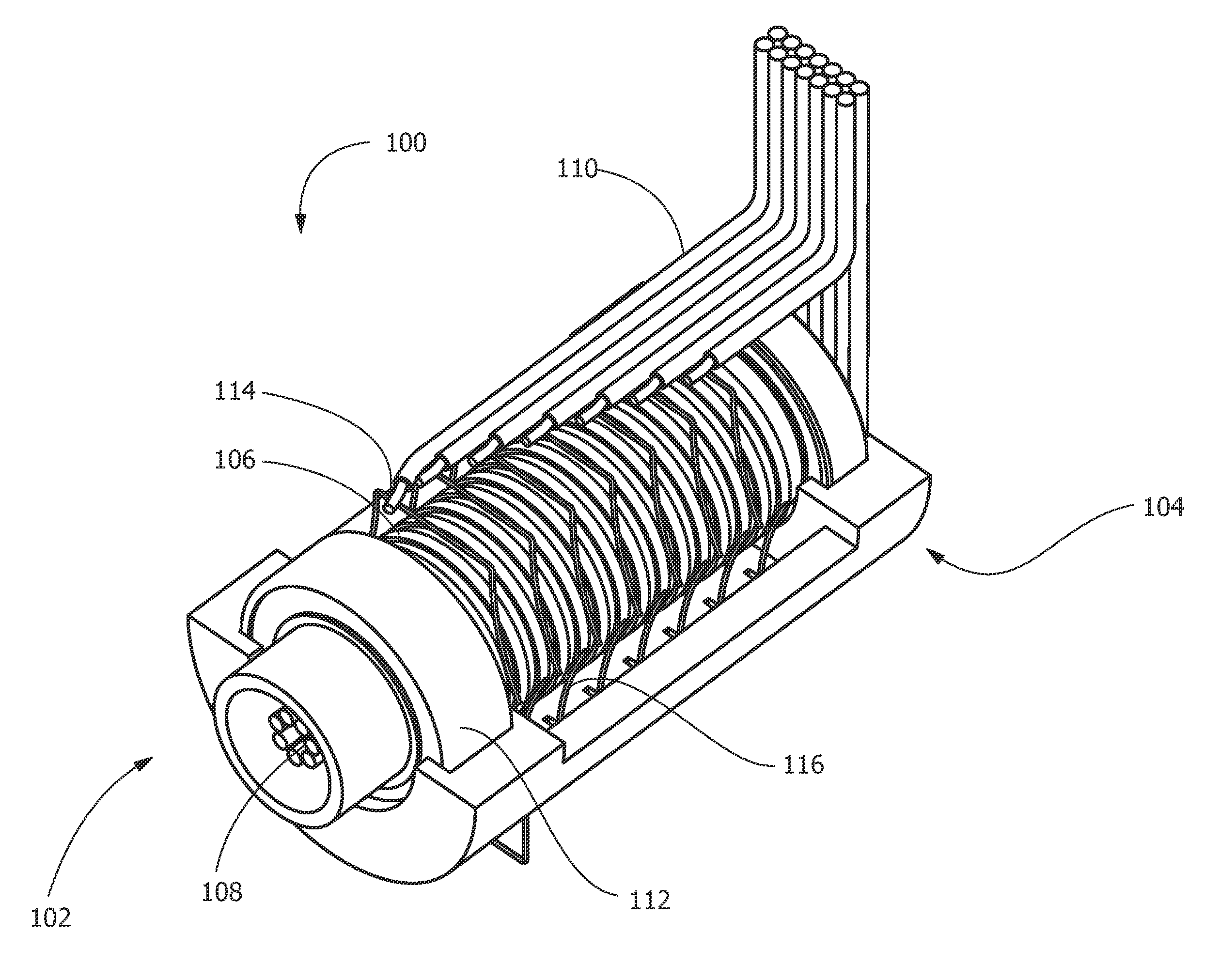

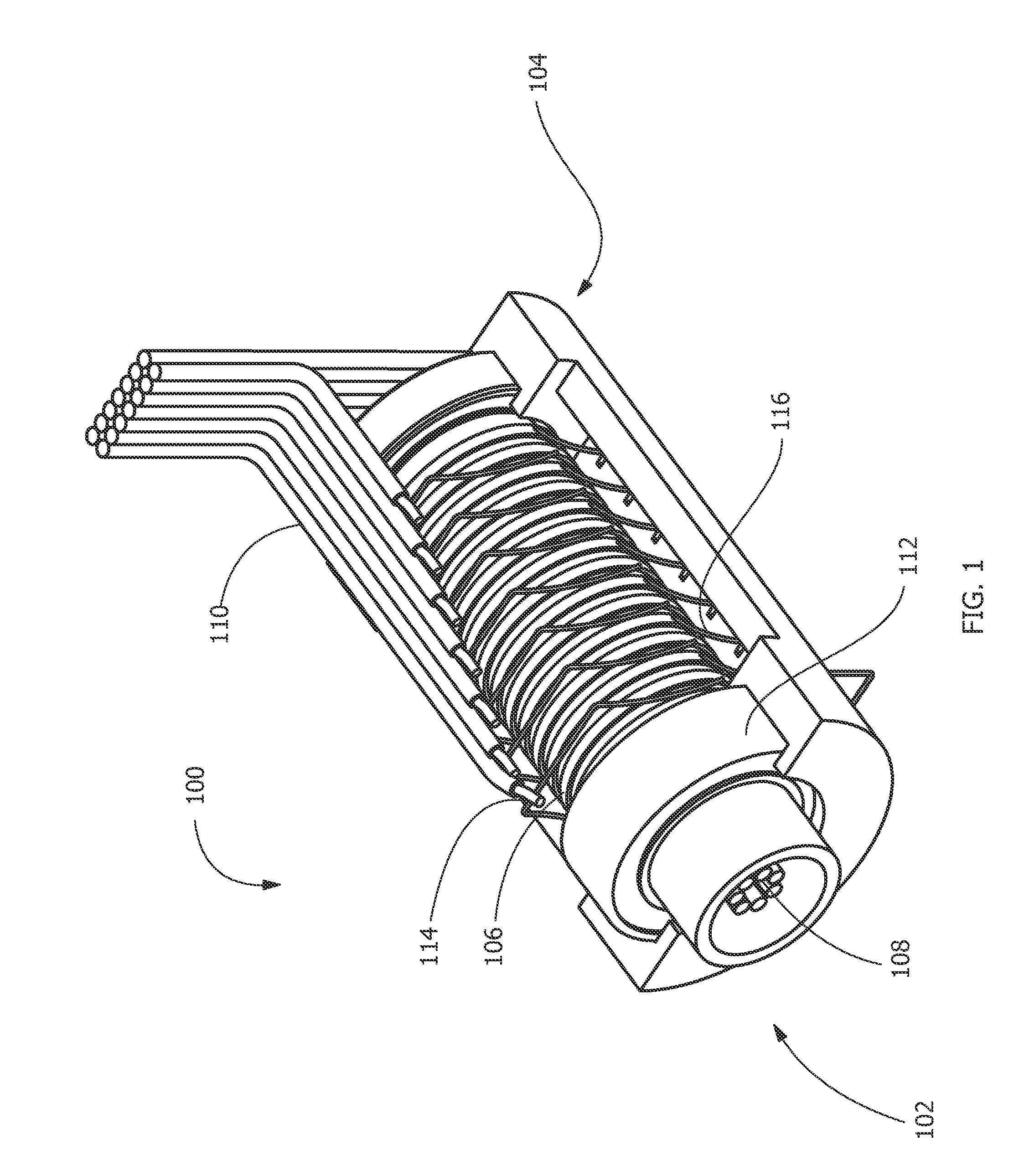

Process of fabricating a slip ring component, a slip ring component and molded interconnect device including a slip ring component

A process of fabricating a slip ring component, a slip ring component, and a slip ring assembly are disclosed. The process includes forming a first shot, forming a second shot, and immersion bathing the first shot and the second shot. The immersion bathing applies an electrically conductive plating to exposed surfaces of the second shot.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

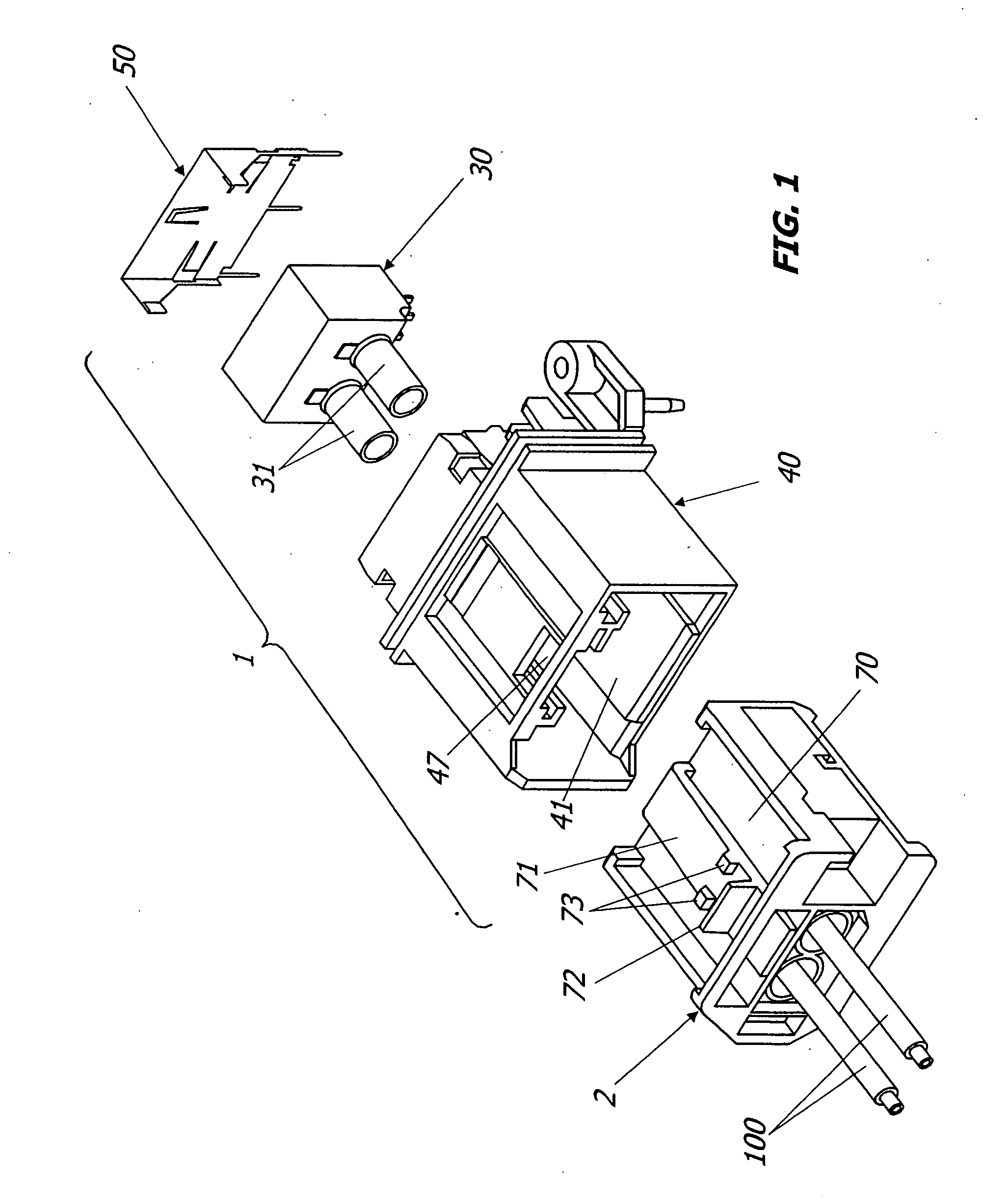

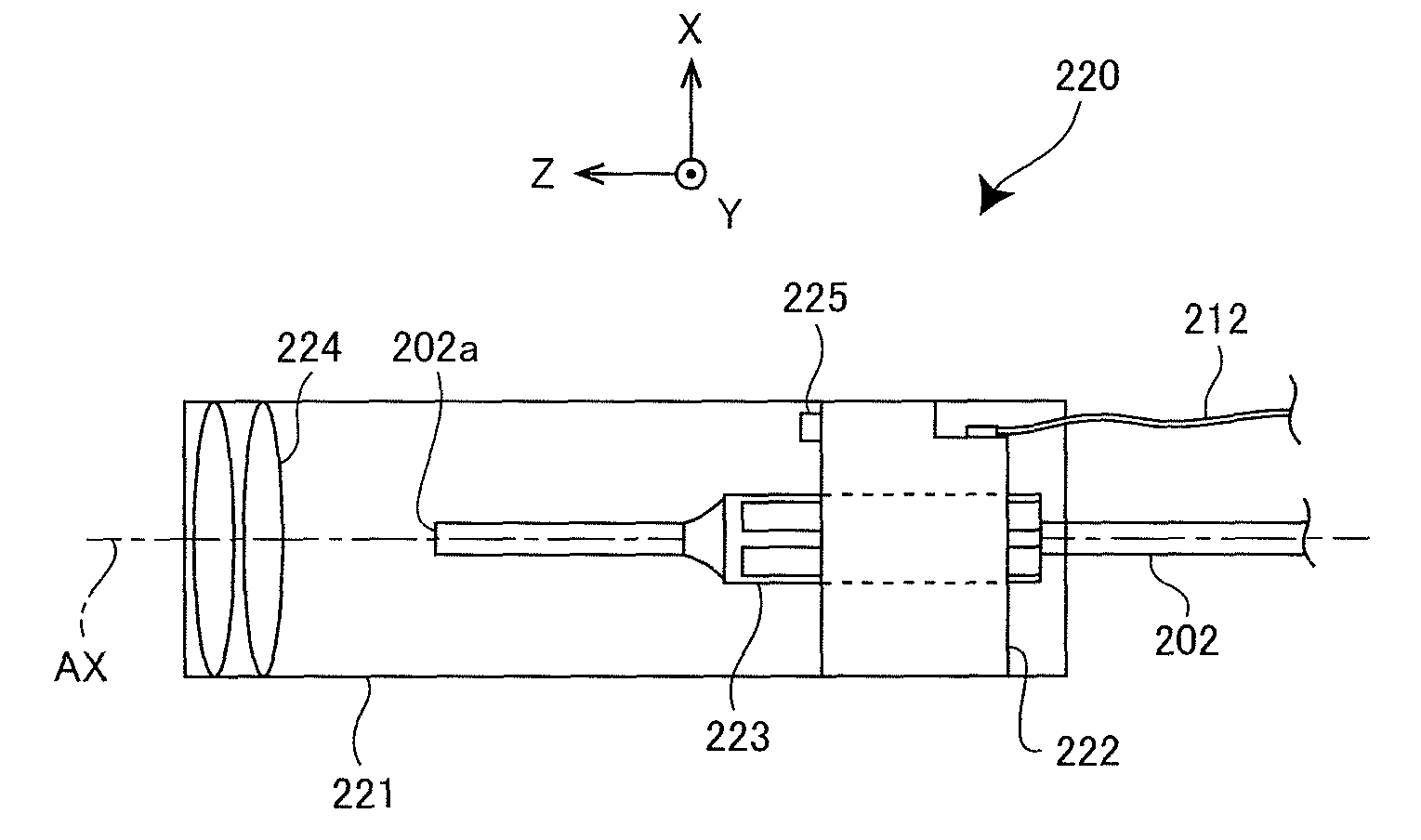

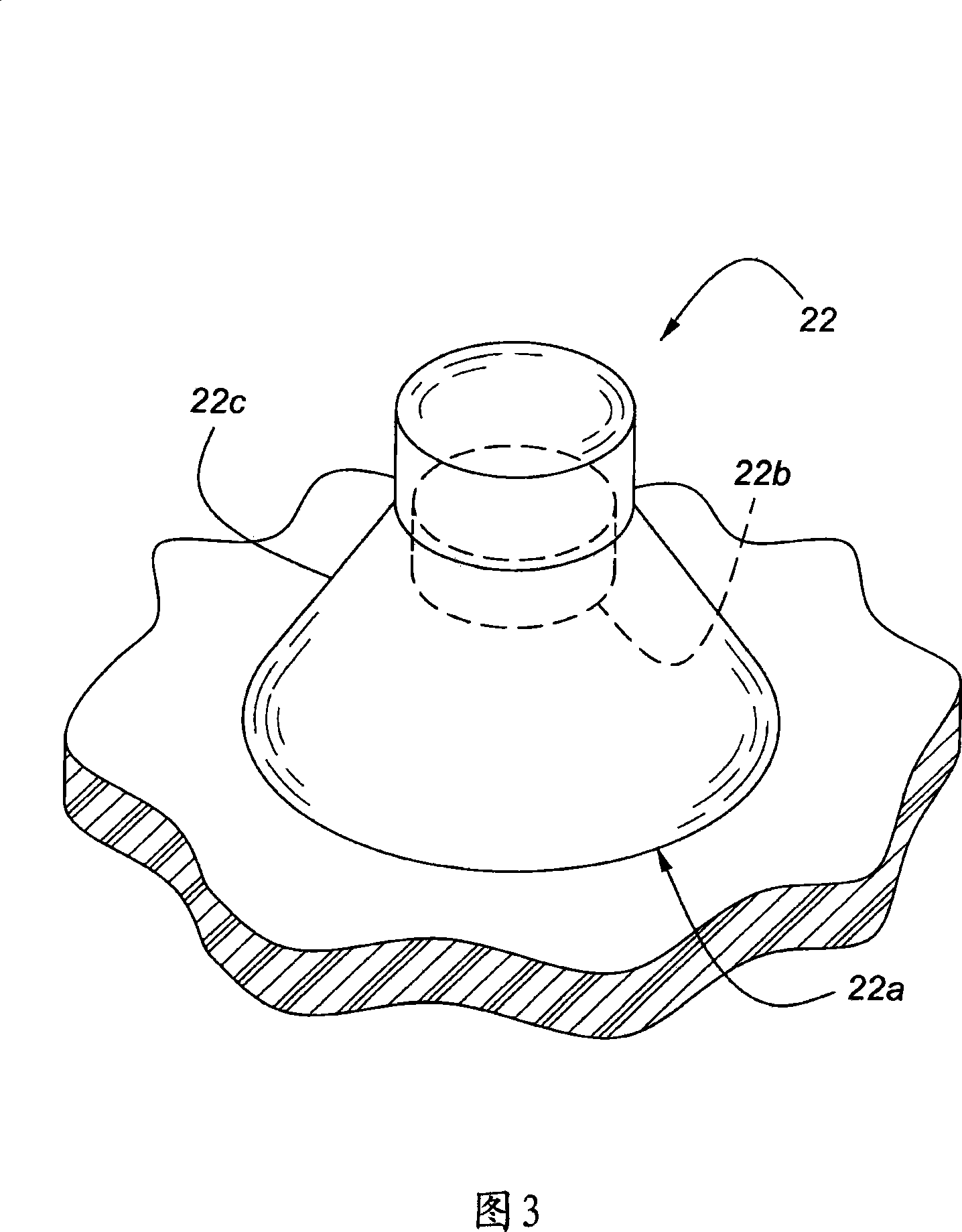

Optical receptacle with low transmission and photoelectric conversion module for the same

InactiveUS20060045435A1Reduce transmission lossMinimize changesCoupling light guidesTransmittanceEngineering

An optical receptacle with low transmission loss, which is connectable with an optical plug, is provided. The optical receptacle includes a photoelectric conversion module having the capability of making photoelectric conversion between light signals and electrical signals, and a module housing. The photoelectric conversion module is a molded interconnect device (MID), which is provided with a module body having a post, an optical device mounted on the post, and an electrical circuit mounted on the module body. The module housing has a tubular projection, into which an end of the optical fiber supported by the optical plug can be inserted. When the optical plug is connected with an optical receptacle, the end of the optical fiber is positioned in the tubular projection so as to be in a closely opposing relation to the optical device mounted on the post.

Owner:MATSUSHITA ELECTRIC WORKS LTD +1

Plug-socket connector apparatus for optical fiber termination

InactiveUS7510336B2Add dimensionAvoid problemsElectric connection structural associationsCoupling light guidesEngineeringMechanical engineering

Plug-socket connector apparatus for optical fiber termination comprises first and second plugs and a socket. The first and second plugs are both single ferrule plugs. The socket is a molded interconnect device and a plug holder, and includes terminals located on the bottom face of the socket, first and second bores located at one side of the socket, and first and second retainers. The retainers retain latches formed in the plugs so as to prevent the plugs from falling out of the bores and to restrict rotation angles of the plugs around the axes within predetermined rotation angle ranges, when the plugs is plugged in the bores.

Owner:MATSUSHITA ELECTRIC WORKS LTD

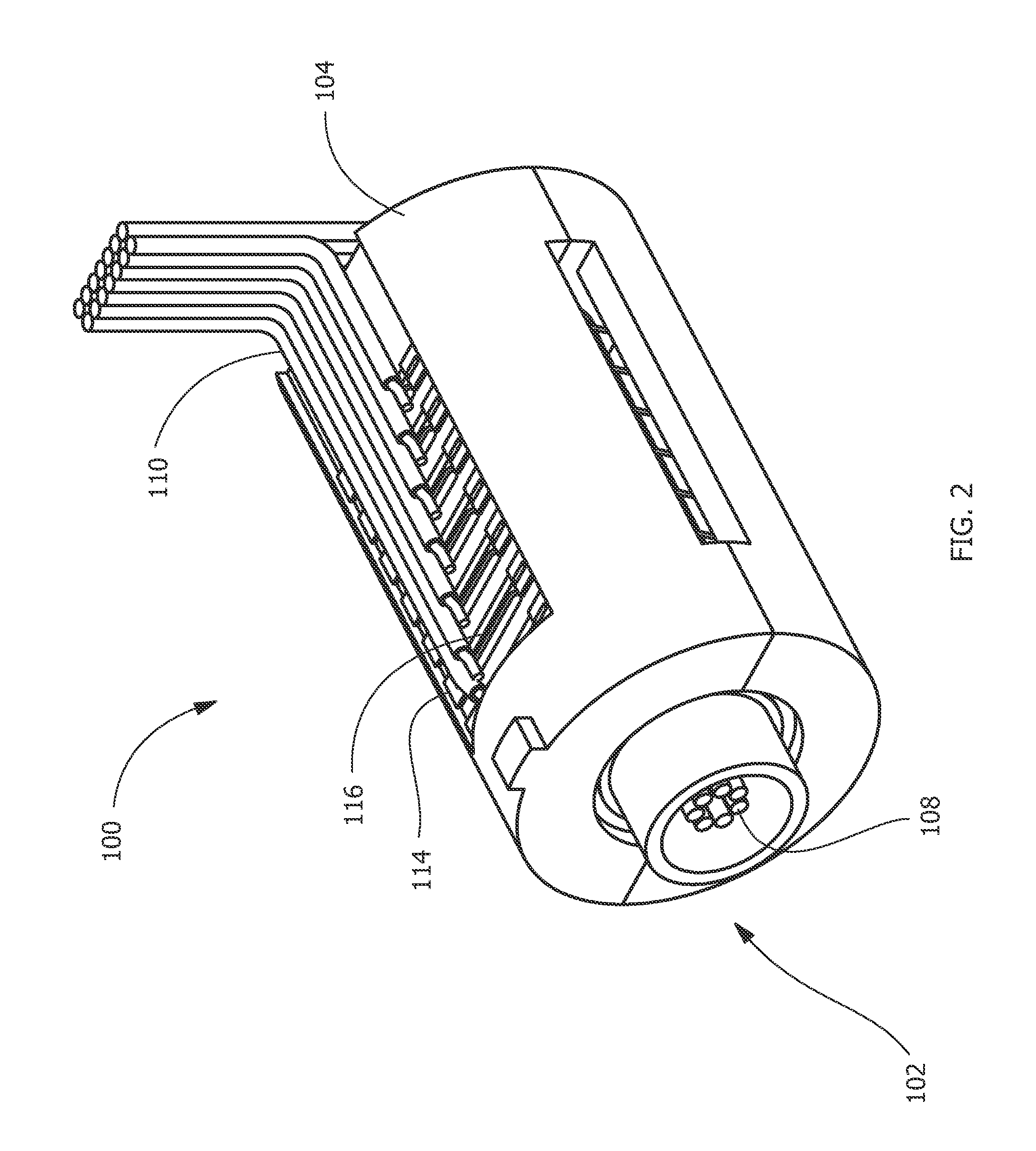

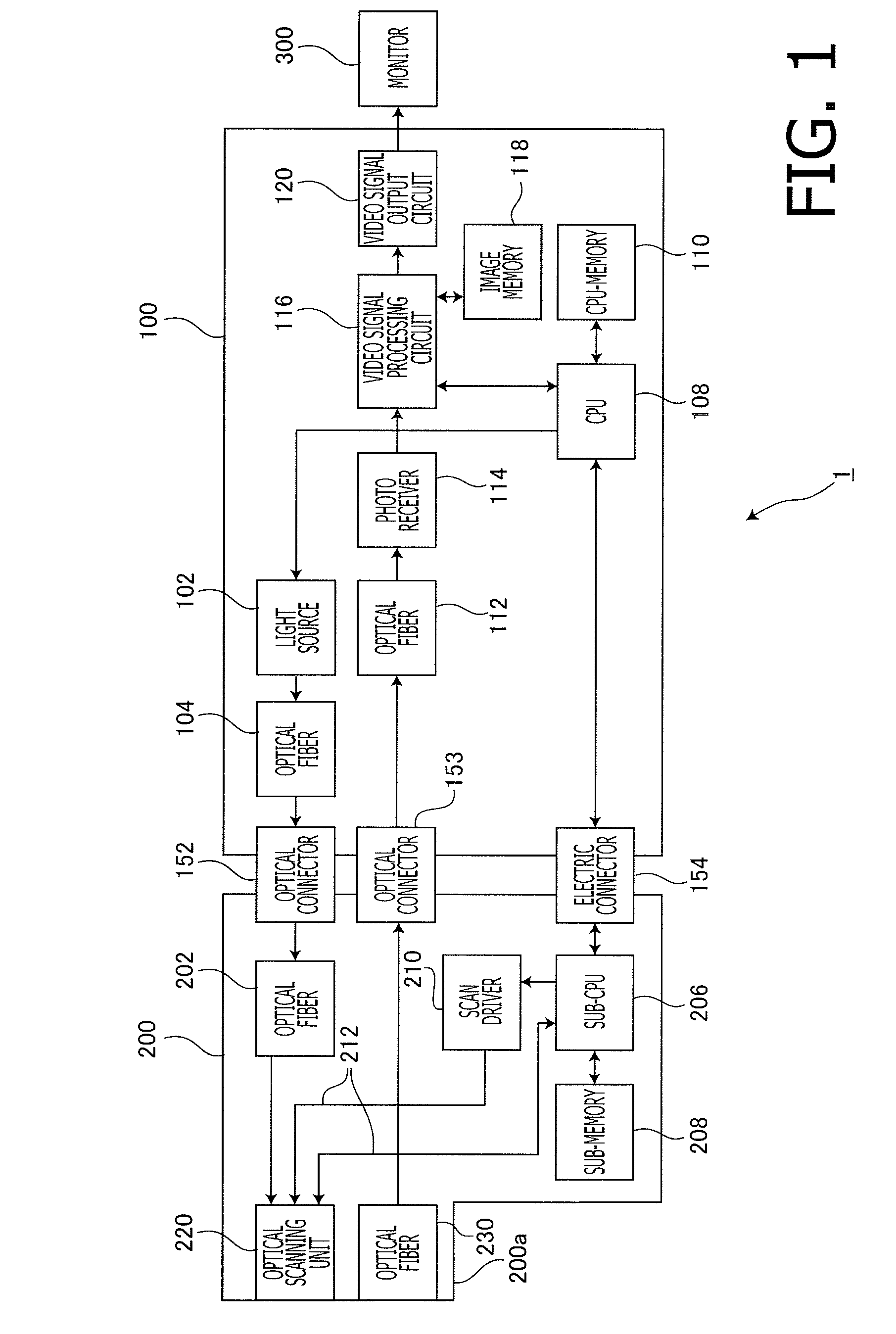

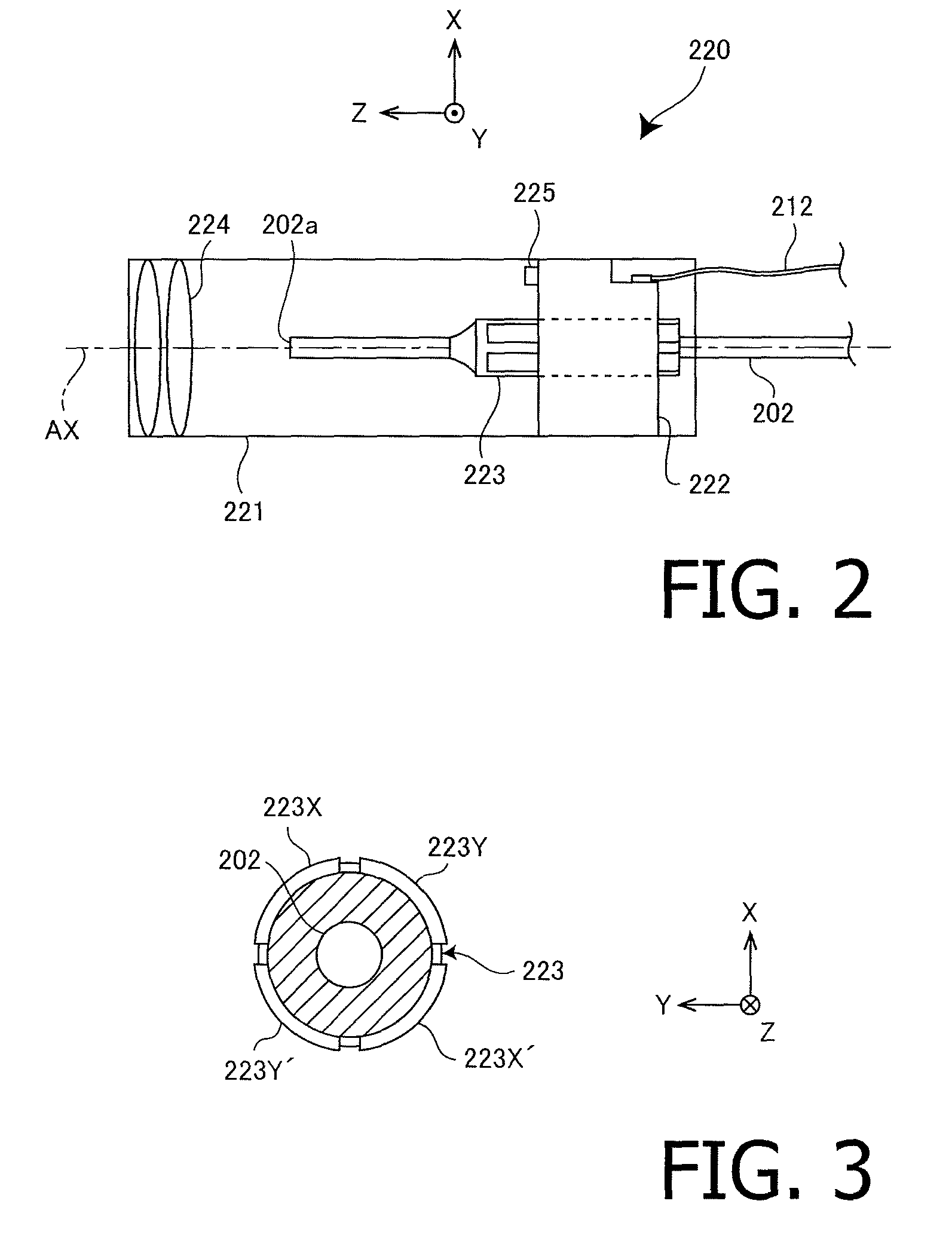

Optical scanning endoscope

An optical scanning endoscope with an optical fiber, and a fiber driving unit with a plurality of actuators which bend side surfaces of the optical fiber by applying a pressing force. A mounting member is a substantially cylindrical molded interconnect device (MID) component which supports the fiber driving unit. A control circuit supplies driving signals to each of the actuators to control the bending amount and direction of the optical fiber. A wiring member electrically connects wiring patterns on the mounting member with the control circuit. The mounting member has a planar surface section at one proximal-end-surface side of the cylindrical outer-peripheral surface. The wiring patterns include at least first patterns having one end portion disposed on the planar surface section to form soldering lands. The other end portions are electrically connected to the actuators on the proximal-end surface of the mounting member. The wiring member is connected to the soldering lands.

Owner:HOYA CORP

Moulded interconnect device with heat conduction property and manufacturing method thereof

InactiveCN102480908AImprove thermal conductivitySemiconductor/solid-state device detailsPrinted circuit aspectsMaterial elementMaterials science

A molded interconnect device (MID) with a thermal conductive property and a method for production thereof are disclosed. A thermal conductive element is set in a support element to improve the thermal conductivity of the support element, and the support element is a non-conductive support or a metallizable support. A metallization layer is formed on a surface of the support element. If a heat source is set on the metallization layer, heat produced by the heat source will pass out from the metallization layer or the support element with the thermal conductivity material element.

Owner:KUANG HONG PRECISION

Optical receptacle with low transmission loss and photoelectric conversion module for the same

An optical receptacle with low transmission loss, which is connectable with an optical plug, is provided. The optical receptacle includes a photoelectric conversion module having the capability of making photoelectric conversion between light signals and electrical signals, and a module housing. The photoelectric conversion module is a molded interconnect device (MID), which is provided with a module body having a post, an optical device mounted on the post, and an electrical circuit mounted on the module body. The module housing has a tubular projection, into which an end of the optical fiber supported by the optical plug can be inserted. When the optical plug is connected with an optical receptacle, the end of the optical fiber is positioned in the tubular projection so as to be in a closely opposing relation to the optical device mounted on the post.

Owner:MATSUSHITA ELECTRIC WORKS LTD +1

Thermosetting resin composition for lds, resin molded article, and three-dimensional molded interconnect device

ActiveUS20190292386A1Improved deposition characteristicsAdditive manufacturing apparatusPrinted circuit aspectsIrradiationTin

The thermosetting resin composition for LDS of the invention includes a thermosetting resin, an inorganic filler, a non-conductive metal compound that forms a metal nucleus upon irradiation with active energy rays, and a coupling agent, in which the non-conductive metal compound includes one or more selected from the group consisting of a spinel-type metal oxide, a metal oxide having two or more transition metal elements in groups adjacent to each other, the groups being selected from groups 3 to 12 of the periodic table, and a tin-containing oxide, and the coupling agent includes one or more selected from the group consisting of mercaptosilane, aminosilane, and epoxysilane.

Owner:SUMITOMO BAKELITE CO LTD

Core-shell composite inorganic metal oxides and method of preparing for prevention of thermal oxidative degradation in polymer and resin compositions

This invention relates to products of aqueous and other chemical synthetic routes for encapsulation of a core material with an inorganic shell and finished compositions of a core-shell particulate material for application in thermoplastic, thermoset, and coatings resins prior to compounding or application or subsequent thermal processing steps. Disclosed is a composition of particles containing a shell of inorganic oxides or mixed-metal inorganic oxides and a core material of complex inorganic colored pigment, laser direct structuring additives, laser marking, or other beneficial metal oxides, metal compounds, or mixed-metal oxide materials, wherein the shell material is comprised of any single oxide or combination of oxides is taught. Preferred elements of composition for the shell are oxides and silicates of B, Ni, Zn, Al, Zr, Si, Sn, Bi, W, Mo, Cr, Mg, Mn, Ce, Ti, and Ba (or mixtures thereof). Applications may include, but are not limited to, coatings or plastic articles or materials for molded interconnect devices, durable goods, housings, assemblies, devices, and articles that are to be exposed to additional thermal processing. The resulting core-shell materials function in plastic and coatings formulations by minimizing or eliminating detrimental interactions with the resins and metal containing additives resulting in loss of mechanical properties.

Owner:SHEPHERD COLOR COMPANY +1

Electrical switch

InactiveUS7518070B2Manual control with multiple controlled membersEmergency actuatorsSwitching signalEngineering

Owner:LEAR CORP

Molded Interconnect Device

ActiveUS20220037050A1Magnetic/electric field screeningPrinted circuit aspectsLiquid crystallinePolymer science

A molded interconnect device that comprises a substrate and conductive elements disposed on the substrate is provided. The substrate comprising a polymer composition containing a polymer matrix that includes a thermotropic liquid crystalline polymer and from about 10 parts to about 80 parts by weight of a mineral filler per 100 parts by weight of the polymer matrix. The mineral filler has an average diameter of about 25 micrometers or less. The polymer composition contains copper in an amount of about 1,000 parts per million or less and chromium in an amount of about 2,000 parts per million or less, and further exhibits a surface resistivity of about 1×1014 ohm or more.

Owner:TICONA LLC

Electrical switch

InactiveCN101241815AEmergency actuatorsManual control with multiple controlled membersElectricitySwitching signal

Owner:LEAR CORP

Tri-axis closed-loop anti-shake structure

Owner:TDK TAIWAN

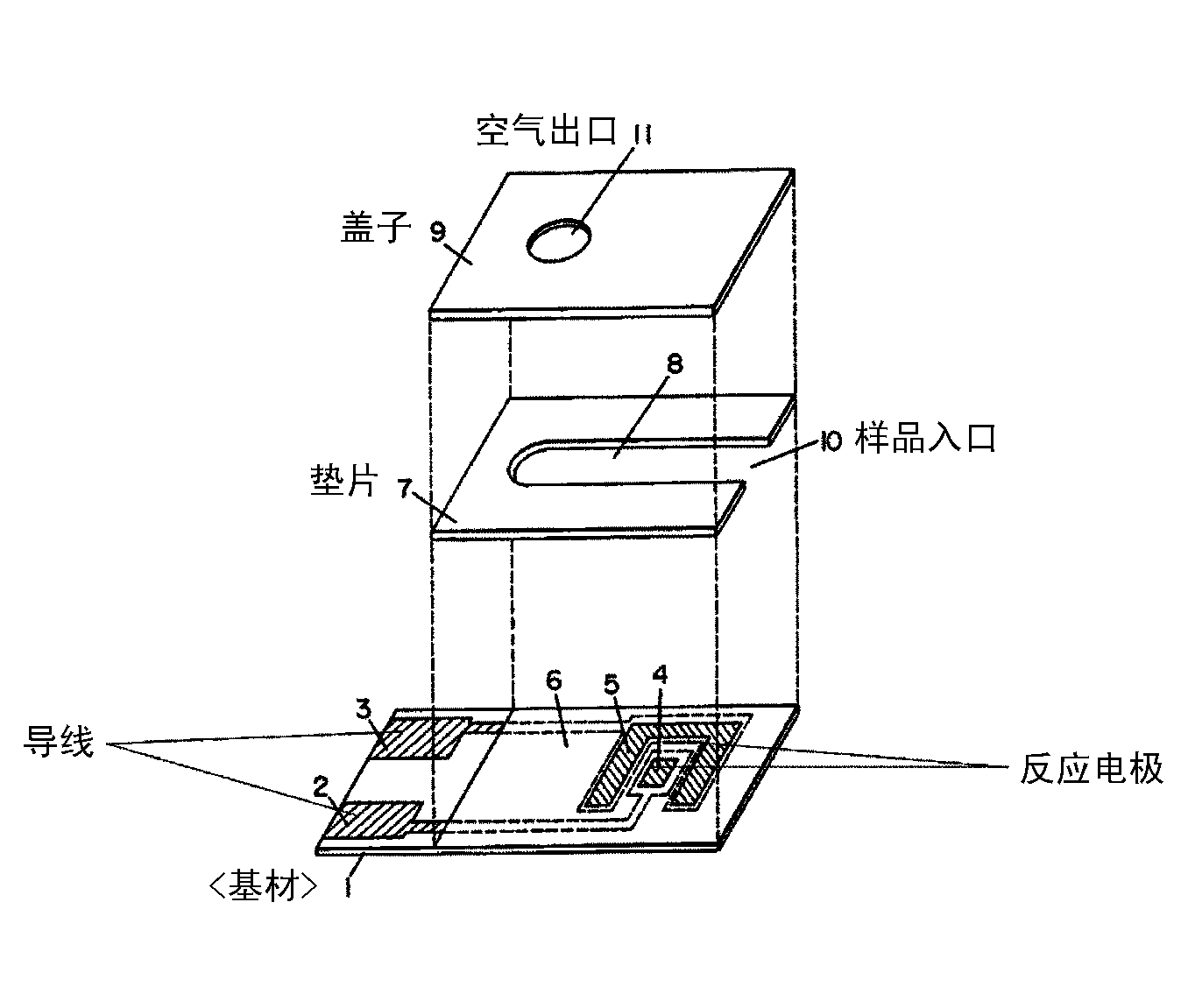

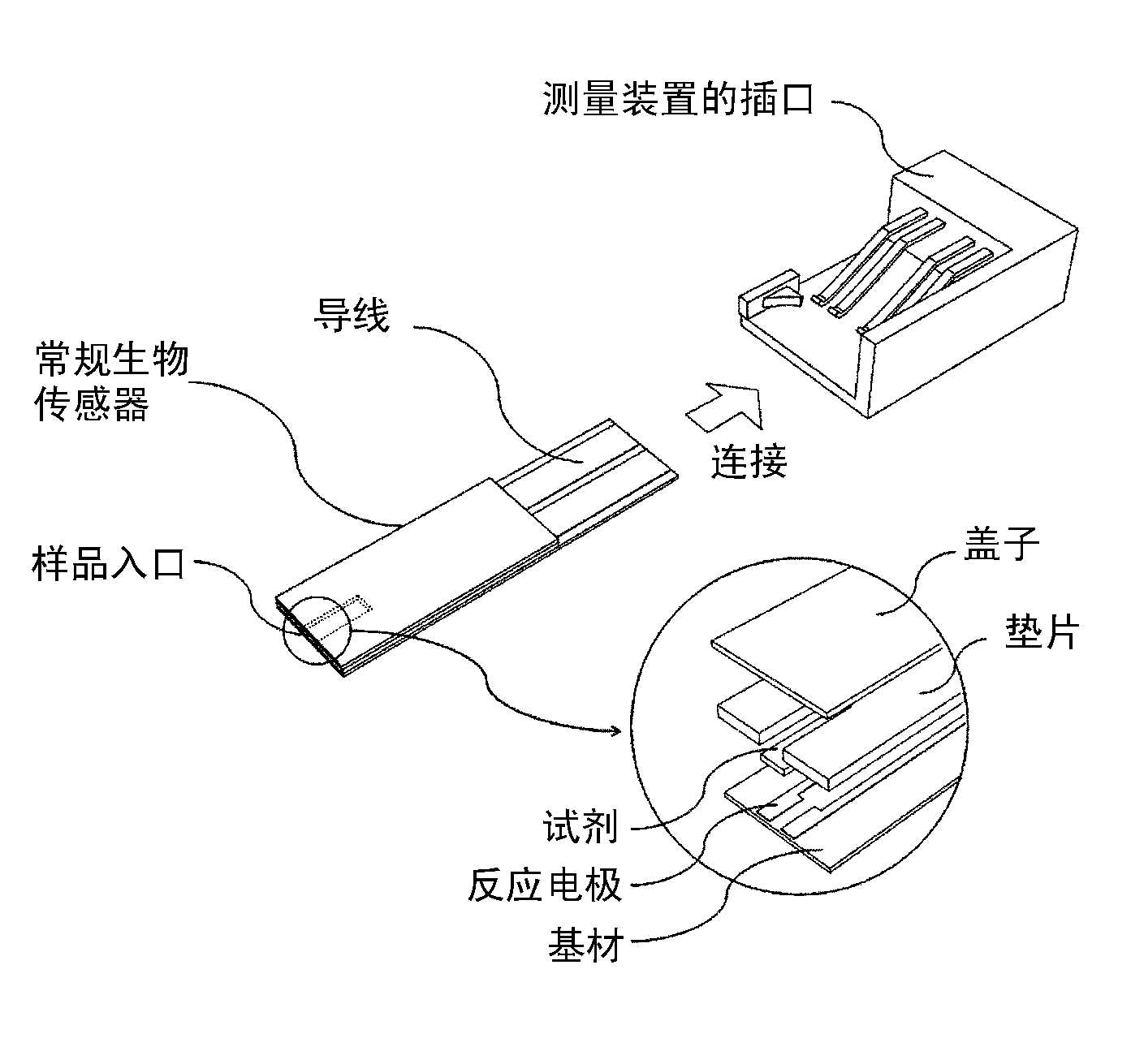

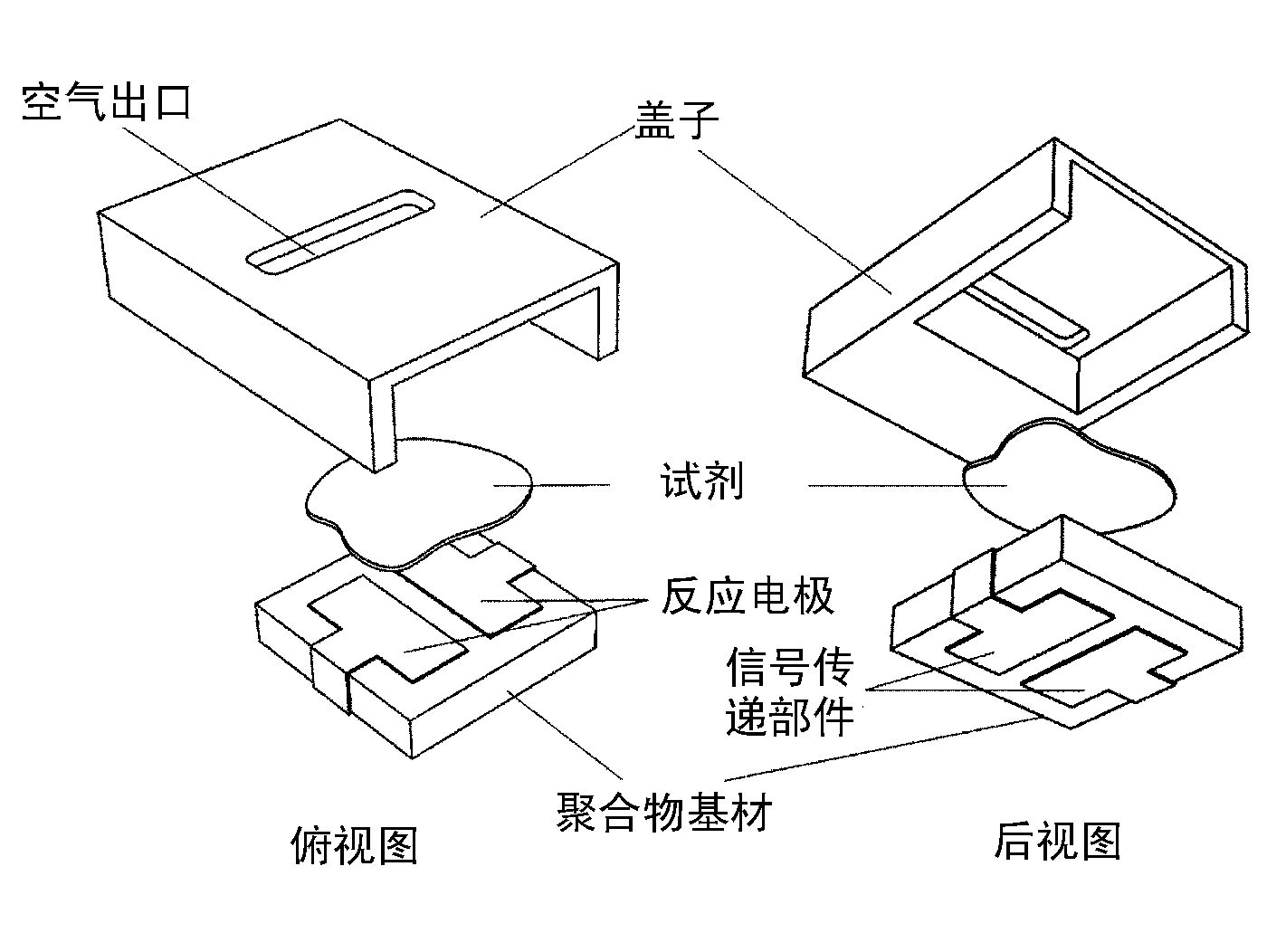

Biosensor with three-dimensional structure and manufacturing method thereof

InactiveCN103210309ASimple manufacturing processReduce manufacturing costMaterial analysis by electric/magnetic meansPretreated surfacesBiomedical engineeringPolymer

The present invention relates to a biosensor which is formed with a three-dimensional structure using 3D Molded Interconnect Device (MID) technology and a manufacturing method thereof. The present invention provides a biosensor in which reactive electrodes and signal transfer parts are formed in a three-dimensional structure on a surface of a polymer using the 3D MID technology, and the manufacturing method thereof.

Owner:喜来健迈德斯

Thermosetting resin composition for LDS, resin molded article, and three-dimensional molded interconnect device

ActiveUS11174402B2Improved deposition characteristicsAdditive manufacturing apparatusPrinted circuit aspectsPolymer scienceBis epoxide

Owner:SUMITOMO BAKELITE CO LTD

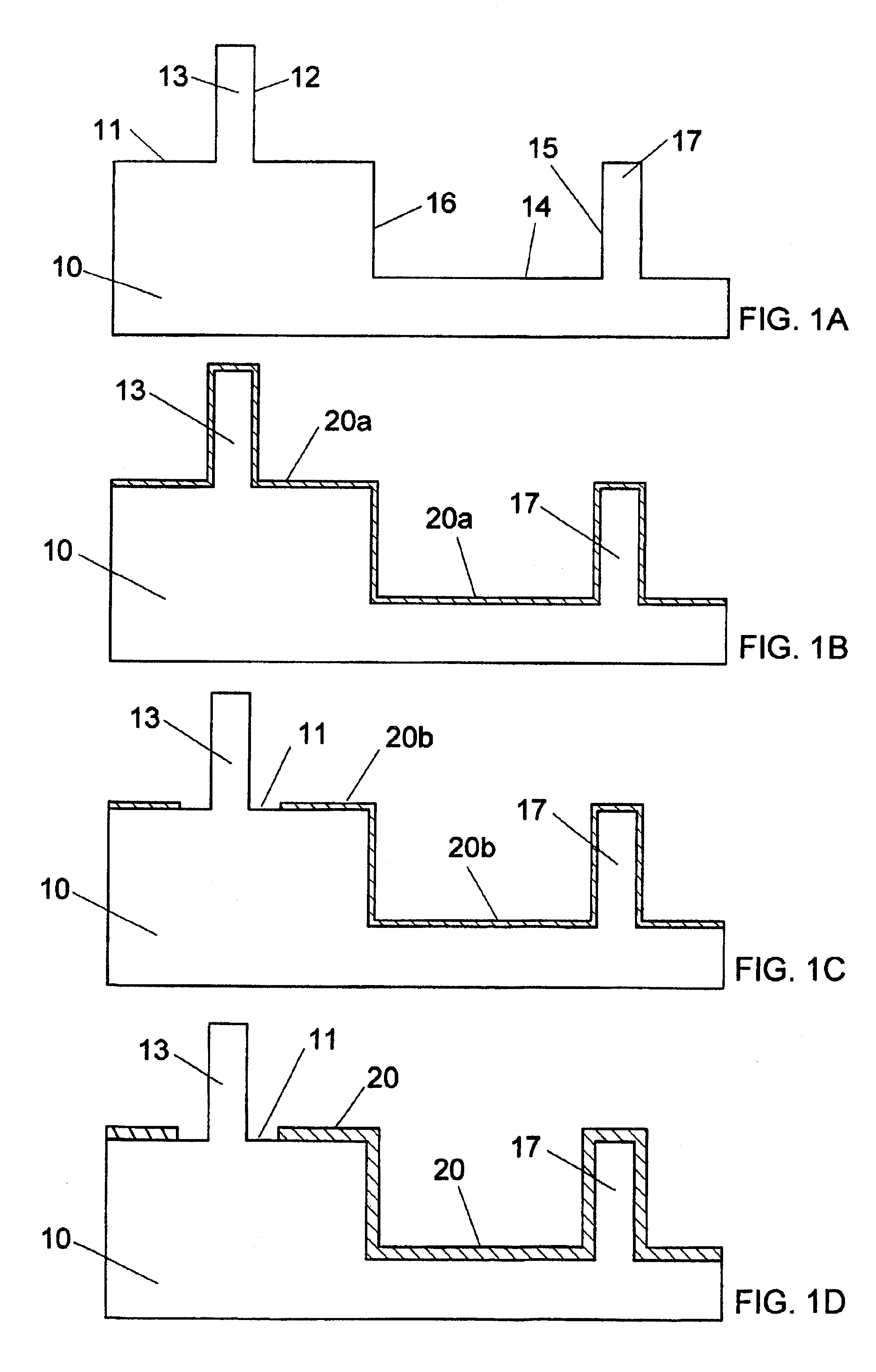

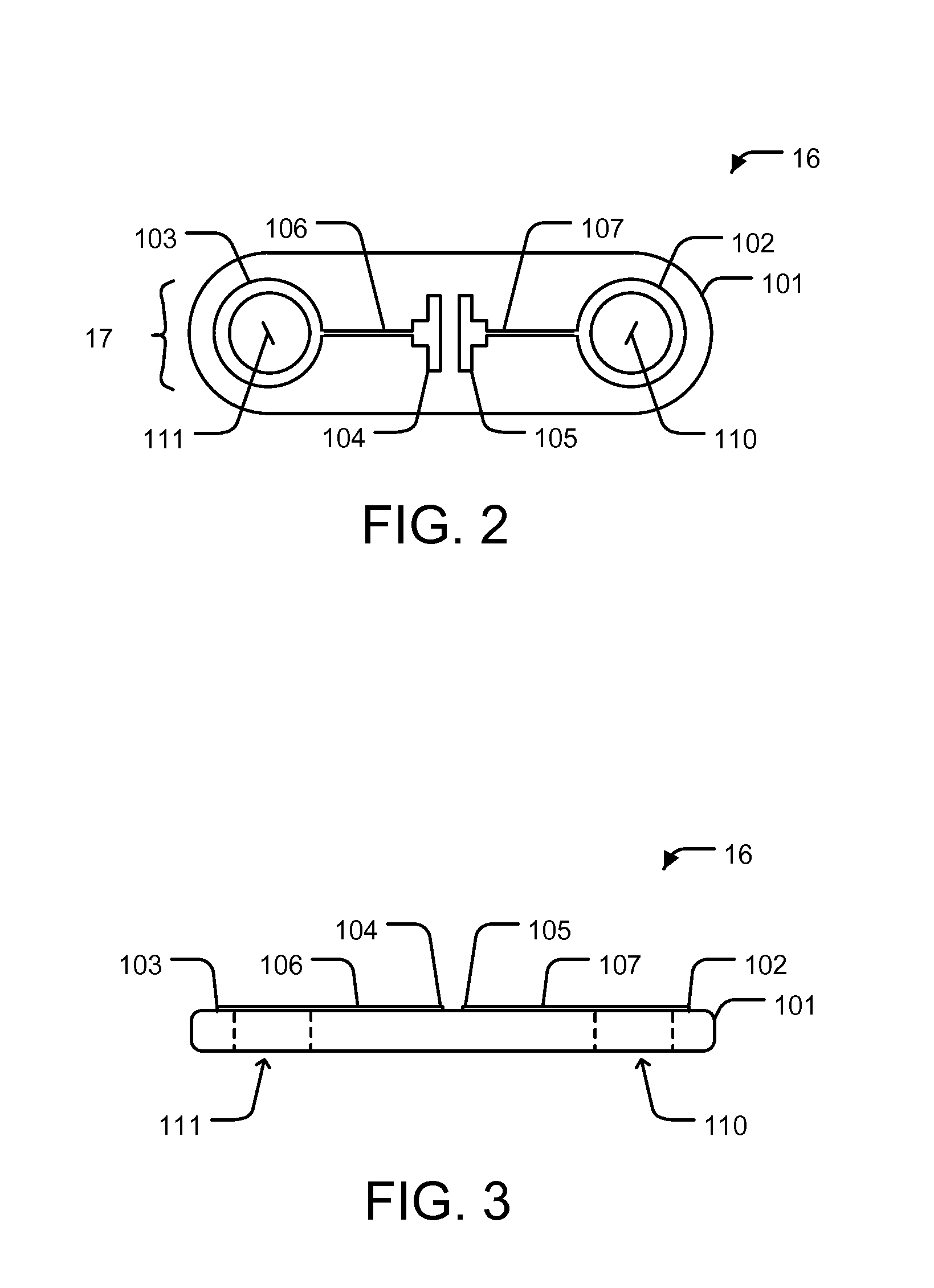

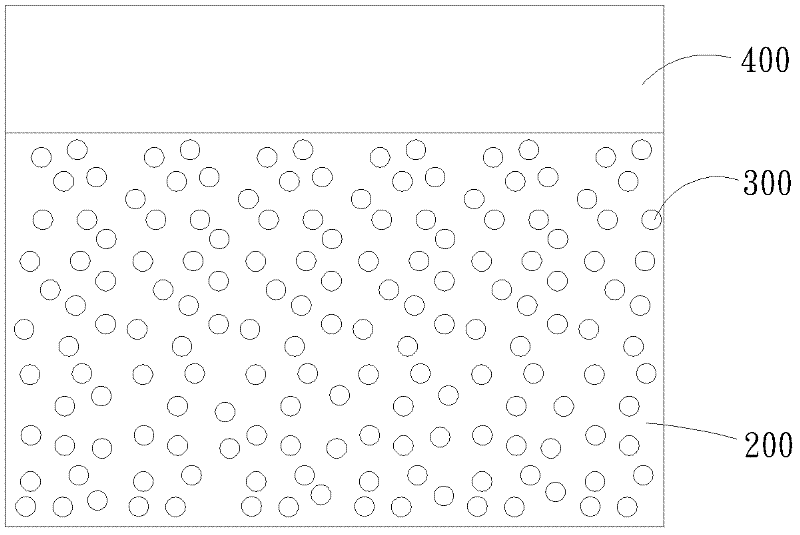

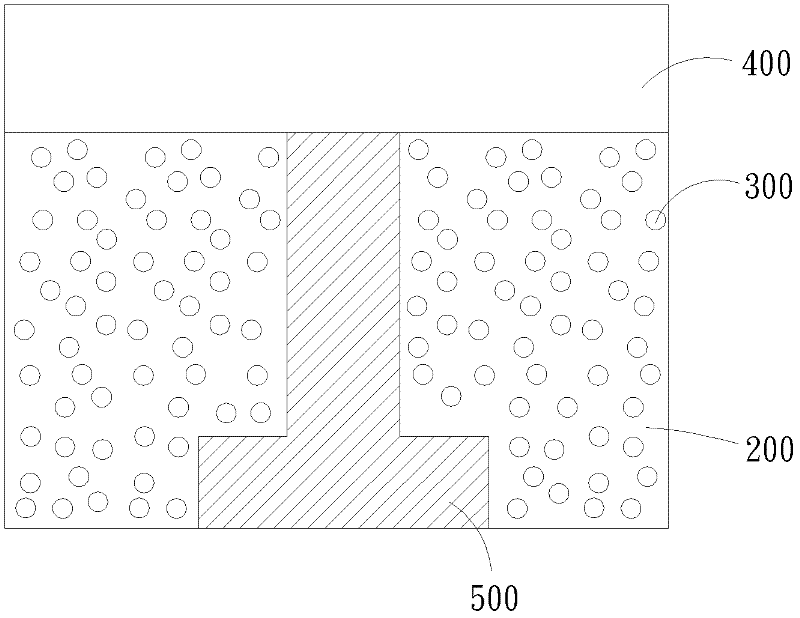

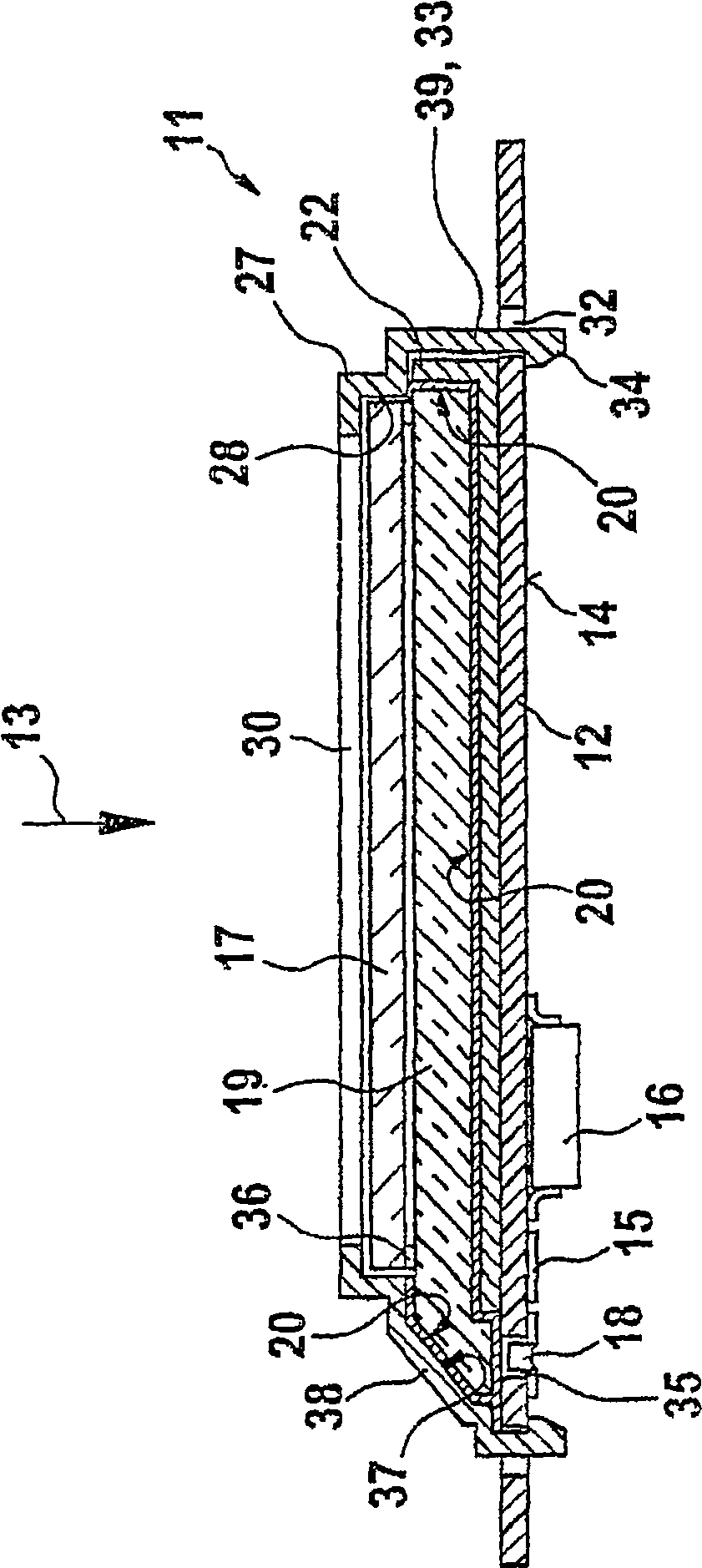

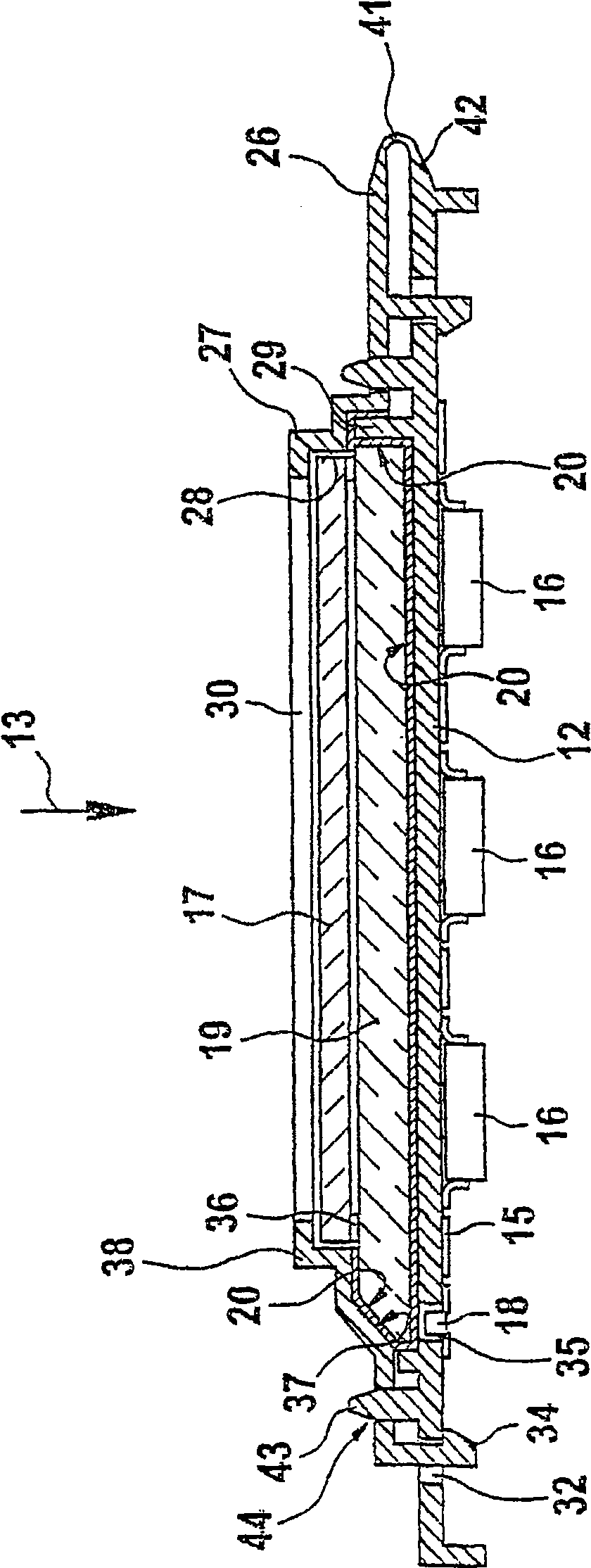

Backlight liquid crystal display

InactiveCN100526940CRealize the sandwich structureTableware washing/rinsing machine detailsOther washing machinesEngineeringSurface plate

The invention relates to a display module (11) comprising a backlit liquid crystal cell (17) like one located, in particular, in the operating panel of a large household appliance. A particularly economical design is achieved when the height of module (11) is determined by the tensioning of a frame (27), which surrounds the liquid crystal cell (17) and the light guide plate (19), against a circuit support (12) whose surface is provided in the form of a reflector surface (20) upon which the light guide plate (19) rests. The circuit support (12) is preferably manufactured using MID (molded interconnect device) technology in the form of an injection molded part with integrated conductor paths (15) and a molded holding fixture (22) provided for holding the light guide plate (19). The frame (27), which can be slipped over the sandwich structure consisting of the light guide plate (19) and liquid crystal cell (17), is coupled via a film hinge (41) to the injection molded part while forming one piece. The fastening between the frame (27) and the circuit support (12) is effected by elastically arresting barbs (34) with the passing through of positioning posts (43) whose free faces are hot-pressed in order to fix the position.

Owner:DIEHL AKO STIFTUNG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com