Backlight liquid crystal display

A liquid crystal display and liquid crystal unit technology, applied in optics, instruments, nonlinear optics, etc., can solve problems such as dark lighting and uneven illumination of the display area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

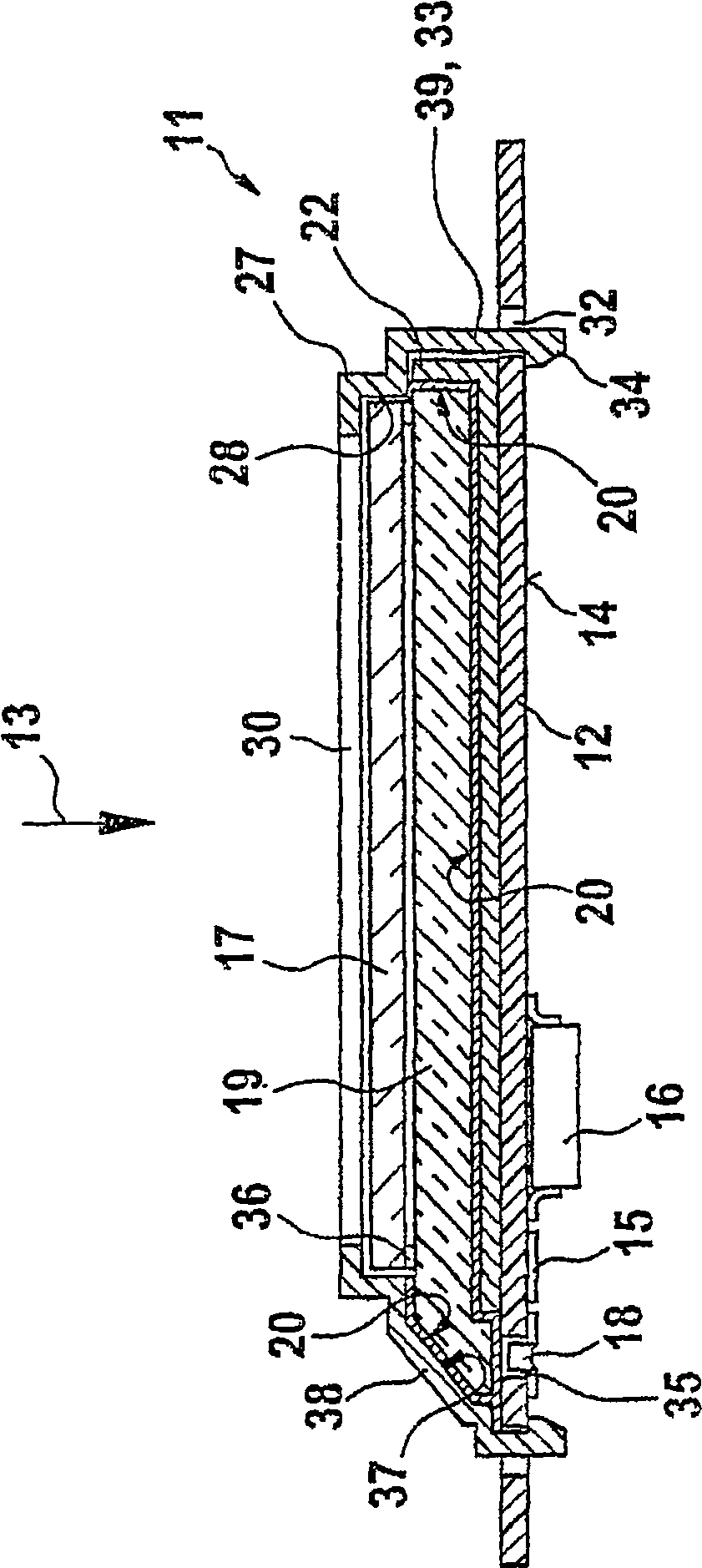

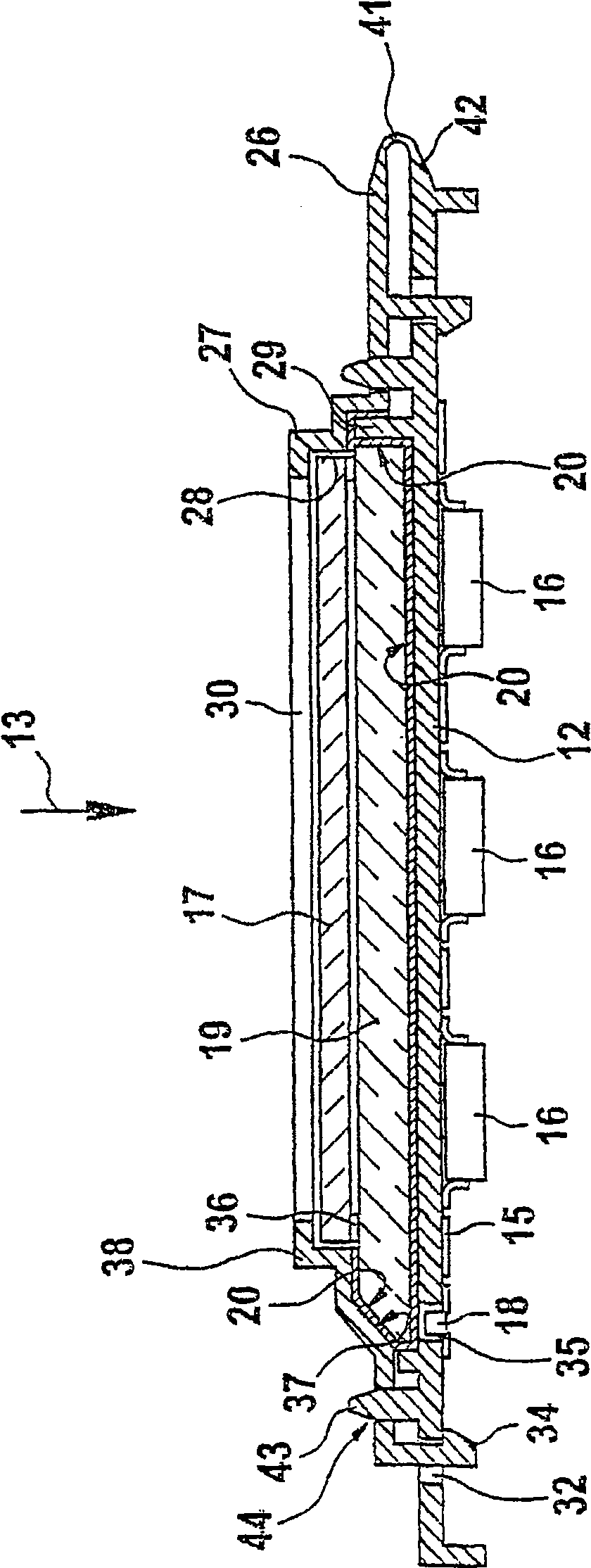

[0014] The basic structure of the sandwich structure for the display module 11 is the circuit carrier 12, such as figure 1 As shown, the liquid crystal cell 17 with its backlighting, at least on its rear side 14 away from the viewing direction 13, is provided with a printed circuit 15 for fixing and wiring of the components 16, especially for activating the liquid crystal cell 17 and the light source 18.

[0015] The light source 18 shines through the circuit carrier 12 in a direction opposite to the viewing direction 13 into an angled limb on the light guide plate 19 and is deflected at the reflector surface 37 so as to pass sideways into essentially a The light guide plate 19 is parallel to the plane. The light passes from the light guide plate, through the liquid crystal cell 17, which is arranged in front of the viewing side, perpendicular to the main plane of the light guide plate 19, again in the direction opposite to the viewing direction 13, in order to make the momen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com